Replacing the Lada Kalina catalyst: reasons for replacement

The most common reason that entails the installation of a spider instead of a catalyst is clogging of the honeycomb of the base of the catalytic element, both by fuel combustion products and by exfoliating particles of the base itself.

Natural degradation is normal. The catalyst, under favorable operating conditions, is designed for a service life of about 100 thousand kilometers.

Let's take a closer look at the moments when replacing the catalyst on a Lada Kalina car becomes necessary.

There are a number of factors that can significantly accelerate the destruction of the device:

- Problems with the formation of the correct fuel-air mixture. Both rich and lean mixtures have a negative effect here. A rich mixture leads to incomplete combustion of hydrocarbons and their deposition on the walls of the base cells. A lean mixture causes an abundance of oxygen in the exhaust gases, which has an oxidizing effect on the body at high temperatures. Also, due to an insufficient amount of fuel in the cylinder, misfires occur and unburned fuel is released into the catalyst. It can ignite while already in the manifold with the next portion of hot exhaust gases.

- Incorrect ignition timing. The fuel-air mixture is ignited at the wrong time. This leads to improper combustion and the formation of additional thermal loads on the catalyst.

- Gasoline is of poor quality. Gasoline saturated with impurities, after combustion, leaves soot deposits on the walls of the cells. In this case, rapid clogging of the catalytic element occurs.

- Coolant or oil getting into the cylinders. A leak in the lubrication and cooling systems leads to unauthorized penetration of working fluids into the combustion chamber. When they are burned, compounds are formed that lead to clogging or destruction of the catalyst.

In addition to the breakdown of the catalytic element itself, the housing itself often fails due to design flaws. The weld at the junction of the pipes of the first and fourth cylinders with the catalyst body is often destroyed. The escaping exhaust gases create increased noise. Exhaust also penetrates the interior, causing discomfort.

A failed catalyst increases the load on the engine, as it creates resistance to the passage of exhaust gases. This may manifest itself in the following symptoms:

- increased fuel consumption;

- reduction in engine power;

- failures when trying to accelerate sharply;

- reduction in maximum speed;

- problems with starting.

When is it necessary to replace and remove the exhaust manifold on a VAZ-2114

Huge temperature changes are the main problem faced by the exhaust manifold and the gasket, for which it is removed. The collector itself is made of a special grade of cast iron; it can withstand high temperatures (up to 800-900 degrees), however, these are critical values, after which the collector may warp or crack.

Exhaust manifold VAZ-2114

Replacing or dismantling the VAZ-2114 exhaust manifold is necessary in the following cases:

- Mechanical damage to the collector.

- Warping and loss of tightness at the junction with the cylinder head.

- Burnout of the gasket between the head and the manifold.

- The appearance of cracks as a result of engine overheating.

- Replacing the collector with a device of a different configuration, adapted to a more severe operating mode.

In the event that we are not going to participate in high-speed races for the prize of the head of the regional traffic police, replacing or dismantling the collector may be necessary in a number of cases.

Tools and materials for dismantling

There are a number of symptoms that will indicate that you need to prepare to remove the exhaust manifold:

- increased noise level in the engine compartment, the engine produces a characteristic, loud sound in any operating mode;

- breakthrough of exhaust gases into the engine compartment and sometimes into the cabin;

- reduction in engine power due to a mismatch between the exhaust gas outlets in the cylinder head and in the manifold.

Many people decide to replace the standard manifold with a “tuning” one, made of stainless steel and having a different configuration, thereby wanting to increase engine power and reduce the resistance that the standard manifold provides to exhaust gases. As a rule, the most common reason for dismantling a unit is gasket burnout.

Exhaust manifold gasket

To dismantle the manifold, you will need a standard set of tools, a set of sockets with extensions, and WD-40 penetrating lubricant or its equivalent. In case of broken studs, a stud extractor, drill, drill bits and a set of taps will be useful. A day or two before dismantling the collector, it is worth moistening all the fasteners several times, this will significantly simplify the removal procedure.

