Detailed algorithm for turning on the LED to 12 V

Based on the above information, we will create a step-by-step algorithm for connecting LEDs to a 12 V power source. 1) Determine the type of power supply:

- If the power supply looks like a network adapter, then you can find out its type by its weight. A pulse-type device will weigh 100-200 g, which is 2-3 times less than the mass of a linear analogue;

- from the inscription on the case, find out the type of voltage at the output (DC, AC);

- from the inscription find out the power and maximum current that it is capable of delivering to the load, that is, to the LEDs;

- plug the power supply into the network and measure the output voltage with a multimeter to make sure it is working properly.

2) By the type of LED, find out its rated current, voltage and power consumption. 3) Draw a conclusion about the possibility of connecting an LED to an existing power supply. For example, there is a pulse adapter with the following parameters:

- input voltage – AC: 230 V ~50 Hz;

- output voltage – DC: 12 V = 1 A;

- power – 12 W.

You can connect 3 identical blue, green or white LEDs in series to it through a resistor, calculating its value using the above formula. Their rated current should not exceed 700 mA. Then the load power will not exceed: P=PLED1+ PLED1+PLED1+PR=3.3*0.7+3.3*0.7+3.3*0.7+2*0.7=8.3 W .

The remaining power reserve will allow the adapter to operate for a long time and stably without overload. 4) The LEDs should be connected with correct polarity, and the resistor can be placed in any part of the electrical circuit. 5) All contacts of the finished device must be securely sealed and insulated after successful startup.

Connection errors

Let's consider ways to connect medium-power ice diodes to the most popular ratings of 5V, 12 volts, 220V. Then they can be used in the manufacture of color and music devices, signal level indicators, smooth switching on and off. I’ve been planning to make a smooth artificial dawn for a long time in order to maintain my daily routine. In addition, dawn emulation allows you to wake up much better and easier.

Read about connecting LEDs to 12 and 220V in the previous article; all methods are discussed, from complex to simple, from expensive to cheap.

- 1. Types of circuits

- 2. Designation on the diagram

- 3. Connecting the LED to a 220V network, diagram

- 4. Connection to DC voltage

- 5. The simplest low voltage driver

- 6. Drivers with power supply from 5V to 30V

- 7. Turn on 1 diode

- 8. Parallel connection

- 9. Serial connection

- 10. RGB LED connection

- 11. Turning on COB diodes

- 12. Connecting SMD5050 for 3 crystals

- 13. LED strip 12V SMD5630

- 14. LED strip RGB 12V SMD5050

Calculation of a quenching resistor for an LED

First of all, let's figure out how to calculate the resistance of the quenching resistor, what it depends on and what power the resistor should be to power the LED from the power source. The current (I) flows through the resistor and the LED from the same source. The voltage across the resistor is equal to the difference between the supply voltage and the voltage across the LED (VS-VL). Here we need to calculate the resistance of the resistor (R), at which voltage I will flow through the circuit, and voltage VL will flow across the LED.

Let's assume that we will power the LED from a 5V battery; as a rule, this supply voltage is used to power microcontroller circuits and other digital equipment. Let's calculate the voltage value across the quenching resistor, for this we need to know the voltage drop across the LED, this can be found in the reference book for a specific LED.

Approximate voltage drop values for LEDs (AL307 and other low-power ones in a similar package):

- red – 1.8…2V;

- green and yellow – 2…2.4V;

- white and blue - 3...3.5V.

Let's say that we use a blue LED, the voltage drop across it is 3V. We calculate the voltage on the quenching resistor – Udres = Upit – Ulight = 5V – 3V = 2V. To calculate the value of the quenching resistor, we need to know the current through the LED. The rated current of a particular type of LED can be found in the reference book. For most low-power LEDs (like AL307), the rated current is in the range of 10-25mA.

Let's assume that for our LED the rated current for its sufficiently bright glow is 20mA (0.02A). It turns out that a voltage of 2V will be extinguished across the resistor and a current of 20mA will pass. Let's perform the calculation using the formula of Ohm's law:

R = U / I = 2V / 0.02A = 100 Ohm.

In most cases, a low-power resistor with a power of 0.125-0.25 W (MLT-0.125 and MLT-0.25) is suitable. If the current and voltage drop across the resistor are very different, it would not hurt to calculate the power of the resistor:

P = U * I = 2V * 0.02A = 0.04 W.

Thus, 0.04 W is clearly less than the rated power even for the lowest-power resistor MLT-0.125 (0.125 W). Let's do the calculation for a red LED (voltage 2V, current 15mA).

- Udream = Upit – Ulight = 5V – 2V = 3V.

- R = U / I = 3V / 0.015A = 200 Ohm.

- P = U * I = 3V * 0.015A = 0.045 W.

When connecting LEDs, do not forget that they have polarity. To determine the polarity of the LED, you can use a multimeter in continuity mode or an ohmmeter. The use of quenching resistors is justified for powering low-power LEDs; when powering high-power LEDs, you need to use special LED drivers and stabilizers.

Calculation of a quenching resistor for an LED.

KIA Sportage 'Bᴇᴀsᴛ ғʀᴏᴍ ᴛʜᴇ Eᴀsᴛ' › Logbook › We correctly connect the LEDs in the car

Over the past few years, many owners have been using various types of LEDs to style their cars.

LED manufacturing technologies are constantly being improved, but in most cases this does not save LEDs from their rapid failure. As a result, partially burnt-out LEDs in the interior lighting or, for example, in LED rear lights (original lights do not suffer from this, since they have serious protection for both current and voltage). Roughly speaking, LEDs can be divided into two types: low-power and high-power. The first type is widely used in various LED strips, matrices, LED lamps and in finished lighting devices such as retrofitted flashlights. The second type is usually used in headlights and daytime running lights. All these devices have one thing in common. In the vast majority of cases, they are all designed for stabilized current and voltage, which are usually not found in the vehicle’s on-board network. Normal voltage in a car can range from 11.7V when the engine is off to 14.8V when the engine is running.

