Anti-slip devices

In the harsh Russian winter, using a vehicle is not an easy task. Especially if you live in a rural area or, out of necessity, you often have to drive through difficult-to-pass places where the risk of getting stuck in deep snow or mud is very high. In such cases, it is simply necessary to install a limited-slip differential on your car or buy comfortable and effective anti-skid bracelets. Because only they can help in an emergency situation, when your car is stuck or you need to drive through a difficult section of the road that cannot be overcome in the usual way.

To solve such problems, we offer such devices as: Differential locks: Val Racing and Avtoprodukt, Antibuks “Z-Track” tracks and Snow chains “Bars”.

Differential Lock

If your car is not equipped with a limited slip differential (LSD) and you want to install it in order to feel more confident off-road, then you can choose and buy proven self-locking differentials for VAZ from us. It is worth remembering that the selection of differential lock depends on the operating mode of the machine. And of course, it’s better to take a new one: it’s more expensive, but there will be 100% confidence that it will be installed on the car without any “jambs.” It is also important that the manufacturer tested the self-block for the VAZ and selected the best characteristics for it, so that the screw differential lock of the VAZ would work reliably and help to truly unleash the potential of the car.

Antibuks "Z-Track"

If we talk about the use of Z-Tracks, they are used in cases where the car is already stuck or stuck in snow or mud. Then Antibuks "Z-Track" is the best way to help your car get out of trouble. This is done by placing tracks under the necessary wheels, as a result of which the car’s wheels stop “slipping” and the car gets out of the stuck place. A distinctive feature of Antibux, unlike its competitors, is its high quality of workmanship. It can withstand the weight of the car and does not collapse under its influence, and also retains all its characteristics without cracking in the cold.

There are two types of tracks: Z-Track and Z-Track Pro. This anti-slip device is most popular among Gazelle drivers during snowfalls and icy conditions.

Wheel chains or snow bracelets

Another device that can dramatically increase the cross-country ability of almost any vehicle is anti-slip bracelets for wheels.

Our store presents snow chains for passenger cars "Bars" of the "Master" series with pendulum clamps, which are the latest development of this company in the line of devices designed to increase the cross-country ability of vehicles in difficult places.

The very first bracelets for Bars wheels of the Standard series were made according to the most common and simple scheme, in which bolted connections were used, however, after cases of bolts breaking on trucks, the Standard series was modified. Instead, the “PRO” series appeared in which bolted connections were replaced by welding, and the chain itself was used for fastening. The drawback of this series was the buckles, which were bought ready-made, and therefore they did not always fit, which led to difficulties with the use of anti-skid bracelets. Therefore, after the fastening mechanism was refined, chains for wheels of the “Master” series appeared, which combined developments from the “PRO” series and a specially designed pendulum clamp, which had not previously been used in bracelets from other manufacturers. At the moment, there are no disadvantages in using anti-skid bracelets of the “Master” series.

Summary

Currently, the range of anti-skids and similar devices is expanding and many similar devices are appearing on the market, and not always of high quality. Most often these are Chinese fakes, which, although they are cheap, are of low quality and therefore quickly fail. We offer our customers proven Russian-made products directly from the manufacturer. And the optimal combination of price and quality makes these products very popular among car enthusiasts.

Manufacturer's warranty. Delivery throughout Russia with a guarantee.

How to repair a differential yourself?

Attention! To successfully repair and replace this VAZ 2110 and 2112 unit, you must purchase instructions, a diagram and a set of additional tools. If you do not have these 2 components at your disposal, it is best to entrust the repair to professionals in a car service center.

For adjustment and repair you will need:

- Set of socket wrenches (heads),

- Universal round nose pliers,

- Special version of pliers for removing the retaining ring system,

- Thin chisel

- An ordinary hammer.

Stages of repair.

The stages of work on adjusting and replacing the differential on the VAZ 2110 and 2112 are as follows:

Attention! At the factory, specialists select a set of gears for the main drive only in pairs according to the characteristics of the contact patch. That is why replacing the driven gear must be accompanied by replacing the drive gear.

At this point, the stages of replacing and repairing the differential end. All that remains is to adjust and check the operation while driving around the car.

Types of forced blocking

Let’s make it clear right away that we are not considering barbaric options like welding satellites on the “native” differential. Also, the partial option of establishing “preload” is not considered.

