With the advent of injection engines, a significant number of sensors were added aimed at improving power and environmental characteristics. In the article we will touch on a little-known rough road sensor and talk about the absorber - what it is and why they are needed.

What is DND?

The rough road sensor is a small device that temporarily disables the engine diagnostic system so that the Check Engine is not constantly displayed on the instrument panel during a misfire. The sensor has a protective function. On engines with Euro-3 and higher environmental standards, in the event of a misfire, the on-board system must react immediately, since this significantly exceeds gas emission standards. On average, up to 4 misfires occur per 100 operating cycles, so the modern automotive industry has long been concerned about the implementation of sensitive on-board diagnostics.

In general, a rough road sensor is necessary to recognize and record strong body vibrations that directly affect engine performance.

Masses: Gazelle and UAZ (Part III)

I. N. Skrydlov, aka Aktuator

of the Masses. Part IMass. Part II

Attention! The article contains a large amount of graphic material. UAZ Patriot with Mikas 11 E2. UAZ Patriot with Mikas 11 E2

UAZ Patriot with Mikas 11 E2

The negative battery is screwed to the body on the left mudguard, between the battery and the left headlight, onto a welded pin:

Copper braided engine grounding harness, screwed to the body onto a welded pin at the bottom of the left mudguard:

The harness is attached to the engine under the left engine mount, by one of the oil sump mounting bolts (bottom view):

The ECM ground is taken from the front bolt that holds the intake manifold halves together, next to the throttle pipe.

The ECM controller itself is mounted under the hood, in the rear of the right mudguard. The OBDII standard diagnostic block is located next to the controller.

Gazelle with engine 405, 406

The negative battery is screwed to the cabin mass, onto a welded pin on the platform, above the right side member, under the overhang of the engine shield. A braided grounding harness for the internal combustion engine is screwed onto the same stud. In some versions, there is a ground switch between the welded pin and the battery negative.

The second end of the braided engine grounding harness is screwed to the rear stud of the intake manifold halves, together with the ECM grounding:

The jumper grounding the frame is attached at one end to the cab under the left headlight, with an M6 bolt (together with the masses of the left part of the engine compartment harness),

and the second end to the frame, vertically from the first, on the left side of the frame with an M8 bolt.

The bolt goes through a hole in the frame, so to securely tighten the bolt connection, you must hold the head of the bolt from inside the frame, in front, through the tow hole. In practice, turnkey bolts of 10, 11 and 12 mm were encountered. The nut is always 13mm wide.

Gazelle with engine 4216

The minus of the battery is similar to the version with internal combustion engines 405 and 406. But the fastening of the braided grounding harness of the internal combustion engine is somewhat different. On the 4216 engine, the internal combustion engine grounding is attached to the head cover mounting stud on the rear of the engine. To avoid burns, it is advisable to tighten this fastening on a cold engine. 13mm key.

Frame grounding is similar to engines 405, 406:

The weight of the ECM (before 2010) is taken from the mounting pin of the internal combustion engine transportation eye, in its left front part. Wrench nut 15mm.

The photo also shows an additional braided harness from the frame to the indicated eye, but in my opinion, it would be more correct to secure it by analogy with the 405 engine.

Since 2010, the mass of the ECM is taken directly from the negative terminal of the battery:

Since in Gazelles the negatives on the EBN and rear lights are taken from the frame, unreliable grounding of the frame can cause the fuel pressure to depend on the number of external lighting lamps turned on (dimensions, stops, reverse, etc.).

And further:

Since 2010, a new type of fuse block began to be used on Gazelles:

And on the ICE 4216 there is also a new type of ignition coil, externally reminiscent of the VAZ ignition module for the ECM January 5.1.

The rough road sensor on vehicles with internal combustion engine 4216 is located in the front right part of the frame.

If the harness going to the DPM is not secured with ties to the generator belt tension bracket and the cooling pipe, it can be damaged by moving engine parts and ultimately cause a failure of the DPM signal processing channel in the ECM.

Let me give you an example of a mechanic's carelessness when replacing a generator.

The DND harness got caught between the tension bar and the generator pulley, which caused its damage and failure of the DND, MAP_a and TPS. In this case, the controller survived.

Volga, ICE Chrysler, ECM Motorola.

Jumper Minus battery - body and ground of the front engine compartment harness, mounted on a stamped protrusion, below and to the right of the left headlight

A thick grounding wire for the internal combustion engine is attached with an M8 bolt, key 13, to the left side of the engine block, under the intake manifold.