A little theory.

The voltage (voltage drop) of a typical LED is 3.5V. Depending on the color, this can be: for yellow and red LEDs - 2 - 2.5V; for blue, green, white - 3-3.8V. The typical current of a low-power LED is 20mA, and a high-power LED is 350mA. The LED is powered by current and does not have such a parameter as voltage, but it does have a voltage drop parameter. Those. what voltage is lost on it. If the LED says: 20mA 3.5V, then this means that it needs no more than 20 mA of current and at the same time 3.5V will be lost on it (i.e. the voltage after the LED will drop by 3.5V). To limit the current, resistors are installed on LED devices, but do not forget that the devices are designed for a voltage of exactly 12V and as the voltage increases, the current will also increase. As a result, the LED will quickly overheat and burn out.

So, as we found out above, the simplest driver (current stabilizer) is a resistor and the devices are designed for a stabilized voltage of 12V, which is practically not found in a car’s on-board network. Accordingly, for low-power diodes, which are widely used in cars, only one device is needed - a voltage stabilizer.

The DC-DC step-down converter LM2596, which can be bought on Aliexpress for a ridiculous 50₽, is proven and affordable today. The principle of its operation is very simple. When up to 40V is applied to the input of this switching voltage regulator, the output will always be exactly 12V (the value is set manually), and the current will be supplied exactly as needed to power the LEDs. These are the voltage stabilizers I use for LED styling of my cars. The case is not difficult to choose. I use standard cases purchased from the Chip and Dip store. If desired, the housing can be made sealed for use in all weather conditions.

To power high-power LEDs, a voltage stabilizer is not enough and it is necessary to install a driver (current stabilizer). One of the most affordable ready-made drivers is also built on the LM2596 and is also easy to buy on Aliexpress. It differs from a DC-DC converter in that you can set not only a stabilized output voltage, but also a stabilized current. When choosing a driver for high-power LEDs, you must take into account its maximum current, otherwise there may simply not be enough current or the driver will overheat.

Alternatively, the current driver can be assembled independently, for example, based on the LM317 chip. The circuit is as simple as possible, but you will need to select a resistor directly for a specific device, depending on the power of the LEDs installed in it.

I have already seriously confused some readers, so let’s summarize. If you want to extend the life of LEDs installed in a car or series-connected assemblies (clusters), then follow simple rules: - for each LED or cluster you must use its own current limiter: a resistor (quite enough for low-power assemblies) or a driver (for high-power ones), — for low-power LEDs or clusters with a current of up to 350 mA, we always install a voltage stabilizer

for each circuit, - for powerful LEDs or clusters with a current above 350 mA, we always install

a driver (current stabilizer)

on each circuit.

If you follow these simple rules, your LEDs will burn for a long time and delight you with their magic of light. Good luck and good luck to everyone.

Source

Connecting an LED through a resistance to 12 volts in a car (via a resistor)

Let's start, as in the paragraph above, with the option of connecting the LED to a voltage of 12 volts through a resistor. In order for you to better understand how the voltage drop occurs, we will present several options. When 3 LEDs are connected to 12 volts, 2 and 1.

Connecting 1 LED through a resistance to 12 volts in a car (via a resistor)

So we have an LED. Its supply voltage is 3.3 volts. That is, if we took a 3.3 volt power source and connected an LED to it, then everything would be great. But in our case, there is an increased voltage, which is not difficult to calculate using the formula. 14.5-3.3= 11.2 volts. That is, we need to initially reduce the voltage by 11.2 volts, and then only apply voltage to the LED. In order for us to calculate the resistance, we need to know what current flows in the circuit, that is, the current consumed by the LED. On average, this is about 0.02 A. If you wish, you can look at the rated current in the datasheet for the LED. As a result, according to Ohm's law, it turns out. R=11.2/0.02=560 Ohm. The resistance of the resistor is calculated. Well, drawing a diagram is even easier.

The resistor power is calculated using the formula P=UI=11.2*0.02=0.224 W. We take the closest one according to the standard series.

Connecting 2 LEDs through a resistance to 12 volts in a car (via a resistor)

By analogy with the previous example, everything is calculated the same way, but with one condition. Since there are already two LEDs, the voltage drop across them will be 6.6 volts, and the remaining 14.5-6.6 = 7.9 volts will remain for the resistor. Based on this, the scheme will be as follows.

Since the current in the circuit has not changed, the power of the resistor remains unchanged.

Connecting 3 LEDs through a resistance to 12 volts in a car (via a resistor)

And one more option, when almost all the voltage is extinguished by LEDs. This means that the resistor will be even smaller in value. Total 240 ohms. A diagram for connecting 3 LEDs to the machine's on-board network is attached.

Finally, all we have to say is that the calculations used a voltage of not 12, but 14.5 volts. It is this increased voltage that usually occurs in the electrical network of the car when it is started. It is also not difficult to estimate that when connecting 4 LEDs, you will not need to use any resistor at all, because each LED will have 3.6 volts, which is quite acceptable.

Methods for connecting LEDs to a 12 volt power supply

To connect one 3 V LED to a 12 volt stabilized power source, you will have to compensate for the excess (about 9 V) with a resistor or zener diode. This is extremely inefficient, since the bulk of the energy will be dissipated on the auxiliary elements of the circuit.

To increase the efficiency of the circuit, the LEDs are connected in series in threes. If we consider that the voltage drop on the most common white LEDs is approximately 3.3 V, then one low-power resistor is enough to extinguish the remaining 2 V (12-3.3*3=2). Yellow and red LEDs can be combined in series in groups of 5, since their voltage drop does not exceed 2.2 V.

