Long-term and intensive use of the car leads to the accumulation of faults that can cause problems with starting the engine. Often, the power unit of the carburetor model VAZ 2107 starts poorly or does not turn on at all in the morning or after a long stay. The cooling time of the oil to ambient temperature in summer is about six hours.

At the end of this period, to start the VAZ 2107 engine, you need to close the air damper in the carburetor by pulling the choke all the way. If it does not start, as drivers usually say when it is cold, the cause of this phenomenon should be determined and eliminated. To do this, it is necessary to carefully examine the power unit and carry out a number of measures aimed at putting the components and mechanisms in order.

Pre-launch inspection and preparatory activities

If a VAZ 2107 car starts poorly when hot or does not function at all in normal mode, this means a loss of settings or an accumulation of minor faults. Engine technical inspection includes the following steps:

- Checking the levels of operating fluids in the engine crankcase, gearbox, cooling system and brake system.

- Carefully inspect the external surfaces of the engine for oil, antifreeze or fuel leaks. Particular attention is paid to the high-voltage wires that are connected to the spark plugs; the contacts must be clean without signs of burning or damage.

- During long-term parking of several days, gasoline evaporates from the float chamber, and the level is replenished using a hand pump.

The next action of the driver of the VAZ 2107 is an attempt to start the engine. To do this, you need to take a seat behind the wheel and set the gear shift lever to neutral. When turning on the starter, it is recommended to depress the clutch pedal to reduce the load on the battery. If the engine does not start after 5–10 rotations with the starter, you should stop trying and carefully inspect the carburetor and other components.

Demi-season reasons

- The funniest reason: the fuel has run out... No comments needed: look for what has run out. By the way, many people carry 5-liter cans with them just for this case: they don’t take up much space. And the good ones don’t stink, which is important.

- The anti-theft alarm went off. Or - even simpler: you yourself forgot to remove some kind of engine start lock. And it also happens: they tried to steal a car, but they didn’t have enough talent... In general, check your “security” just in case - what if this is the case?

- The fuel pump has failed. Everything is clear here: we are going broke installing a new one.

- The timing belt has broken. Note that the first sign of such a malfunction is easier rotation of the starter. If the motor is not plug-in, then just change the belt. If it’s plugged in, then you’re very unlucky. Expensive engine repairs are guaranteed.

- The timing belt jumped several teeth, completely throwing off the valve timing. We need to return to the “status quo”.

In modern cars, the hoods are most often opened only to fill the washer fluid.

Therefore, frankly, it will be better if an inexperienced person does not unscrew something without preparation. At the factory, we once used the following speech pattern: they say that unskilled intervention can aggravate the defect. In modern cars, the hoods are most often opened only to fill the washer fluid. Therefore, frankly, it will be better if an inexperienced person does not unscrew something without preparation. At the factory, we once used the following speech pattern: they say that unskilled intervention can aggravate the defect.

I ask everyone to whom the listed reasons seem elementary, to add your own examples to the proposed list. This will be useful - at least for beginners. Indeed, today, for a number of reasons, few people read all our publications, keeping the subscription “on the treasured shelf.” Therefore, sometimes you have to repeat yourself in something.

Good luck to everyone on the road. And... fewer reasons to climb under the hood!

Photo: depositphotos.com

Main reasons for difficult starting

Each of the car models, both domestic and foreign, has its own operating characteristics. The engine most often starts if one of the systems is not functioning well: ignition, power or starter. A clogged carburetor, worn distributor or insufficient battery charge are the most common causes of difficult starting.

The VAZ 2107 car in this regard is no exception to the general rule; it has all the features of carburetor engines. Difficulties related to hot starting or the car not starting after a long period of parking, all this happens quite often. Qualified diagnostics of the systems mentioned above will eliminate the causes and significantly simplify the life of the driver.

Why is a cold engine difficult to start?

There are many reasons for this. But among them we can distinguish those that occur in almost 90% of cases.

First of all, it is necessary to exclude the influence of low temperatures. In cold weather, the car may not start due to insufficient battery power, as well as due to the use of summer oil, which becomes very thick (these are two main reasons, but there may be others: for example, bad spark plugs or a clogged fuel pump).

Installing an automatic engine warm-up system can help here. If problems with operation occur even at positive temperatures, then it is necessary to continue troubleshooting.

