The service book for a new car indicates the frequency of oil changes. Some manufacturers recommend doing it every 1500-2500 km. Others consider this approach completely inappropriate, proposing the first replacement after 10-15 thousand km, or even after 20 thousand km. But there are also unscheduled procedures - changing the oil after repairs and engine running-in.

Important recommendations for running the engine after a major overhaul

As usual, after an engine repair, young or rather inexperienced drivers want to “drive” their car with a new heart as quickly as possible.

Which leads to troubles or repeated engine overhauls in the future. Remember that after any repair, and especially after a major overhaul, the engine loses its power. The loss reaches even 70% of the nominal value. Why break in the engine?

In order for the engine to serve you for a long time, you need to break in the engine after a major overhaul. This operation is performed:

When the car comes off the assembly line;

After repair of the unit.

You must understand that when replacing parts, these are not the same parts that were used during assembly, but were machined in a different place. As a result, it takes more time for them to get used to each other.

Usually this requires 3-5 thousand km in the warm season and 6-7 thousand km in the cold season. These figures depend not only on the quality of the parts, but also on the oil, fuel, road surface, and of course the driver’s skills.

Running in engines from VAZ and other manufacturers

Before you start running in, you need to follow a number of simple but necessary recommendations. If during everyday operation you neglected the manufacturer’s requirements for oil tolerances, then during the break-in period you need to fill in high-quality oil with the necessary tolerances specifically for your engine. It is necessary to check that the oil flows to all engine components within a few seconds, as oil starvation may occur. You also need to check the oil pressure at idle speed, usually this parameter ranges from 0.5-1 atm, depending on the type of engine.

Starting the engine after repair should be done in a gentle manner and can be done in several ways. One of the easiest ways is to run it at idle speed. The essence of the approach is that you need to cyclically warm up the engine for five to ten minutes, then you need to let it cool. Then we repeat the cycle, checking:

- All oil lines must be tight, smooth, like everything else;

- We monitor the oil level and fuel consumption;

- Pay attention to the antifreeze (coolant) level.

Afterwards comes the second stage of running-in - the “long” stage. In total, the engine will run at idle for about 10 hours. During this, the mechanic or owner monitors the parameters described above and every 15-20 minutes, pressing the accelerator pedal, increases the engine speed, holding it for 5-10 seconds.

Every hour you need to turn off the engine and let it cool completely. The antifreeze temperature should be around 80 degrees while the engine is off. After completing the 10-hour cycle, you need to change the oil filter, the oil itself and inspect the valve mechanism (paying special attention to thermal clearances).

Let’s call the second method the old fashioned way, i.e. we start it up and start accumulating mileage in a gentle mode, following some rules:

For the first 50 kilometers we try not to exceed the speed of 40 km, of course we don’t let the engine get tight, we drive in low gears (about 3rd gear);

For the next 200 km, we increase the speed to 60 km, and we also do not climb up the gears (4th gear);

After that, for every 100 km you can add 10 km/h, but we do not go beyond the threshold of 90 km/h.

After the car has traveled 2000 km in this mode, you need to change the oil and oil filter. We increase the speed limit to the usual levels, but we must avoid sudden acceleration and engine braking.

Recommendations from experienced craftsmen and drivers

Naturally, it is impossible to give all recommendations only on the basis of documented information. It is necessary to listen to the advice of craftsmen who have sufficient experience in carrying out major repairs.

Charge your battery

For example, before breaking in, you will need to check that the battery has a full charge level. The fact is that the first start of the power unit is the most important. And the crankshaft will turn very tightly, so maximum effort will be required from the battery.

Change the oil and filter

What follows is that you need to install a completely new oil filter, and also fill the same oil into the car. The filter should not be soaked in oil before installation, as this may cause an air lock . And the engine, at the most important moment for it, will receive the effect of oil deficiency. This can lead to further damage to the power unit.

Read more about how to change oils on Lifan cars:

- Solano (here)

- Smiley (here)

- X60 (click here)

- Breeze (tuta)

Idle speed and oil pressure

When the engine is already started, you should leave it idling until the oil pressure returns to its normal level. If everything goes well, this should not take more than three or four seconds. But, if the oil pressure does not decrease, then this may indicate the need to immediately turn off the ignition. It is possible that the problem lies in the oil supply process.

