VAZ 2101 is one of the first mass-produced Soviet cars, which was produced for two decades. The famous “penny” was equipped with a 1.2-liter carburetor four-cylinder engine. The VAZ 2101 gasoline engine established itself as an unpretentious, economical and easy-to-repair engine that could run on 76 gasoline and lasted on the assembly line for more than 20 years without any upgrades.

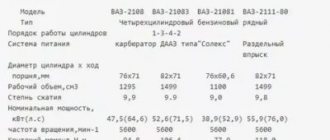

Characteristics of the VAZ 2101 engine

Years of production – (1970 – 1983) Cylinder block material – cast iron Power system – carburetor Type – in-line Number of cylinders – 4 Valves per cylinder – 2 Piston stroke – 66 mm Cylinder diameter – 76 mm Compression ratio – 8.5 Engine displacement VAZ 2101 – 1198 cm cube Engine power VAZ 2101 – 59 hp. /5600 rpm Torque - 89 Nm Fuel - AI92 Fuel consumption - city 9.4 l. | track 6.9l. | mixed 9.2 l/100 km Weight of the VAZ 2101 engine - 114 kg Overall dimensions of the VAZ 2101 engine (LxWxH), mm - 540x522x621 What kind of oil to pour into the VAZ 2101 engine: 5W-30 5W-40 10W-40 15W-40 How much oil is in the 2101 engine: 3.75 l. When replacing, fill in about 3.5 liters. Service life of VAZ 2101: 1. According to the plant – 125 thousand km 2. In practice – 200 thousand km

TUNING Potential – 200 hp. Without loss of resource, about 70-75 hp.

Engine 2101 was installed on: VAZ 2101 VAZ 2102 VAZ 21035 VAZ 21041 VAZ 21051

Story

New reforms, technical measures, and the organization of various improvements at the Volzhsky Automobile Plant led to the idea of creating a new, multifunctional car. Therefore, they began to cooperate with the Italian company Fiat, starting to create a new VAZ-2101.

The designers agreed that the style and the whole car would look like the FIAT 124, which was a very popular and cool car. This was how it should have been until inconsistencies were discovered during the development process, and therefore the machine was created in a completely different design, the one that exists today. And the reasons for rejecting the idea of creating a design, like that of the Italian brand Fiat, were as follows:

- The body would not have been able to withstand the car during turns, intense and aggressive driving, coupled with a weak suspension; it was fragile and of poor quality.

- The low ground clearance did not correspond to the idea: the VAZ-2101 should at least somehow be able to drive off-road.

- If the car broke down, towing did not help, since there were simply no elements to support it.

It is for these reasons that the Italian brand and the Soviet one did not compromise and did not make a design like the Fiat 124.

Engine malfunctions and repairs 2101

Engine VAZ 2101 1.2 l. base for the entire classic VAZ family, contrary to some opinions that the VAZ 2101 has a Fiat engine, this is not entirely true, the 2101 engine was created from a crude prototype of the FIAT 124 engine. Due to the increased center-to-center distance in relation to the Fiat engine, it allowed VAZ engineers to repeatedly increase the working engine capacity. Subsequently, 1.3 l., 1.5 l., 1.6 l engines were built from it. up to 1.7 l. and 1.8 l. The kopek engine is an in-line 4-cylinder carburetor with an overhead camshaft, the gas distribution mechanism 2101 has a chain drive. The motor belongs to the Zhiguli so-called “classic” series with a low block. The service life of the VAZ 2101 engine, in quiet operation and timely maintenance, reaches 180-200 thousand km.

On models 1970-1974, the penny engine has higher reliability, since production was controlled by specialists from FIAT. Before describing the endless problems of the engine, I would like to answer the question where is the engine number on the VAZ 2101. We stand in front of the car, on the left side, looking at the front of the engine block, in the area where the breather and crankshaft pulley are located. Look carefully, the writing is small. Let's move on to the problems of the VAZ 2101; on engines there is a problem of increased camshaft wear. The engine also needs systematic (every 7-10 thousand km) adjustment of the valve clearances; this will be indicated by a loud knocking noise heard from the driver’s seat when the engine is idling when the hood is closed. Weber and Ozone carburetors constantly require CO adjustment and cleaning. High oil consumption of VAZ 2101, up to 0.7 liters per 1000 km. The VAZ 2101 engine gets hot very often, the reason for this is a malfunction of the cooling system thermostat. Occasionally, the cause of overheating of the VAZ 2101 engine can be a fan failure, a pump malfunction, the use of gasoline with an octane rating higher than the recommended one, and a number of various minor reasons. It is very common for a VAZ 2101 engine to smoke, for which there are a number of main reasons: burnt out piston rings, rich carburetor, faulty valve seals, wear of valve guides and much, much more. Most often, this is a sign that you are waiting for a major overhaul of the VAZ 2101 engine. It is also not uncommon for the VAZ 2101 engine to malfunction, which leads to its rapid wear. Among the reasons for VAZ 2101 engine malfunctions, the list can be endless, the most basic ones are described above, in other cases you need to contact the experts.