Replacing the catalyst on Kalina: preliminary diagnostics

When an error “Check Engine” appears on the dashboard, it is necessary to perform computer diagnostics of the electronic control unit.

Our service specialists will perform computer diagnostics and determine the causes of errors that appear. If the error is caused by the operation of the catalyst, it is necessary to either replace it or install a spider. Thus, diagnostics allows you to make an informed decision about what would be better: replacing the catalyst with a Kalina flame arrester or installing a spider.

What part in a car is called a spider?

Spiders. Most of the exhaust losses occur in the exhaust manifold. In sports and tuning, the standard one is replaced with the so-called “spider” - it differs in the shape and order of connection of the exhaust pipes with the exhaust windows. “Spiders” are “short” and “long” (two U). If we take a 4-cylinder engine, then the pipe diagram for the “long” one is built according to the formula 4->2->1, and for the “short” one 4->1. The “long” spider has a 2->1 coupling, while the “short” one has a more complex geometry. The 4->1 manifold provides additional power only in a very narrow rev range, beyond 6000 rpm, and is usually used for highly boosted engines with wide-phase camshafts, that is, sports cars. 4->2->1 manifolds are suitable for amateur tuning, as they provide a certain increase in power and torque over a fairly wide speed range. Adding power gives about 5-7% for VAZ engines. In a direct-flow system, intermediate straight pipes of increased diameter and resonators of reduced resistance are also used. Instead of rigid connections, “corrugations” (bellows) or ball joints are often installed. The latter do not create parasitic resonance frequencies, but are short-lived. But the “corrugations” soften shocks during startup and a sharp increase in power.

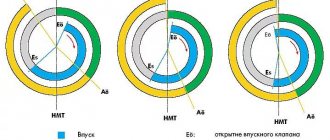

All these parts are not difficult to install yourself, if only you had a lift or a pit, a tool, dexterous hands and a clear head. But it’s better to entrust the work to a service: considering the price of the parts, installation is cheap, and also requires an angle grinder, welding and a pipe bender. And you shouldn't lose the warranty. The movement of exhaust gases in the exhaust pipe is an oscillatory process that can be experimentally coordinated with the oscillatory process of movement of the combustible mixture in the suction tract in such a way as to improve the cleaning of the cylinder from exhaust gases and its filling with a fresh mixture. The pressure in the exhaust pipe is subject to sharp fluctuations throughout the entire exhaust period. At the first moment after the opening of the exhaust valve, combustion products rush into the exhaust pipe at a very high speed, exceeding the speed of sound. The rapid removal of 50% of combustion products entails the formation of a vacuum in the cylinder, which can reach up to 0.5 kgf/cm2. In the same way, periods of low pressure are formed in the exhaust pipe.

Experiments with exhaust pipes have proven that the length of the pipe does not affect the efficiency of cleaning the cylinder in the first stage of the exhaust process, but with increasing pipe length, within certain limits, the duration of the period during which the vacuum is maintained increases. With a change in rotation speed, the period of low pressure in the exhaust system not only changes in duration and magnitude of the vacuum, but also shifts along the angle of rotation of the crankshaft. Therefore, each engine operating mode corresponds to a certain optimal length of the exhaust pipe. There are two processes in the exhaust system of an internal combustion engine. The first is the gas flow through the pipes, damped to one degree or another. The second is the propagation of shock waves (sound) in a gaseous environment. Both processes affect the cylinder filling ratio. In the first case: high resistance to gas flow (plug the exhaust pipe!) will cause a decrease in the quality of purging and loss of power. It is absolutely clear that the shorter and larger the diameter of the pipe, the lower its flow resistance. In real life, for a one and a half liter engine operating at speeds no higher than 8000, a diameter of 45 - 50 mm with a length of 3 - 3.5 meters is sufficient. A further increase in diameter does not cause a significant decrease in dynamic resistance. It is further clear that if a reflector, called a resonator, is built in the exhaust system at a certain distance from the valve, then at certain speeds the purging of the cylinders will improve, which will increase the engine torque. This phenomenon is called "tuned exhaust" and is used to adjust the torque curve. If the task is to increase power, as for a sports engine

Source

Replacing the catalyst with a spider

Replacing the catalyst with a spider on Kalina begins with selecting a substitution element.

