05/14/2021 21,670 VAZ Chevrolet Niva

Author: Ivan Baranov

In any vehicle, the gearbox is one of the main units that determine the quality of the car's ride. Accordingly, the occurrence of breakdowns in the operation of power units will, one way or another, affect the driving of the car, especially when it comes to the gearbox control lever. Today you will learn how the Niva Chevrolet rocker is changed and adjusted and how to choose a new component for your car.

[Hide]

Removal

Place the car over an inspection ditch or on a lift, put supports under the front wheels and hang the rear axle on one or both sides.

Release the parking brake and place the gearshift lever in neutral. Disconnect the battery cables. Remove the front floor mat and outer covers from the transfer case and transmission levers. Remove the lever hatch covers and seals. Unscrew the handles from the transfer case levers. Press down on the lever rod 29 (Figure 3-12) and use a screwdriver or other pointed tool to remove the locking sleeve 33 from the groove on the lever rod; remove the rod.

Disconnect the pipe suspension and turn off; it in the rear of the car, and then the muffler pipe from the exhaust pipe. Disconnect the clamp securing the exhaust pipe to the gearbox. Using a spanner, unscrew the nuts securing the front muffler pipe to the exhaust manifold and remove the pipe downwards.

Unscrew the lower bolts securing the clutch housing cover. Disconnect the ground wire from the clutch housing and the wire from the reverse light switch.

Unhook the release spring 1 from the clutch release fork 5 (Fig. 3-13) and remove the cotter pin 4 from the pusher 6. Disconnect the slave cylinder 8 from the clutch housing. In this case, cylinder 8, connected to the pipeline going to the clutch release drive master cylinder, remains on car, which eliminates the loss of brake fluid and the need for subsequent bleeding of the hydraulic clutch release drive.

Rice. 3-13. Clutch release drive:

1 – fork release spring; 2 – lock nut; 3 – adjusting nut; 4 – cotter pin; 5 – clutch release fork, 6 – pusher; 7 – bolt securing the working cylinder to the clutch housing; 8 – clutch release working cylinder

Place clamp 2 (A 70025) on elastic coupling 3 (Fig. 3-14) and tighten it. This will facilitate the removal and subsequent installation of the elastic coupling. Unscrew nuts 1 and, turning the intermediate propeller shaft, remove the bolts securing the elastic coupling 3 to the flange of the secondary shaft of the gearbox.

Rice. 3-14. Elastic coupling connecting the propeller shaft to the gearbox:

1 – nuts securing the propeller shaft flange to the elastic coupling; 2 – clamp a 70025; 3 – elastic coupling; 4 – cross member of the rear engine mount.

Note. You can remove the gearbox assembly with the intermediate shaft. In this case, disconnect the intermediate driveshaft flange from the transfer case shaft flange.

Disconnect the speedometer flex shaft from the speedometer drive on the transfer case.

Disconnect the transfer case driveshaft flanges. Lower and move the axle drive driveshafts to the side.

Unscrew the bolts securing the transfer case brackets to the body and remove it along with the driveshaft.

Using a hinged socket wrench 02.7812.9500, unscrew the bolts securing the starter to the clutch housing and loosen it. Unscrew the bolts securing the clutch housing cover.

Disconnect the rear engine mount from cross member 4 (Figure 3-14), and then remove the cross member while supporting the transmission from below.

Repair of the gearshift mechanism of the transmission (slide) Niva Chevrolet - niva chevrolet (VAZ 2123, Chevy)

See also Disassembly and assembly of the gear selection mechanism drive)

| You will need: a 10mm wrench, a screwdriver, a hammer, and a bit. |

2. Remove the clamp from the mechanism rod.

| 1. Remove the gear selection mechanism (see “Disassembling the gearbox”). | |

4. Knock out the rod joint axis.

| 3. Remove the cover of the mechanism rod. | |

| 5. Remove the joint from the gear selector lever. |

8. Remove the protective cover of the mechanism housing and the spring.

| 7. Remove the rod eye bushings. Replace them if necessary. | |

10. ... sealing rings. Replace rings if necessary.