- Quite often, poor car starting is due to low fuel quality. In this case, the injectors and fuel filters may become clogged.

- The air filter may also become dirty. Replacing it is quite simple and completely solves the problem.

- On diesel engines, poor starting can be caused by incorrectly selected fuel. Such motors require a seasonal change in types of diesel fuel (“summer”, as well as “winter” or “arctic” - for especially cold regions).

- Low compression in the combustion chamber. A decrease in pressure can occur due to engine wear (during its operation, the gaps are closed by an oil film, while when they cool, they reappear), as well as due to incorrect installation of the timing belt.

- Another reason why an injection engine has difficulty starting when cold is the failure of the sensors (DPRV, DPS, DMRV).

- It was already written above that problems with starting in winter can arise due to bad spark plugs or a clogged fuel pump. It is worth noting that these problems can also arise at positive temperatures.

- Sometimes poor starting is caused by a lack or, on the contrary, an excess of fuel when supplied. On injection engines, spark plugs may flood in the winter (this problem usually occurs in used cars). In this case, you need to unscrew them and dry them.

- A fairly common reason why a cold engine does not start well is contamination of the throttle valve. In this case, it does not open completely, which is why the motor does not work properly.

- There is a fault in the electrical circuit. If the battery has a charge, but there is no spark at the spark plugs, you need to make sure that the high-voltage wires are intact, as well as the functionality of the ignition coil (checked with a multimeter). True, with such a breakdown, starting problems will arise not only on a cold engine.

- Sometimes the cause of poor starting is a dirty idle air valve. After cleaning it, problems with engine operation should disappear.

Ignition system malfunctions

If the engine has trouble starting hot or cold, one possible problem may be intermittent sparking. Checking the serviceability of the ignition system includes the following operations:

- Inspection of spark plugs, high-voltage wires, distributor, ignition coil and other elements.

- Checking their installation correctly.

- Monitoring the state of the breaker contacts, the size of the gap between them and the ignition timing.

- Checking the functionality of the ignition system as a whole.

This operation is performed together with an assistant, whose task is to turn on the ignition and try to start the engine. In the meantime, the driver removes the high-voltage wire from one of the spark plugs and puts it on a cold spare part. It must be pressed tightly against any metal part of the engine and a test run must be performed.

A spark should jump between the spark plug contacts. A working ignition system ensures trouble-free operation of the VAZ 2107 engine in all modes. Next in line are the carburetor and the fuel pump, on the proper functioning of which the correct mixture formation depends.

About the causes of poor starting and how to combat them

The list of reasons why a cold engine is difficult to start is quite wide. Before starting diagnostics, it is necessary to more accurately localize the fault. Make sure the battery is charged and the starter turns the engine smoothly (at the same speed). Additionally, it is worth excluding the possibility of refueling with low-grade gasoline.

Fuel supply

Problems with starting the engine can arise both as a result of the fact that there is no fuel supply, and due to failures in the process of its ignition in the engine cylinders. As for the fuel supply, there may be too little fuel to start. It is also possible that the spark plugs are flooded with excess fuel.

- It's worth starting the check by making sure there is an exhaust. If light smoke appears from the exhaust pipe after turning the starter, then this indicates that there is fuel supply to the cylinders.

- The next step is to remove the spark plugs. The spark plugs must be unscrewed after an unsuccessful attempt to start the engine. If the spark plug is flooded with gasoline, then this can often indicate problems with injector sealing or ignition. Check the integrity of the spark plugs themselves and the high-voltage wires, and also make sure that there is a spark at the spark plugs. A dry spark plug will indicate that fuel is not being supplied to the cylinder.

- Clogged coarse and fine filters, as well as faulty or heavily coked injection nozzles, can also hinder the normal supply of fuel to the engine. Fuel may also not enter the engine due to a sharp decrease in the performance of the fuel pump. This means that the fuel pump is not creating the required pressure. To find out the reasons, you will need to check the fuel pressure in the rail and the fuel pump itself.

An additional nuance may be air leaks in the fuel system. It is necessary to examine the lines for damage, bends, cracks, etc. Gasoline leakage is a clear sign of loss of seal in the fuel lines.

Electronic sensors

The electronic injection system is equipped with special sensors, thanks to which interaction with the engine ECU is realized. Failure of individual electronic components can result in incorrect signals being sent to the control unit and the engine cannot be started.

