Low beam does not work when the engine is running

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Look: 1 - terminal under the ignition switch. I had a bad contact there and as a result the terminals burned and the casing melted. 2 - All connections to the mounting block, especially loaded (thick wires are mostly pink). I had a very similar situation. While there are few consumers, everything is fine, but no matter how many things you turn on, the terminal overheats and the voltage drops, though not everywhere, but in some circuits.

1. Disconnected and connected the connector under the lock - if we are talking about it. Did not help. 2. I see. When the light went out, I touched the battery terminals - they were absolutely normal, no overheating. There was no smell of anything burnt either. There are no bells and whistles (additional consumers), everything is standard. What happens during these five minutes while it stands is unclear. When everything works, there are no signs of a wiring fault - everything flashes, lights up, lights up, lights up, etc.

And the tension disappears everywhere for me

if the car is absolutely dead from an electrical point of view, it can only be something with two wires coming from the battery - minus to ground and plus.

Well, there would be a lack of contact in the block, “why turned green”, etc. (see above) - this should also appear when the engine is running, the wiring is still there

Even if something is wrong, at least something should be on, well, brake lights, a beep on the steering wheel - or I’m wrong.

Source

Problem with fuses, switches and relays

If you notice that your high beam has completely disappeared, then the problem is unlikely to be incandescent lamps. Such simultaneous failure of both lamps is practically impossible and can only occur if the voltage relay regulator on the generator breaks down, but in this case the problem would affect not only the headlights, but also all automotive electrical equipment.

First of all, we advise you to start your search with fuses - look in the instruction manual for information on fuses, namely the exact location of the fuses responsible for the operation of the high-beam lamps. Take them out and check their condition, they may have burned out. The next step is to check the condition of the steering column switch. Note that this problem is quite common in VAZ cars. If the switch and fuses are good, all you have to do is check the status of the high beam relay. You will need a multimeter for this test.

Is it dangerous to drive with low fuel in the tank?

Many people do not know, but in addition to the risk of being left without fuel if the warning about low fuel level is ignored, there are a number of problems that any car owner who often drives on an empty tank may encounter.

For example, frequent trips on an empty tank can prematurely damage the catalyst in the exhaust system, which will have to be repaired or purchased a new one, which is associated with huge financial expenses.

Frequent trips with low fuel levels in the tank can damage the fuel pump. The fact is that the fuel that we fill at gas stations is actually not clean (especially in Russia) and it contains various fractions of pollution that settle at the bottom of the tank. When the fuel level is low, we risk that such sediment may enter the fuel system through the fuel pump. Especially when the fuel is completely running out. It is at this moment that sediment particles from the tank can enter the fuel pump. At a normal fuel level, such a risk of contamination of the fuel system is minimal.

So if you do not want to damage your car, then refuel your car regularly and on time, without bringing the fuel level to low levels that lead to the appearance of a burning lamp on the dashboard.

Fuses, switches and relays

If your high beam has completely disappeared, then it is unlikely that the problem is incandescent lamps - the simultaneous failure of two lamps is only possible if the generator voltage relay-regulator is faulty, which will most likely affect not only the headlights.

First, check the fuses - find the fuses corresponding to the high beam lamps in the owner's manual, remove them and make sure that they have not blown.

The next step will be to check the functionality of the steering column switch - this malfunction occurs quite often on rear-wheel drive VAZ cars.

After making sure that the relays and switches are working properly, check the functionality of the high beam relay - use a multimeter to do this. If you do not know how to use a multimeter, we recommend that you read the descriptions, photos and videos on the Internet.

Thanks for subscribing!

Snail installation

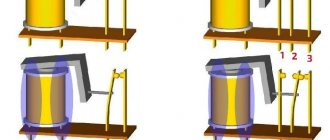

When reassembling, the front wheels must be aligned and the rotating contact plate must be locked in the middle position by the safety lock. For this:

- we determine the maximum number of revolutions of the contact disk (No. 2) by rotating it from the extreme left to the extreme right position (without using force);

- turn the contact disk to the middle position, counting half the maximum number of revolutions from the extreme position;

- align the holes (No. 4) for the fuse on the disk and the hole (No. 5) in the body of the rotating device and install the fuse (No. 6).

The screw tightening torque is 1.6…2.4 N.m (0.16…0.24 kgf.m).

Let us remind you that the website contains other instructions for servicing and repairing Vesta or XRAY with your own hands. The necessary information can be easily found using the search (in the upper right corner of the site) or by content (Vesta, XRAY).

Keywords: Lada Vesta steering wheel | Lada Xray steering wheel | turn signals Lada Vesta | turn signals lada xray | fog lights Lada Vesta | fog lights lada xray | headlights of Lada Vesta | headlights lada xray | tail lights of Lada Vesta | rear lights lada xray | windshield wipers for Lada Vesta | windshield wipers lada xray

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

The left high beam headlight on the VAZ 2106 does not light, both on the low beam are on, what is the reason?

circuit breakers. may have oxidized. rotate the fuses in their sockets.

