Transfer case control

These include:

- Switching the transfer case should only be done when the car is not moving.

- You can also engage the differential while the vehicle is moving.

- You can switch to a lower gear while the car is moving.

- To ensure long-term and uninterrupted operation of the differential, it is necessary to periodically turn it on, especially in winter. This should be done once every 7 days.

In the interior of the Niva Chevrolet there are two levers between the front seats

. Using one of them you can change gears in the gearbox, and using the other you can control the transfer case.

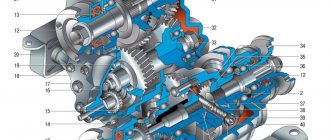

The transfer case is based on a gearbox consisting of two stages

. The control lever comes out of it into the cabin. He can move forward or backward. At the same time, it switches on/off downshift. If the lever is moved left or right, it can turn the differential lock on/off.

Gear shift and transfer case diagram

The main component of the transfer case is the reduction gear

. If the control lever is in the rear position, then the number of transfer cases decreases and is 1.2. When the lever is in the forward position, the gear ratio increases. It will already be 2.1. When the lever is in the neutral position, the gear ratio is 0.

The differential is an integral part of the all-wheel drive mechanism in any car. It is recommended to use it only when the car is moving off-road.

The lower part of the lever is inserted into a groove on the rod, and fixation occurs using a figured spring. The other end of the rod, in turn, is connected to a fork, which moves the shift clutch. The rigidity of this connection is ensured by the bolt. The rod at the outlet of the transfer case is sealed with an oil seal, and dirt and dust are protected with a rubber corrugation. The entire switching drive is fixed in the set position by a spring-loaded ball that fits into special grooves in the rod.

Among domestic car enthusiasts, the Chevrolet Niva is a fairly popular SUV that appeals not only to fans of extreme driving, but also to fans of measured driving outside the city. Many people know that one of the features of a car of this brand is the presence of a transfer case in it.

It should be immediately noted that you can engage both the lock and the transmission at the same time using the Chevrolet lever that changes gears. So, the lever shifts to the right, and then immediately up to engage a lower gear. To switch back to higher, the lever should simply be moved back.

Using a Niva Chevrolet transfer case, in addition to the above, neutral gear is also engaged, while the car will remain reliably in one place. The lock can be engaged at any time - in normal gear, in low gear - just switch the Chevrolet lever to the left.

Eliminate vibration with additional fasteners

Vibration in the body is the main “disease” of the Niva; it often occurs due to improper alignment of the transfer case. Most often, vibration occurs on VAZ 21213/21214 cars, since the transfer case is mounted only on two supports on the sides of the body; on the Chevrolet Niva, the transfer case is already installed on three supports.

- driveshafts are poorly secured;

- wheels are not balanced;

- there is play in the cardan crosspieces (vibration is especially affected by play in the rear driveshaft crosspieces);

- The vibration comes from the engine itself.

Vibration when starting off on a Niva can also occur for the following reasons:

- the mounting supports of the transfer case have become loose;

- The rubber on the RK supports themselves broke.

Installing the third support of the transfer case on VAZ 21213/21214 vehicles allows you to reduce the level of vibration of the transfer case; with this support it is easier to center the transfer case. The part can be purchased at auto stores or made yourself. The finished product comes with three long studs (for model 2121); to install the third support on this machine, you will need to unscrew the short studs from the transfer case housing and install new studs from the kit. We carry out repairs as follows:

- dismantle the front passenger seat in the cabin;

- remove the floor tunnel lining;

- in the cabin we move aside the carpet covering the body amplifier (in front of the handbrake lever);

- remove the transfer case (alternatively, you can simply hang it up, but removing the third support makes it easier to install);

- We attach the bracket of the new support to the body of the RC;

- we install the transfer case in place, center it in the optimal position, and fasten the side supports;

- we combine the third support with the body, drill two holes in the bottom;

- Using washers, bolts and nuts (from the kit) we attach the support to the bottom of the body.

Vibration is eliminated more effectively by installing a subframe under the transfer case. You can also make such a device yourself or buy a finished product at a car store.

In order to install the subframe, the transfer case must be removed. It is more convenient to carry out such work in a pit; we carry out repairs as follows:

- leave the car in neutral gear;

- disconnect the propeller shaft from the transfer case, it is advisable to mark the driveshaft flange and the drive shaft so that during installation, align the driveshaft according to the marks - this way, the occurrence of unnecessary vibrations is eliminated;

- dismantle the muffler mounting bracket;

- remove the gearbox traverse;

- jack up the transfer case, remove the side fastenings of the transfer case;

- We treat the places where the subframe fits to the body with Movil;

- place the subframe on the gearbox studs;

- we mark the attachment points of the subframe on the side members, drill holes, attach bolts to the body;

- we tighten all fastenings, except for the transfer case supports themselves;

- we perform alignment of the steering wheel;

- Finally tighten the transfer case supports.

It should be noted that installing an additional support or subframe on the steering wheel does not always lead to the desired effect; in some cases, vibration only increases.

How does blocking work?

In order for the differential to transmit torque from the engine to the wheels and automatically distribute it between them, its design contains gears and shafts. Due to the blocking action, which is carried out by a special locking clutch, the rotation of the gears stops. As a result of the Niva's cross-axle differential locking, the wheels are now firmly connected to each other, due to which their angular velocity is equalized. The interaxle mechanism has the same principle. Only the front and rear drive shafts are already in close connection. Thanks to this, both axles (front and rear) receive the same torque value. And in this case, a domestic car can overcome serious road obstacles.

Definition of the term

What is a differential? Its mechanism includes a group of planetary-type gears. Its main purpose is to transmit torque from the engine to the drive wheels of one axle. In this case, the wheels rotate relative to each other at different speeds.