This could be an air lock, pump failure, or any other deficiency. If you do not turn off the engine, this may lead to its breakdown and the need for a new overhaul.

Constantly monitor the oil pressure (using a domestic car as an example)

But, if the pressure is at its level, then the motor needs to be given time to reach the desired temperature. As soon as the temperature of the oil increases, it will become much thinner and the pressure will decrease to its normal values. As a rule, we are talking about an indicator from 0.4 to 0.8 kilograms per square centimeter.

It is noteworthy that after a major overhaul, additional problems may arise. We are talking about leakage of working fluids. Such shortcomings, if they occur, will need to be resolved very quickly. If this is not done, the oil or coolant level may drop. And this, in turn, will lead to the motor overheating and failure.

If the injection engine does not maintain speed at idle, then the idle speed regulator may be to blame.

Go

The engine can be started several times to warm it up to the required level. In this case, it should only work at idle speed. If after several startup cycles you do not hear any extraneous sounds, including rustling or knocking, then you can immediately leave the garage. Also, when stopping and starting, the engine should not detonate.

Before repairs, the engine could operate unstably not only due to its own wear and tear, but other elements of its power supply could also be the culprits. If the engine is not running smoothly, you should check:

How to properly break in an engine after a major overhaul

Running in an engine after a major overhaul is a mandatory test. In normal mode, the internal combustion engine operates at high speeds, has rubbing surfaces and local overheating. Running in the engine helps you “prepare” for hard work and check the quality of the assembly. The choice of test method depends on the recommendations of the manufacturer and the capabilities of the service station. The owner of the vehicle can carry out the running-in, but a number of conditions must be observed so as not to harm the engine.

Diesel running-in

There are no significant differences in the running-in of a diesel engine compared to a gasoline power unit. But you will have to take several recommendations into account. Firstly, it will not be possible to limit the run-in to 3000 km. For a diesel engine, the minimum mileage is 12,000 km. Having covered such a distance, the driver will have the opportunity to operate the vehicle at full capacity.

Another small nuance is the muffling of the engine after braking. There is no need to do this immediately after stopping. You should wait a few seconds and only then turn off the system. This rule is relevant for turbocharged cars.

With an oil change, things are different. If gasoline engines need to be replaced after running-in, then for diesel engines - every 500 km of distance traveled.

Why is the engine broken in?

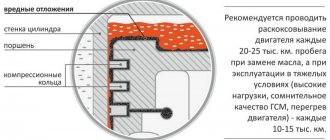

Running in the engine after a major overhaul is necessary to ensure uniform grinding of the rubbing surfaces. Despite the fact that modern materials and processing methods make it possible to obtain surfaces without scuffing, rubbing parts have some roughness. For the most part, this applies to the cylinder-piston group. Thus, a repaired cylinder block and new pistons have deviations in size and surface defects.

- adjust the mating of parts and reduce wear;

- minimize deformations;

- stabilize oil consumption;

- check the result of the overhaul.

During operation of the internal combustion engine, a large amount of heat is generated. Thus, the piston bottom heats up to 300℃ from interaction with the combustible mixture. The part is cooled through compression rings. In contact with the cylinder walls, the piston rings release heat, which goes away along with the lubricant.

During long-term operation, the piston rings rub against the cylinder walls. After the overhaul, the “connection” disappears. This is why you cannot reinstall used rings: they were “sharpened” to fit other dimensions of the cylinder and are not suitable for further work.

Failure to run-in leads to poor heat transfer from the piston to the cylinder. In turn, this causes overheating of the piston, detonation, deformation of the piston rings, or burning of the entire part.

To reduce break-in time, spare parts manufacturers have developed new profiles of compression rings: beveled, rounded, ribbed with tin filling, etc. Two-stage cylinder honing also affects the running-in regime, since the surface is run-in at a micro level.

How long to break in the engine and how to do it

The first 1000 km are considered the most important. During this period, it is not recommended to travel at speeds above 60 km/h: it is better not to engage fifth speed at all. During the initial run-in, bluish smoke may appear from the muffler pipe: there is no need to panic: this is natural, since new piston rings are being broken in. Unstable idle is also not a reason to worry. Adjustment should be done after 500-1000 km. How long does it take to break in the engine in total? After the car has traveled 2.5-3 thousand km, increase the maximum speed to 85-90 km/h, gradually increasing the load. The engine can be considered finally run-in after running 8-10 thousand km.