A intact fuse differs from a blown fuse by the presence of a jumper between the contacts (inside the fuse)

Is the high beam indicator light on the dash lit? So it's not a fuse. Look at the lamp and the wiring to it.

Well, it’s easy to sniff a two-ruble coin instead... But the burnt-out light bulb doesn’t ring, it’s black and you can see a break inside….

look at the wires, I had this happen, the wires melted next to the fuses

A light bulb with wiring will help you.

another car will help you

I have a VAZ 2106 and this is the reason why neither high beam is on, but both low beams are on, what could be the reason!!! help me please

Car headlights - a guarantee of your safety

Safety behind the wheel plays an important role for every motorist.

In this regard, drivers should remember some factors that ensure their safety. However, the most important thing is that, while driving, you need to clearly see the road along which the car is moving. This is why driving lights are so important. They provide the driver with good visibility in cloudy weather or at night.

Today, the auto parts market offers several types of headlights.

All of them can be divided into several categories.

- Of course, something needs to be said about the fog lights. As the name suggests, fog lights are designed to provide additional illumination of the road during thick fog. Most cars come with a set of fog lights from the factory. Typically, this type of headlight is installed on the front bumper. However, to increase the illumination area, you can purchase an additional set of headlights yourself. Some car brands provide wide lighting angles initially.

- When traveling on unfamiliar roads, the driver must have good visibility in front of him. For this you need a powerful high beam. Here, car spotlights produced by some companies come to the driver's aid. But it is necessary to keep in mind that such headlights are not intended for city roads, since their light can blind other drivers. But for country roads this type of lighting will come in handy.

- On the one hand, we can talk about the uniqueness of high beam headlights. They are typically placed lower than off-road headlights. However, their purpose is to improve road illumination in addition to low-beam headlights. For natural reasons, their light is directed forward, unlike fog lights. Before using high beam headlights, you need to remember that its brightness can blind drivers of cars in front. Therefore, it is better to turn it on when the track is empty.

- An auxiliary lighting system offers several benefits. First of all, it's a great way to stand out. Also, auxiliary lights will help others easily spot your vehicle at night. And finally, they help the driver to navigate well in the dark.

There are other types of headlights on a car. For example, xenon headlights or high intensity discharge lamps. The most important thing is to have a proper headlight leveling and cleaning system to get the most out of your vehicle.

Vote, did you like the article?

Handmade production of LED lights

Due to insufficient funds or the impossibility of finding the best option for tuned headlights, the motorist decides to make LED optics with his own hands. In fact, making your car truly unique is not that difficult. To build LED boards you need to purchase:

- LEDs designed for 3–5 V, the diameter of which is 10 mm;

- 500 mlA resistors (1 resistor provides 4 diodes);

- plastic or textolite blanks (the base must be created exclusively from dielectric materials). It is preferable to paint the structural element black.

In order for a tuned car to have an attractive appearance, it is extremely important to correctly assemble the LED boards. To do this, it is necessary to cut elements of the required size and shape from pre-prepared blanks.

The second step is to create small holes using a drill, in which the purchased LEDs will later be located.

It is best to install LEDs using superglue, placing the contacts of the lighting fixtures in the holes made and placing the “pluses” and “cons” on different sides. When creating unique headlights, you need to use a soldering iron to connect together the positive contacts of each three elements, connecting in addition to them one resistor. The same rule applies to negative contacts of lighting fixtures.

After the previously described manipulation is completed, it is necessary to solder an additional wire to the ends of all resistors present on the segment. Using the same principle, you should connect the “cons” of the LED contacts with a separate wire.

At the final stage of assembling a new lighting fixture, the light bulb should be broken, in the place of which the diode base will subsequently be located. Using a soldering iron, attach the wire coming from the resistors to the positive side of the base contact, and to the negative side - the wire with which the negative contacts are connected. At this point, the work on creating original LED boards can be completed; the car owner will only need to check their performance.

One of the high beam lamps has burned out

With such a malfunction, the high beam does not fail completely - as a rule, only one lamp turns off. Almost every car owner knows the solution to the problem in this case, but we will still remind you how to make a replacement:

- Unscrew the bolts securing the rim of the faulty headlight

- Turn the glass clockwise and pull the headlight out of the housing

- Disconnect wires from contacts

- Press the latch and carefully remove the light bulb

You can verify that the lamp is faulty by examining the filament (as is the case with ordinary household lamps). If the lamp is faulty, you need to purchase a new lamp and install it in place of the old one, without touching the glass with your hands. After that, reassemble everything in reverse order and make sure the high beam is working.