Cars that have only a pair of driving wheels have a planetary mechanism placed between their drives, which is otherwise called a cross-axle differential. However, most SUVs have all-wheel drive, and in this case it is located between the axles - this is the center differential. The traction force of a wheel depends on its radius and the supplied torque.

Before installing a differential lock on the Niva, it is worth understanding its mechanism. As a rule, many SUVs have only one differential installed - inside the drive axle. There are three of them on the Chevrolet Niva car. In this case, each of the two is located in the rear and front axles, respectively. They allow all wheels to rotate relative to one axis at different angular speeds. The third mechanism, as described just above, is located between the axles and distributes the torque from the engine between the two axles.

How does the differential lock work on the Niva, the principle of operation

When driving on a normal road, torque is distributed relatively evenly between all wheels. But off-road, in the mud, this is not enough. A simple situation - the car has skidded, for example the left rear wheel.

Then all the torque will go there, and the car will not be able to drive. In such a situation, no all-wheel drive will help.

But there is a way out. You need to turn on the center lock. How does such a device work on Niva?

The transfer case has a special clutch. When the lock is activated, it connects the shafts that transmit torque to the axles. Let's just say that the force produced by the engine is forcibly divided equally between them.

Now the four-wheel drive starts working. When the locking is on, the front axle is forced to receive half the torque produced by the engine. Thanks to this, the car starts to move.

As soon as it starts moving, the slipping of the rear wheel will stop, and torque will flow to all the others. Then the Niva will safely overcome the difficult section.

It should be noted that the Lada 4x4 car is not the only owner of the described device. A similar differential lock works both on the Chevrolet Niva and on other SUV models, however, it can be implemented in different ways. But nevertheless it performs similar tasks.

Advantages of forced blocking from IZH-TECHNO

What are the advantages of our forced blocking over existing analogues?

- The first and no less important point is ease of installation and the availability of all components necessary for installation. The differential assembly with lock is installed in its standard place in the gearbox. You can avoid the need to modify the transmission or purchase certain parts such as dog clutches or original axles. Our locks are compatible with OEM axles. To assemble it, you only need a standard set of plumbing tools. No welding machine or angle grinder.

- Our lock consists of original parts produced by IZH-TECHNO. Therefore, we guarantee the high quality of its individual parts and locking elements; The high quality of its components is a guarantee that you will not need spare parts throughout the entire service life of the product - there is nothing in it that could break.

- We paid special attention to such a parameter as the durability of satellites. This is not true: it transmits torque to both wheels of the axle and is subject to the greatest loads. The durability of the satellite installation has been confirmed by a series of tests both in laboratory and in real field conditions.

- Lock has four satellites instead of the standard two. This design provides even distribution of torque and is more reliable than factory-installed units. Particular attention was paid to the parameters of the satellites, increasing the thickness and height of the fragment (see photo below):

On the left is the original satellite, on the right is the satellite produced by IZHTEKHNO.

- Pneumatic drive with positive locking. The pneumatic cylinder is hidden in the axle housing and is protected from mechanical influences; it cannot be broken or damaged.

- The differential housing is made with high precision and strict tolerances, which is associated with the absence of vibration and noise in the axles when driving on the highway.

Niva differential housing cover

- blockade speed. By increasing the number of teeth involved in locking the differential, we got the locking mechanism to work faster. You don't have to wait for the wheel to rotate 120 degrees for the system to finally work. In our case, only 9 degrees is enough.

- Versatility. The lock is suitable for all modifications and variants of Niva and Chevrolet Niva cars, can be installed on both the rear and front axles, in steel and aluminum gearboxes on the front axle. Locks are available with 22 and 24 slots.

Read more about the forced locking function on the Niva and Chevrolet Niva in the description on our website.

Replacing the cuff

If the lip seal has become unusable, it only needs to be replaced, since the element is non-repairable (rubber ages over time and cannot be restored). To replace the oil seal, you need to know the size of the element:

- outer diameter 68 mm;

- internal diameter 35.8 mm;

- height 12 mm.

To carry out repairs, you will need to prepare the following list of tools:

- key to 13;

- 24mm head and knob;

- hexagon 12;

- powerful slotted screwdriver;

- hammer;

- dynamometer and torque wrench;

- container for draining oil.

The process of replacing the shank oil seal is carried out with the rear axle hanging and is carried out as follows:

- Unscrew the rear axle housing plug and drain the lubricant into a prepared container.

- We unscrew the fastening bolts of the rear cardan to the RZM flange, move the shaft to the side and secure it with wire to the longitudinal link of the bridge.

- Using a dynamometer, we determine the moment of resistance to gear rotation by turning the flange nut clockwise.

- To hold the flange, insert the cardan bolts into the holes and screw the nuts onto them.

- We place a mounting spatula or screwdriver between the bolts and unscrew the nut with a socket and wrench.

- Remove the nut and washer from the shank.

- We dismantle the flange itself by hitting it with a hammer through a wooden adapter.

- To remove the oil seal, hook it with a screwdriver and remove it.

- We apply Litol-24 to the working edge of the new cuff, after which we mount the part into the crankcase using a suitable attachment.

- We put the flange and washer in place and tighten the nut with a torque wrench with a torque of 117–255 N*m (12–26 kgf*m), using a dynamometer to control the moment of resistance of the bearings to turning the drive gear. If during the initial measurement of the moment of resistance the value was at least 6 kgf*cm, then when re-tightening it is necessary to increase it by 1-2 kgf*cm. If initially the value was 6 kgf*cm, then we achieve a torque of 6-9 kgf*cm. At the same time, the tightening torque should not exceed 12-26 kgf*m. If, while tightening the nut, the moment of resistance exceeds 9 kgf*cm, the spacer sleeve on the bevel gear will need to be replaced.