Overhaul of VAZ engine

Most car enthusiasts carry out VAZ engine repairs with their own hands. The simple design and arrangement of components makes it easy to troubleshoot. But the overhaul of a VAZ engine will require special equipment, such as boring and honing machines.

The engine overhaul is often done with your own hands, but the cylinder block and crankshaft are taken to a specialized car service center for boring. The crankshaft repair sizes are 0.25, 0.5, 0.75 and 1.0. As for the block, the repair size step is 0.5 mm.

The most common question that motorists ask is: on which VAZ engines does the valve bend? The valves can bend on any engine where the timing drive mechanism breaks.

But this does not threaten the classics, since they do not have a belt drive, but a chain drive. Thus, the chain takes care of itself from one major overhaul to the next.

Engine tuning 2101

Description of the VAZ 2101 engine tuning process

Tuning a penny engine, or as they also say, boosting the engine of a VAZ 2101, is a risky business, taking into account what is written above and taking into account the general wear and tear of the engine, if this does not stop, then let's go... first, let's look at it from the point of view of increasing the engine displacement. This is the most affordable method to improve your engine, increasing power and torque throughout the entire range. We will also describe the option of installing sports camshafts, boring cylinder head channels, compressors, etc. in detail below. But given the fact that your engine is a used 2101, hanging too much on it is fraught with consequences. To increase the power of the VAZ 2101 engine, let's start with cars produced in 1970-1974; they are distinguished by the ability to install Niva pistons with a diameter of 82 mm from the VAZ 21213 Niva, thanks to the thick-walled cylinder block. To prevent the compression ratio 2101 from sagging (a puddle in the pistons 21213), you need to take Niva pistons with a flat bottom or lighter pistons 2112 and cut off the displacer from the pistons. With a standard stroke of 66 mm, the engine volume will be 1.4 liters. We will get an increase in power, but the engine itself will be very high-speed. The increase in engine volume of the VAZ 2101 produced after 1974 is somewhat different, the cylinder block has become thin-walled in order to save metal, the maximum possible piston diameter is 79 mm from the VAZ 21011 or 2105. The piston stroke has increased to 80 mm . implemented by installing a crankshaft from a VAZ 2103 and connecting rods with a reduced center-to-center distance (129 instead of 136) or installing pistons with a reduced compression height, produced by TRT. Disadvantages of short connecting rods - the angle of inclination of the connecting rod, the greater the angle of inclination, the greater the force it presses the piston against the cylinder wall, the resistance to movement increases, lubrication conditions worsen, the cylinder walls wear out, the connecting rod works under greater load (especially in the center of the connecting rod), engine reliability 2101 decreases. Among the advantages, we note a good cylinder filling rate at medium and low speeds, a more homogeneous mixture, and improved combustion. The disadvantages of TRT pistons are their lower strength compared to standard VAZ 2101, thermal load on the ring and the likelihood of piston burnout. Increased piston stroke to 84 mm. VAZ 2130 crankshaft, as well as use TRT pistons, connecting rods shrink to 134 mm.

Boring of VAZ 2101 engine

- larger diameter piston, standard stroke 1.3 liters. 79x66 (cylinder diameter X piston stroke) ~64 hp—larger diameter piston, standard stroke 1.4 liters. 82x66 (until 1974) Such VAZ engines were not produced in series; there is little information about the construction of such engines. This is explained by the fact that in order to adequately use such a motor, you need a reinforced bottom, forged pistons, selecting the desired top shaft, etc., plus everything needs to be properly configured. The maximum speed of the correct configuration is more than 9000 rpm. The service life of such an engine is about 20 thousand, depending on operation. - standard piston, increased stroke 1.5 liters. 76x80 ~70 hp Maximum torque is approximately 105 Nm at 3000 rpm Analogue of the VAZ 2103 engine on a low block. This option is the answer to all questions about how to improve the VAZ 2101 engine. - larger diameter piston, increased stroke 1.6 liters. 79x80 ~75 hp - larger diameter piston, increased stroke 1.7 liters. 82x80 (until 1974) ~ 80 hp - larger diameter piston, increased stroke 1.8 liters. 82x84 ~80 hp (until 1974)

- VAZ 2103 engine: features, replacement with analogues, malfunctions and repairs

Tuning cylinder head VAZ 2101

A good option for upgrading the VAZ 2101 engine by removing the roughness of the channels, polishing the cylinder head channels and the VAZ 2101 manifold reduces the intake resistance, the power of the penny engine increases by about 5-8 horsepower, and the torque increases throughout the entire range. To polish, it is necessary to remove the cylinder head and wash it with the mixture. With additional boring of the channels, the VAZ 2101 engine is capable of producing about 75 hp. It is also recommended to use T-shaped valves on classics instead of tulip-shaped ones.