The “six” light acquires special importance when a motorist has to drive in conditions of poor visibility, in difficult weather conditions and at night. However, any driver must remember that defects in the vehicle’s electrical equipment system, one way or another, affect the functionality of the power plant. And this is despite the fact that the main electrical circuits are protected by relay elements, just as the lighting of the “six” is protected, the safety devices of which are routed to the vehicle’s fuse box.

On the VAZ 2106, the headlight relays, along with other main electrical equipment of this vehicle with high current consumption and high voltage, are connected via relay elements. The main purpose of the VAZ 2106 light relays, whose price is low, is to protect the switch contacts from energy overload.

Car enthusiasts often ask where the high and low beam relays are located on the “six” and what they look like. Let us explain that almost all relay devices, as well as the relay - voltage regulator, are located in the power plant compartment. The exception is the turn signal and hazard warning relays, which are located under the instrument cluster in the car interior, covered by a front panel. Both relays are identical in appearance (they can be easily found on the mudguard on the right as the car moves) and are located next to the battery charging indicator relay.

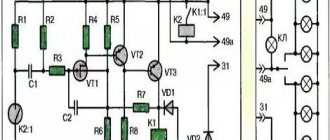

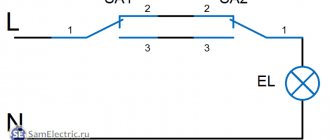

The electrical diagram of the light relay is located below:

On the general diagram of the electrical equipment of the “six” you can see at number 5 the VAZ 2106 low beam relay, and at number 6 the VAZ 2106 high beam relay, which are interchangeable elements. Also here you can see the integration of the main electronic devices of the vehicle into the general electrical supply circuit of the vehicle of this modification.

Relay for high and low beam "six"

As already mentioned, the standard high and low beam relays of the VAZ 2106 are absolutely identical, have similar catalog numbers (90.3747-10 or 113.3747-10), are of the same type as the initiation relay for the radiator fan device of the cooling complex of the power plant and can be replaced with each other friend.

To connect the light relay to the VAZ 2106, devices with item number 113.3747 are used, which are installed in a mounting-type block device. Similar devices are installed in the system to turn on the EDC fan device, heat the stern glass and produce alarm sounds.

The initiation voltage of the device at an average temperature of about 23 °C is within 8 V, and the resistance of the device winding at a temperature of 20 °C is 85 ± 8.5 Ohms.

Instead of products under catalog number 113.3747, it is allowed to use updated high and low beam relays VAZ 2106 90.3747-11 in a plastic case and with increased dimensions. It is also allowed to replace products 113.3747-10 with a mounting bracket with gadgets with fasteners under the nomenclature value 90.3747-10 with the same characteristics.

The automotive industry practices the production of light relays for the VAZ 2106 under the nomenclature numbers 902.3747 (version 11 - without fasteners and 10 - with fasteners), used on injection "sixes", because The device integrates an additional resistance to suppress interference, connected in parallel to the relay winding. For such high and low beam relays, the resistance between connectors “85” and “86” is 65 - 80 Ohms. They are interchangeable with the VAZ 2106 light relay

with the numbers 113.3747.

Replacing the "six" light relay

Russian car enthusiasts driving Zhiguli “classics” ask the question of how to connect a light relay to a VAZ 2106 so that it can function without problems in the future. Similar work is carried out when replacing the “six” light relay.

The work is carried out in the following sequence:

- We unscrew the fasteners and dismantle the headlight relay for subsequent replacement;

- We remember the frequency of connecting electrical wiring or mark them with a marker. Remove the wiring from the device connectors;

- We install the updated device in the reverse order.

A node such as a relay is a kind of switch that allows, using nodes with low current (buttons and switches), to turn on nodes with high current (starter, signal, headlights, etc.)

If this unit did not exist, the button could simply melt due to high load, so the importance of the relay is very great; today we will consider this element as an important part of the low beam system in a car

In modern cars, relays are most often present, but in older cars they were not always installed, so it makes sense to upgrade the system to remove the load from the steering column switch, which over time often fails precisely because of its absence in the circuit

In addition, you will notice an improvement in the quality of light, which is also important

In the photo: all relays look something like this, the size and position of the contacts may vary slightly

So, first of all, you need to purchase everything you need:

It is better to have a voltmeter on hand to find the power wire going to the car headlight. If you know its location, then this device will not be needed.

An excellent solution - a waterproof safety unit

If a relay for switching low and high beam headlights is already installed on the car, then you do not need to upgrade the system; if problems arise, you need to use the diagram to figure out where the required element is located to check its functionality.

Everything here is simple and clear, but if there are no relays, then we recommend installing them, as this will increase the reliability of the system and improve its operation.