| 9. Remove the locking and... | |

12. Unscrew the three nuts securing the gear selector flange.

| 11. Remove the spherical washer. | |

14. Remove the guide plate washer.

| 13. Remove the flange, seal and two lever gaskets. | |

| 16. ...lever from the guide plate. |

| 17. Assemble the gear selection mechanism in the reverse order of removal. |

Video

Signs of trouble

Symptoms of malfunction depend on which component is experiencing problems:

- Clutch. In case of breakdowns, jerking occurs when starting to move, slipping under load, or “driving” when trying to stop or change gear. Sometimes the malfunction manifests itself in the form of noise when pressing the clutch pedal or in other conditions.

- Gear box. This unit is more complex, and accordingly, its breakdowns are more varied. They manifest themselves in unclear or difficult gear shifting. Oil leaks, crunching noises and extraneous noises are also possible.

- Cardans and intermediate shaft. Here, malfunctions manifest themselves in the form of knocking during acceleration, squeaking or vibration while driving.

- Main bridge. In the event of a breakdown, the mechanism begins to make noise, knocking noises occur when accelerating and oil leaks.

- Transfer case. Problems make themselves felt in the form of spontaneous shutdown of bridges, noise and knocking. There may also be an oil leak.

- Constant velocity joints. Worn parts begin to crunch and knock while driving. The crunch is especially noticeable when the steering wheel is turned hard.

Malfunctions

The most common causes of malfunction:

- the backlash and vibration of the gearshift lever has increased;

- 5th speed goes out or reverse gear is engaged;

- It is difficult to engage reverse;

- fuzzy long-term switching of speeds.

Also interesting: Lada Largus 2021 new body, prices, configurations, photos, video test drive

Reference! Vibration of the gearshift lever is the most common problem that occurs in many vehicles when the internal combustion engine is running in the range of 2500 - 3500 rpm.

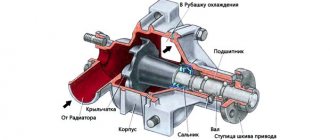

Structure

Lada Granta hatchback Logbook Unsuccessful replacement of CV joint boot

Important! If you decide to replace the CV joint yourself completely or change its individual parts, you need to understand its design, and only after that dismantle and subsequent replacement

Replacing a CV joint is an expensive procedure, which in a service center will significantly affect the thickness of the car owner’s wallet. The part is made of heavy-duty materials that are resistant to mechanical stress and aggressive environments. Accordingly, these materials, like the part itself, are quite expensive. It is designed for long-term operation, but not always road conditions and the driving style of the drivers themselves allow all parts of the chassis to be used for many years without the slightest breakdown.

And the cost of replacing a CV joint will be approximately half the cost of the mechanism. That is why many try to replace it themselves in order to save some money on repairs. But not everyone is born an auto mechanic, so the average person must first find out what parts the mechanism consists of. Here is their list:

- separator;

- balloons;

- fist;

- frame;

- outer and inner anthers.

The anthers perform two functions at once: they protect the hinge from dust and dirt. After all, in essence, a CV joint is an external part that is located on the bottom of the car. This means that all small particles when driving fall on the hinges in the same way as on the rest of the chassis.

On each wheel drive there are two mechanisms, which have almost the same structure, only slightly different in shape and size. As a rule, left and right CV joints are interchangeable on most car models. If you are in doubt, it is better to go to a car service center and ask if it is possible to buy left-handed hinges for right-hand drive on such and such a VAZ model for installation on right-hand drive, or vice versa.

Sometimes the entire mechanism requires repair, but more often it is the outer one that is worn out, while the inner one, as a rule, is almost eternal. But sometimes it may require replacement.

The design of the mechanism is not that complicated. The separator rotates the balls, which are located in the grooves of the fist and the outer housing. All this is covered by anthers that protect the parts from dirt and dust, as well as from leakage of lubricant. When replacing, the most difficult thing is to dismantle the mechanism itself so that you can install a new one entirely or change its individual parts.

