Tuning the Niva Chevrolet engine can be done in several ways. First, let's consider the option of completely changing the engine, as well as the intake and exhaust.

The first step is to remove and disassemble the Chevrolet Niva engine, then change the crankshaft and piston rings. After which the engine volume will increase to 1.8 liters.

After such modification of the cylinder head, it is necessary to change the injectors and throttle assembly. Next, you need to increase the diameter of the exhaust pipes and replace the catalyst with a flame arrester. After all of the above, you can replace the control unit. All these actions help increase the power of the Chevrolet Niva engine.

Tuning the Niva Chevrolet engine by improving the cylinder head and engine geometry An excellent option for tuning the Niva Chevrolet engine is changing the cylinder head (cylinder head) and correcting the engine geometry. After such transformations, the filling of the cylinders with the combustible mixture will improve.

First, you need to increase the diameter of the pusher well, valve, as well as the inlet and outlet channels. Then the old valve seats are boldly cut out, and the diameters of the well for the pusher are increased. The camshaft requires solid pushers with a diameter greater than 1 mm.

Then we need to make new valve seats. But first you need to measure the holes for the saddles. Then these seats are placed in nitrogen, the cylinder heads are placed in an oven, and the cylinder head seats are installed in place.

Next, you need to assemble the cylinder head and check that the valves are tight. This simple procedure will increase the power of the Chevrolet Niva engine by 10%.

Common ways to increase power rating

There are quite a few different methods of tuning internal combustion engines, many are aimed at increasing the power of the installed power unit. In the case of the Chevrolet Niva, power is most often increased. Common ways to increase engine performance are as follows:

- Turbine installation. Almost all modern mid- and high-class cars have a turbine engine. This relatively simple unit in design is capable of increasing engine power by a significant 20% of the nominal value. However, this tuning method has a fairly large number of features that are worth considering.

- In most cases, chip tuning is carried out. This kind of modification involves unlocking the full potential of the installed engine. However, not in all cases it is possible to increase engine power in this way, which should be taken into account.

- Factory components of the power unit are often replaced. Due to this, it is possible to eliminate all defects and imperfections that were made at the production stage of the vehicle.

Let's take a closer look at the most common methods of tuning a Chevrolet Niva engine.

Installation of turbocharging on a Chevrolet Niva

Turbine for Chevrolet Niva

The second method of tuning the power plant of a Chevrolet Niva is to install a turbocharger. Moreover, this method allows you to significantly increase power and also increases torque.

Turbocharging provides significantly better filling of the engine cylinders with air due to forced injection.

With this tuning option, you should carefully select a turbine, otherwise the positive effect of its use may be significantly lower than expected.

Tuning in this way allows you to achieve an increase in engine power by 30%. At the same time, turbocharging only has a positive effect on fuel consumption, since it is reduced. And the increase in power is achieved due to better fuel combustion and ventilation of the engine cylinders.

Replacement of factory components

In order to obtain significant engine performance and increase its reliability, the main factory elements are often replaced with more advanced ones. An example would be:

- Modernization of the cylinder-piston group.

- Modernization of KShM.

- Carrying out boring of sleeves.

All of the above work makes it possible to slightly increase the volume of the combustion chamber, which leads to an increase in engine power.

In most cases, work begins with boring the inner diameter of the liners. Thereby:

- The combustion chamber increases.

- As the volume of the combustion chamber increases, the amount of fuel burned per stroke increases.

- The more fuel the engine burns, the more energy is released, which causes increased power.

Sidebar: Important: It is worth considering that after boring you will have to install new pistons and piston rings. This is due to the fact that even a slight deviation in the size of the resulting gap between the piston and the surface of the liner becomes the reason why the engine will start to operate incorrectly. Due to the fact that new pistons and rings are needed, the cost of the tuning in question increases significantly.

Quite often, an upgraded crankshaft is installed. Its features include the following points:

- Reduced weight, which reduces the structure's resistance to rotational motion, resulting in an increase in efficiency.

- The design has elongated shoulders. Due to this, the stroke of the rod increases and the torque increases.

The new crankshaft will also require shortened connecting rods.

If you bore the liners and install a new crankshaft, the volume of the combustion chamber increases from 1.7 liters to 1.9 liters. However, only increasing the volume of the combustion chamber does not give the desired result, since the engine in this case requires a larger amount of flammable liquid and more efficient saturation with oxygen. That is why, when tuning, the block head is also replaced or modernized.