Ideally, before calculating the resistor, you need to know exactly the operating voltage of each LED. You can take it from your passport or measure it yourself. The measurement is made with the LED turned on, through which the rated current flows. Then, according to Ohm’s law, the rating and power of the current-limiting resistor are determined: R=Upit-(ULED1+ ULED2+…+ ULEDn)/ILED. P=(Upit-(ULED1+ ULED2+…+ ULEDn))*ILED.

More details about the calculation and selection of a resistor are written in this article.

The number of LEDs connected to the power source depends not only on the availability of the required voltage, but also on the load capacity of the power supply. This means that the total current in the load should not exceed the maximum output current of the power supply.

Today, some manufacturers produce LEDs with high voltage dropout. These include 12 volt LEDs, which must be connected strictly through a stabilized current source.

Also a separate case is connecting an LED strip to a 12 V power source. Here the connection diagram is much simpler, since there is no need to stabilize the current, and there is a limiting resistor in each group of several LEDs. The simplest and most inexpensive option for turning on an LED strip is to use a power supply from a computer. To do this, just connect the plus of the tape to the yellow (+12 V), and the minus of the tape to the black (common) wire.

COB matrices also have their own nuances. Like other LEDs, they must be driven by a driver and, depending on conditions, their brightness can be adjusted by changing the current. The passport for the COB matrix must indicate the operating current and the approximate voltage drop at this current.

It is not correct to design an LED lamp based on a COB matrix powered by a 12 V unit for several reasons. Even if the voltage drop across the matrix is close to 12 V, it can be connected to the same stabilized power supply only through a limiting resistor. As a result, the current will be lower than rated, reducing the brightness and efficiency of the entire device.

The situation can be resolved by adding a voltage-to-current converter to the power circuit. To do this, a low-voltage driver board is connected to the 12 V output of the power supply, the output current of which is equal to the current consumption of the COB matrix. Such converters are mass-produced and have a low price, a wide range of operating currents and voltages, and compact dimensions. For high-voltage LEDs and assemblies (with a direct voltage of more than 12 V), a boost-type driver should be selected. If desired, you can assemble a converter with the necessary parameters yourself.

Effective connection to one IP

We have already found out above that an unlimited number of LEDs can be powered from one power source. The main thing is that there is enough power. However, simply connecting bulbs in parallel with a resistor for each is ineffective. From the previous paragraph we saw that more than 2/3 of the power is dissipated in the current-limiting resistor. Therefore, the question often arises of how many LEDs can be connected to 12 V.

The most effective connection to 12 volts is considered to be a chain of three serial LEDs with one resistor. All LED strips powered by a 12 V power supply are produced using the same scheme.

Parallel connection

Parallel connection of LEDs is quite rare. To prevent the lamps from burning out, a contact modulator is used. If we consider the option with a 12 V LED strip, then it is more advisable to use a pulse transceiver. It is sold on the market with a security system. On average, its current conductivity parameter does not exceed 30 microns. Amplifiers for connection are rarely used. In order to regulate the power of the light flux, it is allowed to use triggers.

If we consider double-digit modifications, then capacitors are used with one adapter. It is also important to note that the level of nominal resistance depends on the throughput of the resistor. If we consider the connection option with a three-digit trigger, then capacitors are used without an adapter. In this case, the modulator can only be used with a thyristor. Filters for voltage stabilization are rarely installed.

How to determine LED polarity

LED polarity can be determined in three ways:

- With a traditional LED, the long leg (anode) is a PLUS. And the short one (cathode) is correspondingly MINUS. There is a cut on the plastic base (head) of the LED; it indicates the location of the cathode or minus.

- Take a closer look inside the light. A contact in the form of a flag is a minus. Thin contact is a plus.

- Use a multimeter. Set the central switch to dial mode. Using the probes, touch the contacts of the LED being tested. If the LED lights up, then the red probe is pressed to the plus of the LED and the black probe, respectively, to the minus.

NB Although in practice the latter method is sometimes not confirmed.

The nominal voltage for most LEDs is 2.2 - 3 volts. LED strips and modules that operate at 12 volts or more already contain resistors in the circuit.

- https://ledjournal.info/shemy/podklyuchenie-svetodioda.html

- https://le-diod.ru/podklyuchenie-ustanovka/podklyuchenie-svetodiodov/

- https://svetilnik.info/bez-rubriki/kak-pravilno-podklyuchit-svetodiod.html

- https://lampagid.ru/vidy/svetodiody/podklyuchenie-k-220-v

- https://svetosmotr.ru/kak-podklyuchit-svetodiodnuyu-lentu-v-avto/

- https://ledno.ru/svetodiody/podklyuchenie-svetodiodov.html

- https://elektronchic.ru/domashnij-elektrik/podklyuchenie-svetodioda.html

- https://silatoka.net/kak-podklyuchit-svetodiod

- https://electrohobby.ru/kak-podkl-svetdiod-220-hgt.html

What LEDs are connected to 12 volts?

To briefly answer the question posed as a subtitle, the answer will be: none! To a non-specialist, such an answer will seem paradoxical, because there are LEDs on sale that, as sellers claim, are designed to be powered by a 12-volt source.

Let us undertake to assert that only LED-based products can be designed for a specific voltage. It is not correct to talk about a specific LED operating voltage. This is due to the physical processes occurring in it when light is emitted.

The main characteristics of these processes are the operating current and the maximum permissible current of the device. Reference books and datasheets indicate the voltages on the LEDs when operating current flows. These values are used for calculating LED designs, and not for selecting a power source.

By the way, the voltage in operating mode only ranges from 1.5 V to 3.5 V. The value depends mainly on the color of the emitted LED. Lower voltages drop on red LEDs; higher values are considered super-bright. Commercially available 12 volt light emitting diodes are not isolated devices.

Twelve-volt LEDs are matrices consisting of several light-emitting diodes. Matrices are LED assemblies assembled from chains of sequentially connected devices.