- After the adjustment work, we install all the elements in the reverse order.

5.1.6 The car moves jerkily

Necessary explanation:

— jerk

— short-term spontaneous change in engine speed regardless of the position of the gas pedal. In everyday use, as a rule, there are a series of jerks; - failure

— noticeable delay in the engine response to pressing the gas pedal. Approximately can be considered as a limiting case of a jerk.

Conventionally, three types of jerks can be distinguished:

- at the moment of starting movement; — during acceleration; — with steady motion, i.e. with the gas pedal in constant position.

Warning

When using the DAAZ Solex carburetor, a very unpleasant defect occurs: when you press the gas pedal, a strong dip occurs, the engine stalls, and often there is no idle speed. Movement is only possible when the gas pedal is pressed to the floor, or you have to continuously “pump” the pedal. The reason is clogging of the fuel nozzle of the main metering system of the first chamber.

For an experienced car enthusiast

it is necessary to remove the top cover of the carburetor, as described above, unscrew the two air jets, use a thin screwdriver to unscrew the two fuel jets and remove them from the wells with a long wooden toothpick or a pointed stick. Do not mix up the jets when reinstalling them!

Then, use a syringe or a clean, lint-free cloth to remove gasoline from the float chamber and blow out the carburetor with compressed air, especially carefully - the fuel nozzle wells.

For an inexperienced car enthusiast

It is better to immediately contact a car service center. To get to the service center, cut off a piece of vinyl chloride tube 1–1.5 cm long (at least from the windshield washer tubes) and place it on the thrust lever of the second chamber drive. The engine speed will be approximately 2000 rpm. Use the clutch and brake pedals to maintain a safe speed.

Jerking when starting to move

At the moment the movement begins, the limiting case of a jerk—failure—occurs more often. The most unpleasant sensations are associated precisely with the delay in the engine’s response to pressing the gas pedal. Sometimes the engine even stalls.

The cause of failure may be either a malfunction of the carburetor accelerator pump or a malfunction of the vacuum corrector of the ignition distributor.

For work you need: wrenches “8” and “10”, Phillips and slotted screwdrivers, a clean rag, a piece of thin copper wire without insulation with a diameter of less than 0.3 mm, a compressor, a can of wd40 type liquid, possibly a portable lamp.

PERFORMANCE ORDER Jerking during acceleration The cause of jerking may be a low fuel level or a clogged fuel filter in the carburetor, a malfunction of the fuel pump or a clogged additional fuel filter, or a malfunction of the ignition system. For work you need: wrenches “8”, “10” and “13”, Phillips and slotted screwdrivers, a clean rag, a piece of thin copper wire without insulation with a diameter of less than 0.3 mm, a compressor, a can of wd40 type liquid, possibly - portable lamp. PERFORMANCE ORDER Jerks during steady motion GENERAL INFORMATION Such jerks are most often caused by a malfunction of the ignition system. Diagnostics is required, contact a car service. The only thing you can try to do yourself: - carefully inspect the engine compartment. Turn off the ignition and check the secure fastening and seating of all wires and connectors at the switch, coil and ignition distributor. Start the engine and listen to its operation - the crackling sound when the high voltage breaks down to ground is weak, but distinct. In complete darkness, the spark during breakdown is clearly visible; - replace spark plugs regardless of their condition and mileage

Pay attention to the condition of the spark plugs - if it is abnormal, you may have to contact a car service

Types of blocking

If you want to install a locking mechanism on a differential, you should know that there are two types: full locking; partial blocking. Full blocking mechanisms can operate manually (forced differential locking on the Niva) or automatic mode, while partial blocking is carried out only automatically. Just don’t forget that driving a car with a full lock on a good road leads to premature tire wear. In addition, some parts also fail quickly. Thus, the whole choice comes down to which mechanism to choose: manual or automatic. The manual system has one advantage - the driver himself decides whether to engage the differential lock or not. However, there are also a number of disadvantages: to use the system, you need to remove your hand from the steering wheel; It is imperative to disable the lock in a timely manner, otherwise the chassis of the vehicle may be damaged; high price. The automatic differential lock on the Niva has its own characteristics, among which is the need to customize it to the individual driving style of the car owner. At the same time, the mechanism does not load the car’s transmission as much as its manual counterpart. The system provides complete comfort for the driver, since, if necessary, it is activated without human intervention. It also all depends on your driving style. For those drivers who prefer a quiet ride on a flat road surface, it is better to opt for a viscous coupling or a disc clutch. In case of extreme driving style, you cannot do without a forced differential locking system on the Niva.

Turning on all-wheel drive.

The use of blocking will be justified in the following cases:

- If there is a possibility of wheel slipping, in areas with poor surface conditions,

- If there is a lack of engine thrust at high speeds,

- When driving on roads with loose surfaces, snow, ice.

You should also take into account some features of the Chevrolet Niva, namely, the helplessness of the transmission when hanging diagonally. In this mode, the wheels begin to spin, so if necessary, you need to dig under the wheel or make an embankment under the raised axle.

Many car enthusiasts like SUVs due to their high maneuverability in difficult terrain. Among domestic cars, a striking example is the Chevrolet Niva brand. And in order for the car to be able to overcome hard-to-reach obstacles, you cannot do without differential locking on the Niva. Regardless of the brand of SUV, including the aforementioned Niva, all cars have one characteristic feature, which is the presence of all-wheel drive and differential. More detailed information is provided below.