Camshaft for classics

A correctly selected camshaft for the 2101, as well as a modified head, can produce more than 80 hp when boosting the VAZ 2101 engine.

Compressor for VAZ 2101

The market offers ready-made compressor installation kits for the VAZ 2101, for example an auto-turbo compressor with a pressure of 0.5 and 0.7 bar. The 0.5 bar auto-turbo compressor is installed with minimal modifications. When installing a compressor on a VAZ with a pressure of 0.5 bar on a modified cylinder head with a volume increased to 1.5-1.6 liters, the car will produce more than 120 hp. With standard volume up to 90-100 hp. The installation may reduce the service life of the VAZ 2101 engine.

Rotary engine on VAZ 2101

An extreme measure because the price of a rotary engine for a VAZ will force you to immediately discard this idea. Among the rotary engines, the classics include the VAZ-411 RPD with a power of 120 hp, and the VAZ-413 with a power of 140 hp. and VAZ-415 with a power of 140 hp, but lighter. A VAZ-411 RPD with a power of 120 hp was installed on a penny. with it the car was traveling about 180 km/h. The disadvantages of the VAZ RPD are its low service life (with 125 thousand km declared by the manufacturer), high fuel consumption and high oil consumption (up to 1 liter per 1000 km).

ENGINE RATING: 2

<<BACK

ENGINE VAZ 2106-1000260.

CHARACTERISTICS OF THE VAZ 2106 ENGINE.

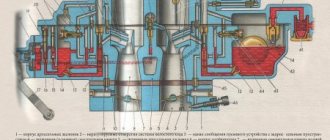

The engine is four-stroke, carburetor, in-line, with an overhead camshaft. The engine cooling system is liquid, closed type, with forced circulation of liquid. The engine has a combined lubrication system: pressure and splash.

| Number of cylinders: | 4 |

| Cylinder displacement, l: | 1,57 |

| Compression ratio: | 8,5 |

| Rated engine power at a crankshaft speed of 5400 rpm: | 54.8 kW/74.5 hp |

| Cylinder diameter, mm: | 79 |

| Piston stroke, mm: | 80 |

| Number of valves: | 8 |

| Minimum crankshaft speed, rpm: | 850-900 |

| Maximum torque at 3400 rpm, N*m: | 104 |

| Cylinder operating order: | 1-3-4-2 |

| Octane number of gasoline: | 91-93 |

| Fuel supply system: | carburetor |

| Spark plug: | A17DVR, A17DV-10 |

| Weight, kg: | 121.0 |

Engine Features.

Engine 2106-1000260 is installed on VAZ 2103, 2106, 2121, 21053, 2107.

The VAZ 2106 engine is a modified VAZ -2103 engine

The change in engine power was achieved due to the engine displacement by increasing the cylinder diameter to 79mm.

Cylinder block 2106-1002011 with a cylinder diameter of 79 mm.

Five classes of cylinders are defined: A, B, C, D, E. (The difference in size between classes is 0.01 mm (the designation of its class is applied on the lower plane of the cylinder block, next to each cylinder)

Block head 21011-1005011-10.

New head gasket.

The 2106 engine has pistons from the 21011 engine with a diameter of 79mm.

The model 21011 piston differs from the 2101 piston by the presence of a cylindrical hole on the bottom of the piston and has an increased diameter. During operation, different zones of the piston heat up unevenly. To compensate for thermal deformation, the shape of the piston differs from the shape of a regular cylinder. Also in the piston bosses are steel temperature control plates. To reduce dynamic loads on the piston, the hole for the piston pin is offset to the right from the central axis by 2 mm. To ensure correct assembly, next to the hole for the piston pin, there is a marking in the form of a “P” symbol. During assembly, all pistons are oriented so that the marks are directed toward the front of the block.

Five classes are defined for piston diameters, with a difference in size of 0.01 mm. Classes are designated in Latin letters, similar to the designation of classes for block cylinders.