The controller masses are attached two to three centimeters above, with a bolt securing the oil dipstick mounting bracket. Bolt M8, key 13.

Volga, ICE Chrysler, ECM Mikas 11CR.

The difference from the Motorola ECM is the presence of an external generator regulator relay. The relay regulator is attached to the right mudguard.

The diagnostic connector of the OBDII standard on such Volgas is located at the bottom of the dashboard, near the driver’s left knee.

What is an adsorber?

After the introduction of EURO-1 toxicity standards, the need arose for maximum control of exhaust gas emissions into the atmosphere, as well as control of gasoline evaporation. The adsorption system does not allow gasoline vapors to enter the atmosphere, thereby relieving the driver and passengers of the smell of gasoline, thereby increasing environmental friendliness and fire safety standards.

The adsorber itself contains activated carbon, which absorbs all harmful substances when the engine is not running. The system is called EVAP and works as follows:

- at the end of engine operation, vapors appear in the fuel tank, which rise to the fuel filler neck and tend outward, creating dangerous excess pressure in the tank;

- near the neck there is a separator that separates liquid from steam, which flows through special tubes back into the tank in the form of fuel condensate;

- the remainder of the vapor that the separator could not cope with enters the adsorber, and after starting the engine, gasoline vapor enters the intake manifold through the ventilation valve, and then into the engine cylinders.

How does the misfire check mechanism work?

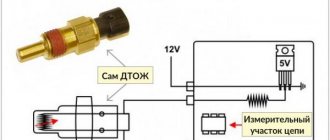

Any injection engine is equipped with a self-diagnosis system for misfires. A crankshaft position sensor is installed near the crankshaft pulley, which is an electromagnetic element that reads the speed and stability of rotation of the pulley and sends impulses to the engine control unit.

If the sensor detects unstable rotation, misfires are immediately checked, after which “Engine Error” may appear on the instrument panel, and when a diagnostic scanner is connected, a history of misfires will appear in the report.

Electronic engine control unit

The unit is installed in the engine compartment and secured with special brackets. AC power supply. The main function of the ECU is diagnostic, monitoring the operation of the power unit, identifying faults, and notifying on the central dashboard. To avoid negative consequences, the ECU transfers faulty units to emergency operation mode.

When you start the Chevrolet Lacetti engine, a number of indicators on the center console light up, after two seconds they go out, which indicates that all vehicle systems are working properly. If any of the indicators does not go out, it is obvious that the mechanism is faulty; prevention and diagnostics are required. After switching to emergency operation mode, engine power decreases, fuel consumption increases, the accelerator pedal becomes uninformative with periodic dips when pressed. Emergency exit is possible using software or automatically after the third trouble-free trip.

All system errors, even those that have already been eliminated, are recorded in the memory of the control unit. If necessary, they are read by a diagnostic scanner connected to a block under the steering wheel, to the right of the hood release lever.

How does the rough road sensor work?

The sensor, depending on the design features of the vehicle, is usually installed on the front side member; it can also be located on the frame or suspension element. Its operation is based on the principle of a piezoelectric element - electrical impulses are generated during deformation. By the way, the operating principle is similar to the knock sensor.

If the deformation of the piezoelectric element exceeds the permissible level, then the sensor output signals movement on an uneven road surface.

Anti-lock braking system

ABS (ABS) - the sensor is installed on each of two brake circuits: front left (right), as well as rear. In addition to the mechanical part, a block with electrical power is connected to the sensor. If the sensor malfunctions, it displays an alarm notification.

The price of each sensor is specified at the time of purchase. Often other parts and assemblies necessary for repairs are purchased

Always check the catalog numbers with the factory ones, pay attention to the cost. Original products are never cheap. In the maximum configurations of the Chevrolet Lacetti or on an individual order, the following installations are carried out: parking sensors, shock sensor, rain sensor on the windshield

As well as other options that are not included in the basic models

In the maximum configurations of the Chevrolet Lacetti or on an individual order, the following installations are carried out: parking sensors, a shock sensor, and a rain sensor on the windshield. As well as other options that are not included with the basic models.

Why do you need a rough road sensor?

When driving on an uneven road, a situation may arise in which the wheel briefly lifts off the surface, which immediately leads to a change in the rotation of the crankshaft. Thanks to the high-precision crankshaft rotation sensor, the slightest deviation is immediately recorded as a misfire error.