Rules for using differential

In the Chevrolet Niva interior, on the central tunnel there is a transfer case control lever. It is located slightly below the gearshift control lever. In addition to controlling the differential lock, the transfer case lever is responsible for engaging downshifts.

The lever has several positions:

- central - turn on “neutral”;

- moving forward - downshifting;

- shifting back - turning off downshift;

- movement to the left - turning on the lock;

- Move to the right - turn off the lock.

Another element of the transfer case is the reduction gear. Once turned on, it increases the torque supplied to the car's wheels. A reduction gear is used when there is a lack of power, for example, when driving on difficult surfaces, when climbing, etc.

Controlling the transfer case lever requires compliance with several rules:

- You can turn on the lock both when stopping and while driving;

- downshifting is possible only when the car is stopped;

- You can turn off a lower gear and turn on a higher one, as well as unlock the differential while driving;

- You can only downshift and lock at the same time while stopping.

One of the problems of the Chevrolet Niva is the locking lever getting stuck in the on position. Many owners of the model continue to drive with a locked differential, since at first glance this does not cause problems.

However, a constantly disabled differential has a bad effect on the transmission and efficiency of the Chevy Niva engine. Therefore, the problem inherent in the model needs to be solved. You can disable a jammed lock by switching the lever when moving in reverse. If this does not help, then you can try turning off the lock while moving forward.

Differential with viscous coupling

These are perforated discs in a sealed casing, which are filled with silicone-based liquid. Part is connected to the housing, the rest is fixed to the drive shaft. When the shaft and differential speeds are approximately the same, the elements rotate together. If the shaft rotates faster, then the disks that correspond to it also gain speed. The liquid mixes and hardens. As a result, the differential is locked. Nowadays, on a Niva 4x4 car, differential locking of this type is not very popular.

How to determine whether the differential lock is engaged on a Chevrolet Niva

You can determine whether the inter-wheel differential device is locked without even leaving the Chevrolet Niva interior. Let's look at how to do this:

- Find two control levers between the passenger and driver's seats:

- gear shift lever (with long handle);

- machine transfer case control lever (with short handle);

- move the transfer case control lever forward - this will engage a lower gear to the drive axles of the wheels from the gearbox.

- Move the transfer case control lever back - this will disengage the downshift.

- Move the transfer case control lever left and right. This will switch the blocking of cross-wheel differential devices:

- to the left - switch on;

- to the right - shutdown.

As you can see, with the transfer case control lever you can not only change gear levels, but also control the process of blocking the cross-wheel differential device. This is due to the fact that the car differential lock is part of the functioning of the all-wheel drive mechanism of the Chevrolet Niva. The locking switched on at the right moment facilitates the unhindered movement of the SUV in difficult road conditions.

Niva is a car that has been produced since 1977. It differs from other domestic cars in that it has permanent all-wheel drive. Few car enthusiasts know what this means, although they have heard a lot about this feature of the vehicle; a diagram of the device can easily be found on the Internet. All-wheel drive in the Niva is equipped for all 4 wheels, and the center differential is locked. The mechanism consists of a gearbox, a transfer case designed for 2 stages, and cardan shafts located in the front and rear of the machine. This also includes the front and rear axles.

When the engine starts to rotate, an impulse is sent to the gearbox and transfer case, after which the torque is distributed to the front and rear axles simultaneously. Afterwards, the gearboxes are activated, and behind them the front and rear wheels of the Niva begin to rotate. Torque causes 4 wheels to rotate at once, which is why it is called full torque. But the rear wheels still drive.

Nivov transmission units

The legendary Niva is an all-wheel drive vehicle. This ensures unprecedented road holding and reliability comparable to expensive high-performance cars. With the exception of updated versions under the Chevrolet brand, the traditional Niva has always had a rather modest design, but this did not prevent it from being the undisputed leader among car owners who prefer high-end car platforms.

What distinguishes the Niva's chassis from other all-wheel drive vehicles is the transmission of torque to two axles at once without disabling the axles, which significantly affects cross-country ability while simultaneously reducing the influence of critical loads on the transmission. This same quality makes this legendary Russian SUV very uneconomical in terms of fuel consumption.

The developed Niva transmission turned out to be so successful and efficient that it later became a prototype for the Vitara. This made the new model more adaptable to difficult roads. Niva transmission units can easily meet the requirements of any engine up to 2 liters, so if you want to upgrade, think about the fact that each car has its own capabilities. Many advantages are due precisely to the circuit and design of the transmission.

Niva transmission and its components:

- front-wheel drive;

- front axle;

- wheel grip;

- manual transmission;

- driveshaft (front);

- shaft (intermediate);

- transfer case;

- shift lever;

- center differential and locking lever;

- wheel differentials;

- driveshaft (rear);

- rear axle;

- rear drive.

The design implies the following states:

- unlocked differential;

- locked differential;

- low gear when engaged;

- neutral position;

- top gear engaged.

The features of the Nivov transmission include the presence of a center differential that connects the rear and front axles. As a result, the wheels can rotate not only at different angles, but also at different angular speeds, which significantly affects controllability in impassable roads.

The key difference between the Niva’s center differential is the ability to lock when driveshafts rotate with the same characteristics. The center differential is manually locked only in difficult terrain conditions, when you need to overcome a large hole, rut or snow drift without slipping.

In practice, mechanical locking, although somewhat inconvenient, turns out to be better than the modern electromagnetic clutch used for these purposes. For example, the Renault Duster is not so easy to cope with the task in harsh off-road conditions, since the digital control unit can provide limited torque transmission. However, this effect will not be observed in a Niva with a mechanical lock.