Pistons, based on the hole for the piston pin, are divided into three size categories - every 0.004 mm (categories are designated - “1”, “2”, “3”). At the bottom of the piston, the piston class and piston pin size category are stamped.

Since 1986, two repair sizes for pistons have been determined: with an increase of 0.4 and with an increase of 0.8 mm.

Piston ring set 2106-1000100-10.

A special feature of this kit is that the oil scraper ring is chrome plated (unlike kit 2101). Chrome plating is performed to increase the service life of the ring, which was required to be carried out under increased load associated with an increase in engine power.

Set of steel rings - 2106-1004029.

Steel connecting rod, forged model 2101.

A 2103 crankshaft is installed on the engine (it differs from the 2101 crankshaft in the crank radius increased by 7 mm). On the crankshaft 2103, on the main journal cheek, the marking “2103” is applied. Instead of shaft 2103, it is recommended to install crankshaft 21213 , which has the appropriate mounting dimensions.

Crankshaft 21213 has improved dynamic characteristics due to additional counterweights.

Carburetor "Ozone" 2107-1107010-20

Ignition distributor with vacuum ignition timing regulator. Ignition distributor 30.3706.01

Ignition coil B-117A.

Generator G221 42A.

Starter 35.3708 with a power of 1.3 kW.

The remaining components correspond to the elements of the VAZ-2103 engine.

Equipment of the VAZ-21213 engine Characteristics of the VAZ-21214 engine

“Zhiguli” is the most common car of Soviet, and later Russian production. Under this name, seven models are united on a common rear-wheel drive platform, which were produced at the Volzhsky Automobile Plant (VAZ) from 1970 to 2012. Today they are called “classics” to separate them from the next front-wheel drive family, the VAZ Sputnik (Lada Samara). The ancestor of the series was the VAZ-2101 - the first car produced in Tolyatti, a twin of the Italian Fiat 124 sedan. It was also the first Soviet model designated in accordance with the industry norm of 1966, which established standard indices for cars of different classes (in this case, the number " 21" meant a small class with an engine capacity of 1100-1800 cm3, "01" was the serial number of the model, and subsequent numbers indicated the modification). On the territory of the USSR, the first generation Zhiguli was sold under the official name VAZ-2101, and in the 80s. The nickname “Kopeyka” stuck with them. In other countries, the car became known as the Lada 1200/1300, since the word “Zhiguli” is difficult to pronounce in European languages and is consonant with the negative concept of gigolo. With the collapse of the Soviet Union, VAZ began to produce all its models under the Lada brand.

At the end of the 60s. The largest automobile factories of the USSR - Izhevsk and AZLK - produced no more than 200,000 cars per year. This was not enough to satisfy the need for personal transport for a rapidly growing population, and besides, Moskvich brand products by that time no longer met international standards. Another reason for the construction of a new enterprise is the need to put into circulation the funds accumulated by Soviet citizens due to the general shortage: a modern car could become a very popular product for many years to come. In 1966, Soviet Vneshtorg concluded an agreement on scientific and technical cooperation with the Italian company Fiat, according to which Fiat provided the Russian side with a plant design and a license to produce one of its small cars, modified for operation in unfavorable climatic and road conditions, and also carried out training of Soviet specialists in Italy. In 1967, in the city of Stavropol, renamed Togliatti (in honor of the Italian communist who staged a strike at the Fiat plant in the 20s), construction of the auto giant Volzhsky Automobile Plant began.

The Fiat 124, recognized as the “European Car of the Year” in 1967, was chosen as the prototype for the basic VAZ model. However, tests carried out on Russian roads showed its unreliability and poor cross-country ability, so the Italians had to significantly revise the design of the car and designate the resulting version as the Fiat 124R. The main changes affected the chassis and transmission: the car received drum brakes on the rear wheels instead of disc brakes, a reinforced front suspension on wishbones and coil springs, a new rear axle on springs and five reaction rods instead of one reaction pipe, increased clutch and improved synchronizers in 4- step manual transmission. In addition, Soviet engineers demanded that an essentially new power unit be developed for the VAZ-2101 - an in-line 4-cylinder with a camshaft in the cylinder head (OHC) and a two-chamber vertical carburetor DAAZ-2101 (Weber 32 DCR), with a volume of 1198 cm3 and a power of 64 hp The original Fiat 124 engine with the same displacement developed 60 hp, but its OHV valve design was unpromising for further development. The wheelbase remained unchanged - 2424 mm.