Each matrix has several chains that are connected in parallel to each other. When they say that an LED is designed for twelve volts, they mean that the voltage drop across a series chain of them when operating current flows is approximately 12 V.

Connection

There are LED panels (clusters) on sale that are powered by 12 V. You can immediately connect them to the mains and enjoy the wonderful lights. But as the engine speed changes, the brightness of their glow will change. In fact, they will normally glow at a voltage of about 12.5 V; low voltage will cause the clusters to glow dimly.

Each cluster consists of LEDs and a resistor. There is one resistor for three lamps, which is needed to dampen excess voltage. The LED strip is designed in a similar way, and if you need a piece, you can cut it at a specific location.

Serial connection

Our lamps can be switched on in series, thereby making a homemade cluster. To do this, you need to connect them to each other, and connect the remaining two terminals to the on-board electrical network. For example, for a voltage of 12-14 V you will need three white LEDs. As you know, LEDs of different colors have different supply voltages. Thus, in this example we get the following supply voltage: 3.5x3 = 10.5 V.

For an LED, one terminal is considered “plus” (cathode), and the second is considered “minus” (anode). A serial connection means that the “plus” of one terminal is connected to the “minus” of the next and so on until the end. But they still cannot be connected directly to the network. We connect a quenching resistor (resistance) of 100-150 Ohms with a power of 0.5 W in series with the resulting chain.

This circuit also depends on the voltage of the on-board network. However, using it, you can connect any number of LEDs in chains of 3 pieces in parallel with a resistor. A parallel connection means collecting several identical chains, where the plus of one chain is connected to the plus of another chain, and the minus to the minus. The nominal resistance is calculated according to Ohm's law.

Remember, if you just take and connect an LED to the car’s electrical network, you are guaranteed to burn it out.

Calculation of LED connections in 12 and 220 volt circuits

A separate LED cannot be connected directly to a 12V power source because it will burn out immediately. It is necessary to use a limiting resistor, the parameters of which are calculated using the formula: R= (Upit-Upad)/0.75I, in which R is the resistance of the resistor, Upit and Upad are the supply and drop voltages, I is the current passing through the circuit, 0.75 – LED reliability coefficient, which is a constant value.

As an example, we can take the circuit used to connect 12-volt LEDs in a car to a battery. The initial data will look like this:

- Upit = 12V – voltage in the car battery;

- Upad = 2.2V – LED supply voltage;

- I = 10 mA or 0.01A – current of a separate LED.

According to the formula above, the resistance value will be as follows: R = (12 – 2.2)/0.75 x 0.01 = 1306 ohms or 1.306 kohms. Thus, the closest would be a standard resistor value of 1.3 kOhm. In addition, you will need to calculate the minimum resistor power. These calculations are also used when deciding how to connect a powerful LED to 12 volts. The actual current value is preliminarily determined, which may not coincide with the value indicated above. For this, another formula is used: I = U / (Rres. + Rlight), in which Rlight is the resistance of the LED and is defined as Up.nom. / Inom. = 2.2 / 0.01 = 220 Ohm. Therefore, the current in the circuit will be: I = 12 / (1300 + 220) = 0.007 A.

As a result, the actual voltage drop of the LED will be equal to: Udrop.light = Rlight x I = 220 x 0.007 = 1.54 V. The final power value will look like this: P = (Usupply - Udrop)² / R = (12 - 1.54)²/ 1300 = 0.0841 W). For practical connection, it is recommended to increase the power value slightly, for example to 0.125 W. Thanks to these calculations, it is possible to easily connect the LED to a 12 volt battery. Thus, to properly connect one LED to a 12V car battery, you will additionally need a 1.3 kOhm resistor in the circuit, the power of which is 0.125 W, connected to any contact of the LED.

The calculation of connecting an LED to a 220V network is carried out according to the same scheme as for 12V. As an example, we take the same LED with a current of 10 mA and a voltage of 2.2V. Since the network uses alternating current with a voltage of 220V, the calculation of the resistor will look like this: R = (Up.-Up.) / (I x 0.75). By inserting all the necessary data into the formula, we get the real resistance value: R = (220 - 2.2) / (0.01 x 0.75) = 29040 Ohm or 29.040 kOhm. The closest standard resistor value is 30 kOhm.

Next, the power calculation is performed. First, the value of the actual consumption current is determined: I = U / (Rres. + Rlight). The LED resistance is calculated by the formula: Rlight = Up.nom. / Inom. = 2.2 / 0.01 = 220 Ohm. Therefore, the current in the electrical circuit will be: I = 220 / (30000 + 220) = 0.007A. As a result, the actual voltage drop across the LED will be as follows: Udrop.light = Rlight x I = 220 x 0.007 = 1.54V.

To determine the power of the resistor, the formula is used: P = (Upit. - Upad.)² / R = (220 -1.54)² / 30000 = 1.59 W. The power value should be increased to the standard 2W. Thus, to connect one LED to a network with a voltage of 220V, you will need a 30 kOhm resistor with a power of 2W.

However, alternating current flows in the network and the light bulb will burn in only one half-phase. The light will flash quickly at 25 flashes per second. For the human eye, this is completely invisible and is perceived as a constant glow. In such a situation, reverse breakdowns are possible, which can lead to premature failure of the light source. To avoid this, a reverse directional diode is installed to ensure balance in the entire network.

Instructions for connecting LEDs

How to connect an LED to your car? What resistance should be selected for the LED? Do I need to use resistors?

Below we will describe how the diode module should be connected:

- The procedure for connecting LEDs to a 12-volt network begins with calculating the power supply. The main disadvantage of clusters is that their brightness will depend on changes in engine speed. If the rpm drops, the power will also decrease. Consider the fact that the most optimal indicator for a good glow of clusters is the voltage parameter of 12.5 volts - if it is lower, the glow will be weak.