Repair and replacement of the rocker on a Chevrolet NIVA

Lower into the overpass and loosen the bolt of the rocker clamp. Inside the car we find a plastic traction lock and move it to the extreme left position until it stops. After this, you should go down into the pit again, but tighten the loosened clamp bolt.

At this point, the gearbox thrust adjustment is completed, and you can check its performance.

If the adjustment does not help, then the product will need to be removed and repaired. View from the interior Mechanism malfunctions If, after the procedure for regulating the traction of the Niva Chevrolet gearbox, further malfunctions are identified, which manifest themselves in the form of: If such problems are identified, the need for more serious work arises - repair or replacement of the rocker.

But to be able to carry out such actions, the device must be removed. Removing the gearbox linkage You can remove the linkage in the following sequence: Having opened the hood of the Chevrolet Niva, you need to find the connection between the tip of the lever and the gearshift linkage.

Comments and reviews

An axle clamp is attached to the gearshift lever: Then the lever axle is dismantled with parallel removal of this axle from the holes of the lever and the rocker. After dismantling the axle, the gearshift lever is removed.

Using a wrench, you unscrew several screws holding the gear shift lever housing to the car body.

After dismantling the housing, the gearbox shaft is removed from it. Next, the guide rod is removed from the shaft.

If there is a large play in the hinges of the detected link that cannot be adjusted or the hole for the axle is too worn, then the mechanism is removed and replaced with a new one. Images of cars on the website may differ from cars sold in the Russian Federation.

How to replace the secondary shaft oil seal

Every car has its own weak technical link. For many models of domestic cars, this is a gearbox; the VAZ Niva is not one of them. The transmission of this car is quite reliable and wear-resistant. But, like any technical unit, it is not insured against breakdowns. The Niva gearbox may fail for one of 3 reasons.

- The device has a manufacturing defect. In this case, the Niva 2121 gearbox is simply replaced with a new one.

- Damage is caused by user factors (poor care). Diagnostics are carried out to identify faults. More often than not, simply adding oil is enough to restore the unit’s functionality, and the Niva gearbox works like a clock again.

- The device is worn out or mechanically damaged. In this case, the feasibility of the repair is assessed and it is carried out or the gearbox on the Niva is replaced.

Boxes of all models are repairable

To ensure a high-quality restoration of the unit’s performance, it is important to correctly determine the type of fault. To do this, just listen to the car. Chevrolet Niva gearbox operation

Chevrolet Niva gearbox operation

Repair of the Niva, Chevrolet Niva gearbox - 2000 rubles. Exchange of the Niva, Chevrolet Niva gearbox with installation - 6000 rubles.

Node device

On older models, this unit is located under the bottom of the car, thereby being exposed to increased contamination and moisture.

The design of the gear shift mechanism does not have complex connections, the work is carried out without much load, but owners often encounter wear and tear on this unit.

Read news about the new Niva

- AVTOVAZ announced prices and configurations of Lada Niva Travel » Lada.Online - all the most interesting and useful about LADA cars

- Amphibious all-terrain vehicle Pacher

- Do-it-yourself adjustment of the front gearbox Niva 21213 - Online reference book to help the car owner - looking for and troubleshooting problems

- Towbar for Lada (VAZ) Niva 2121 4x4 – buy at a great price in Moscow

- Computer diagnostics of Niva Chevrolet: engine, ECU, ABS, sensors

- Replacing the drive gear oil seal of the front axle VAZ 2121 Niva 2131

- How does all-wheel drive work on Niva 2121?

- Niva Chevrolet alarm connection points

Replacing the drive boot on Niva

The method described below allows you not only to replace the anthers on the hinges, but also to apply lubricant if it is not enough.

- wrenches 17.13;

- large pliers;

- a pair of flat-head screwdrivers - one larger, the second smaller;

- hammer;

- a soft metal drift (if available, a CV joint puller);

- special lubricant for hinges;

- clean rags.