Considering the modernization of the cylinder head, we note the following points:

- The inlet and outlet holes are often bored, which increases their throughput.

- Enlarging the intake and exhaust ports means that larger valves have to be installed. Very often the valve seat is bored, which also increases engine output.

Other features of the tuning carried out include the following points:

- An almost complete exhaust replacement is being carried out. Similar work is represented by increasing the diameter of the exhaust pipes. The essence of this modification is that increasing the diameter of the pipe that removes exhaust gases reduces the pressure in the system. The lower the resistance, the higher the efficiency value. You can replace the neutralizer with a flame arrester, which will also improve performance.

- It is worth considering that such serious changes to the engine require an almost complete reconfiguration of the fuel supply system. This is due to the fact that with standard settings the units will not receive the required amount of fuel. Most often, tuning the fuel system involves performing chip tuning, that is, reconfiguring the on-board computer program.

The above work makes it possible to increase the power indicator by approximately 15% of the nominal value. At the same time, do not forget that the improvements are based on increasing the volume of the cylinder block. Therefore, a certain increase in the flow rate should be expected. Nobody pays attention to the following points:

- An increase in engine power always leads to an increase in the load it experiences.

- When the load is applied, the structure becomes less strong, as the metal is ground down.

- It is very important to select high-quality and most suitable components, otherwise serious problems with engine operation may arise.

That is why today this kind of tuning is carried out extremely rarely, since it has a very large number of disadvantages. You can increase power and torque by installing a turbine. Moreover, the cost of such a modification will be much less than the above. However, it is worth remembering that if the engine is in poor technical condition, the turbine will only worsen the situation and lead to faster wear and tear of the structure. This device ensures more efficient filling of the combustion chamber with air due to artificial injection, which leads to increased power.

Engine VAZ 21213 - 1.7 l.

Niva engine characteristics

Years of manufacture – (1994 – present day) Cylinder block material – cast iron Power system – carburetor (21213) / injector (21214) Type – in-line Number of cylinders – 4 Valves per cylinder – 2 Piston stroke – 80mm Cylinder diameter – 82mm Compression ratio – 9 .4 Niva engine capacity 21213 – 1690 cm3. Engine power Niva 21213 – 81 hp. /5200 rpm Torque - 125 Nm / 3000 rpm Fuel - AI93 Fuel consumption - city 11.5l. | track 8.3 l. | mixed 10.5 l/100 km Oil consumption - 700 g per 1000 km Niva engine weight - 117 kg Overall dimensions of the Niva 21213 engine (LxWxH), mm - Oil in the Niva 21213 engine: 5W-30 5W-40 10W-40 15W-40 How much oil in the Niva 21213/21214 engine: 3.75 l. When replacing, fill in about 3.5 liters.

Niva engine life: 1. According to the plant – 80 thousand km 2. In practice – up to 150 thousand km

TUNING Potential – 200 hp. Without loss of resource - 90 hp.

Malfunctions and repairs of the VAZ 21213 / 21214 Niva engine

Engine VAZ 21213 1.7 l. carburetor/injection (21214) in-line 4-cylinder with overhead camshaft, Niva timing belt has a chain drive. Based on the 214 engine, the VAZ 2123 engine is produced for the Chevy Niva; the differences in adapting the block for installing a pulley in the engine compartment and mounting attachments are technically almost identical. The main differences between the VAZ 21213 engine and the 2106 are the cylinder diameter is 82 mm, the cylinder head, the Niva 21213 engine block from the 2106 is smaller in height. Among the advantages of the 213 engine, it is worth noting the presence of a chain tensioner (no need to tighten it) and hydraulic compensators (no need to adjust the valves). Disadvantages of the Niva engine - noisy, consumes oil, prone to overheating and vibrations, low resource. The motor has all the problems of the classic series, the 21213 Niva engine still heats up, troits, knocks, etc., what the problems are, for each case, are described in detail HERE, in the problems and malfunctions section.

Tuning the Niva 21213 and 21214 engine

Chip tuning of Chevrolet Niva or 21214 engine

There is no point in writing about this for a long time because the Niva chip is useless, the atmospheric engine cannot be stirred up with a chip, and all the rave reviews are nothing more than an attempt to justify a waste of money, let’s move on.