- The cluster design includes diode elements and a resistor, which, by the way, is an important component of any cluster. The resistor device used to absorb excess voltage is installed at the rate of one per three diode elements. So if you bought a whole strip to install in an optic, you will most likely need to cut it. Moreover, circumcision should be carried out only on certain segments.

- The connection procedure is carried out in a sequential manner. That is, you will need to first make a cluster by connecting several diodes to each other in turn, and the ends of the cluster are connected to the on-board network. As an example, consider white diode components with a power of 3.5 volts. For a regular 12 V on-board network, you will need three diode bulbs, which will consume a total of 10.5 volts. Daisy chaining means that the positive terminal of one component must be connected to the negative terminal of another.

- There is no need to directly connect the cluster yet; a resistance, that is, a resistor, is connected in series. It should be taken into account that the resistance should be about 100-150 Ohms, and the resistor power parameter should be 0.5 W (the author of the video is the Auto Repair and Tuning channel).

Parallel connection method

To connect an LED to 12 volts in parallel, follow these steps (an example is considered with a 3.5 volt diode element and a current of 20 mA):

- Measure the voltage where the light source will be connected to ensure that the connection will be effective. For example, this is 13 volts.

- After this, 3.5 volts of the diode are subtracted from 13 volts, resulting in 9.5 volts. All measurements are made using Ohm's formula - in our case, 20 mA is divided by 100, resulting in 0.02 A.

- The same formula is used to calculate the resistance; to do this, 9.5 volts must be divided by 0.02. As a result, we find out that we need a 475 Ohm resistor.

- The next step is to calculate the power - you need to know this in order to prevent overheating of the resistor element. According to our parameters, 9.5 is multiplied by 0.02 - we get 0.19 W. To prevent possible failures, power can be taken in reserve.

- Next, using a multimeter, the current is measured in the area between the diode lighting source and the resistor element. After this, the tester is set to 10 amperes, and the positive terminal of the device must be connected to the battery positive, the negative terminal to the lamp positive.

- Ultimately, a reading of around 20 mA should appear on the multimeter display. Depending on the light source, as well as the resistance used, the parameters may differ.

Photo gallery “Diode connection diagrams”

How to determine LED polarity

Determining the polarity of an LED by appearance

All 12 volt LEDs (white, red, blue and other colors) have an anode and a cathode (polarity). These must be taken into account when connecting LEDs. Polarities can be determined in one of the following ways:

- By design. One of the legs on the light bulb base is always several mm longer. This is the anode. It is marked with a “+” sign or a green dot.

- One bowl inside the flask. If you look closely, you can see two crystals on it. The larger one represents the cathode. The smaller one is the anode.

- Using a multimeter. To do this, the device must be set to “Dialing” mode. Then the probes of the device are brought to the cathode and anode. The first one is black, the second one is red. When they are positioned correctly, the light bulb should glow. If this does not happen, it means that the master incorrectly identified “+” and “-”. You need to change the position of the probes. If this does not help, the LED is simply faulty.

What does a car owner need to consider before replacing?

In order to correctly connect LED light bulbs with your own hands, using a connection diagram, you first need to understand the basic information. First you need to understand that a 12-volt blinking car diode is not a lamp.

Connecting LEDs to a 12-volt on-board network should be done taking into account some points:

LEDs with different bases

To choose the right 12V diode elements, you need to navigate their varieties, and they are divided among themselves by power:

Diagram for connecting a diode in a car

In what cases is it permissible to connect an LED through a resistor?

In some cases, connecting LEDs is possible not through a driver, but through a current-limiting resistor.

- If the glow is needed as an indicator, where it does not matter how bright the diode will burn, but the fact of the glow itself is important.

- To check the performance of the diodes, they are connected through a resistor to a high-voltage battery, due to which the LED element may break. The resistor limits the voltage supplied to the diode and you can check its performance without the risk of breaking parts.

- To determine the negative and positive fields of an LED.

- When studying how a new LED will work, limiting resistors are used so that the element does not burn out during testing.

Correct connection of a 10 Watt 12 Volt LED Part 2 | Peling Info solar panels

In this topic, I will tell and show you the advantages of powering LEDs at 10 watts 12 volts, from the well-known DC-DC step-down converter.

DC-DC - this means that the converter converts DC voltage into DC, and higher or lower it is designated UP - step-up DoWN- step-down.

The converters are quite versatile and can serve as both a power supply with voltage regulation and a charger.

In this topic we will talk about LEDs with a buck converter. I hasten to note that by using these converters we also reduce the consumption of LEDs from the battery or power sources. And also recently I saw that by converting the power supply downwards and reducing the output voltage, the output current increases. The opposite effect can be seen with boost converters. Here we will observe the opposite picture, increasing the output voltage, the input current will increase until the converter and the output current will decrease.

Additional information on testing 10 Watt 12 Volt LEDs.

When powering LEDs at Max voltage, even with a reduced current, the degradation time also increases. If you initially assemble and get used to the brightness the LED produces, then for a long time it will delight you with its light, while the brightness will long be equal to what it was when you first turned it on. But if you suddenly need to get more lumens from it, I recommend improving its cooling, and prepare for the fact that after some time the brightness will drop!

There is a direct dependence on how long the LED will work, and unfortunately, the time indicated by the manufacturer refers to the minimum voltage and current at which the LED operates. The minimum parameters for working with an LED lifetime can be 50,000 hours at a supply voltage of 9 Volts and a current of 500 mA. The higher the voltage and current, the lower the lifespan of the LED!

It is a very big misconception that if you set 900 mA and 12 volts or even 11 volts, the LED will do well and will work for years. Given these parameters, it wears out and its lifespan will immediately depend on its cooling system and the ambient temperature. If manufacturers are told how long this or that LED will last, the manufacturer will immediately begin to wag and avoid a direct answer. Like, it all depends on your network, the cleanliness of the room or the temperature. But in fact, manufacturers test almost every batch of LEDs for wear selectively and can answer it directly. That in such conditions it will last so long and in such conditions for so long.