Leaving the center differential locked will not only cause increased wear, but will also significantly reduce the vehicle's handling. The activated differential lock mode will be indicated by a lit indicator on the Niva dashboard. Please note that locking will not prevent one wheel from losing traction.

To overcome difficult areas, the transmission allows the use of a low gear with a high gear ratio (2.135); in the highest gear, the parameter is 1.2 and is intended for driving in normal conditions. The transfer case indicates different high and low gear modes. The lower one is turned on before entering a snowy area, unsteady soils, hills, and when a towed load is connected.

Some drivers master the skill of shifting gears at speeds of 30-35 km/h. Otherwise, you will have to stop the car and perform the operation in the parking lot.

Please note that Niva requires a competent approach to the selection of tires, the quality of which can affect the degree of wear of the transmission in just one season. The tires must be the same in terms of wear and, of course, in size. Different characteristics will lead to increased load on the transmission and slipping in low gear, and during normal driving will increase wear on the differentials.

1, 3 – Front wheel drive; 2 – front axle; 4 – clutch; 5 – gearbox; 6 – front driveshaft; 7 – intermediate shaft; 8 – transfer case; 9 – transfer case gear shift lever; 10 – differential lock lever;

11 – rear propeller shaft; 12 – rear axle; I – differential unlocked; II – differential locked; III – low gear engaged; IV – neutral position; V – high gear engaged

Transmission Specifications

The Niva car is all-wheel drive, i.e. All wheels are driven. All-wheel drive is permanent: torque from the engine is always transmitted to both axles at once (the axles are not disabled). This scheme increases the vehicle’s cross-country ability, while simultaneously reducing the load on the transmission units, but slightly increases fuel consumption.

The front and rear axles are connected through a center differential, allowing the front and rear wheels to rotate at different angular speeds depending on the trajectory and driving conditions. The center differential is located in the transfer case and is similar to the cross-axle differentials located in the front and rear axles.

However, unlike them, the center differential can be forcibly locked (the locking lever is located on the floor tunnel). In this case, the front and rear driveshafts become rigidly connected to each other and rotate at the same frequency. This significantly increases the vehicle’s maneuverability (on slippery slopes, in mud, snow, etc.

), but worsens handling and increases wear on transmission parts and tires on surfaces with good grip. Therefore, the differential lock can only be used to overcome difficult areas and at low speeds. A warning lamp on the instrument panel serves to warn the driver that the locking mode is on.

Also interesting: How to properly use the transfer case on Niva 2121

You can engage the differential lock while the car is moving, if the wheels do not slip. Locking the center differential does not relieve the car from the danger of “diagonal hanging”, when one of the wheels on each axle loses traction with the ground - in this case, pour soil under the suspended wheels or dig it under the others.

To increase the torque supplied to the wheels, a low gear in the transfer case is used, its gear ratio is 2.135. The highest gear, intended for normal driving conditions, has a gear ratio of 1.20. Thus, the driver can use one of two rows of gear ratios - with a high or low gear in the transfer case.

The total gear ratios of the “top” row (from 1st to 5th gear) are 4.40; 2.52; 1.63; 1.20; 0.98, “lower” – 7.82; 4.47; 2.90; 2.13; 1.75. The low gear in the transfer case is switched on before overcoming snowy, sandy areas, steep climbs, when towing loads, etc., when there is a lack of engine traction or for driving at very low speeds.

It is necessary to engage a low gear in the transfer case in advance, with the car stationary, since the gear shift clutch does not have synchronizers. With some skill, it is possible to engage the highest gear even when driving at a speed no higher than 30–35 km/h, however, if possible, it is better to reduce the speed or stop.

A vehicle with permanent all-wheel drive places special demands on tires. They should be the same not only in size, but also in the degree of wear. Different tire rolling radii will cause increased wear on the differentials under normal driving conditions, and when the lock is engaged, increased wear on other transmission parts and wheel slip.

Video

The normal position for the RK handles, ensuring adequate behavior on the road of good quality:

- Front - away from you Back - towards you

The special operating mode of the transmission is switched on not long before the car begins to overcome an obstacle (rut, mud, ford or rise). The transition to the lowest row must be done while stopping. Returning to top gear is allowed on the go, although it causes problems for beginners due to the lack of the usual synchronizer.

It is somewhat more difficult to properly handle the forced manual locking of the center differential. On the contrary, it turns on when the car moves slightly (up to 20 km/h) due to misalignment of the grooves on the locking clutch, satellites and ring gear. To simplify turning the lever into the desired position, taking into account the Niva 2121 transfer case, pick up a small speed, then, shaking the steering wheel, pull the handle towards you.

Problems can also arise when disengaging the lockout, as the clutch teeth literally catch on the ring gear. Engage reverse and, rocking the steering wheel, push the lever away from you. This action is performed immediately after overcoming a difficult section in order to avoid overloading the gearbox. It is most effective to disable the differential together with the transition to lower stages.

How to enable blocking

It's quite easy to do. On the Lada 4x4 car there are three levers to the right of the driver, we are interested in the smallest one. When the driver moves it back, the lock on the Niva 2121 works; as soon as the driver moves the handle forward, the mode will turn off. It is best to carry out all manipulations while the vehicle is stationary.

Experienced drivers know that the lock does not always turn on (off) the first time. The fact is that the shafts may not be in the right position or they may “bite” if additional force is applied to the coupling (for example, the car has stopped while turning). Then you need to drive forward or backward a little, align the wheels and try again. As a rule, in this case everything turns on.

On the Chevrolet Niva, this procedure is performed differently. There are not two levers to control the transfer case modes, but one. The one we need is located closer to the driver.