Torn boot

Place the car on the inspection hole, tighten the handbrake, and engage first or second speed. Next steps:

- Loosen the wheel nuts, jack up the wheel and remove it.

- Place a small block of wood under the lower arm to compress it and lower the jack.

- Unscrew the nuts and remove the 3 ball joint bolts.

- Unscrew the shock absorber from below and push it up.

- Knock the hub cap through the wood spacer.

- Pull out the cone-shaped washer and, pulling the brake disc towards you, move it to the side.

- Remove the grenade.

- Having descended into the hole, turn the drive shaft by hand to grab the protrusions of the inner CV joint clamp with pliers.

- Scratch the marks on the grenade body and the drive shaft to put it “as was.”

- Move the boot away from the grenade.

- Feel for the retaining ring inside the hinge and pull it out using a flathead screwdriver.

- Pull out the joint: if you are not going to change the lubricant, put it in a plastic bag.

- Move the plastic casing with the boot at the outer “grenade” towards the inner hinge so that it does not interfere.

- Knock down or use a puller to remove the clip.

- With the device in a vise, remove both retaining rings using a flathead screwdriver.

- Pull out the old boot. If new grease is added, flush everything.

- Place a new boot and boot, add lubricant to it and reassemble the unit in the reverse order.

In the article, we discussed the removal and installation of front wheel drives in the article - “Replacing front wheel drives.”

In this article we will look at replacing the angular velocity joints of the front drive VAZ-21213.

We prepare the car for repair. We install it on a viewing hole or on a lift.

We remove the drive from the car. We clean the hinge from the outside and clamp it in a vice with soft pads.

Since the outer hinge is most often replaced, we will consider this operation first.

Using pliers or pliers, we squeeze the small clamp by the protrusions and, prying it up with a screwdriver, disconnect it.

We remove the large clamp in the same way.

If the protective cover is attached using plastic clamps, then simply cut the clamps using side cutters.

We slide the protective plastic and rubber cover along the shaft.

We clean and wipe the end part of the hinge from old grease.

Using a drift made of soft metal or a wooden spacer made of durable wood, we knock down the hinge by striking the end of the cage.

We take into account that the drift should not transfer force to the separator or balls in order to avoid their damage.

This is the case if you need to put this hinge back on the shaft.

We remove the hinge. The joint on the shaft is held in place by a retaining ring, which is located in a groove at the end of the shaft.

The retaining ring is usually sold complete with the hinge. Pry up the retaining ring with a thin screwdriver

Remove the retaining ring

Separate the protective covers

Removing the rubber cover

Removing the plastic casing

If you need to replace the thrust ring, remove it with pliers

Install the hinge in reverse order.

We clean the shaft and joint from old grease, apply a thin layer of new CV joint grease and put a casing and a new cover on the shaft.

We install a new retaining ring on the shaft. We put 60 cm3 of CV joint grease into the joint cavity.

Using a soft metal drift or a strong wooden spacer, press the joint onto the shaft.

We put on a rubber cover. We install clamps. Before tightening the clamps, you need to release excess air from the rubber boot by prying up the seating belt of the boot with a screwdriver.

Repair and replacement of the rocker on a Chevrolet NIVA

To prevent you from falling for a Chinese counterfeit, we publish here a link to the official website of Autoscanner. The need to repair the rocker occurs after repairing or installing the gear shift drive. If, after replacing the drive, while driving, you feel that the vibration of the gearbox lever remains, then most likely there is increased play in the hinge mechanism.

Accordingly, the backstage may need to be replaced. First of all, under the hood of the Chevrolet Niva, the nut of the screw securing the tip of the gearbox lever with the gear shift rod is loosened. After this, the turnbuckle with the protective cover is removed.

Then the front part of the floor covering is removed from inside the car. Next, the frame of the gear lever cover is removed.

The gear shift lever cover is turned inside out in order to see the clamp securing the cover and cut it with pliers and a regular stationery knife.