First launch after major overhaul

The first start of the internal combustion engine is carried out according to the following scheme:

- Fill in engine oil. It will take 10 minutes for the lubricant to fill the system. The oil filter is left dry to avoid air lock.

- Connect the fuel pump or supply fuel manually.

- Open the throttle manually if there is no automatic drive.

- Start the starter.

- Spin the motor up to 2000 rpm.

- Leave to idle for 15 minutes until engine rotation becomes stable at operating temperature.

- Turn off the unit and wait for it to cool completely.

During startup, the pressure in the lubrication system is monitored. The indicator signal for 4 s indicates incorrect engine assembly. We urgently need to turn off the engine! If the pressure quickly stabilizes, the internal combustion engine is warmed up to operating temperature.

There should be no leaks upon visual inspection. In the first 3 minutes, the engine may knock: the hydraulic compensators are being pumped or the cups are running in. In the future, the sound should become uniform, without vibration. The appearance of a burning smell and slight smoke for the first start is normal - the assembly lubricants are burning through.

If the internal combustion engine is operating stably, start running-in. In order to properly run in the engine after a major overhaul, you need to understand the nuances of the test.

Initial engine start

The initial start-up of the internal combustion engine after a major overhaul is as important as its assembly. Inaccuracies and errors will lead to the most serious consequences. Therefore, the success of running in a repaired engine largely depends on the driver’s accurate implementation of the recommended actions.

Sequence of actions when starting the engine for the first time:

- Fill in high-quality motor oil that meets the manufacturer's recommendations. It is recommended to fill in two stages: first to the Max mark, wait a few minutes, top up after the first part of the engine oil has partially drained into the sump. Topping must be done below the maximum mark.

- Check the condition of the battery. Overcoming problems with microscopic irregularities when cranking the crankshaft will depend on the charge level.

- Manually pump up diesel fuel when starting a diesel engine.

- Proceed to start the engine after completing all the specified steps. Pay attention to the time that the engine oil pressure lamp lights up. When first started, the lamp burn time exceeds the standard mode by several seconds. However, the engine must be turned off immediately in cases where the lamp does not go out. The reason is usually that the normal engine oil pressure has not been achieved.

- Do not use the gas pedal when starting the power unit for the first time to avoid increasing the load. Instead of the accelerator, you must use the clutch pedal.

- With the oil pressure lamp extinguished, the engine is heated to a temperature in the range from 85° to 92°C. Note:

when starting the internal combustion engine for the first time after a major overhaul, the applied lubricant begins to burn out and a burning smell appears. It is recommended to pay attention to the oil pressure after the engine reaches operating temperature. A slight decrease in pressure is allowed due to an increase in the temperature of the oil, which will be more liquid in this operating mode. If the pressure drops below 0.4 kg/cm², you need to look for the cause of the problem. It is possible that errors were made when assembling the internal combustion engine or low-quality oil was poured. - Then the engine is turned off and restarted after the temperature drops to 40°C. It is recommended to perform about 15 starts and then stop.

- Run-in should be continued at higher speeds, raising them from 1000 to 1500, then to 2000 rpm. In each mode, the engine should run for 3-5 minutes.

Methods for running in the engine

You can properly run in the assembled engine after a major overhaul using stands or during operation. At the service station, engine testing takes place in 3 stages:

- cold running;

- hot running without load;

- hot running with load.

The stands allow you not only to run in the engine, but also to check the quality of repairs. To do this, during the test the following is monitored:

- oil and coolant temperature;

- line pressure;

- crankshaft speed;

- developed power;

- specific fuel consumption.

Run-in is considered complete when the parameters reach a certain range of values and the engine is operating properly:

- at idle speed and at maximum shaft speed;

- evenly in all modes, without sudden knocks and noise;

- there are no oil, fuel or coolant leaks through the connections.

Let's take a closer look at how internal combustion engines are tested in service stations and in garage conditions. The methods are equally suitable for both gasoline and diesel engines.