There are several options for spiders for Lada Kalina cars:

- designs 4-1;

- 4-2-1 designs;

- 4-2-1 designs with modified sound.

The most common is 4-1. It consists of four pipes welded to the cylinder head mounting plate, which converge into one. Depending on the environmental class, they have one (for EURO-2) or two (for EURO-3) threaded holes for installing lambda probes.

More efficient in terms of exhaust gas removal is the 4-2-1 spider. It also consists of four pipes welded to a thick-walled metal plate, which is the receiving part of the exhaust manifold. The pipes of the first and fourth cylinders are connected into one, as well as the pipes of the second and third. After about half a meter, these two pipes are also connected to each other into one and transmit exhaust gases further into the exhaust system. This design is technologically more advanced, since its resonant oscillations are much smaller. It is more difficult to implement and more expensive. But in some cases it gives an increase in engine power of up to 5%. When installing, it requires shortening the segment of the exhaust pipe following the spider, since the spider itself is longer than a standard manifold with a catalyst.

The 4-2-1 Spider with a sound modifier is structurally the same as a regular 4-2-1. But one of the pipes is extended by creating an additional turn. This gives the exhaust sound an unusual timbre.

How to make a replacement

The entire replacement of the VAZ 2114 spider takes place in several stages:

- Place the car on an overpass or pit, put the handbrake on and secure the wheels with stops (shoes).

- If the car has been running recently, let it cool down.

- Remove the crankcase protection.

- Unscrew the bolts securing the exhaust manifold pants to the catalyst inlet (to make unscrewing easier, they should be treated with WD-40 lubricant before starting work).

- If the replacement is partial, then leave the catalyst and muffler in place; if it is complete, then remove it.

- Unscrew the nuts securing the manifold to the cylinder head.

- Dismantle the “original” manifold and the gasket located under it.

- Install the spider instead of the standard manifold (if the spider matches the model, then it will definitely fit into its place). Before installation, you should place a new gasket under it.

- If the old fasteners are severely corroded, then new ones should be installed instead, preferably coated with copper or brass.

- If a partial replacement is performed, then you need to check the alignment of the spider pipe with the catalyst inlet. As a rule, the exhaust pipe of the spider is longer, so you will have to cut off and dismantle not only the catalyst, but also part of the exhaust pipe, instead of which a resonator should be welded.

- Connect the spider's output pipe to the resonator.

- If a complete replacement occurs, then the same operations are performed as in the previous paragraphs, but instead of the entire “original” exhaust system, a direct-flow exhaust system is installed.

After installing the spider, you will also have to replace the lambda probe (with a new one, with an extended wire). The completion of the entire modernization process will be the flashing of the ECU, which should be performed at a car service center. It will help register the new system in the computer as “standard”, and will also show the increase in power obtained as a result of the upgrade.

Replacing the catalyst on Kalina (8 valves): installing a spider

All threaded connections are pre-filled with a liquid wrench. As a rule, nuts are highly corroded when exposed to high temperatures, and unscrewing them is a big problem.

After this, disassembly is carried out in the following sequence:

- the coolant is drained;

- the lambda probe chip (or two, depending on what class) is disconnected;

- unscrew the bolts securing the intake manifold from the cylinder head and the exhaust pipe;

- the holding bracket is removed;

- the exhaust manifold is dismantled;

- the front lambda probe wire is extended;

- spider is installed;

- the system is assembled in reverse order.

The main signs and causes of failure of the VAZ 2114 intake manifold

- The main symptom of a failed intake manifold is a sudden loss of car engine power.

- at the same time, there is an increase in fuel consumption, with a deterioration in traction and a drop in engine performance.