In general, when taking any LED, read between the lines. And if you’re really curious about how long it can last, assemble two stands, one according to my scheme and one according to yours, and see what happens to the brightness of the LEDs after thirty days of operation. By the way, as an option, you can do a similar test yourself. If I have time, I'll do this experiment.

I won’t bother you with my thoughts and what I’ve learned, and I’m trying to share it. And let's move on to watching the next video where you can see everything clearly.

Assembly steps

Approximate sequence of assembly and testing in operating mode.

- find the technical specifications in the documentation, how many volts drop on each LED;

- draw up a connection diagram taking into account the supply voltage;

- calculate the power consumption of the entire electrical circuit;

- select a power supply or driver suitable for power;

- calculate the resistor when using a stabilized voltage supply;

- find the correct polarity on the LED legs;

- solder the wires to the diode components;

- connect the power supply;

- place the diodes tightly on the radiator and secure them;

- we turn on the entire structure to the 220V network after closing our eyes;

- if nothing exploded, then we measure energy consumption, heating, current consumption;

- we adjust the current if it turns out to be higher or lower than the calculated one;

- warm up for 30 minutes

- for Chinese diodes, the temperature at the electrical contact should not exceed 60°; for branded ones, this is indicated in the specifications; it can be a maximum of 130° - 150°.

Aluminum star

Installation on a cooling system most often requires good equipment and skills. Therefore, it is better to buy low-power diodes 1W, 3W, 5W directly on an aluminum or copper substrate in the form of a star. This way you will not overheat the legs and damage the diode chip. The star is then placed on the radiator using heat-conducting paste.

Features of connecting LED bulbs

Appearance of LEDs

The scope of application of LEDs is quite wide - from the production of TV equipment to lighting in residential and commercial premises. However, not every craftsman knows how to connect small lamps. Everyone distinguishes three methods of LED installation:

- consistent;

- parallel;

- combined.

In addition, the LED lamp can be connected to a 220 Volt network. In any case, the connection is made only to direct current sources.

Features of connecting LEDs

In most cases, plug-in LEDs require current limiting using resistors. But sometimes it is quite possible to do without them. For example, flashlights, keychains and other souvenirs with LED bulbs are powered by directly connected batteries. In these cases, the current limitation occurs due to the internal resistance of the battery. Its power is so low that it is simply not enough to burn the lighting elements.

However, if connected incorrectly, these light sources burn out very quickly. A rapid drop in the brightness of the glow is observed when normal current begins to act on them. The LED continues to glow, but it can no longer fully perform its functions. Such situations occur when there is no limiting resistor. When power is applied, the lamp fails in just a few minutes.

One of the options for incorrect connection to a 12-volt network is to increase the number of LEDs in the circuits of more powerful and complex devices. In this case, they are connected in series, based on the battery resistance. However, if one or more light bulbs burn out, the entire device fails.

There are several ways to connect 12 volt LEDs, the circuit of which allows you to avoid breakdowns. You can connect one resistor, although this does not guarantee stable operation of the device. This is due to significant differences in semiconductor devices, despite the fact that they may be from the same batch. They have their own technical characteristics, differing in current and voltage. If the current exceeds the rated value, one of the LEDs may burn out, after which the remaining light bulbs will also fail very quickly.

In another case, it is proposed to connect each LED with a separate resistor. It turns out to be a kind of zener diode that ensures correct operation, since the currents become independent. However, this scheme turns out to be too cumbersome and overly loaded with additional elements. In most cases, there is nothing left to do but connect the LEDs to 12 volts there in series. With this connection, the circuit becomes as compact as possible and very efficient. For its stable operation, care should be taken to increase the supply voltage in advance.

DIN › Blog › 左 LEDs in cars…

The on-board network of a passenger car is 12-14.5 Volts. Depending on whether the engine is turned off or on.

Typical LED characteristics: (drop voltage 3.2 Volts and current 20mA = 0.02 Ampere)

“Voltage drop” and “operating current” are the main characteristics of an LED. The LED is powered by current - this is IMPORTANT! It will take as much voltage as it needs, but the current needs to be limited. The voltage drop of a typical white LED is 3.2 Volts. But for LEDs of different colors it is different for yellow and red LEDs - 2 - 2.5 Volts.; for blue, green, white - 3-3.8 Volts. So when choosing an LED color, consider its voltage drop. The current of low-power LEDs is usually no more than 20mA

What is voltage drop? If we connect our white LED with a voltage drop of 3.2 Volts and an operating current of 20 mA = 0.02 Ampere to a 12 Volt source, then this LED will consume 3.2 Volts. The voltage after this LED will decrease (fall) by 3.2 Volts. 12-3.2=8.8. But don’t forget that the LED is powered by current and not voltage, i.e. how much current you give - so much it will pass through itself, and the current must be set. How to understand asking?! To set means to limit. You can limit the current with a resistor, or power the LED through a driver. Let's look at examples of how to calculate and connect an LED to a source of an imaginary vehicle on-board network, the voltage of which ranges from 12 to 14.5 Volts. So that our LED does not burn out when turned on for a long time, we will calculate based on the fact that in our car there are 14.5 Volts and not 12.5 Volts. In this case, the LED will shine less brightly, but will last longer. In one of the points of this article we will look at how to connect an LED or chains of LEDs through a voltage stabilizer chip. This connection method will maintain the brightness of the LEDs when the engine speed changes.

Smooth turning on and off of LEDs

There are cases when it is necessary to ensure smooth switching on of LEDs used for lighting or backlighting, and in some cases, switching off. Smooth ignition may be required for various reasons.

Firstly, when turned on instantly, the light “hits the eyes” hard and makes us squint and squint, waiting for our eyes to get used to the new level of brightness. This effect is associated with the inertia of the eye's accommodation process and, of course, occurs not only when LEDs are turned on, but also any other light sources.