Although the locks on the Niva-Chevrolet, as well as on the Lada 4x4, work in the same way, they are activated differently. On a Chevrolet, to do this, the transfer case mode control lever must be moved with the clutch depressed while the car is stationary to the left (towards you). To disable the blocking, go in the opposite direction.

Why is downshift needed?

It is difficult to imagine a transfer case without the main functional component - a reduction gearbox. Positioning the lever in the rear direction reduces the transfer case value to 1.2.

By fixing the lever at the front, the gear ratio can be increased to 2.1. The lever in neutral indicates gear ratio 0.

To use the lock installed on the Niva effectively, use the following recommendations from experts:

- When driving on good quality road surfaces, install the front transfer handle at the front and the rear at the rear.

- The front handle is moved back if the road becomes slippery. Once the slippery area has been passed, switch the levers to normal mode.

- If the Niva is stopped, the lock may not engage when the clutch is depressed. This occurs due to the alignment of the teeth with the gear teeth. What should you do in this case? Moving as if on a turn, engage the lock. The differential will turn and the gear teeth will come closer to the teeth. If turning off is difficult, do it while the vehicle is moving, maintaining a minimum speed and squeezing the clutch.

Why does Niva need blocking?

Wheel differential is a mechanism that allows a car to rotate its wheels at different speeds, which does not mean changing gears, but changing when cornering, when one wheel describes a small diameter and the other a large circle. In the absence of a differential, the wheels in the Niva would begin to slip, which could result in damage and rapid wear of the rubber.

When at least one wheel slips, which often occurs on an icy road, the differential puts more force on the slipping wheel. In other passenger cars, such a device involves installation on a drive-type axle. Niva has it in other areas:

- on the rear and front axles;

- in the center between the axles, located near the gearbox and axles.

Lada 4×4 3D BORT-186 › Logbook › Forced locks in NIVU

Hi all! Finally, the time has come to write about the work done again. Implementing locks was not as difficult as I thought before. The main thing is to find the right components. And so, in order: By introducing locks into the gearbox and installing them on the car. Next, I routed the pipes from the compressor through the switches to the bridges. I installed mechanical switches. Initially, it was planned to take a KAMAZ “flag” for each blocking. But everyone knows that the field does not have excess space. And then I saw a compact toggle switch working as required:

I integrated the controls for the entire system into a standard panel; to do this, I cut out the repeating outline of an ashtray from a piece of plastic, drilled holes and inserted keys. And I removed the ashtray; I didn’t have to cut anything.

Controls from left to right: 1) forced button to turn on the compressor (working on the “doorbell” principle) 2) on/off automatic compressor 3) locking in the rear axle 4) locking in the front axle.

I have this pressure regulator installed at 6-8 atm:

If the system is less than 6 Atm, then it turns on and the compressor is activated, and as soon as the compressor is pumped up to 8 Atm, the sensor is activated and the compressor stops rattling (that’s all the automation is). To preserve the miracle of the sensor, it was decided to hook it through the relay. Thus, there is a zone in the system where there is still more than 6, but less than 8 Atm. To activate the interlocks well, you need 8 Atm. This is why I made a button to force the compressor on. And once the locks are turned on, the pressure in the system is maintained automatically. I connected the pneumatic system control according to the diagram:

To monitor the pressure in the system, I messed around with a pressure gauge. It was possible to take the simple route and take it to any place, but my car and I are not looking for simple ways. Therefore, the instrument panel has undergone a massive revision! For the sake of perfection, I sacrificed the tachometer and dismantled it (for what purpose is this device needed in the field, in it you can clearly hear how and at what speed the engine operates).

How to enable differential lock on Niva

- carburization - diffusion saturation of the surface layer of steel with carbon in order to increase hardness and wear resistance;

- heat treatment, in accordance with GOST standards for materials, in order to obtain the properties of the part necessary for the stated operating conditions;

- grinding;

A distinctive feature of electric locking differentials is their ease of installation, ease of connection and simplicity of the unit itself. Air-locking differentials and hydraulic locking differentials require complex installation. They include many components, which significantly reduces the reliability of the unit, and poor installation leads to damage to the wiring and failure of the entire system as a whole.

When installing differentials with electric locking, there are no unnecessary installation diagrams where mistakes can be made: there is no need for compressors or cylinders to turn on pneumatic and hydraulic drives. Electrical locking, when the control button is pressed, is carried out by an electromagnet and the electrical circuit activates the locking mechanism.

The 100% locking differential has been proven on millions of off-road vehicles around the world. Developed in accordance with Russian climatic and road operating conditions, the Autogur73 differential:

- allows you to completely lock the axle shafts at the driver's request

- can be controlled by hand switch

- Quadruple design provides maximum strength

- maintenance-free, no special lubricants or additives required

- Compatible for use on front or rear axles

- in off mode it functions as an open differential

The Niva and its various modifications allow you to operate 3 differentials at once. Thanks to this factor, the vehicle’s cross-country ability increases significantly when driving in rural areas. The forced locking format involves connecting the driving wheels together, causing them to spin at different speeds. This approach allows you to use the maximum possible traction characteristics of the engine, which are transmitted to the wheels.

To lock the differential on the Niva, the manufacturer has provided a clutch for the locker. When forced locking is turned on, the wheels become interconnected and rotate in the same mode. When the inter-axle lock is activated, the axles located at the front and rear interact and distribute traction to all wheels. This mechanism is easy to use, which is confirmed by the unique cross-country ability of the Chevrolet Niva.

Installation procedure

The work itself at a service station is usually highly valued, so many drivers prefer to do it themselves in their garage in order to save money. If the car is no longer new, then you should prepare for additional expenses, since in addition to the locking mechanism itself, you may need to purchase worn parts.