- Often a problem is indicated by a missing stud in one of the manifold flanges. It simply comes off when the collector goes “screw”, that is, due to temperature changes, for example in winter, or over time (average service life is 7 years), the collector begins to bend along the plane, and the pin simply “spits out”, pulls out .

- Due to the fact that the manifold has “leaded”, a crack may form and, as a result, exhaust gases from the engine escape, and the manifold must be replaced.

Replacing the catalyst on Kalina (16 valves): installing a spider

Due to a more complex and extensive power supply and gas distribution system, installing a spider on a 16 valve engine is a more energy-intensive task.

The sequence of work is as follows:

- The terminals are disconnected from the battery and the coolant is drained.

- The clamps securing the air duct pipe from the throttle assembly to the filter are loosened. The pipe is removed.

- The chip is disconnected from the throttle assembly connector and the oxygen sensor chip.

- The crankcase ventilation system hose is disconnected.

- The adsorber purge hose is disconnected.

- The receiver mounting bracket is unscrewed.

- The fastening nuts are unscrewed and the receiver is removed.

- The upper and lower nuts securing the heat-insulating shield and the eye are unscrewed and dismantled.

- The fastening of the spacer to the exhaust manifold is unscrewed.

- The heat shield is dismantled.

- The intake manifold is removed. To do this, unscrew nine fastening nuts at the cylinder head and three nuts at the exhaust pipe.

- The exhaust manifold is dismantled.

- The spider is installed.

- The wire of the first oxygen sensor is extended. Lambda probes are screwed into the spider. For the control sensor, a mechanical blende is provided in the spider. It is also possible to flash the ECU at the request of the client. If the car is EURO-2 class, then there is only one hole for the sensor.

- Installation is carried out in reverse order.

- high noise level;

- exhaust gases entering the cabin;

- increased fuel consumption;

- reduction in engine power.

How to make a replacement

The entire replacement of the VAZ 2114 spider takes place in several stages:

- Place the car on an overpass or pit, put the handbrake on and secure the wheels with stops (shoes).

- If the car has been running recently, let it cool down.

- Remove the crankcase protection.

- Unscrew the bolts securing the exhaust manifold pants to the catalyst inlet (to make unscrewing easier, they should be treated with WD-40 lubricant before starting work).

- If the replacement is partial, then leave the catalyst and muffler in place; if it is complete, then remove it.

- Unscrew the nuts securing the manifold to the cylinder head.

- Dismantle the “original” manifold and the gasket located under it.

- Install the spider instead of the standard manifold (if the spider matches the model, then it will definitely fit into its place). Before installation, you should place a new gasket under it.

- If the old fasteners are severely corroded, then new ones should be installed instead, preferably coated with copper or brass.

- If a partial replacement is performed, then you need to check the alignment of the spider pipe with the catalyst inlet. As a rule, the exhaust pipe of the spider is longer, so you will have to cut off and dismantle not only the catalyst, but also part of the exhaust pipe, instead of which a resonator should be welded.

- Connect the spider's output pipe to the resonator.

- If a complete replacement occurs, then the same operations are performed as in the previous paragraphs, but instead of the entire “original” exhaust system, a direct-flow exhaust system is installed.

Installed spider on a VAZ 2114

After installing the spider, the lambda probe will also have to be replaced (with a new one, with an extended wire). The completion of the entire modernization process will be the flashing of the ECU, which should be performed at a car service center. It will help register the new system in the computer as “standard”, and will also show the increase in power obtained as a result of the upgrade.

Spider or Flame Hider

The exhaust system consists of several parts, each of which plays an important role. These include the exhaust pipe, catalyst, resonator and the muffler itself. The main functions it performs are noise reduction and reduction in the emission of harmful gases. Also, there is often a corrugation on the receiving pipe, designed to reduce vibration. A malfunction of any part of the exhaust system can affect the condition of the entire car and many other parts in particular, so it is necessary to regularly diagnose this element of the car.