Gearbox slide: what it is, signs of wear, how to adjust it yourself

Not all motorists have any idea what the name of this or that part in their car is. In this case, we are talking not only about the mechanisms “hidden” in the engine, but also about the devices with which they interact literally every day. One of these parts is the gearbox linkage.

Please note: The name "slide" is not official for this mechanism, but it is generally accepted. In fact, this part is called the transmission control rod

1. What is a gearbox rocker 2. Signs of gearbox rocker wear 3. Adjusting the gearbox rocker

What is a gearbox rocker?

Many drivers mistakenly believe that the rocker refers to the gear shift lever, but this is not entirely true. If we are talking about a gearbox rocker, we mean a composite mechanism whose task is to connect the gearshift lever and the rod. That is, the driver cannot see the backstage, much less touch it. This element is located between the lever and the gearbox itself, and it is located under the bottom of the car, near the driveshaft, and in some cases under the gearshift lever itself.

As can be understood from the description, the rocker regularly has to deal with serious loads, so this element must have good strength. Despite this, the slide is susceptible to damage. If it does not contain enough lubricating components, drops of water, dust or other “debris” have entered it, there is a high risk of part failure.

Please note: On some cars, the rocker can last 200-300 or even more than thousands of kilometers without replacement. But, if we take the average result, the gearbox usually fails after 100 thousand kilometers of operation

Signs of gearbox wear

The driver must pay attention to possible failure of vehicle components, including knowing the characteristic signs of wear on the gearbox linkage in order to take timely action to replace it. Despite the fact that the mechanism is quite reliable, you should be aware of the following “symptoms” of its imminent breakdown:

- Increased play at the gearshift knob. This can be noticeable both when the handle is in neutral and in one of the gears;

- Difficulty shifting gears. For example, one or more gears are difficult to “stick”, or maybe a crunching noise occurs when the lever moves in their direction;

- It feels like changing gears has become more difficult, as if the lever has become much heavier;

- Gears are engaged incorrectly, for example, instead of fifth, third is engaged or vice versa.

Drivers often ignore the appearance of play in the gearbox, believing that this is a normal situation. In fact, if backlash occurs, it is imperative to diagnose the gearbox, and, if necessary, adjust or replace the linkage. The fact is that a slight play is already a fairly serious symptom of a faulty gearbox linkage.

If it “breaks” while the car is moving, this can lead to serious consequences for both the car and the driver, since in such a situation there is a high risk of getting into an accident.

That is why, if you notice problems with gear shifting, be sure to contact a service center for diagnosis and repair of the linkage, if necessary.

Adjusting the gearbox rocker

It is not always necessary to completely or partially replace the scenes. Quite often you can limit yourself to simple adjustments. At the same time, it is possible to adjust the link with your own hands, without contacting a service center. There are two ways to adjust:

- In reverse gear. In order to adjust the rocker for reverse gear, you need to loosen the clamp on it, and then move the gearshift lever to the position that corresponds to the ideal engagement of reverse gear. After this, the clamp is tightened, and the work is considered completed;

- On the first transfer. If it is not possible to engage reverse gear, you can adjust the gearbox rocker in first gear. To do this, engage first gear, and then loosen the rocker clamp. Next, rotate the rocker drive counterclockwise until the gearshift lever stops in the plastic reverse speed lock, and then tighten the clamp.

It is worth noting that the general processes for adjusting the gearbox rocker are described above.

It is important to say that the process may differ depending on the car, so before starting work it is recommended to read the instructions specifically for your car model

(353 votes, 4.49 out of 5) Loading...

Backstage repair

The gearbox linkage is an element of a multi-lever assembly, which is designed to connect the gearbox lever and the rod that fits the power unit. In Niva Chevrolet cars, the rocker is located under the bottom of the vehicle, next to the cardan. This component is susceptible to contamination and the formation of moisture on it, which over time can deteriorate the quality of lubrication of rubbing parts. As a result, parts begin to wear out, which can subsequently lead to various problems.