Preparatory activities

When doing the work yourself, make sure that all the required elements are at hand, after which you can begin the process:

- To begin with, place the car so that you can work comfortably and nothing will disturb you. Of course, the ideal option is a garage, but if you don’t have one, then you can do everything you need right on the street;

- First of all, you need to open the hood, then turn on the low beam in the car and use a tester to find the power supply. The work is simple: you measure the voltage at each contact where it is - that’s where the power supply is supplied;

- Next, you need to turn off the ignition and remove the terminal from the battery to eliminate any troubles in the working process;

- Then you disconnect the connector from the low-beam headlight and try to get the power wire out of it, if it works - great, if not - cut the wire, strip it and crimp it with a terminal; it is best to close all open areas with a cambric;

The power wire is carefully removed from the connector

You also need to connect a long wire to the positive terminal of the battery, how to do this depends on the characteristics of your car, decide for yourself how to do this most reliably and efficiently. This wire is carefully routed from the battery to the headlight. It is best to lay it in a standard corrugation or attach it to the car’s wiring harness from the outside, the main thing is that it does not dangle haphazardly;

The wire should be laid along existing harnesses and secured with plastic clamps

Connection

The instructions for connecting the relay are quite simple and clear; first, read the diagram to understand the design.

Connecting low beam headlights via a relay is such a simple operation that even someone who knows nothing about car electrical equipment can handle it

- First of all, take a short-length wire to ground, the easiest way is to connect it to the ground on the lamp connection chip, this is the simplest and fastest option (most often it is a double brown wire);

- Now you need to connect all the wires to the relay, let's look at the work using the example of a relay from a VAZ: the wire from the steering column switch is connected to the 86th terminal, the line coming from the lamp connector is connected to the 87th, the ground is placed on the 85th, and the supply wire from the battery is located on terminal No. 30. All connections are made using chips - no twists or tape;

Electrical wiring

Electrical wiring is designed to supply electrical current to the consumer, in this case the high beam lamps. Problems with electrical wiring, partial lack of insulation, overheating of the wiring due to incorrectly installed fuses can cause a fire in the car, and you need to monitor the serviceability of the wiring as carefully as other mechanisms and devices of the car.

Important! A non-functioning high beam in conditions of insufficient visibility does not allow the driver to drive a car safely, and if problems arise with the high beam headlights on a VAZ car, knowledge of repair and diagnostics will help to quickly and effectively eliminate the problems that have arisen

Low beam doesn't come on

Why isn't the low beam on? If the low beam does not light up, then the following causes of the malfunction are possible:

- The low beam lamp does not light up. Our cars are equipped with double-filament halogen lamps, i.e. Both the low and high beam headlights are provided by one lamp, the different filaments of the lamp just light up. Replace the lamp with a known working one. To find out how to properly replace a lamp, see the article

- The fuse has blown. The low beam fuse has blown, check the fuse and replace it. You will find answers on how to find, check and replace the fuse in the article.

- The wires have oxidized. We look at the fuse block, namely the blocks of all tires to the fuse and relay block. They can become detached, poorly secured, or oxidize. Let's fix it. We also look at the wires connected to the lamp itself; the contact group of the headlight may have oxidized.

- Low beam power button. The fact is that the switch (button) for the low beam or side lights may have broken. The problem is typical: the wire has come loose or oxidized.

- The low beam fuse keeps blowing. This situation often occurs among owners of our brands. There may be 2 options:

- there is a short wire somewhere;

- again poor contact with the fuse.

If nothing helps you, then I advise you to call the wiring. If you are not comfortable with electricians, then it is better to turn to a professional.

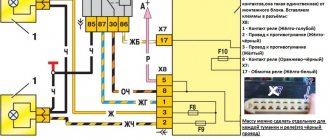

Engine fan diagram

- Electric motor activation sensor;

- Fan motor;

- Motor start relay;

- Main fuse box;

- Ignition switch;

- Additional fuse box;

- Generator;

- Accumulator battery.

Since 2000, a relay for turning on the cooling fan motor has not been installed, and the wires connected to the relay have been removed from the wiring harness. In addition, since 2000, the electric motor has been switched on by sensor type 661.3710. The temperature of closing the sensor contacts is (92±2.5) °C, and the opening temperature is (87±3) °C.

Low beam does not work: reasons

So, proper lighting of the road while the car is moving is a very important factor that ensures the safety of the driver, his passengers and other road users.

While driving a vehicle, the driver needs to clearly see the road along which the car is moving.

High/low beam headlights are very important because they provide good visibility both at night and in cloudy weather conditions. Today there are several types of car headlights, which can be divided into the following categories:

- Main headlights using halogen, xenon, high-intensity discharge lamps, diodes, etc.;

- Fog lights - the main purpose is additional illumination of the road while driving in thick fog (most often, the manufacturer already supplies cars with a set of fog lights);

- Spotlight headlights - powerful headlights provide the driver with good visibility, especially when driving on unfamiliar roads (headlights are not intended for city driving, as they can blind other drivers);

At the same time, for low and high beams, as well as for fog lights, halogen lamps are most often used, designated by the type of base as R2, H1, H3, H4, H7, HB3, HB4.