It’s just that in the case of LEDs it is aggravated by the fact that the emitting surface is very small. In scientific terms, the light source has a very high overall brightness.

Secondly, purely aesthetic goals may be pursued: you must agree that a light that smoothly lights up or goes out is beautiful. The LED power supply circuit must be improved properly. Let's look at two different ways to smoothly turn on and off LEDs.

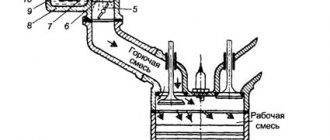

RC delay

The first thing that should come to mind for a person familiar with electrical engineering is introducing a delay by including an RC circuit in the LED power supply circuit: a resistor and a capacitor. The diagram is shown in Fig. 1. When voltage is applied to the input, the voltage on the capacitor, as it charges, will increase over a time approximately equal to 5τ, where τ=RC is the time constant.

That is, in simple terms, the time the light is turned on will be determined by the product of the capacitance of the capacitor and the resistance of the resistor. Accordingly, the greater the capacitance and resistance, the longer it will take for the LEDs to ignite. When the power is turned off, the capacitor will discharge to the LEDs.

The time during which smooth decay will occur will also be determined by τ, but in this case, instead of R, the dynamic resistance of the LEDs will be included in the product. For example, a 2200 uF capacitor and a 1 kOhm resistor will theoretically “stretch” the turn-on time by 2.2 seconds.

The simplest diagram presented makes it possible to understand the operating principle of this method well, but it is of little use for practical implementation. To obtain a working solution, we will improve it by introducing several additional elements (Fig. 2).

The circuit works as follows: when the power is turned on, capacitor C1 is charged through resistor R2, transistor VT1, as the gate voltage changes, reduces the resistance of its channel, thereby increasing the current through the LED. Turning off the power will cause the capacitor to discharge through the LEDs and resistor R1.

Let's turn on our brains...

If the circuit needs to provide greater flexibility and functionality, for example, without changing the hardware, we want to get several operating modes and set the ignition and decay times more accurately, then it’s time to include a microcontroller and an integrated LED driver with a control input in the circuit.

The microcontroller is capable of accurately counting the required time intervals and issuing commands to the driver control input in the form of PWM. Switching operating modes can be provided in advance and a corresponding button can be displayed for this. We only need to formulate what we want to get and write the appropriate program.

An example is the LDD-H high-power LED driver, which is available with current ratings from 300 to 1000 mA and has a PWM input. The connection diagram for specific drivers is usually given in the technical specifications. manufacturer's description (data sheet).

Purpose of elements and principle of operation of the circuit

Many readers have LED light switches installed in their homes. The LED backlight circuit looks like this:

- A chain consisting of a quenching resistor, an LED and a simple silicon diode is switched on parallel to the switch contact.

- When the switch is open, electric current flows through a quenching (current-limiting) resistor, back-to-back LEDs and an incandescent lamp.

- During one of the half-waves, when a positive voltage is applied to the anode of the LED, the light-emitting diode glows. This not only provides illumination of the switch, but also provides LED voltage indication.

If we remove the switch, light bulb and wires from the circuit, we are left with a chain consisting of a resistor and two diodes. This chain is the simplest indicator (pointer) of 220 V alternating current.

Let us dwell in more detail on the purpose of the circuit elements. We indicated above that the operating current of the signal LED is about 10-15 mA. It is clear that when a light-emitting diode is directly connected to a 220 V network, a current will flow through it many times greater than the maximum permissible value. In order to limit the current of the LED, a quenching resistor is connected in series with it. You can calculate the resistor value using the formula:

R = (U max – U led) / I led

In it:

- U max – maximum measured voltage;

- U led – voltage drop across the LED;

- I led – operating current of the light-emitting diode.

Having performed the simplest calculation, for a 240 V network we get the value of resistor R1 equal to 15-18 kOhm. For a 380 V network, you need to use a resistor with a resistance of 27 kOhm.

The silicon diode performs the function of overvoltage protection. If it is missing, with a negative half-wave U, the locked LED will drop 220 V or 380 V. Most light-emitting diodes are not designed for such reverse voltage. Because of this, breakdown of the pn junction of the LED may occur. When a silicon diode is connected back-to-back, during the negative half-wave it will be open and U on the LED will not exceed 0.7 V. The LED will be reliably protected from high reverse voltage.

Based on the considered circuit, you can make a voltage indicator of 220/380 V. It is enough to supplement the radio elements with two probes and place them in a suitable housing. To make the indicator body, a large marker or thick felt-tip pen is suitable. You can place radio components on a homemade printed circuit board or make connections using a hinged method.

A hole is made in the marker into which an LED is inserted. A metal probe is attached to one end of the body. A wire is passed through the second end of the housing, going to the second probe or an insulated alligator clip.

Despite the simplicity of the design, the device will allow you to check the presence of voltage at the output of a circuit breaker or in a socket, and find a blown fuse in the distribution board. Note that the above indicator diagram is also used in industrial products.

Connecting an LED to a 220V network, diagram

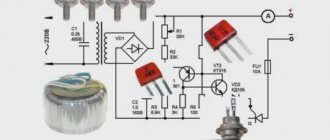

To connect to a 220 volt network, a driver is used, which is a source of stabilized current.

The driver circuit for LEDs comes in two types:

- simple on a quenching capacitor;

- full-fledged using stabilizer chips;

Assembling a driver on a capacitor is very simple; it requires a minimum of parts and time. The 220V voltage is reduced by a high-voltage capacitor, which is then rectified and slightly stabilized. It is used in cheap LED lamps. The main disadvantage is the high level of light pulsations, which is bad for health. But this is individual, some people don’t notice it at all. It is also difficult to calculate the circuit due to the variation in the characteristics of the electronic components.