Also, you cannot do without measuring tools and adjusting rings of different diameters. The entire procedure for installing a Niva differential lock with your own hands can be done in the following order:

- The vehicle should be driven into the pit, and then its position should be firmly secured. You can use jacks and supports under the body.

- Having raised the car, you need to remove the rear wheels by unscrewing the mounting bolts.

- The next step is to remove the drum brakes.

- Then you should unscrew and remove the axle shafts.

- Next comes the removal of the cardan and dismantling the gearbox.

- Now all that remains is to install the differential lock on the Niva, after which everything needs to be assembled in the reverse order.

As you can understand, the work is moderately difficult, but every Niva owner can cope with it, especially if he has car repair skills. Perhaps there are drivers who are thinking about installing locking mechanisms, but doubt the legality of these actions. It’s safe to say that in Russia, installing the Niva’s center differential lock, like any other car, is a legal procedure. And there is nothing wrong with wanting to equip your car with improved cross-country ability.

About the device

Despite the difference in varieties, the structure and operating principle of these boxes are the same. How does the transfer case (Niva Chevrolet) work? This node includes several elements:

- Drive shaft.

- Center differential locking mechanism.

- The differential itself.

- Chain or gear transmission.

- Drive shaft of the rear and front axle.

- Downshift.

All this is controlled from the interior. There is a transfer lever for this. "Niva Chevrolet" has both locking and downshifting. The torque that goes from the main transmission to the transfer case is transmitted through the drive shaft.

Next, the torque force is distributed between the axes. This is where the center differential comes into play. This unit allows the wheels to rotate at different angular speeds. By the way, the differential itself can be of several types:

- Asymmetrical (distributes torque in different ratios).

- Symmetrical (distributes forces equally).

Technical characteristics of the VAZ 2121 gearbox

| Type | Mechanics |

| Number of gears | 4 |

| For drive | front |

| Engine capacity | up to 1.6 liters |

| Torque | up to 116 Nm |

| What kind of oil to pour | Lukoil TM-5 80W-90 |

| Lubricant volume | 1.35 liters |

| Change of oil | once every 50,000 km |

| Replacing the filter | every 50,000 km |

| Approximate resource | 150,000 km |

Rules for applying blocking on Niva

To ensure that the locking mechanism lasts for a long time, use the following rules:

- It is necessary to switch the transfer case when the Niva does not move.

- The differential can also be engaged while the vehicle is moving.

- To ensure efficient and long-term operation of the device, it is advisable for the Niva driver to turn on the lock from time to time. Once a week in winter is enough.

Where is the lever responsible for switching located? Pay attention to the area between the wings located in front, there are 2 levers there. One makes it possible to change gears at the gearbox, the other successfully controls the transfer case

A series of downshifts

You can often encounter the following type of misconception: switching the rear handle can increase the power characteristics of the motor. But this is not true. It serves to change the gear ratio between the engine and the wheels. By increasing it, the traction forces on the wheels will increase. There is also a reduction gear in the dispensing mechanism.

DON'T SPEND MONEY ON REPAINTING! Now you can remove any scratch from the body of your car in just 5 seconds.

Its operation can be controlled using the rear handle. When we shift the lever back, we will have a gear ratio of 2.135 - this is a low gear. It is recommended to downshift such a gear only when the car is stationary and the clutch is depressed. Despite the fact that the manual does not contain such a restriction, novice and inexperienced Niva drivers are not recommended to switch while driving, since the Niva transfer mechanism is not equipped with a synchronizer.

Turning the electric lock on and off.

Manual activation of the lock is possible by pressing and holding the button until the lock indicator turns on. Manual shutdown is done in the same way - by pressing a button.

Attention! Engage with the vehicle stationary or at speeds up to three miles per hour with minimal slippage. Switching on at a higher speed may damage the locking mechanism with subsequent denial of warranty repairs.

We will deny warranty if the locking coupling or pins are damaged. After passing a difficult section, the blocking must be turned off.

On the Chevrolet Niva it is possible to turn on all three differentials at the same time

. Thanks to this, the vehicle’s cross-country ability increases several times when driving off-road.

. In this case, when the driver turns on the forced locking, the wheels “become” connected to each other. This helps ensure that they rotate evenly.

Differential assembly

If the center lock is forcibly engaged, then the front ones are also rigidly connected at once, which guarantees an even distribution of traction to all four wheels. Thus, the vehicle’s cross-country ability will be increased several times.

, which makes the Chevrolet Niva a real SUV.

Not all cars are equipped with blockers, and therefore they will be vulnerable off-road. In this regard, Chevrolet is a unique car that can move with both one-wheel drive and all-wheel drive.

, which allows him to feel confident even on mountain roads.

Forced blocking should be enabled in the following cases:

- When overcoming difficult sections of the route. In this case, the blocking should be turned on in advance, even before leaving for such an area.

- On steep climbs or slopes when wheel slip is possible.

- When driving on sand.

- When driving on snow or ice.

When the Niva moves on a regular road with a smooth surface, it will not need to lock all wheels. They will adhere normally to the surface and not slip, since the traction force from the engine will be distributed evenly over them. For this reason, when the car is moving on a good road where the wheels will not slip, the use of a differential will not be required.

Modified versions

The Niva's standard transmission, for all its advantages, often causes uncomfortable noise in the cabin. This is generally related to the design, but using engineering developments, you can modernize it and make the car much quieter.

This approach has already been applied in VAZ-21213 cars; as a result, even at a speed of 100 km/h you don’t feel any unpleasant noise, you can talk calmly and hear your interlocutor without effort. For these purposes, a number of modernization methods have been used: from unloading the floor near the transfer case and manual transmission mounts, reducing the load on shaft bearings to smoothing out peak torques under conditions of increasing loads on the transmission.