As for the problem itself, if the low beam does not work, the reasons may be different. It is important that the cause of the malfunction of the low beam or high beam headlights is accurately determined. Here are some of the main reasons why the low beams do not light up:

- low beam lamps have burned out;

- the fuse threads have melted (since basically the power circuits of the left and right headlights are not interconnected and are protected by separate fuses, a failed one of the fuse elements can lead to the failure of one headlight), the malfunction is diagnosed visually. In case of difficult access to the mounting block, check the operation of devices receiving power from circuits protected by the same fuses;

- faulty headlight relay (lighting systems stop working, there is either low or high beam). The malfunction can be detected by ear, by turning on the headlights and listening to the sounds that arise; if short, loud clicks are heard, the relay is working properly; if there are no clicks, the relay is faulty;

The connectors of the electrical wires going to the headlights are not connected correctly or are not connected at all (for example, they forgot to connect them after repairs). In this case, only one of the two headlights does not light up.

- water entering the engine compartment of the car (oxidation of the “chips” at the junctions of the wires, as a result of which the “chips” cease to perform a conductive function). Diagnose the malfunction by checking all the named wires and connections suitable for the headlights;

- voltage surge in the on-board network (both lamps burn out at the same time);

- other non-standard reasons (for example, a crack in the headlight through which water gets in and moisture condenses).

Please note that if a malfunction is not identified, additional diagnostics of the electrical wiring are carried out using the procedure of “testing” the electrical circuits of the car with a multimeter. By the way, to quickly determine the cause, you need to make sure that there is power at the terminals. Of course, the lack of current at the terminals supplying the low beam headlight bulbs will result in no low beam

Of course, the lack of current at the terminals supplying the low beam headlight bulbs will result in no low beam.

By the way, to quickly determine the cause, you need to make sure that there is power at the terminals. Of course, the lack of current at the terminals supplying the low beam headlight bulbs will result in no low beam.

To diagnose such a malfunction, you must do the following:

- insert a working lamp into the socket and “strike” the plus wire against the minus wire;

- a spark jumping between the wires or the lamp turning on indicates the presence of current in the network and, accordingly, indicates a malfunction in the headlights or lamps themselves;

- if there is no spark or the lamp does not light up, there is a break in the headlight power supply.

Please note that this method of checking is only suitable for simple cars where the ECM system is not complex. In turn, an attempt to short-circuit the plus and minus wires on many modern cars can lead to serious failures, errors in the ECU memory, etc.

Turn relay switching diagram

Turn signal diagram

How to connect fog lights via a relay?

642 Google+

Turn signals are very important in busy modern traffic, and malfunctions cause great inconvenience. The turn signal design on domestic and imported cars is almost the same. Depending on the year of manufacture of the car, electromagnetic-thermal or electronic relays are used as a breaker. The principle of connecting all relays is almost identical. Currently, some imported cars and VAZ 2170 Priora do not have a turn signal relay; its function is performed by an electronic control unit for power accessories. This article only discusses the classic turn signal design. Consider a turn signal circuit using a relay. In these circuits, the relay is connected in series with the signal lamps through the turn switch. An exception is the connection diagram of the turn relay type RS 950 and its analogues used on trucks. We will return to the connection diagram for this relay a little later. First, let's look at the connection diagram for direction indicators with an electromagnetic-thermal relay of type RS 59. As can be seen from the figure, the diagram is very simple.

When the ignition is turned on, power is supplied to the turn relay, and when the turn switch is moved in one direction or another, the relay is connected through the signal lamps to the minus. In this case, when the relay contacts close, the lamps light up, and when they open, they go out. The use of an alarm system with this relay is not possible due to its heating during operation and rapid failure due to the high power consumed by the lamps. In addition, this relay will not work with diode lamps, since the current consumption of these lamps is not sufficient to close the contacts. The operation of such a relay is described in detail in the article “VAZ-2101 Turning Relay.” The following connection diagram with an electronic relay, except for the RS 950 type relay and its analogues. Electronic relays, as a rule, have from 3 to 5 pins, and their connection diagram is fundamentally identical to that described above. Since electronic relays allow switching large currents, unlike electromagnetic-thermal relays, it becomes possible to activate an alarm through them. To implement this, the circuit additionally includes an alarm button. The methods for enabling it on different cars may differ, but not significantly. In turn signal mode, power to the relay is supplied through the hazard warning button contacts from the ignition switch, and in hazard warning mode directly from the battery. Also, in the emergency mode, the button connects the output of the relay signal lamps with its contacts to the signal lamps, bypassing the turn switch. Connecting an electronic relay from an electromagnetic-thermal one differs only in the presence of a terminal connected to the vehicle ground.