Run-in on the stand

The stands are suitable for both cold and hot running. The equipment is an installation with an electric motor, control and measuring devices and a cardan shaft for transmitting rotation. The equipment is controlled automatically according to a given program.

The stand is selected according to the engine power. After a major overhaul, the motor is mounted on the unit, lubricant and coolant are added, and the necessary pipes and electrical connectors are connected. The test is completed by inspecting the internal combustion engine:

- remove the pallet;

- inspect the main bearing shells and crankshaft journals;

- If necessary, remove the cylinder head and remove the pistons.

Cold running, unlike hot running, is performed at low speeds of the electric motor, not the motor. The test lasts 20 - 40 minutes with a gradual increase in the rotation speed of the electric motor. During the process they control:

- heating the area where the cylinders and main bearings are located by checking by touch;

- tightness of connections;

- uniformity of engine noise;

- oil pressure and temperature.

For example, KamAZ-740 engines are tested according to the following scheme:

Crankshaft speed, rpm

Mode time, min

To reduce the inspection time by 2 times, low-viscosity oils and special additives are added to the internal combustion engine. This technological technique also makes it possible to reduce metal removal from running-in.

Benchless cold running

This option of cold engine running after overhaul is outdated. The car is attached to a tow rope and pulled in 3rd gear for several hours. This method does not allow tracking individual motor parameters and monitoring its condition.

Hot running

Hot running is the most popular method of testing a overhauled engine. It is carried out on a stand or on a machine with or without a load. Before testing on the stand, spark plugs are installed on the engine, the timing gaps are adjusted, and the power and fuel supply systems are connected. Running in the internal combustion engine is accomplished by rotating the crankshaft, so it is important to monitor the parameters of technical fluids.

During hot running without load, the internal combustion engine is started at a reduced crankshaft speed of 800 - 1100 rpm with a smooth increase in speed. The process takes from 20 minutes to several hours and is completed when half the nominal shaft speed is reached.

For example, the mode for engines ZMZ-405, 406 and 409 is as follows:

Crankshaft speed, rpm

Mode time, min

The ZIL-645 test is carried out in 8 stages:

Tips and tricks

The information below will be useful to those who do engine overhauls with their own hands or are directly involved in this process.

- Before the first start and during break-in, you need to pay special attention to the condition of the battery. Please note that during the first start it is most difficult to crank the crankshaft, so the battery must be properly charged.

- Some precautions should be taken when filling the oil and installing the oil filter before the first start. The main task is to prevent the formation of air pockets so that the unit does not experience oil starvation at the time of start-up.

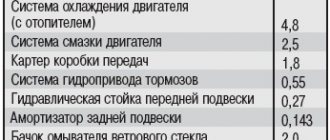

- Lubricant and other liquids must be filled strictly according to the level. The fact is that exceeding the recommended volume can lead to leaks and other malfunctions.

- After the first start, the oil pressure should return to normal within a few seconds while operating at idle. It is forbidden to gas if the pressure light does not go out. If the oil pressure at idle is low, the power unit must be turned off immediately.

- Then it starts again. If the situation does not change, then a malfunction is obvious. Any problems with the oil supply, air locks, incorrect operation of the oil pump and other reasons may lead to the need to re-repair the internal combustion engine.

- If the lubricant pressure at idle is normal, you can warm up the engine. As the temperature rises, the lubricant dilutes, and the pressure should also decrease slightly to a certain value. However, it should not fall below 0.4-0.8 kg/cm2.

- While the engine is warming up, you need to carefully inspect the power unit for leaks of oil, antifreeze and other fluids. If leakage is noticeable, the engine is immediately turned off, after which the problem should be immediately localized and corrected.

- If the pressure in the lubrication system is normal, the unit is dry and runs smoothly, then it is also recommended to carefully listen to the sound of the engine. There should be no extraneous noise or knocking.

Normal and stable operation of the internal combustion engine indicates that you can begin running in the engine under load. Take a short test drive while observing the oil pressure light in the lubrication system and the engine temperature on the instrument panel. After 2-3 km. along the way, stop the car and inspect the engine again for leaks of technical fluids.