The VAZ-2101 was more advanced than its Italian counterpart in many respects. Its body was made of thicker sheets of metal, which increased its durability, but affected the weight of the car. Increased ground clearance and the addition of towing eyes made it easier to use on country roads. Safety has been improved by strengthening the supporting structure in some areas, installing recessed door handles and “fangs” on the front and rear bumpers. In the cabin, the VAZ-2101 was equipped with seats that could be transformed into full-fledged berths. Standard equipment included a heater, windshield washer, side window vents and a Hungarian RD-3602 radio. Early examples were equipped with floor pedals instead of outboard pedals, an auxiliary fuel pump and a handle for starting the engine in winter. It should be noted that in terms of manufacturability, dynamic characteristics, build quality and ease of maintenance, the VAZ-2101 was an order of magnitude higher than all other Soviet-made cars, which ensured high consumer demand for the entire production period.

The first VAZ-2101 rolled off the assembly line of the Tolyatti plant on April 19, 1970. By the end of the year, 21,530 units were built, in 1971 - already 172,175 units, and the planned production volume was 660,000 units. per year the enterprise reached in 1974. Sales of the car were high from the very beginning, so that most Soviet citizens were forced to sign up and wait for a car for years. In 1971, the Lada 1200 was exported to Yugoslavia, Finland, Czechoslovakia, Hungary, East Germany and Cuba, and in 1974, when the Fiat 124 was discontinued, AvtoVAZ was able to sell the model in Western Europe. In the UK the Lada 1200 cost £979. Almost immediately, the VAZ-2101 demonstrated its racing potential inherent in the design of the power unit. In 1971, the car took part in the USSR rally and circuit racing championships, as well as in the 14,000 km Tour of Europe-71 marathon, where the factory team won the silver cup. The high power density made it possible to use the VAZ-2101 as a police vehicle in the USSR and the countries of the socialist bloc.

In 1974, a modernized version of the Zhiguli appeared - VAZ-21011 (Lada 1300). It was equipped with an engine capacity of 1294 cm3 (69 hp) and was distinguished by a radiator grille with more frequent horizontal crossbars and ventilation slots above the front bumper, rubber pads on the bumpers instead of “fangs”, interior ventilation holes in the rear pillars, rear reflectors with a rear light travel, more comfortable seats and a modified location of some controls. The modification of the VAZ-21011 with a 1.2-liter engine was called VAZ-21013 (Lada 1200S), and the modification of the base VAZ-2101 with a 1.3-liter engine was called VAZ-21016. There were also right-hand drive versions of the VAZ-21012 and VAZ-21014 and experimental series of the VAZ-21018 and VAZ-21019 with rotary engines. High-performance modifications for the police and special services were called VAZ-21015 “Karat” (with a VAZ-2106 engine) and VAZ-2101-94 (with a VAZ-2103 engine). Total from 1970 to 1988 About 4.85 million VAZ-2101 sedans of all modifications were produced. In 2000, according to the results of an all-Russian survey conducted by the magazine “Behind the Wheel,” the VAZ-2101 was named the best domestic car of the 20th century.

Engine VAZ-21213 technical characteristics

| Engine index | 21213 |

| Manufacturer | AvtoVAZ |

| Years of manufacture | 1994 — … |

| Type | petrol |

| Supply system | SOLEX carburetor |

| engine's type | in-line |

| Working volume | 1690 cm3 (1.7 l.) |

| Maximum power | 81 hp (61 kW) |

| Maximum torque | 126 Nm at 3000 rpm |

| Compression ratio | 9,3 |

| Ignition | distributor |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Cylinder head material | aluminum alloy |

| Cylinder block material | cast iron |

| Intake manifold | duralumin |

| An exhaust manifold | cast, cast iron |

| Camshafts | original cam profile |

| Cylinder diameter | 82 mm. |

| Piston stroke | 80 mm. |

| Pistons | original |

| Cylinder operating order | 1-3-4-2 |

| Number of valves | 8 |

| Idle speed | 750-800 min-1 |

| Fuel supply system | carburetor |

| Valve train chain | double-row chain, from VAZ-2103 with tensioner shoe |

| Engine weight | 117 kg. |

| Adjustment of valves | nuts |

| Dynamic characteristics | |

| Oil volume | 3.75 l. |

| Coolant volume | 10.7 l. |

| Cooling system | forced, antifreeze |

| water pump | with plastic impeller |

| Candles | BCPR6ES from NGK or domestic AU17DVRM |

| Spark plug gap | 1.1 mm. |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | with check valve |