Chevrolet Niva car - 2013 model

As stated above, the rocker is an integral part of the transmission system in Niva Chevrolet cars. Compared to other components of the transmission system, the rocker, which is also commonly called the gearbox control rod, is a relatively simple mechanism in its structure. However, for correct operation, the condition of the scenes should also be given special attention.

In particular, we are talking about timely repair and adjustment of drive traction. If you want to avoid unexpected unpleasant surprises while driving, then the condition of the scenes should be at the appropriate level.

On most cars, this element is a fairly reliable mechanism that can easily last up to 100 thousand kilometers without replacement. But no one is immune from the breakdown of this unit. How to determine the need for backstage repair? This can be done based on several factors:

If the speeds start to turn on very slowly or the speed that should turn on is not the one that should turn on, you can try to adjust the mechanism. Of course, this is only relevant if the condition of the drive can be visually assessed as working. If the connecting elements of the mechanism's hinges operate with a large amount of play, then it would be more advisable to replace the component.

How to remove the gearbox on a Chevrolet Niva yourself. Video

Begin:

- Remove the ground from the battery (using the “10” key).

- Then unscrew the bolt securing the starter from above (using a “13” wrench).

After this, you begin to work inside the car:

- Remove the handles from the transfer case levers by turning them and pulling them up.

- The casing of the boxes (both transfer case and gearbox) must be removed. To do this you will have to remove six screws.

- By turning the casing, it can be removed.

- Remove the housing and boot from the transfer case lever (removing the three screws).

- Remove the connectors from the blocking sensor. Do not pull on the wire itself so as not to tear it off.

- The cover on the slide can be removed by unscrewing two self-tapping screws.

- Then engage reverse gear. To remove the lever itself, you will have to hook the locking sleeve with a screwdriver. When removing plastic and rubber parts of the lever, do not break the collet.

The main stage of work is directly removing the box. Watch the video - removing the gearbox on a Chevrolet Niva. If protection is installed under the crankcase, it must be removed. This also applies to the soundproof casing.

- It is advisable to mark the flanges of the shafts and boxes. This will allow the parts to be positioned correctly during installation.

- The bolt on the flange may be tight. Then you can help with a chisel, which is inserted between the flange and the bolt itself. A couple of hits should be enough.

- Disconnect the rear propeller shaft from the transfer case. Stuck flanges are “treated” again with a chisel.

- Remove the front driveshaft.

- Disconnect the speedometer cable. When removing the oil deflector washer, be careful. Move the cable to the side.

- If the car has a speed sensor, its connector must be disconnected.

- Then unscrew the fastening of the elastic coupling onto the flange of the input shaft of the box.

- The bolts are pulled out when the flange is in a strictly defined position.

- To remove the transfer case, unscrew the four nuts (using a 13mm wrench).

- After removing the cotter pin, remove the spring and fasteners on the clutch cylinder.

- Move the starter closer to the radiator, after loosening its fasteners.

- Remove the bolt holding the clamp from the muffler pipe. For greater convenience, you may also have to remove the muffler bracket (with the same “13” key).

- Loosen the bolts on the gearbox housing (using a 10mm wrench) and the nuts on the traverses.

- The box is attached to the engine with 19mm bolts. There is no need to remove the bottom bolt on the left completely yet, just loosen it. The rest will have to be removed using an extension cord. Now remove all bolts.

- Carefully remove the box and disconnect it from the motor. Already holding it in your hands, move it back, right up to the stop of the scenes. The box should not be left hanging on the shaft.

Installation is carried out in reverse order.

Adjusting the rocker of the Niva Chevrolet - Diablo

How to choose a new backstage?

What kind of rocker should I put on a Niva Chevrolet? This question came to the mind of every Niva car owner who had to deal with a malfunction of this element.

Before installing the seals, they will need to be lubricated with Litol. This completes the repair of the product; all that remains is to assemble all the parts in the reverse order of removal.

Once assembly is complete, don't forget about the new clamp that had to be cut when removing the cover. instructions: From this it follows that the transfer case rod has a much longer service life. If similar problems are noticed as in the gearbox, then it is worth replacing the transfer case, since its mechanism does not allow repair or replacement.