The RS 950 type turn relay is included in the turn signal circuit before the turn switch, in contrast to a simple electronic relay. This is due to the way the control lamps are connected. A relay consists of an electronic part that controls an electromagnetic relay. When turning on one of the sides of the car, current pulses from the electromagnetic relay are supplied to the turn switch, then through the turns relay terminals, electromagnetic relay coils or warning lamp reed switches, they are supplied to the warning lamps. Below is a schematic diagram of connecting the relay.

“If you notice an error in the text, please highlight this place with the mouse and press CTRL+ENTER”

admin 03/12/2013 “If the article was useful to you, share a link to it on social networks” avtolektron.ru

Turn relay circuit

- How does an electromagnetic-thermal relay work?

- Electronic relay: circuit and principle of operation

- Turn signal relay pinout

- DIY turn relay

All drivers are required to indicate maneuvers on the road by turning on the direction indicator. This flashing signal is found in every car. Its operating mode creates a turn relay, the circuit of which supplies current to the light bulbs and causes them to blink. At the same time, an audible signal sounds in the form of clicks, reminding you that the direction indicator is on. All these actions are provided by a special turn relay circuit.

Among various designs, electromagnetic-thermal and electronic relays are most widespread. The latest devices are considered more modern and are installed on all later car models.

Problem with fuses, switches and relays

If you notice that your high beam has completely disappeared, then the problem is unlikely to be incandescent lamps. Such simultaneous failure of both lamps is practically impossible and can only occur if the voltage relay regulator on the generator breaks down, but in this case the problem would affect not only the headlights, but also all automotive electrical equipment.

First of all, we advise you to start your search with fuses - look in the instruction manual for information on fuses, namely the exact location of the fuses responsible for the operation of the high-beam lamps. Take them out and check their condition, they may have burned out. The next step is to check the condition of the steering column switch. Note that this problem is quite common in VAZ cars. If the switch and fuses are good, all you have to do is check the status of the high beam relay. You will need a multimeter for this test.

Lighting repair

Replacing fuses

If after replacing the light bulb the low beam headlight on 2106 still does not light, you should check the fuses. They are located under the instrument panel.

In this case, you need to pay attention to two fuses:

- – protects the left headlight from short circuit;

- – protects the right headlight.

It must be said that the low beam on the VAZ 2106 often does not work due to the fuse contacts being bent or oxidized. In this case, they need to be bent and cleaned. If the protective element has melted, it must be replaced.

The contacts in the fuse box cannot be closed directly, since the protective element could burn out due to the failure of the electrical equipment; accordingly, this could lead to more serious damage or even a fire in the VAZ wiring.

Replacing a light bulb

First of all, it should be said that the low beam lamp on the VAZ 2106 complies with the H4 standard, i.e. It has two threads, which allows the headlight to operate in two modes. Currently, such light bulbs are produced by different companies, both well-known brands and little-known companies.

It should be noted that domestic light bulbs are very popular among car owners. Their price is significantly lower than their imported counterparts, but at the same time they are not inferior in quality.

It is advisable to change the bulbs in two headlights at the same time, since their service life is approximately the same. In addition, different lamp models may differ in glow.

Instructions for doing this work look like this:

- First of all, you need to use a flat-head screwdriver to dismantle the plastic panel that frames the headlights.

- Then use a Phillips screwdriver to loosen the clamps that hold the headlight.

- Next, you need to slightly turn the metal hoop and dismantle it.

- Now you can pull out the headlight with your own hands and disconnect it from the block. At this stage, you need to pay attention to the connector contacts. If necessary, they need to be cleaned.

- Then you need to unfasten the clamp and remove the light bulb.

- Next, the work is performed in the reverse order - a new lamp is installed, which is pressed with a clamp, and the block is connected to the contacts. The headlight assembly must be installed in place and secured with a hoop. To complete the work, a plastic panel is inserted, on which you need to press lightly until you hear a characteristic click.

READ Ford Focus 1 wipers do not work

When replacing a lamp, do not touch its glass bulb with your fingers, otherwise it may quickly burn out. If you do touch glass, you should wipe the surface with a cotton swab soaked in alcohol.

This completes the process of replacing the light bulb.

Burnt out filament in a lamp

If you notice that one headlight in your car has failed, then the problem may lie in the light bulb. The device of this element includes two filament coils, one of them is responsible for the operation of the low beam, and the second for the high beam. One of these threads can easily burn out, which is why the high or low beam will not work.

In this case, it is impossible to repair the failed spiral and the only way out is to replace the light bulb. You can do this yourself.

This is interesting: Choosing auto refrigerators for cars

Healthy! When replacing a lamp on a car, do not touch it with your bare hands, as if there is grease or dirt on the bulb, it may burn out immediately. It is also recommended to wipe the light bulb with alcohol before installation.