| Flywheel | 21213 with a bore diameter of 200 or 215 mm. |

| Flywheel mounting bolts | M12 x 1.25 mm, length 26 mm. |

| Valve stem seals | |

| Compression | from 14 bar, difference in adjacent cylinders maximum 1 bar |

| Oil consumption | 0.7 l. per 1000 km. |

| Oil viscosity | 5W-30, 5W40, 10W-40 15W40 |

| Recommended oil brand | Liqui Moly, Lukoil. Rosneft |

| Operating oil temperature | 95o |

| Fuel consumption | |

| Fuel consumption highway | 8.3 l. per 100 km. |

| Fuel consumption mixed | 10.5 l. per 100 km. |

| Fuel consumption city | 11.5 l. per 100 km. |

| Gasoline brand | AI-92 |

| Unit resource | |

| Tightening forces of threaded connections | |

| Candle | 31-39 N.m |

| Flywheel | 62-87 N.m |

| Clutch bolt | 19-30 N.m |

| Bearing cap | main 68-84 N.m connecting rod 43-53 N.m |

| Cylinder head - three stages 20 N.m | 69-85 N.m + 90o + 90o |

| Environmental standards | Euro-0 |

| The VAZ-21213 engine was installed on: |

Engine characteristics Lada 4x4 Files Design and repair 2101, 21011pdf45.35 MB

By default, ICE 2101 has become the base option for cars of the VAZ family. The first experiment was modification 21011 - the piston stroke of the engine became shorter, but the cylinder diameter increased. In fact, this was a factory boost of the engine by specialists in order to increase power and save users from the need to carry out major repairs more often than the specified frequency.

ICE 21011

VAZ. Which engine is better???VAZ 2106 or 2103?

just a little boost

yeah, right now, the same. The volumes are different, some 2106 have 1.5

so they look the same...

The troechny has always been the best engine on VAZ..

Calla and both - they were invented in Italy in 1969, for VAZ, and in Tolyatti they are still installed on new cars - cunt. ts!!!!

2106 is 1.6l, 2103 is 1.45l. 2106 is a little more powerful.

1500 and 1600 volume—All the difference

2106 which, with a volume of 1600, is the most durable of the Zhiguli ones

depending on the engine modification

The most reliable engine is 1300 cc for classics, followed by 1600 and the last 1500. I have arguments and gained experience in the 80-90 years of repairing hundreds of these engines.

basin-shaped, all the same

definitely 2103!!! I drove this one myself for 195,000 km. There were no problems and no repairs either. Timely adjustment of valves, tightening of the chain, Castrol oil 10 Dabolyu 60 replacement every 10,000 km.

C grade - the most repairable! By the way, the 21063 was equipped with a 21011 engine - 1300cc.

touch.otvet.mail.ru

Operating parameters of motor 21011

The classic modernization of the 2101 internal combustion engine increased the volume of combustion of the fuel mixture while simultaneously reducing the piston stroke. Fuel consumption has changed slightly upward, but the engine has become “reactive.” The main technical characteristics of version 21011 are as follows:

| Manufacturer | AvtoVAZ |

| Engine brand | 21011 |

| Years of production | 1974 – 2006 |

| Volume | 1294 cm3 (1.3 l) |

| Power | 50.7 kW (69 hp) |

| Torque | 94.3 Nm (3400 rpm) |

| Weight | 114 kg |

| Compression ratio | 8,8 |

| Nutrition | carburetor Ozone DAAZ 2105 |

| Motor type | in-line, upper |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Intake manifold | "long" partitions |

| An exhaust manifold | "spider", scheme 4/2/1 |

| Camshaft | upper location inside the cylinder head |

| Cylinder block material | cast iron |

| Cylinder diameter | A class – 79 – 79.01 mm B class – 79.01 – 79.02 mm C class – 79.02 – 79.03 mm D class – 79.03 – 79.04 mm E class – 79.04 – 79.05 mm |

| Pistons | 79 mm |

| Rings | not symmetrical, uncoated |

| Piston diameter | A class –78.94 – 78.95 mm B class – 78.95 – 78.96 mm C class – 78.96 – 78.97 mm D class – 78.97 – 78.98 mm E class – 78.98 – 78.99 mm |

| Crankshaft | VK cast iron, short crank radius |

| Number of main bearings | 5 |

| Piston stroke | 66 mm |

| Fuel | AI-93 |

| Environmental standards | Euro 2 |

| Fuel consumption | highway – 8 l/100 km combined cycle 9.5 l/100 km city – 11 l/100 km |

| Oil consumption | maximum 0.7 l/1000 km |

| Engine oil for 21011 | 5W-50 and 10W-40 |

| Engine oil volume | 3.75 l |

| Working temperature | 80° |

| Motor life | declared 125,000 km actual 200,000 km |

| Adjustment of valves | nuts |

| Cooling system | forced, antifreeze/antifreeze |

| Coolant quantity | 9.75 l |

| water pump | with plastic impeller |

| Candles for 21011 | A-17-DV |

| Gap between spark plug electrodes | 0.5 – 0.6 mm |

| Valve train chain | 114 links, double row |

| Cylinder operating order | 1-3-4-2 |

| Air filter | seasonal temperature switching, cardboard cartridge with pre-cleaner |