Sequence of work

With all this at hand, you can get to work:

We install the VAZ-2114 on the inspection hole and immobilize it. If the car is just from a trip, give the exhaust system time to cool. Remove the crankcase protection. We unscrew the bolts securing the exhaust manifold pants from the exhaust pipe of the catalyst and disconnect them. It is better to pre-treat the fastening bolts with WD-40. If the replacement is only partial, leave the catalyst and muffler in place for now. But with a complete replacement, we remove everything that comes from the collector’s pants from the VAZ-2114. Let's move on to the engine compartment. We unscrew the nuts securing the exhaust manifold to the block head, having previously treated them with WD-40. Carefully remove the standard manifold and the gasket located under it. Next, the Spider is installed. If the choice is made correctly, it will fall into place without any problems.

It is important not to forget to install a new gasket under it. If the old fastening nuts are heavily rusted, it is better to replace them with new ones, copper-plated or brass. Let's go under the car

In case of partial replacement, we try on the coincidence of the “Spider” with the exhaust pipe of the catalyst. Usually the “spider” is longer than the standard manifold, so the exhaust system will have to be shortened, which is why a grind is needed. machine (grinder) and welding machine. Then the catalyst is completely cut out. Along with the catalyst, it may be necessary to remove part of the pipe that goes behind it. And in its place a resonator is welded in, everything is first adjusted to the length. We connect the “Spider” to the receiving pipe of the resonator. This completes the partial replacement. For a complete replacement, we do the same as for a partial replacement, but with a new direct-flow system and resonator. That is, we hang a new exhaust system with a resonator on the car, take measurements, adjust it to length if necessary, connect and secure everything.

How to repair a muffler

If your car's muffler requires repair or complete replacement, it is not recommended to do this work yourself, since there is a high risk that you will only worsen the condition of the exhaust system, and possibly the entire vehicle as a whole. In order to prevent such a situation, contact only specialized car services. In our car service center, qualified specialists with the necessary competence in the field of working with exhaust systems will competently diagnose the exhaust system of your car, and, if necessary, repair or install a new muffler in the shortest possible time.

If you encounter any malfunction in the exhaust system and you need to diagnose it, repair it or replace the muffler, then our salon specialists will be happy to help you with this, since we carry out all types of this work!

When developing most modern cars, technical solutions are widely used in their design, the main task of which is to ensure maximum comfort for the driver and passengers of the vehicle. In addition, a car that comes off the assembly line today simply must be environmentally friendly: it pollutes the air minimally and creates a low level of noise when driving. Environmental standards are especially strict in Europe and the United States, but Russia is gradually moving in the same direction.

Reducing the amount of harmful exhaust into the atmosphere and the noise level of the machine is achieved through the design of the exhaust system and the operation of the catalyst, whose task is to neutralize the main toxic gases generated during engine operation. This is a necessary part of any car; in the West, a car cannot be operated without a catalyst, but in Russia the situation is somewhat different. The fact is that the catalyst is quite expensive (precious metals are used in its design), therefore, after the end of the service life of this element, various cheaper alternatives are sought for it.

One of the most common ways to replace a catalyst is to install a flame arrester in the vehicle's exhaust system. Currently, you can easily find a flame arrester for any type of engine; many well-known foreign and domestic manufacturers of automobile parts are engaged in their production. The most common is the so-called universal flame arrester; they are manufactured by such well-known brands as “Platinik”, “Asmet”, “Ferroz” (Poland), “Asso” (Italy), “Simons” (Finland), “Walker”, “ Universal" (Estonia), "Marmittesara" (Italy).

What is the design of a flame arrester? What are its pros and cons compared to a catalyst? Is it possible to install it yourself or is it better to contact a service station, and what is the optimal size of the flame arrester? What types of flame arresters are there?

Open heating system: operating principle

The main feature of an open heating system, in addition to the absence of a circulation pump, is the presence of a leaky expansion tank, also called a damper. It is necessary to compensate for the increase in coolant volume when heated. The hot water leaving the boiler is directed upward, creating an area of reduced pressure at the boiler inlet.