Types of fuses

How to correctly change the low beam light bulb on a Grant

Fuses Hyundai Accent

The choice of fuses must always be approached carefully. This video will help you find out a lot of interesting things about fuses. If you select fuses incorrectly, this can lead to serious problems that can even lead to a car fire

Additionally, the majority of motorists will agree that a lot of time is wasted on the selection of expensive parts that our client needs to do, and special attention is rarely paid to fuses. First, you need to be able to identify the fuse. So, they have a certain current strength, expressed in Amperes

In the photo below we see fuses of various ratings:

So, they have a certain current strength, expressed in Amperes. In the photo below we see fuses of various ratings:

The headlights don't light up - what's the reason?

- Lamp. Car headlights are equipped with special lamps, inside of which there are two spirals, one providing high beam, the other low beam. When turned on, a certain filament glows. It is impossible to correct this breakdown; you will have to replace the lamp completely.

- Dimensions button. This problem most often occurs in economy class cars. It is necessary to carefully check the element; if the wire has come loose or the contact has oxidized, the fault can be easily fixed on your own. If the button mechanism itself is broken, you should replace it with a new device.

- Contacts. It is necessary to check all contacts (relay, lamp, fuse box and steering column switch). They may become separated or oxidize. The solution is simple, clean and securely fasten. You can also check the wiring for breaks, insulation defects, and so on.

- Circuit breakers. This is one of the most common reasons why the low beam headlight does not light up. It is necessary to carefully check all fuses; if you find a blown one, replace it with a new analogue.

- No lamp contact. This problem most often occurs in foreign-made cars. To eliminate it, you need to check the reliability of the minus contact from the lamp to ground.

After this, draw three vertical lines: the axis of the car and two in the center of the headlights. If the optics are represented by separate elements of high and low beam, you need to draw vertical lines for each headlight. The distance of the car from the wall is determined by the car model. As a rule, for domestic cars - 5 m; for foreign countries - 7 meters.

Headlight faults and repairs

During operation, the owner of a VAZ 2106 does not always notice that the headlights are gradually becoming paler, forcing the driver to look closely at the road. The reason is the inevitable clouding of the lamp bulb after a certain time, so experts recommend getting into the habit of regularly replacing the lamps of the front lighting devices. If individual lamps or lights in the car do not light up, this may be due to:

- failure of one of the fuses;

- lamp burnout;

- mechanical damage to the wiring, oxidation of the tips or loosening of the electrical wires.

If the high or low beam does not switch, then most likely the high or low beam relay has failed or the contacts of the steering column switch have oxidized. In both cases, as a rule, replacement is required - respectively, a relay or a switch. It is also necessary to replace the three-lever switch if its levers do not lock or switch.

Experts recommend getting into the habit of regularly replacing headlight bulbs on your VAZ 2106

How to disassemble a headlight

To disassemble a VAZ 2106 headlight (for example, to replace the glass), you need to heat the sealant around its perimeter with a hairdryer, then remove the glass with a thin screwdriver or knife. A hairdryer is a convenient tool in this case, but not necessary: some people heat the headlight in a steam bath or in the oven, although this risks overheating the glass. The headlight is assembled in the reverse order - a layer of sealant is applied and the glass is carefully installed in place.

Replacing light bulbs

To replace a VAZ 2106 headlight bulb, you must:

- Remove the plastic cover using a flat-head screwdriver.

- Use a Phillips screwdriver to loosen the fastening screws of the rim holding the headlight.

- Turn the rim until the screws come out of the grooves.

- Remove the rim and lens.

- Remove the headlight from the niche and disconnect the power cable plug.

- Remove the clamp.

- Remove the lamp from the headlight.

Reassembling the structure after replacing the lamp is performed in the reverse order.

Headlights corrector

A device such as a headlight range control is not used every day, but it can be useful, for example, when driving at night with an overloaded trunk. At the same time, the front part of the car “lifts up”, and the low beam is more like high beam. In this case, the driver can use the corrector to lower the beam of light down. In the opposite situation, when the corrector is configured for a loaded trunk and the car is empty, you can perform the opposite manipulation.

If the car is not equipped with a corrector, you can install this device yourself. Based on the type of drive, correctors are divided into hydraulic and electromechanical. The hydraulic one consists of the main cylinder and headlight drive cylinders, as well as a pipe system and a manual regulator, which is installed on the instrument panel. Electromechanical - consisting of a servo drive, wires and a regulator. The headlights are adjusted using a hydraulic corrector by changing the pressure of the working fluid (which must be non-freezing) in the cylinders. The electric corrector changes the position of the headlights using a servo drive, which consists of an electric motor and a worm gear: after applying voltage to the electric motor, the rotational movement is converted into translational motion, and the rod connected to the headlight by a ball joint changes its angle.

Video: operation of the electromechanical headlight range control on a VAZ 2106

Periodic cleaning is required not only on the outside, but also on the inside of the VAZ 2106 headlights. If you need to get rid of dirt and dust accumulated during operation, you can use one of the many special cleaning products

It is important that the product does not contain alcohol, which can damage the coating of the reflector and the optics will have to be changed. In some cases, toothpaste or cosmetic micellar nail polish remover may be sufficient to clean the surface of the headlight.