- Increased friction disc locking. Friction clutches are installed. When the wheels begin to experience different resistance, the friction inside the clutch increases and locking occurs. Locking with discs requires adjustment due to their wear and the use of special gear oil.

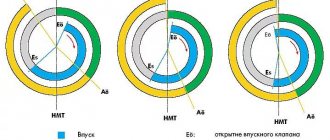

- Viscous coupling blocking (viscous coupling). Its principle is similar to a disk clutch, but a hydraulic clutch has many sticky disks (Fig. 7). The discs are immersed in a special viscous liquid. The basis of this liquid is silicone, which hardens when heated. When the rotation of one axle shaft is ahead of the other, heating occurs, solidification of the liquid and rigid engagement of the disks occurs. This type of blocking begins to work softly at first, then as it hardens, the effect increases sharply, and lasts until the axle shafts begin to work evenly, then, along with cooling, the gel liquefies. The big plus is the lack of maintenance. A necessary condition for long-term operation is complete tightness. Such viscous couplings are installed on “parquet” city SUVs. On severe off-road conditions they work poorly and overheat.

- Self-locking helical worm gearbox. Reliable option. When moving in a straight line, the worm-shaped screws rotate freely in the housing (Fig. 8). When the nature of movement changes, the screws move to their extreme positions and are fixed in the grooves. In this case, the blocking is triggered. The response time depends on the screw profile. When the torque is equalized, the screws again protrude from the grooves into free rotation. The advantage is low wear, the service life is equal to the life of the “native” differential. In addition, no special oil is required, just regular transmission oil. The cost of a screw lock on a VAZ 2107 is about 10–13 thousand rubles.

- Planetary differential locking mechanism (DAK), or Krasnikov scheme (Fig. 9). This mechanism uses a classic differential circuit, but instead of satellites, chains of balls work. This differential is locked not due to the difference between the load on the wheels, but when a change occurs between the axle load and engine traction. The cost of installation on a VAZ 2107 is about 10,000 rubles.

Dismantling and assembling the VAZ-2109 gearbox differential

1. Remove one side gear from the differential housing by rotating it 90° around the pinion axis.

2. Remove the second side gear from the differential housing.

3. Remove the retaining ring from the pinion shaft.

4. Remove the pinion shaft from the differential housing.

5. Remove two satellites from the differential housing.

6. Remove the bolts securing the driven gear to the differential housing.

7. Press the driven gear off the differential housing.

8. Use a puller to compress the differential bearings. Warning: When pressed with a puller, the bearings are destroyed. Therefore, remove bearings only when replacing them.

If you need to replace the speedometer drive gear, you can compress the bearing without destroying it using two screwdrivers, applying force to the inner ring of the bearing.

The gear will be destroyed, but it still needs to be replaced.

Inspection and troubleshooting of differential parts

Main gears with different gear ratios are installed on the car.

The final drive gears are selected in pairs at the factory based on noise and contact patch.

Therefore, when replacing the driven gear, also replace the output shaft with the drive gear: they are sold in pairs. To check, count the number of teeth on the drive gear on the output shaft.

The number of teeth of driven 1 and driving 2 gears is stamped on the driven gear.

1. Inspect the working surfaces of the pinion gears, pinion axles, side gears and the spherical surfaces of the differential housing in contact with them.

Remove small irregularities with fine-grained sandpaper. Replace parts with significant defects.

2. Inspect the bearing seats on the differential housing.

If these areas are significantly worn out, replace the differential housing.

If there is pitting (sinks) on the raceways and rolling elements, traces of indentation of the rolling elements on the raceways, or damage to the cages, the bearings must be replaced.

3. Check the condition of the transmission driven gear. If there are chips, chipping or significant tooth wear, replace the gear.

Differential assembly

Reassemble the differential in reverse order.

Before installation, lubricate all parts with transmission oil.

The driven gear is installed with the teeth markings facing out.

The tightening torque of the driven gear mounting bolts is 65.0-84.0 Nm (6.5-8.4 kgf m).

Differential VAZ 2114 and its types

There are several varieties of the product. The differences depend on the types of automobile bodies and the very principles of operation of the element. Additionally, the actual location of the differential itself may vary. For example, for front-wheel drive the location in the gearbox is relevant, for rear-wheel drive - in the rear axle housing, and so on.

There are canonical, cylindrical, and the most common - worm differentials. In addition, the self-locking differential of the VAZ 2114 is gaining great popularity among car owners.