In an open heating system, water always acts as the coolant, since other substances evaporate very quickly through the expansion tank.

The amount of water in the system must be replenished from time to time, since its lack can lead to the formation of air pockets that prevent the circulation of the coolant and reduce the efficiency of heating the premises. It is enough to check the water level in the system only a couple of times during the heating season, which is not a big problem. To eliminate air pockets, special taps are integrated into the system through which air can be released.

Open heating system: 1 - boiler 2 - cold water 3 - boiler 4 - expansion tank

An open heating system consists of the following components:

| Hot water boiler . It can run on a variety of fuels: natural or liquefied gas or electricity. Liquid or solid fuel models are extremely rare, as they require a separate room for storing energy reserves. |

| Heating radiators . They can be made of aluminum or cast iron. Steel radiators are susceptible to the influence of oxygen, which is necessarily present in the coolant, so it is not recommended to use them in an open heating system. But you can use bimetallic batteries. Sometimes a thick steel pipe with a diameter of at least 10 centimeters is used as a radiator, which encircles the entire house along the perimeter. |

| Pipeline . To ensure unimpeded circulation of the coolant in the system, it is necessary to choose pipes of large diameter, from 2.5 to 5 cm. They can be made of polyethylene or polypropylene with fiberglass piping. In this case, at the outlet of the boiler the diameter of the pipes should be maximum, and at the inlet - minimum; it is due to the difference in diameters that the necessary pressure drop is created. |

| Expansion tank . Dampers are usually made of stainless steel. They are located at the highest point of the system, on the return pipe or on the attic floor or in the attic, if it is possible to maintain a constant positive temperature of the coolant there. The minimum installation height of the damper is 2.7 meters. Its design provides several pipes: expansion, overflow, control. |

When installing an open-type heating system, it is necessary to observe the required pipe slope: at least 5 mm for each linear meter. The pipeline diagram is conventionally divided into two parts: supply, through which hot water moves from the boiler to the radiators, and return, through which cooled water returns from the radiators to the boiler.

How long does a flame extinguisher last? Pros and cons of the device

Flame arrestors installed separately usually operate successfully for five to ten years. Collective flame arresters last less (up to five years), since they have to work in the “hottest” conditions. The lifespan of this car part can be even longer if it is made by a reputable company using high-quality materials. It is also necessary to take into account operating conditions, vehicle characteristics and mechanical effects on the product.

It should be noted that more often than the flame arrester itself, welds and exhaust pipes are destroyed.

Now a few words about the pros and cons of installing a flame arrester. The most significant advantage is the price of this device. By installing a budget flame arrester instead of an expensive catalyst, you can save a lot of money. The flame arrester is less demanding on fuel quality compared to the catalyst - this is its second absolute advantage. Since the quality of gasoline at our gas stations often leaves much to be desired, this advantage is quite significant. In addition, the flame arrester slightly increases engine power, since it has a direct-flow structure (and not a honeycomb, like a catalyst).

Of course, the flame arrester also has disadvantages (where would we be without them). The main one is environmental pollution. Without a catalyst, all outgoing exhaust gases go outside without any purification. So, if you care about clean air on the planet, then it is better to install a new catalyst.

To install a flame arrester, electric or gas welding is required, so doing it yourself is quite problematic. The installation of a manifold and a free-standing flame arrester is different because in the first case the exhaust manifold must be removed. However, it is hardly worth saving on this procedure: installing a collector flame arrester costs 6-8 thousand rubles, and a free-standing one costs 3-5 thousand rubles.

Manifold dismantling procedure - step-by-step instructions

The dismantling process itself is not so complicated; access to some nuts is difficult, so it is advisable to carry out the work on a lift or in an inspection pit. The algorithm of actions for the injection VAZ-2114 in this case looks like this:

- Remove the negative terminal from the battery or turn off the mains switch.