How to cheaply increase the power of a VAZ 21213 engine

The question on the agenda: how to increase the power of a Niva engine without any special tricks? The first stage is to increase the piston stroke to 84 mm using a crankshaft from a VAZ 2130, 82 mm pistons with a piston pin offset of 2 mm and we already have 1.8 liters. The second stage is to bore the cylinders for an 84 mm piston, thus assembling the 1.9 engine for the field. To fully boost the VAZ 21213 engine, you need to add a more efficient carburetor, bore the cylinder head channels (how to do this is described HERE), the intake diameter is 33 mm and the exhaust diameter is 31 mm, it is advisable to use light connecting rods, in the end we will get about 100 hp. The third stage - we build a 2 liter motor. We buy on the market a tuning crankshaft with an 88mm stroke and 84mm pistons with a pin offset of 4mm. A complete modification of the VAZ 21213 engine will be completed after installing a Nuzhdin camshaft (or an analogue) with a lift of 11.2, a light flywheel, light connecting rods and a modified carburetor, all of which will give a total of about 110 hp.

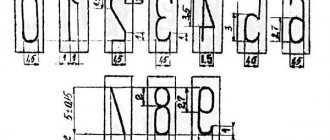

Niva engine boring options

— piston of standard diameter, increased stroke 1.8 liters. 82x84

85 hp Maximum torque

135 Nm at 3000 rpm - larger diameter piston, increased stroke 1.9 liters. 84x84 - larger diameter piston, increased stroke 2.0 liters. 84x88

16 valve engine for Niva

From time to time on forums they raise the issue of installing a 2112 engine in a Niva; this is a rather difficult and pointless task, due to the fact that 16V engines love speed and are not well suited for an SUV. If you want speed, sell your car and buy a Priora. The Niva is not suitable for high speeds and its tuning should be aimed, first of all, at increasing traction at the bottom.

Expert opinion

Vadim. After I moved to Niva from a foreign car, it immediately became clear that the engine would need to be completed. The lack of traction in almost any gear determines that you cannot drive comfortably off-road, and the car will not perform well on the highway. I did the tuning in stages, starting with the simplest

Egor. I decided to install a turbine on the car in question. The increase in power is quite impressive, but I decided to increase the figure by installing new sports-type consumable filters and replaced the exhaust system. I will say that the difference between 80 and 100 hp. very big.

Dmitriy. Conducted a modernization of the standard engine. I’ll say right away that no amount of tuning will solve one problem - engines of domestic origin have low reliability, you have to constantly change and finish something.

The lower classes can't, the upper classes don't want to

I won’t bother you - I have a modified 105 hp engine under the hood. with a maximum torque of 160 N.m versus 79.6 “horses” and 127 N.m for the standard car.

Who is Volodya? The head of the LSGA engineering center, Vladimir Sharandin, is a specialist in engine development and has been a good friend of mine for almost two decades.

The idea to start working on Niva was born spontaneously. We discussed another car, but the conversation itself led to the all-wheel drive of the GM-AVTOVAZ joint venture. What does Niva lack in driving disciplines? Of course, engine vigor. Especially when driving on highways. Off-road, the lower row of the transfer case helps out, but on the highway... The car frankly falls out of the modern flow. This is especially noticeable during acceleration. Trucks have now become fast and overtaking them on Niva is quite problematic. You have to fire up the SUV ahead of time, calculate the situation almost to the horizon and, without resetting, so as not to lose speed, perform a series of overtaking. Dangerous? Yes! This is the problem Vladimir undertook to solve.

It is clear that no one was going to make a youth car for street racing - the device was not for such an audience. It was about safety: the fight against prolonged overtaking and at least some reserve of agility under the gas pedal. At the same time, it was necessary not to overdo it. It was necessary to maintain all the best off-road qualities, not to overload the transmission with excess torque, keep fuel consumption at the same level and fit all this into a budget feasible for Niv owners. Oh yes, a mere trifle, the cylinder volume is standard - no work on the block, pistons, connecting rods or crankshaft. We don’t touch the bottom of the engine, we only modernize the top: cylinder head, exhaust, intake.

The Niva LSGA with a 105-horsepower engine has not lost its best off-road qualities.

The Niva LSGA with a 105-horsepower engine has not lost its best off-road qualities.