Thanks to the presence of DND, constant error monitoring is temporarily suspended, and on more modern cars the ignition is shifted towards retardation, for the highest quality ignition of the mixture.

Malfunction and solutions

The reasons for the occurrence of tripping and blinking “Check” are almost identical for all power units. The root cause may be improper formation of the air-fuel mixture or a breakdown in the ignition system. But, everything is in order.

Low-quality gasoline, or in common parlance - “bad gas”, leads to the fuel supply elements becoming clogged, and the injection system itself forms a lean mixture. To diagnose and troubleshoot the problem, it is necessary to test the injectors. It is better to carry out this entire operation on a special stand. If it turns out that the elements are clogged, then we can say that the vehicle was operated on low-quality fuel.

Another reason could be a clogged fuel filter, which is recommended to be changed every 20,000 km. Also, it is worth examining the performance of the fuel pump, which may fail.

Ignition system

Breakdowns in the ignition system, namely malfunction of spark plugs, high-voltage wires and ignition coils, can lead to a tripping effect. So, you need to unscrew the spark plugs and inspect them for defects. Also, using a simple tester, measure the resistance of the high-voltage wires, which is 5 ohms.

Air supply

The formation of the air-fuel mixture is influenced by the state of the air supply. A clogged air filter element or throttle valve can cause a rich mixture, which can cause a tripping effect. To eliminate the malfunction, it is necessary to dismantle and inspect the elements.

If the air filter is clogged, it is recommended to replace it, but the throttle valve must be cleaned with a special product or liquid for cleaning carburetors.

https://www.youtube.com/watch?v=ytdevru

Repeatedly, the cause of the tripping and blinking “Check” is a malfunction of one of the sensors or accumulated errors inside the electronic engine control unit. So, it is necessary to diagnose the condition of the elements and replace damaged ones.

When and why did rough road sensors appear on cars?

As soon as automakers began to seriously think about the environment, Euro standards were introduced. In 1995, the Euro-2 standard was adopted, obliging vehicles to be equipped with a catalyst and, accordingly, sensors for detecting oxygen in exhaust gases. At this point, all cars were equipped with rough road sensors.

The logic for introducing DND is simple: unburned fuel quickly damages the ceramic catalytic converter. Accordingly, fixing misfires allows you to stop the fuel supply in the cylinder where the mixture has not ignited, which allows you to protect the catalyst from harmful effects.

If misfires are detected randomly in different cylinders, the Check Engine will notify you about this - it makes sense to carry out computer diagnostics of the engine.

If the misfire is related to the rough road sensor, the warning light will not light up.

Diagnostics

Checking the operation of the sensor can be carried out in 2 stages. To begin with, a regular system scan is performed using conventional equipment (car scanner or laptop with the program installed). On AvtoVAZ cars, the following errors can be seen when the sensor malfunctions:

- P1616

– low pulse value; - P1606

– the pulse has left the limited interval; - P1617

– increased pulse value.

In principle, this is already enough to determine the cause of the “check” that lights up. But in order to fully understand the cause, it is necessary to conduct a more in-depth diagnosis. To check, you will need the DST-2M

. You can use others that are similar in operating principle. Essentially, this is a scanner with advanced functions. It can also evaluate the response of the rough road sensor.

If this sensor is subjected to influence, for example, by knocking on it, it will react, and the scanner will display the acceleration value -g. It should be noted that the sensor is quite sensitive, so it should respond even to slight rocking of the car.

Installing a new sensor is not a difficult job. To carry it out you will need a minimum of tools, as well as a little time:

- The battery turns off;

- The spring clamp of the sensor is compressed;

- Remove the wire block from the sensor terminals;

- A pair of mounting screws is unscrewed;

- The sensor is removed and a new one is installed in the reverse order.

Thus, work to replace the sensor is carried out on Lada Kalina and Lada Priora. On machines of other brands and models, this work may be performed differently.

Manufacturers

. If you have a foreign car, then it is better to purchase an original sensor from official suppliers. Even the most expensive models will cost relatively little. You shouldn’t save money and buy a Chinese “pig in a poke”; no one will guarantee the service life of the part.

Several of our companies produce DND for domestic production. The most famous are Kaluga sensors and those produced in Zelenograd. Connoisseurs of German quality can purchase a device manufactured by BOSCH.