Remove the terminal from the battery

Drain the coolant from the system

Removing the fuel pipes

Search under the hood chapter 1. network spider

Disabling the throttle position sensor

Disconnect the muffler exhaust pipe from the manifold

- Which “spider” insert to choose instead of a catalyst from 2021

Dismantling the exhaust manifold mountings

Removing the exhaust manifold

Replacement of gaskets and installation of manifold

After dismantling the manifold, it is rarely possible to remove the gasket intact. It changes in any case, but parts of the destroyed gasket will definitely remain on the mating plane on the head side and on the manifold side. They must be carefully removed.

Changing the manifold gasket

Also, when installing new exhaust manifold gaskets, it is not recommended to use sealants. They can be of different quality, and during crimping they can form particles that get into the crankcase, which is extremely undesirable.

How does the collector work? What functions does the “spider” have?

It will increase the service life and protect the engine. Here, with the exhaust valve open, the gas is under pressure (in the chamber), and normal pressure is observed in the manifold. This produces a wave that, reflected from the resonator or catalyst, is directed back to the cylinders, where, mainly at medium speeds, it merges with the next exhaust stroke. Thus, an additional opportunity is obtained for the next portion of exhaust gases to escape from the cylinder.

On many cars, manifolds are made of cast iron and are installed so that one part is attached to the internal combustion engine, and the second to the catalyst or (if there is no catalyst) to the exhaust pipe. To avoid burns and increase fire safety, these parts are fenced off with a metal screen.

The exhaust valve of a Priora car operates in very difficult conditions, because... exhaust gases have an outlet temperature of several thousand degrees. On domestic cars in winter, due to rapid cooling, condensation often occurs on this element, which leads to the appearance of rust spots. Therefore, if the valve begins to rust, this is another reason to install a “spider” on the Priora, which will remove gases personally from each cylinder and create standing waves at the required speed.

Tips for replacing the intake manifold

Also, do not neglect the procedures for repairing and cleaning the intake manifold. The stability of the VK is very important for the normal functioning of the car. A certain vacuum is formed in the intake manifold, which is the source of drive force for many systems: cruise control, windshield wipers, vacuum brake booster. In the event of a collector malfunction, this threatens the failure of one or more of the above systems.

To avoid the appearance of cracks and distortions, you must use a torque wrench to tighten the nuts on the manifold and follow the tightening order of 20.9-25.8 (2.13-2.63) N_m (kgf_m). As a rule, it is recommended to start tightening the nuts from the center and gradually move towards the periphery, alternately tightening the nut on one side or the other.

To work on removing and replacing the VAZ 2114 intake manifold on an 8-valve engine, we will need:

- keys “for 8”, “for 10”, “for 13”, “for 17”;

- “cardan” type nozzle and socket heads “17”, “19”;

- magnetic screwdriver;

- screwdrivers, pliers;

- new intake manifold.

By the way, the price for an intake manifold from a VAZ (article 21110100801420) will be 1,350 rubles.

The price is indicated for spring 2021 in Moscow and the region.

Loosen the clamp and disconnect the crankcase ventilation hose.

What is the problem with release anyway?

There are only two problems:

- It's noise. That's why the exhaust system is often called a muffler to dampen loud sounds.

- This is ecology. Not all gases burn in the combustion chamber, and to put it in “simple language” they need to be “burned or decomposed” into more or less safe components, this is done by the catalyst.

If there were no muffler, the engine power would be approximately 10% more by default (depending on the valve and camshaft settings). BUT it would be impossible to drive such a car, firstly, you yourself would become deaf from the crackling sound that escapes from the engine (and you would be fined for disturbing the peace of citizens, this is now punishable by law), and secondly, the environmental component would be worse zero, because there is no catalyst (and we already have a polluted world that requires global cleaning) - it is not possible to pass MOT with such an indicator, and even now traffic police officers can easily check the exhaust.

In general, the gas muffling system CANNOT be removed, but it can be improved, which is exactly what tuners do.