Well, in such a lift with a 105-horsepower engine, we go to a gear higher than in a car with a production engine. |

All-wheel drive is necessary here - immediately after the ford the road goes steeply upward. Previously, to be sure, I included a lower row here. And this Niva allows you to climb hills in first gear. |

And now back. And downwards on the stones, and upwards on the clay. |

Drawing conclusions

When looking for an affordable off-road SUV, many pay attention to this particular offer. However, it is worth considering that the installed motor first requires repair, and then significant modernization. Lack of power off-road becomes the reason why the car cannot overcome difficult areas. There are quite a large number of ways to increase power, they all have their own specific characteristics. Here are the best slots at russvulcans-clubss.com/.

Some modifications can be done independently, others require the intervention of professionals. Note that the power increase is 20 hp. - a completely achievable task without serious intervention in the design of the motor. Of course, many improvements will require significant investments. An example is the installation of sports filters, which are much more expensive than regular filters.

Chip tuning

This method is the cheapest since the engine does not undergo any technical changes. The work of chip tuning comes down to changing and adjusting the software in the ECU, which regulates work processes in the heating system. Using this type of tuning, power increases by 15%. Despite the fact that this method is the cheapest and makes it unnecessary to perform any manipulations with the power unit, it has its drawback: increasing power causes an increase in loads, thereby reducing its service life.

Using all three methods simultaneously, you can achieve a power of 120 hp. which will significantly increase cross-country ability on country roads, while the SUV will become more responsive and dynamic.

Increase compression ratio

Compression ratio is not the same thing as compression. Although the descriptions of the terms are very similar. Compression is the pressure that is created in the combustion chamber when the piston reaches the highest point. And the compression ratio is the ratio of the volume of the entire cylinder to the combustion chamber. It is calculated using a simple formula: Vcylinder + Vchambers, divide the resulting amount by Vchambers. The result will be the compression percentage of the original volume of the fuel mixture. Compression only shows whether the components that contribute to the efficiency of combustion of the mixture (rings or valves) are working properly.

How much will such a service cost from a specialist?

The price depends on whether the car owner will pick up the controller, in this case the cost will be 12,000 thousand rubles. If the controller remains with the master, then this service will cost the driver 10,000 thousand rubles. And for the Niva 21214M version the cost will be 7,000 thousand rubles. Of course, in different regions and cities, prices for chip tuning may increase or decrease, but not by much.

If you still decide to do engine tuning yourself, be sure to watch this video:

Chip tuning of a Chevrolet Niva significantly increases its capabilities, but do not forget that only a professional can perform this procedure efficiently. If you are confident in your abilities and (or) want to save a tidy sum, you can try tuning the car yourself, but the risk of serious damage rests entirely on your shoulders.

Features of operation

To ensure long-term and trouble-free operation of the power unit, it must be very carefully and properly maintained. It is also recommended not to allow the engine to operate in extreme modes.

First, let's look at the VAZ-2123 engine, it is a modified version of the power unit installed on the “classic Niva”. The main differences are as follows.

- There are additional fasteners for installing additional equipment.

- The oil filter is not screwed directly into the block, which was typical for all VAZ engines, but has an intermediate insert. This insert is called the oil pump bracket. The power steering pump is also attached to it.

- The cylinder head has been slightly modified. It is designed for the use of INA hydraulic supports.

- A new pump was used, it is marked 2123. The main difference is the use of a roller bearing instead of a ball bearing.

- The pan has been modified; the front axle gearbox is no longer attached to it.

- The fuel rail used is 2123-1144010-11.

We get rid of vibration and extraneous sounds of the Niva transfer case forever

The characteristic howl and hum of the transfer case on VAZ-21213 cars, alas, is familiar to many owners of such cars. Let’s figure out what is the reason for these problems, and most importantly, how to get rid of them without using “collective farm” methods, such as additional noise reduction.

Content

- Let's understand the terminology.

- We study problems and repair methods. Vibration and how to deal with it.

- We remove the howl and hum.

- We remove the possibility of oil leakage.

- Niva (LADA 4×4)

Understanding the terminology

Let's start by diving into the materiel. Transfer case (TC) is a separate unit of an all-wheel drive vehicle, which provides multi-mode power distribution from the engine to the front and rear axles.

Externally, this is a mechanism located under the bottom of the car, in the body of which a multiplier (divider) is placed in series to obtain an intermediate gear ratio in the transmission and a splitter of one power flow into two. It is with the help of this device and its controls (levers) that go into the vehicle interior that the LADA 4×4 driver selects the all-wheel drive operating mode.