A complete circuit using custom ICs ensures better stability in the driver output. If the driver copes well with the load, then the ripple factor will not be higher than 10%, and ideally 0%. In order not to make a driver yourself, you can take it from a faulty light bulb or lamp, if the problem was not with the power supply.

If you have a more or less suitable stabilizer, but the current strength is less or more, then it can be adjusted with a minimum of effort. Find the technical specifications for the chip from the driver. Most often, the number of Amperes at the output is set by a resistor or several resistors located next to the microcircuit. By adding resistance to them or removing one of them, you can obtain the required current strength. The only thing is not to exceed the specified power.

Working with a 220 V network

The simplest mains voltage indicator without a power source is made from a resistor, a current limiter (transistor), a rectifier (diode) and any LED. Resistor resistance is 100 - 150 kOhm.

Diode characteristics:

- current 10-100 mA;

- voltage 1-1.1 V;

- reverse voltage 30-75 V.

At 220 V, 3 Hz, the LED lights up. You can adjust the frequency and increase the brightness by changing the capacitance of the capacitor. Such an indicator operates at a minimum voltage of 4.5 V. In addition to the mains current, it can determine the serviceability, on and off state of an electrical appliance.

DC Voltage Check

To check the 12-volt network and the integrity of the connections, you can make another LED indicator (you need 2 multi-colored LED elements). To limit the current, you can use a resistor with a resistance of 50-100 Ohms or an incandescent light bulb with low power. One of the LEDs lights up when a voltage of the appropriate polarity is connected.

This device is suitable for working with alternating and constant voltage networks of 5-600 V.

Indicator for microcircuits - logic probe

Devices for indicating microcircuits are called logic probes. This indicator is three-level (3 LEDs are included in the circuit).

A logic probe allows you to:

- determine phase, short circuit, resistance of the electrical network;

- establish the presence of voltage 12 - 400 V;

- determine the poles for direct current;

- check the condition of diodes, transistors and other parts;

- determine the integrity of the electrical network by ringing;

- diagnose relay and coil breaks;

- ring chokes and motors;

- determine the terminals of transformers.

The power source is a 9 V battery. When the pins are closed, a current of 110 mA is consumed. After opening, no current is consumed; there is no need to install a switch or mode switch.

When checking a network with a resistance of 0 - 150 Ohms, 2 LEDs light up, and when the indicator increases, one LED lights up. At 220-380 volts the third one lights up, the rest flicker. If the circuit is broken, the LEDs will not light up. At zero on the contact 0.5 V, one transistor opens (KT315B), at 2.4 V - the second (KT203B).

It is possible to replace transistors with others having similar parameters.

Voltage indicator on two-color LED

Another simple indicator chip - with a two-color LED. Some home craftsmen use it to determine the operating mode of the lamp. For example, a basement light switch equipped with an indicator is mounted on a staircase. If it is on, the glow is red, after turning it off it is green.

Option for car

The circuit for indicating the battery charge and vehicle network voltage consists of:

- RGB LED;

- 3 zener diodes;

- 3 bipolar transistors (BC847C);

- 9 resistors;

The level is determined by color. Green glow at 12-14 V, blue at 11.5 V, red at 14.4 V).

If no errors were made when assembling the circuit, one of the resistors (2.2 kOhm) and the transistor (8.2 V) determine the minimum voltage limit. When the indicator decreases, the transistor corresponding to the blue glow connects the crystal.

If the voltage does not decrease or increase, the current passes through 2 resistors, a 5.6 V zener diode and an LED, a green glow appears (the transistors corresponding to red and blue turn off). When the voltage increases to 14.4 V, the red light comes on.

How many diodes can be connected to a 12 V network?

The question arises of how many LEDs can be included in such a circuit so that the power is not wasted on heat. A lot actually. A certain number of diodes are used to create serial chains that are connected to one voltage-damping element.

To calculate the resistance, the formula is used: R=(Upit. – nUd)/Id, where n is the number of lamps.

To connect to a car battery, it is advisable to use chains of 3 elements (or a multiple of three: 6, 9, 12). On three diodes, the voltage will drop by 10.5 V (on average), the resistor will receive 1.5 V.

To connect 4 elements, they need to be grouped in pairs, each of them powered through a resistor and connected in parallel.

How many LEDs can be connected to 12V?

Obviously, according to the simplest scheme, you can connect as many as you like to a 12 Volt source. The main thing is that the connected power source has enough power. However, we have seen that with such a connection scheme a lot of energy is wasted.

The simplest way out of this situation is to reduce the power dissipated by the current-limiting resistor. To reduce wasted power, several LEDs are connected in series and fed through a single quenching resistor. In this case, the voltage drop across the resistance is significantly less. Consequently, energy losses are significantly reduced. Calculation of resistance for series connection of light-emitting diodes is performed using the formula:

Where n is the number of LEDs connected in series.

In the case of a 12 Volt source, it is reasonable to connect three LEDs and one quenching resistor in series. The voltage drop across the LEDs will not exceed 10.5 Volts and only 1.5 Volts will remain for the resistor.

This technical solution is widely used when the number of LEDs connected to 12 Volts is a multiple of three. That is, you can connect 6, 9, 12, ..., 3N LEDs this way. For example, this is what manufacturers of LED strips do. In them, the LEDs are grouped in groups of three and are powered through one common resistance.

If you need to connect 4 LEDs to 12 Volts, then it is advisable to group them by 2, and feed each pair through a current-limiting resistor.

LEDs with the same operating current should be connected in series. Otherwise, different devices will shine with different brightness or the current of any LED will be exceeded, and it will fail.

As for connecting LEDs “rated for 12 V,” it is better to establish their “operating voltage” experimentally. To do this, they must be connected to a laboratory power supply and, gradually increasing the voltage, control the current consumption. The voltage at which the operating current will be reached can be used to calculate the current limiting resistor.