If the engine does not start, then you need to check several sensors:

- camshaft position sensor (CPR);

- throttle position sensor (TPS);

- mass air flow sensor (MAF);

It is also necessary to simultaneously clean the throttle, check the air filter and the XX valve. Self-diagnosis of sensors can be done using a multimeter.

Ignition check

The engine may not start if the ignition distributor is faulty. This malfunction manifests itself in such a way that when the starter rotates, the so-called seizure does not occur, that is, there are no signs of single attempts to ignite the fuel-air mixture in the engine cylinders.

It is also worth paying attention to the setting of the ignition timing, timing belt and its drive. In some cases, it is worth checking the condition of the variable valve timing system (if equipped). The ignition coil can be checked using a multimeter.

Compression reduction

A loss of compression in one or more engine cylinders is a consequence of natural wear or damage to the power unit. A motor with low compression does not, as there is a strong increase in the gaps between the parts in the cylinder. In other words, it is not possible to achieve the required pressure in the combustion chamber to ignite the working mixture at the time of start-up.

Frequent causes of this malfunction may be piston destruction, broken or stuck piston rings, burnout of the timing valve, wear of the cylinder walls, etc. Low compression most often appears during a cold start, but can also be present constantly (when trying to start a very worn engine “hot”). An engine with such a malfunction is most difficult to start at low temperatures. For an accurate diagnosis, compression must be measured.

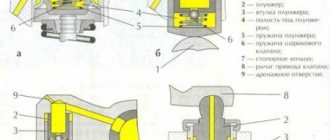

Power system malfunctions

The VAZ 2107 car engine is a proven and reliable unit. If the power unit does not start, the following problems in the power system are possible:

- The standard carburetor is clogged or the fuel level in the float chamber is not correct.

- The starter membrane is damaged.

- The tightness of the tube connecting the device to the vacuum brake booster is broken.

- Damage to the fuel pump membrane.

To eliminate the above listed malfunctions, the carburetor should be disassembled, followed by defective parts and cleaning of all jets and channels. During this operation, special attention is paid to the condition of gaskets and membranes. The car may not start normally due to air leaks in the absence of tightness between parts and damage to the lines.

The VAZ engine does not start well either hot or cold - the fuel pump may be faulty. In this case, the carburetor does not receive the required amount of fuel, which leads to a lean mixture. As a result, the power unit does not start, especially after a long stay, when the fuel level in the float chamber is extremely low.

Difficult to start on cold diesel

As you know, starting a diesel engine occurs due to temperature and compression, therefore, if there are no problems with the battery and starter, there may be 3 main ways to find the reason why a diesel engine does not start well in the morning when it’s cold:

- Insufficient compression.

- No glow plug.

- is missing or interrupted .

One of the reasons that a diesel engine does not start when cold in particular, and poor diesel starting in general, is poor compression . If it doesn’t start in the morning, but seizes from the pushrod, and then there is blue smoke for a certain time, then this is 90% low compression.

Checking engine compression

Checking engine compression with a compression gauge and without instruments with your own hands. How to measure compression in gasoline and diesel engines. Compression diagnostics. More details

An equally common case is when the owner of a car with a diesel engine cannot start a cold engine, but a hot one starts without problems - if there is no glow on the spark plugs . They heat the diesel fuel until the diesel reaches operating temperature completely.

There may be three options why candles do not work

- the spark plugs themselves are faulty;

- It's the spark plug relay. Its operation is regulated by the coolant temperature sensor. During normal operation, the relay makes quiet clicks when the key is turned in the ignition before starting, and if you cannot hear them, then you should find it in the block and check it;

- oxidation of the glow plug connector. There is no point in explaining how oxides affect contact.

3 options for checking glow plugs

To check diesel spark plugs, you can choose several methods :

- measure their resistance (on an unscrewed spark plug) or an open circuit in the heating circuit with a multimeter (checked in the beeper mode, both screwed into the engine and after unscrewing it);

- check the speed and degree of heating on the battery by connecting to ground and the central electrode with wires;

- Without unscrewing it from the engine, connect the central wire to the positive terminal of the battery through a 12 volt light bulb.