How to adjust the gearbox rocker on a Chevrolet Niva From all that has been said, the gearbox rocker and transfer case are important elements of the Chevrolet Niva, without which it is impossible to engage gears.

Removing the gearbox from a Chevrolet Niva Removing and installing the gearbox and minor repairs.

At this point, the gearbox thrust adjustment is completed, and you can check its performance. If the adjustment does not help, then you will need to remove the product.

Mechanism malfunctions If, after the procedure for regulating the traction of the Niva Chevrolet gearbox, subsequent malfunctions are identified, which appear in the form of: If such problems are identified, there is a need for more severe repair work or replacement of the rocker.

But to be able to carry out such actions, the device must be removed. Removing the gearbox linkage Also: The linkage has a turnbuckle and a protective cover that must be removed. But be careful not to destroy the fasteners.

The cover must be unscrewed in the opposite direction, and then the fastening clamp must be cut. Next, remove the cover from the lever. The front of the floor tunnel lining is removed. The latch is unfastened from the lever and the axle is removed.

Adjusting the rocker on a Chevrolet Niva, video tutorials

The shift lever is removed by holding it upward. The remaining rubber cuff must be returned inside the removed lever. The bolts securing the lever housing are removed and the rocker is removed. You will need to remove the rubber bushing rod from the shaft. Next, you need to inspect the traction for any flaws in order to find what you need: An old element of the transmission system that has exhausted its service life. In the event that the speeds become very difficult to switch on or the wrong speed is switched on, then you can try to adjust the mechanism .

To do this, you will need to purchase a special repair kit; how to adjust the gearbox rocker on a Chevrolet Niva includes plastic seals.

Before installing the seals, they will need to be lubricated with Litol. This completes the repair of the product; all that remains is to assemble all the parts in the reverse order of removal. Once assembly is complete, don't forget about the new clamp that had to be cut when removing the cover. And a few words about the transfer case rocker The transfer case rocker performs similar functions to a boxed product, only the speed mode shift lever is not used as often as the transmission.

From this it follows that the transfer case traction how to adjust the gearbox on a Chevrolet Niva has a much longer service life.

We repair and replace the scenes on Niva Chevrolet

If similar problems are noticed as in the gearbox, then it is worth replacing the transfer case, since its mechanism does not allow repair or replacement. Based on all that has been said, the gearbox and transfer case are important elements of the Chevrolet Niva, without which it is impossible to engage gears.

How to adjust the gearbox link on a Chevrolet Niva still seems to you that diagnosing a car is difficult? If you are reading these lines, it means you have an interest in doing something yourself in the car and really saving money, because you already know what: We ourselves tested this scanner on different cars and it showed excellent results, now we recommend it to EVERYONE! Repair and replacement of the rocker on a Chevrolet NIVA To prevent you from falling for a Chinese counterfeit, we publish here a link to the official website of the Autoscanner.

The need to repair the rocker occurs after repairing or installing the gear shift drive. If, after replacing the drive, while driving, you feel that the vibration of the gearbox lever remains, then most likely there is increased play in the hinge mechanism.

Source: https://thedreambag.ru/chevrolet/regulirovka-kulisy-nivy-shevrole-2.html

Transmission linkage: removal

The rocker on a Niva Chevrolet SUV is removed in the following order:

Replacement should be carried out if there is a gap in the hinges or serious wear of the play under the axis of the speed shift knob. If the boot is damaged, you will have to replace it with a new one. So, you need to cut off the worn boot and remove it, installing a new one in its place. You should first lubricate the internal parts with Litol.

In other cases, it’s time to repair the backstage. You will need to buy a repair kit in advance, which contains plastic seals. Before installing the seals, you need to lubricate them with Litol-24. After completing the repair, all that remains is to assemble all the parts in the reverse order of removal. Upon completion of assembly, it is worth remembering the new clamp that was cut when removing the cover.