The RK directly connects the front driveshaft and the intermediate shaft (shaft) with the vibration damper to the vehicle’s gearbox. As is probably already clear from the description, this element is connected to the rear axle of the car via a rear propeller shaft.

We study problems and repair methods.

Any car owner definitely doesn’t need to be told why howling and humming are bad. Vibration of the transfer case on a Niva at low speed is quite common. The driver, of course, gradually gets used to many extraneous sounds in the car, but the noise level is high enough to make it impossible to carry on a conversation with passengers while traveling. Due to excessive noise pollution, you will inevitably have to deal with the problem.

Vibration and how to deal with it.

The main reason for the occurrence of unnecessary sounds is multi-frequency vibrations of the components of the transmission. In general, the vibration of the transfer case on a Niva is one of the most common cornerstones that other car owners are forced to fight (or put up with) constantly.

- Check the cushions (supports) on which the power unit, gearbox and other parts are attached to the body, including the muffler. Any worn-out pad or rubber band can easily cause excessive shaking of the iron and accompanying rumble. It is better to replace worn silent blocks and pillows immediately.

- Be sure to pay attention to the intermediate shaft (inlet shaft). If you see signs of “fatigue” - change the elements that have become unusable, or the entire part!

Perhaps this is the most complete set of measures that experienced auto mechanics advise when the transfer case on a Niva hums and vibrates!

Removing the howl and hum

We will assume that we have dealt with the vibration, but an equally significant problem remains - how to remove the howling of the transfer case on the Niva. Vibrations of the mechanism are not always the only reason for the appearance of extraneous irritating sounds. And the characteristic noise of the transfer case, alas, is one of the “trademark” shortcomings of one of the best domestic SUVs.

- The first thing you should pay attention to is the levers. It is better to immediately replace them with silent ones - with anti-resonance bushings inside. They won’t eliminate all the noise, but they will definitely extinguish some of it.

- The result will be even better if you install a small-module transfer case - with front and rear covers equipped with double-row bearings. In 2010, AVTOVAZ introduced new double-row bearings for output shafts in order to get rid of backlash and runout, as well as extend the life of the seals and, in general, increase the reliability of the mechanism. Here logic is man’s friend: less shaking and hesitation means higher service life and reliability.

Removing the possibility of oil leakage

In an effort to resolve the question of how to get rid of the howling of the transfer case, even before the 2010 update, the manufacturer began assembling this mechanism using silicone sealant instead of cardboard gaskets. And he introduced an improved crankcase ventilation system with an open breather, which was located under the hood. Again, the reliability of the vehicle when passing fords has increased slightly, and most importantly, the load on the seals has also decreased.

We mention them again to point out that the fewer vibrations and shocks, the longer it will not take to detect an oil leak on the transfer case housing due to deteriorated seals. Moreover, the flange in the RC covers can cause noise - during operation, the bearing seats are simply broken.

We hope that the steps listed above will become complete step-by-step instructions on how to eliminate transfer case noise on a Niva.

A universal remedy that will definitely eliminate the noise of the transfer case?

For people who do not want to spend a lot of time modifying the components of their SUV, there is a proven solution. A fairly reliable universal option for how to remove the howling of a transfer case on a Niva, one might say, know-how from the SV-PARTs company, is the installation of a steel four-satellite differential.

How to adjust it yourself?

To adjust the mechanism you will need keys 10, 13 and 17, pliers and a pencil. The operation is performed on a lift or inspection pit. The work order is as follows:

- Using a 10mm wrench, unscrew the locknut of the pedal travel limiter.

- By rotating the nut, set the free play within 0.4-2 mm.

- Tighten the locknut.

Then you need to go down under the car and adjust the free play of the pusher within 4-5 mm (to unscrew the nuts, you need wrenches 13 and 17). The check is performed as follows:

- Using pliers, remove the clutch fork release spring.

- Place a pencil against the boss of the lower mounting of the working cylinder.

- Make two marks: opposite the fork and 5 millimeters to the right.

- Pull the fork all the way back, selecting the free stroke of the pusher.

- The fork should stop exactly opposite the mark on the pencil.

If the gap does not correspond to the nominal one, you need to loosen the lock nut and rotate the nut to achieve the required parameters.

When adjusted correctly, the clutch begins to disengage when the pedal travel is 25-35 millimeters.

The final check is performed with the engine running. If everything is done correctly, the gears change easily, and the car starts to move if the pedal is released approximately ⅓ - ⅔ of the stroke.