Stable operation of the engine and all its systems will indicate that the engine after overhaul is ready for further running-in. To get the best results and extend the life of the motor, you need to adhere to the break-in regimes and follow the recommendations indicated above.

Engine speed and service life. Disadvantages of driving at low and high speeds. At what engine speed is it best to drive? Tips and tricks.

What does it mean to overhaul a car engine, what work is performed. What determines the engine life before overhaul and how to increase it. Useful tips.

How to rinse the engine yourself with diesel fuel or kerosene before changing the engine oil. Advantages and disadvantages of cleaning, features of flushing the engine with diesel fuel.

This is interesting: Timely replacement of engine oil is the responsibility of every driver

Hydraulic compensators: what they are, what function they perform, hydraulic compensator malfunctions and symptoms. Do-it-yourself repair and washing of hydraulic compensators.

Engine knocking or noise after changing engine oil. What causes the increase in noise level, oil or malfunction of the motor itself. What to do in such a situation.

Why is it necessary to break in a new diesel engine? How to properly break in a car, basic recommendations and instructions. How many kilometers does it take to break in a car?

What not to do

To avoid engine wear after repair, during break-in it is recommended:

- do not load the engine, choose routes without difficult road conditions: traffic jams, off-road conditions;

- keep the crankshaft speed no higher than 50 - 70% of the nominal, drive calmly;

- do not run the engine at idle speed, since grinding occurs under load, when the exhaust gases exert a uniform pressure of 15 - 20 atm;

- do not drive in one mode - the internal combustion engine must operate at different frequencies for uniform grinding of parts.

What not to do when breaking in

The battery must only be fully charged. This is due to the fact that at the first start, a lot of force is required to turn the crankshaft. When filling engine oil, air pockets must not be allowed, otherwise the internal combustion engine will experience oil starvation. You should not fill the oil above or below the required level, since exceeding the volume will certainly cause leakage, and reducing it will lead to the same oil starvation. If the oil pressure is insufficient, the engine is turned off and then restarted.

When starting for the first time, do not accelerate. Leakage of any types of technical fluids is unacceptable. Immediately after purchasing a car, it is not recommended to drive on bumpy roads. You should also avoid steep climbs. At this time, you don’t need to drive at high speeds - you need to spare the engine and not let it overwork while its parts have not yet had time to break in.

What is the engine life after a major overhaul?

Quiet driving extends the life of any engine. The more the internal combustion engine spins, the faster it wears out. Therefore, the engine life after a major overhaul largely depends on the driver. If, of course, the master installed good spare parts and did his job conscientiously.

Proper running-in “hardens” the engine and allows it to “get” its clearances. The unit gradually adapts to the loads, which increases its service life. Theoretically, a repaired engine, with proper operation, will be able to go as far as it did before the overhaul. But don’t forget about timely maintenance and filling with high-quality fuels and lubricants.

Changing the oil after engine overhaul

Engine break-in oil is poured after overhaul before the first start. To save money before the first replacement, it is optimal to fill in semi-synthetics that meet the tolerance.

There is an opinion that after the first starts the lubricant becomes contaminated with chips from machining and wear products, so the oil must be changed after 1000 - 2000 km. In practice, a good motor lubricant can last 4000 - 7000 km. To know for sure, check the level and quality of the lubricant once a week.

When changing the oil, be sure to install a new filter.

The rate of oil contamination is also affected by the quality of the overhaul. Mechanical processing of parts using modern equipment, performed by a skilled craftsman while observing clearances and tolerances, does not result in strong grinding. Cleaning and purging the motor after repair gets rid of the main dirt that clogs the lubricant.

Changing the oil before the break-in period

In some cases, it is possible to carry out the first oil change earlier than the car manufacturer recommends:

- If you drive a car in a big city and spend a lot of time in traffic jams, then you are gaining excess engine life - constantly changing gears, driving at low speeds and frequent acceleration on empty sections of the road. These factors contribute to the fact that parts grind in faster and a lot of micro chips appear. Problems also arise in winter. Cars do not have time to reach operating temperature and often drive from home to work and from work to home. In addition, our gasoline is not of the highest quality and is completely unsuitable for winter use. In winter it does not burn out completely due to additives. Due to these factors and cold, the oil life decreases and this greatly increases the load on the parts that are ground in during break-in.