Also interesting: Tow bar for Chevrolet Niva: review, installation, models and owner reviews

The noise in the modernized Niva transmission is comparable to that of a Zhiguli. It becomes more comfortable to be in the car when driving off-road. Upgrade costs are negligible; modification requires only the master's understanding of the design itself and a little time.

Features of cornering

Here it’s worth mentally (preferably on paper) to draw a schematic picture of how the car turns. This promotes better perception. Just when cornering, the differential starts to come into play. And here the differential lock on the Niva can only do harm. The whole peculiarity is that the wheel, which is closer to the center of the turn (inner), moves along a small radius and covers a shorter distance. And the wheel that is located further from the center of rotation (outer), accordingly moves along a large radius and covers a greater distance.

At the same time, increased resistance acts on the inner wheels of the car, which forces them to reduce their speed. On the contrary, the outer wheels need to move faster, due to the same larger radius. And if there were no differential, each turn would lead to increased wear on the tires of the wheels. And if the speed of the car is high, then a skid cannot be avoided. You should know this before installing a differential lock mechanism on the Chevrolet Niva.

This suggests that the wheels must rotate at different angular speeds. When the car begins to turn, the satellites rotate around their axes, which leads to a slowdown in the speed of the axle shaft of the inner wheel, while the angular speed of the axle shaft of the outer wheel, on the contrary, increases.

This is how the vehicle turns smoothly. Despite the difference in angular speeds, the traction force of all wheels is the same, since the main torque does not change. Of course, this is provided that all wheels have the same grip.

DIY self-block installation instructions

To install a Niva self-locking differential, it is not necessary to visit a car service center. It is quite possible to do this with your own hands, provided that the person is well versed in the structure of the car. The type of differential and its installation location are not particularly important.

First you need to decide on a workplace; it should be spacious enough. Using several lifts, you will have to lift the Niva on scales, remove the wheels, then drain the engine oil from the gearbox housing into a container and remove the drive axle drive. To do this, just use a wrench to loosen all the nuts securing the front cover to the gearbox, remove the cover and gasket.

Now it is necessary to reliably and efficiently perform the operation of disassembling the driveshaft, which is very difficult to do without a special puller. The metal is clamped onto the splines of the swivel, which requires a lot of effort, which every person lacks. Dismantling the cardan shaft is carried out as follows:

- Remove all bolts and nuts on the base plate driveshaft.

- The brake mechanism is blocked. This can be done with self-tapping screws or wire. If the mechanism is not secured, the brake hoses may come off.

- The cardan shaft is removable. With the right skill, this can be done manually, but better with a puller.

Then the bearings need to be replaced. To do this you will need a hydraulic press. This will help ensure that the cage fits onto the shaft with fairly high accuracy. To do this, you need to replace the bearings:

- Unscrew the hub bearing nut and remove the hub. Remove the nut securing the lever to the steering knuckle.

- Remove the hub plate and release the arm from the axle journal.

- Release all locking devices and separate the steering knuckle and hub with brake disc. Remove the bearing by first holding the steering knuckle in a vise. During reassembly, the bearing is pressed in.

Having adjusted the gap in the main gear using special washers of variable thickness, you can begin assembly. Adjusting the gap is difficult and requires special equipment, but an injector changer can be used to ensure accuracy. To work with it, wind one end of a 1 m long cable around the collar and attach the other end to the scale. When pulling the device into the winding, it will be necessary to set the torque.

To ensure proper operation of the regulator, the halves are usually sealed before assembly. Failure to comply with this requirement may result in malfunction of the device and failure of some parts. After applying the sealant, wait a while for it to harden. Then fill the transmission housing with new oil. All sealing joints that were damaged during disassembly, as well as those that show signs of oil leakage, should be completely replaced with new ones. Now you can begin to reassemble all the mechanisms in reverse order.

After completing all work related to the replacement and assembly of parts, it is necessary to check the operation of the braking devices. Their malfunction may affect road safety.

Whether you can do something like a Niwa differential lock depends on why the driver needs it. If you need to move to difficult areas, this will be necessary. If the driver also intends to drive on a regular asphalt road, then installing a limited slip differential in the Niva is hardly worth it. What type of unit to choose and where to place it depends on the driver’s preferences.

The reason for the popularity of the Niva and Chevy Niva is that they are just as comfortable to drive on public roads as off-road of varying difficulty.

However, different operating conditions place different demands on a vehicle's transmission.

When off-road, it is sometimes necessary to transmit torque to both wheels, which is accomplished by locking the differential.

But as soon as you leave the ground on familiar asphalt, the differential needs to be unlocked again.

This is where the forced blockade of the Niva River comes to the rescue.

The main advantage of locks of this type over the so-called Niva self-locking differential is that the process of locking the mechanism becomes completely controllable.

When needed, simply press the limited slip differential lock on/off button to have full control of the lock.

The locking is driven by a pneumatic drive, the operation of which we described in our review of the differential lock for UAZ vehicles with a Spicer axle:

Differences between the gearbox and a regular Niva

The car is equipped with a modified version of the classic VAZ 2106 unit with a differential box 21010-2403018-10. It differs from the rear gearbox of the Niva (VAZ 2121) in the gear ratio - 3.9 versus 4.1. This gives the car a higher top speed.

The node also has the following differences:

- a new type of cardan mounting flange;

- reinforced axle gears;

- improved sealing gland.

The last detail deserves special attention.

The oil seal has a protruding rubber boot that rests on a steel dirt-removing disc.

When the axis rotates, dirt and water are thrown away from the contact point due to centrifugal force.

This significantly increases the service life of the unit when used in off-road conditions.