| Oil filter | optimal Mann W914/2 |

| Flywheel | Weight 0.62 kg, 129 teeth, 6 mounting holes without offset, outer diameter 27.75 mm, inner diameter 25.67 mm |

| Flywheel mounting bolts | M10/1.25 mm, total length 23.5 mm |

| Valve stem seals | recommended by the factory from Corteco or Horse |

| Compression | 10 – 14 bar, pressure drop in adjacent cylinders no more than 1 bar |

| Oil temperature | 80°С |

| Thermostat temperature | 80 – 84°С |

| XX speed | 850 – 950 min-1 |

| Tightening force of threaded connections | spark plug – 37.24 Nm flywheel - 83.3 Nm clutch bolt - 29.4 Nm bearing cap - 80.36 Nm (main) and 50.96 (rod) cylinder head - two stages 39.2 Nm, 112.7 Nm |

A positive feature of the ICE 21011 was the fact that it was developed 4 years later than the base engine model. During this time, the DAAZ plant launched a series of Ozone carburetors, which by default exceeded the performance characteristics of the previously used attachments for preparing the Solex fuel mixture.

Ozone carburetor

The manufacturer's plant management included an Ozone carburetor in the 21011 package, further increasing the characteristics of this engine.

ICE design

Despite the increased cylinder diameter (79 mm instead of 76 mm), the overhaul of the 21011 engine is carried out as planned, as indicated in the official manual. All fundamental design features remain the same:

- upper positioning of the camshaft of the timing mechanism;

- cylinder center distance for possible boring;

- timing chain drive;

- machined cylinder head.

Motor design

The layout of the piston group exceeded the capabilities of the original - the engine became torquey with virtually no increase in gasoline consumption.

Motor VAZ 2106

The baton of the engine, which became a real breakthrough in the Soviet market, was taken over by the VAZ 2106 engine.

It became a natural modification of the 2103 in order to increase the technical characteristics of VAZ engines in the direction of power.

The engineers achieved it:

- increasing the working volume to 1600 cm3, using the cylinder diameter, which again became 79 mm.

- The pistons for this VAZ engine were used from 21011 and it, like the donor, had two repair sizes. These VAZ engines had no other fundamental differences from the 2103, since they were equipped in the same way as their older relatives, with an “Ozone” carburetor and an ignition distributor with the same vacuum regulator.

But the 2106 engine did not find much sympathy among the owners, just as rotary engines on VAZs were once exported, since the owners of 2103, 2121, 2107 tried to select the more reliable VAZ 2103 engine.

This was due to the lower viability of the 2106 and instability of operation when using lower quality fuel. The saddest outcome was burnout of the valves and the unit required major repairs in these cases much more often than 2103.

Positive and negative points

The main disadvantages that the 21011 engine has, it retained from the ICE 2101 sample, from which it originated:

- increased noise from chain transmission;

- Suitable only for rear-wheel drive cars;

- periodic adjustment of idle speed;

- complex valve adjustment.

Valve adjustment

Long partitions are used inside the intake manifold, so when throttling the first chamber, cylinders 2 and 3 experience air-fuel “hunger”, and when the damper of the second chamber is opened, on the contrary, cylinders 1 and 4 experience.

However, for its time, 21011 became an advanced technical solution for the domestic automobile industry. Knowing the characteristics of the engine, the user does not have problems with what oil to pour and what coolant the engine cooling system uses.

Maintenance - regulations

A typical internal combustion engine device ensures that the replacement of consumables and maintenance operations are standard for the AvtoVAZ engine family, so the 21011 engine has the following maintenance regulations:

| Maintenance object | Time or mileage (whichever comes first) |

| Timing belt | replacement after 100,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Motor oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

Consumables and spare parts for the engine are not in short supply, despite its discontinuation in 2006.

Service manual 21011

Typical motor malfunctions

Unlike the standard, the 21011 engine is designed for a medium octane number; A-76 gasoline, like the 2101 engine, is not recommended. When the timing chain breaks, the piston usually bends the valve, which is a common problem for AvtoVAZ internal combustion engines, with rare exceptions (for example, 2105). The main faults are:

| Breaking | Cause | Elimination |

| Blue smoke | replacement of seals, rings and consumables | |

| Engine overheating | broken thermostat or fan | installation of new attachments |

| Oil consumption increases | exhaustion of pistons/cylinders, leaks in valve covers | installation of the next repair size of pistons and rings, replacement of gaskets |

| Knock | connecting rod bearings, crank bearings, increasing valve clearance | replacement of consumables after diagnostics |

In principle, the engine circuit, which is simple for today’s level of internal combustion engine development, facilitates independent maintenance of the 21011 drive model. The manufacturer’s instructions clearly indicate which oil is recommended for use and a description of the internal combustion engine parameters.