Its main advantage is blocking forces in one place and transferring the moment to where it is really needed. For example, in a situation where one of the drive wheels is stuck or slips on a smooth surface, the second wheel receives increased torque. The advantages of using the product are obvious:

- the vehicle's cross-country ability increases;

- Full interchangeability with the classic unit is guaranteed;

- reliable operation is ensured.

The most important thing is that the differential lock on the VAZ 2114 allows the car’s wheels to make maximum use of contact with a hard surface to create traction and ensure further movement of the vehicle.

Selection of differential bearing adjusting ring for VAZ 2108, VAZ 2109, VAZ 21099

2108, 2109, 21099

repair

transmission

differential

Selecting a differential bearing ring

Description of the differential structure, manual for assembling and disassembling the Lada 2108 differential with your own hands, replacing parts of the VAZ 21099, VAZ 2108, VAZ 2109. Selection of the differential bearing ring Differential device VAZ 2108, VAZ 2109, VAZ 21099 differential transmission repair, troubleshooting

Selection of the adjusting ring is carried out only when replacing one of the following parts: clutch housing or gearbox VAZ 2108, VAZ 2109, VAZ 21099, differential housing or differential bearings.

The differential bearing preload should be 0.15-0.35 mm. Preload is ensured by selecting the thickness of the adjusting ring from those supplied as spare parts. The adjusting ring is installed in the socket of the Lada Samara gearbox housing under the outer ring of the differential bearing.

| EXECUTION ORDER |

1. Insert a 1.25 mm thick mounting ring into the gearbox housing housing under the differential bearing.

2. Press the differential bearing outer race into the transmission housing housing.

3. Press the outer ring of the differential bearing into the socket of the VAZ 2109 clutch housing.

4. Install the differential into the gearbox housing.

5. Install the sealing gasket.

6. Install the clutch housing onto the VAZ 21099 gearbox housing.

7. Tighten three crankcase mounting nuts equidistant from each other to a torque of 25.0 N·m (2.5 kgf·m).

9. Install a support plate of the appropriate diameter on the end of the differential flange on the clutch housing side.

10. Place the indicator on the stand. Install the indicator leg on the support plate with a preload of 1 mm.

11. Applying force from below, move the differential up until it stops, without turning the differential around its axis.

12. Measure the amount of axial movement of the differential of the VAZ 2108, VAZ 2109, VAZ 21099 by taking the indicator readings. Calculate the required thickness of the differential bearing adjusting ring using the formula:

T – required thickness of the adjusting ring, mm; S – measured value of axial movement of the differential, mm; C – the preload value of the differential bearings, equal to 0.25 mm; Y – thickness of the installation ring, equal to 1.25 mm. Select an adjusting ring with a calculated thickness T±0.1 mm from those supplied as spare parts.

The value of the axial clearance S according to the indicator is 0.95 mm. We substitute this value into the formula, as well as the value of the bearing preload C = 0.25 mm and the thickness of the installation ring Y = 1.25 mm:

T = 0.95 0.25 1.25=2.45 mm.

Thus, the thickness of the adjusting ring should be 2.45 ± 0.1 mm.

13. Install the selected adjusting ring into the socket of the gearbox housing and press in the outer ring of the VAZ 2108 differential bearing. Next, assemble the gearbox in order.

Differential gearbox VAZ 2108, VAZ 2109, VAZ 21099

| 8. Turn the fret satellite differential a few turns to self-install the bearings. | 14. After bolting the clutch and gearbox housings, check that the differential should turn freely and have no axial play. |

Disassembling the differential

Disassembling the differential VAZ 2108, VAZ 2109, VAZ 21099

Defects of differential parts

Inspection and replacement of differential parts VAZ 2108, VAZ 2109, VAZ 21099

Differential assembly

Differential assembly VAZ 2108, VAZ 2109, VAZ 21099

Selecting a differential bearing ring

Selection of differential bearing adjusting ring for VAZ 2108, VAZ 2109, VAZ 21099

Differential device

Differential VAZ 2108, VAZ 2109, VAZ 21099

Transmission units and gearboxes VAZ 2108, VAZ 2109, VAZ 21099

Section for repairing the Lada 21099 transmission, clutch, and wheel drives. Repair of differential fret 2108, secondary and primary shaft fret 2109.