If the spark plugs are working and they are properly supplied with power when the ignition is turned on, then in some cases it is necessary to check the valve clearances. Over time, they become confused and do not close completely when the internal combustion engine is cold, but if you start it and warm it up, they close up and the engine starts normally when it is hot.

Faulty diesel injectors , as a result of natural wear or contamination (sulfur and other impurities), are an equally important aspect. In some cases, the injectors throw a lot of fuel into the return line (you need to do a test) or the fuel filter is dirty.

Interruptions in the fuel supply make it much more difficult to start the engine. So, if the diesel engine stops starting in the morning, regardless of the temperature outside, the diesel fuel is leaving (the return valve does not hold), or it is sucking air, other options are less likely! Air entering the fuel system can cause the diesel engine to have difficulty starting and stalling.

Fuel is out of season or contains foreign impurities . When it is cold outside and the diesel engine does not start or immediately stalls after starting, then the problem may be in the fuel. DT requires a seasonal transition to “summer”, “winter” and even “arctic” (for especially cold regions) diesel fuel. A diesel engine does not start in winter because unprepared summer diesel fuel in the cold turns into a waxed gel in the fuel tank and fuel lines, and also clogs the fuel filter.

In this case, starting the diesel engine helps by heating the fuel system and replacing the fuel filter. Frozen water on the filter element presents no less difficulties. To prevent water accumulation in the fuel system, you can pour a little alcohol or a special diesel fuel additive into the tank, called a dehydrator.

Tips for diesel car owners:

- If, after pouring boiling water on top of the fuel filter, the car starts and works normally, the diesel fuel is summer.

- If there is low pressure in the fuel rail, the injectors are probably leaking and not closing (the operation is checked on a special stand).

- If the check shows that the injectors are pouring into the return line, then the needle in the sprayer does not open (they need to be changed).

10 reasons why diesel engines have trouble starting when cold

If a diesel engine has trouble starting when cold, the reasons can be collected in a single list of ten points:

- Starter or battery faulty.

- Insufficient compression.

- Faulty injector/injectors.

- Incorrectly set injection timing, desynchronization with fuel injection pump operation (timing belt jumps by one tooth).

- Air in fuel.

- The valve clearance is incorrectly set.

- Malfunction of the preheating system.

- Additional resistance in the fuel supply system.

- Additional resistance in the exhaust system.

- Internal breakdown of the injection pump.

I hope that all of the above will help you, and if it does not solve the problem of starting a cold engine, it will at least point you on the right path to eliminating it on your own or with the help of a specialist.

Source

Starter malfunctions

The VAZ 2107 car is started using an electric starter. The main difficulties arise due to the following reasons:

- Low battery level.

- Solenoid relay failure.

- Overrunning clutch failure.

If the carburetor is working properly and the ignition system is configured correctly, then most often the car will not start due to a broken starter. First of all, the charge level is checked; if it is insufficient, we remove it from the car and recharge it. If necessary, the mechanism is dismantled for repair or replacement.

Practice shows that eliminating the above malfunctions on an engine that starts poorly or does not start at all allows you to achieve a good result. Experts recommend checking first the carburetor, which is prone to clogging, and other systems that ensure a reliable start.

Prevention of injector breakdowns

Why the injection engine does not start and how to eliminate possible problems is now known to all readers of our resource. However, it is better to avoid such breakdowns, so let’s pay attention to ordinary procedures that, if carried out systematically, will help minimize the risks of all malfunctions. The simplest but most effective prevention consists of the following measures:

- Firstly, refuel exclusively at proven gas stations and only with high-quality fuel. Remember that most fuel system and engine malfunctions are caused by dirty gasoline;

- Secondly, change all consumables on time and only with high-quality products. The most important thing is periodic replacement of all kinds of filters and engine oil;

- Thirdly, periodically check the main components of the machine for stability. The list of the latter, naturally, includes the injector, elements of the fuel system, ignition and engine;

- Fourthly, never neglect routine diagnostics of your car at a service station. Surprisingly, even a delay of a couple of hundred kilometers can cause serious damage, which previously could have been eliminated with very simple actions;

- And fifth, always operate your vehicle properly. That is, you do not need to overheat, overload or negatively impact your car in any other way.

Perhaps this is where the most important information on today’s issue has come to an end. We hope the material presented above was useful and provided answers to your questions. Good luck in operating and maintaining your car!