Motor VAZ 2111

As mentioned above, the VAZ 2111 engine is the beginning of the era of distributed fuel injection. The appearance of cars of the “tenth family” allowed engineers to work in a qualitatively new direction, and in general, it was successful, completely changing the standard operating parameters of VAZ injection engines.

Motor 2111, like its successors 2112, 21114, 21124, 21118, are installed on car models 2108, 2109, 21099, 2110, 2111, 2112, 2114, 2115 in their various modifications, as well as on Lada Kalina. Many owners of old carburetor cars, without betraying their favorites, simply install a new injection unit in their cars, thereby extending their life by more than a dozen years.

What changed:

- Over a fifteen-year period, these units changed their volume from 1500 cm3 to 1800, and their power increased by 20 hp. With. And if the 2111 engine is a kind of modification of the 21083 and 2110, distinguished by additional mounting holes for the generator, an ignition module and a knock sensor, then, for example, the VAZ 21124 engine is a fundamentally different unit. Chip tuning of the VAZ engine originates from it.

- The only controversial point in the particularity of these VAZ engines is the increase in the number of valves from 8 to 16. And if you are wondering on which engines the valves bend when the timing belt breaks, then you need to remember only one modification of the engine: 2112, despite the fact that it one of the most common VAZ engines for tuning.

- In addition, the VAZ 2112 engine has completely different characteristics among VAZ engines and other typical operating parameters of VAZ injection engines. Unlike 2111, the power here has been increased to 93 hp. With. (2111 – 78), torque 127/3700 (115/3000), with a reduced volume from 1600 to 1500 cm3.

- Another camshaft appears here, as well as a different air supply system to the cylinders. This engine, naturally, has become more powerful, but the driver would rather prefer a calmer and more economical driving style due to the torque at low speeds.

- The difference between the later 21114 and 21124 is that the height of the cylinder block was increased by 2 mm, and the crankshaft stroke increased from 71 to 75.5. These technical characteristics determined the addition of volume to the VAZ engine up to 1600 cm3.

- Plus, the fuel system with the injector ramp has been slightly modified, the fuel return line has been eliminated, and a catalytic converter has been installed.

- The fundamentally new ignition system is now a four-terminal coil, and not an ignition module, as on the 2111. The quality of this ignition is certainly better, but some problems may appear during the plant in winter, but this is only out of habit.

Most often, when choosing a car, taking into account the technical characteristics, owners try to avoid this unit, but this is done only by those who are not very meticulous about caring for the engine, since troubles can be avoided by timely replacement of the belt, and the purchase of this part should be treated more responsibly .

When choosing a belt, you can only trust a trusted manufacturer, information about which can be found on the Internet or from friends, since you cannot trust salespeople in stores 100%. Frequent counterfeits of well-known companies cannot be ruled out, which leads to underestimation of a particular belt. Accordingly, at least within the time specified by the standard characteristics, the belt simply must be checked by the owner.

In what models was the VAZ used?

Over the years of production, the 21011 engine was mounted on VAZ cars of the following modifications:

- 21011 – sedan;

- 21021 – station wagon;

- 21033 – sedan;

- 21063 – sedan.

VAZ 21063

By default, the engine is designed with a high service life; all of the specified machine models are still in use.

Engine maintenance, valve adjustment intervals.

True, the engine requires timely maintenance. In particular, it is picky about the valve clearance. Approximately once every ten thousand kilometers, adjustments need to be made. If this is not done, a knock will appear, and after warming up the engine may simply stall. As for the injection system of the penny engine, it also needs adjustments and repairs. It is worth noting that the motor has many shortcomings if you look at it from the point of view of modern technology. About 700 grams of oil is consumed per thousand kilometers; if you have a high mileage engine, then even more. It is also quite common for the engine to overheat. And the reason for this may lie in both the thermostat and the liquid pump. Much less often it is caused by a fan failure. On some you can still find a cooling system that uses a mechanically driven impeller. Sometimes high engine temperatures appear after refueling with gasoline with a very high octane number. On a VAZ 2101 car, engine power can be increased if some modernization is carried out. This will be discussed below.

An interesting article about biofuel produced from ordinary sawdust, read more here.