To wash the inside surface of the headlight without removing the glass, you need to remove the lamp from the headlight, pour water diluted with a cleaning agent inside and shake well several times, then rinse the container with clean water and dry.

The left high beam headlight on the VAZ 2106 does not light, both on the low beam are on, what is the reason?

circuit breakers. may have oxidized. rotate the fuses in their sockets.

A intact fuse differs from a blown fuse by the presence of a jumper between the contacts (inside the fuse)

Is the high beam indicator light on the dash lit? So it's not a fuse. Look at the lamp and the wiring to it.

Well, it’s easy to sniff a two-ruble coin instead... But the burnt-out light bulb doesn’t ring, it’s black and you can see a break inside….

look at the wires, I had this happen, the wires melted next to the fuses

A light bulb with wiring will help you.

another car will help you

I have a VAZ 2106 and this is the reason why neither high beam is on, but both low beams are on, what could be the reason!!! help me please

touch.otvet.mail.ru

Diagram and device of optics VAZ 2106

Vehicle lighting includes front and rear lights. There are four front ones: two external and two internal. External ones are used for low beam and high beam on VAZ. The internal ones turn on only together with the high beams. The taillights are multi-colored lights that serve as an indicator of reverse gear, dimensions, brakes, etc. The lighting system also includes daytime running lights (DRL),

Six lighting scheme

The sixth model's optics scheme includes:

- headlights;

- two relays for the low and high beam register;

- speedometer with high beam indicator;

- a switch that turns on either high or low beam;

- generator;

- fuse box;

- battery;

- external lighting switch;

- ignition key.

Some modifications of the 2106 have a rear fog lamp installed. The exterior lighting switch is located on the instrument panel. The turn signals of the VAZ 2107 are turned on using a switch on the steering column. The flashing of the VAZ turns is ensured by a relay breaker. On the dashboard, the blinking of the VAZ turn signals is reflected by the blinking of the corresponding light bulb.

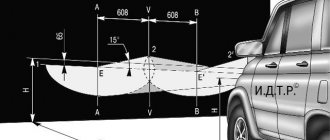

The VAZ 2106 headlights are adjusted on a horizontal surface 5 meters from the screen or wall.

Markings for adjusting the light

Before adjusting, you should check the tire pressure and rock the car so that the suspension springs are installed. It is advisable to place a load weighing about 75 kg on the front seat or ask an assistant for a net. This is necessary to take into account the driver's weight. The corresponding markings are made on the screen, according to which the optics are adjusted. The adjusting screws are located on the back side of the optics under the hood (the author of the video is Engine Repair! And interesting!).

Work principles

The variety of turn relays is quite large, but they are all divided into two main types:

- classical electromagnetic-thermal relays;

- electronic relays.

Electromagnetic-thermal relays are considered obsolete and can now only be found on very old cars, for example, classic Zhiguli cars. This type of relay consists of a core with a copper winding. There are two contact groups in the upper part of the core, and metal anchors in the sides. The structure is placed in a metal case, in the lower part of which contacts for connecting to the network are output.

When the turn switch is turned on, the network is closed - the lamp does not light. Then one of the anchors, under the influence of the nichrome string in the core, straightens and closes the contacts. After this, the current begins to flow in a bypass circuit, and the lamp lights up at full power. The click of the turn signals is ensured by the impact of a metal armature on the contacts.

An electronic relay consists of two main parts: a classic electromagnetic relay and an electronic key that ensures the frequency of operation of the relay. In a relay of this type, the operating principle of the nichrome string, which ensures the closure of the contacts, is assigned to a separate circuit board (key). Otherwise, the operation scheme is similar: the flowing current closes the contacts, after which the indicator lamps and the light on the dashboard light up. Interruption of the current leads to lowering of the armature and opening of the contacts - the indicator lamps go out. A characteristic click is also provided by the impact of the armature on the contacts.

Low beam problems

- The driver does not switch from high beam to low beam when entering a lit street, in the dark.

- The driver does not switch from high beam to low beam when an oncoming car is moving at night.

- Not turning on the low beam on a car with daytime running lights on at night.

- The low beam lamp has burned out. Solved by replacing it with a new lamp.

- The contacts of the negative wire going to the low beam (ground) have oxidized. It is necessary to clean all contacts of the negative wires coming out of the headlight unit.

- The low beam fuse has blown. It is necessary to replace the fuse with a new one of the appropriate rating. If, after replacement, the fuse blows again when the light is turned on, it means that there is a short circuit in the on-board network and you need to contact an auto electrician to troubleshoot the problem.

- The low beam relay is faulty. The malfunction is eliminated by replacing the relay with a new one.

- Faulty high/low beam switch lever (tube).

Also read: Why They Don’t Give You a Rehabilitation Ticket to a Sanatorium After a Lacunar Stroke