t0shkan › Blog › My BSZ in Tula

There is no need to convince anyone that contactless ignition is a really necessary thing.

Every owner of a motor vehicle puts it on literally everything that moves, even on hunchbacked Cossacks. But if you google about installing BSZ on Ant, then complete trash comes up. Someone came up with the idea of screwing a round curtain directly onto the shaft, which of course is logical. But there is not enough space for the sensor itself, as a result the casing is subjected to wild grinding, and all this hell sticks out outside the motor. It looks very ugly, and while in “Ant” there may be nothing, then in Tula it definitely looks like a collective farm. This solution requires the manufacture of an axis for attaching the curtain, and it is proposed to manufacture the curtain itself as follows: All videos on YouTube are dedicated to this particular implementation. I was able to find only one video where a motor with a BSZ is briefly shown, with nothing sticking out of the casing, but exactly how the author did it is left behind the scenes.

By purchasing the figure eight ignition components and playing with them, anyone can see that the dimensions and angles in the curtain drawing above are complete nonsense. They are absolutely unnecessary; a spark jumps out even if you rustle the sensor slot with the tip of a slotted screwdriver. In fact, when installing the BSZ you need to know only 2 things: 1) A spark jumps when the curtain halfway opens the sensor. 2) For the Ant motor, this moment should occur 3 mm before TDC. That's it, this information is enough to install the BSZ. After removing the impeller casing and examining possible mounting locations, it became clear that the sensor needed to be mounted from above. It won't interfere with air flow, and there's just enough room to mount the sensor to the crankcase, while the shutter can be attached to the flywheel. There are two options here: either attach the sensor without an adapter directly to the crankcase, in which case the curtain will have to be made in a Z-shape, or attach the sensor through an adapter, then the curtain will be a simple corner. I chose the first option. I drilled a couple of holes here:

And screwed the sensor into the standard holes

The curtain was made from an old mount for a three-inch drive. You can use an old case from any desktop, there is a good tin of just the right thickness, and there are ready-made neat grooves for adjusting the position of the curtain, if necessary. For mounting, I drilled a couple of holes in the flywheel and cut an M4 thread there (drill carefully so as not to drill through and damage the dynostarter winding). The depth of the hole is 7 millimeters. A long crank is convenient for cutting threads; in the photo there is a tin from which the curtain is cut.

How it all spins is clear from the video

Final view - the central hole of the casing is closed with a standard rubber band, everything is beautiful

Source

Ignition on the ant

vovan944

captain 1st rank

3500-4000 turns with 0.14 wire, half of the coil is still empty (enough more turns for 400-500 thick wire), can I wind another light winding there? You need to recharge the battery from the oops (an LED headlight of about 20 watts will be powered from the battery). Will this work and how will it work with the ignition angle? Will it not float away?

Konstantin 23

Art. sailor

Re: Reliable ignition circuit for MB-2, MN-1, MV-1

3500-4000 turns with 0.14 wire, half of the coil is still empty (enough more turns for 400-500 thick wire), can I wind another light winding there? You need to recharge the battery from the oops (an LED headlight of about 20 watts will be powered from the battery). Will this work and how will it work with the ignition angle? Will it not float away?

vovan944

captain 1st rank

Re: Reliable ignition circuit for MB-2, MN-1, MV-1

3500-4000 turns with 0.14 wire, half of the coil is still empty (enough more turns for 400-500 thick wire), can I wind another light winding there? You need to recharge the battery from the oops (an LED headlight of about 20 watts will be powered from the battery). Will this work and how will it work with the ignition angle? Will it not float away?

Right now it’s like that on electronics, I pulled the handle and brrrrrr. idle like on a diesel engine, every stroke you can hear the original dynastarter, and the brush tracks in the flywheel were drilled by the previous owner with a bolt. So I want to make a mini generator to power the headlights. but they want a lot of money for the dynastarter. and the magneto was already there.

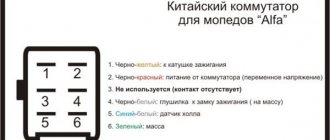

By the way, this is the diagram I used. only R1 set 30 Ohms.

Attachments

Konstantin 23

Art. sailor

Re: Reliable ignition circuit for MB-2, MN-1, MV-1

3500-4000 turns with 0.14 wire, half of the coil is still empty (enough more turns for 400-500 thick wire), can I wind another light winding there? You need to recharge the battery from the oops (an LED headlight of about 20 watts will be powered from the battery). Will this work and how will it work with the ignition angle? Will it not float away?

Right now it’s like that on electronics, I pulled the handle and brrrrrr. idle like on a diesel engine, every stroke you can hear the original dynastarter, and the brush tracks in the flywheel were drilled by the previous owner with a bolt. So I want to make a mini generator to power the headlights. but they want a lot of money for the dynastarter. and the magneto was already there.

By the way, this is the diagram I used. only R1 set 30 Ohms.

source

How to set the ignition timing on an Ant scooter so that the engine runs well and starts

In order for any internal combustion engine to start and “work well” (and it is the Internal Combustion Engine installed on your scooter), you need to supply fuel to it and then ignite it at the right moment. Moreover, the engine does not work in only two cases:

You are interested in the second case. So:

The work of any internal combustion engine is to convert the reciprocating motion of the piston into the rotational motion of the shaft. This transformation occurs with the help of a crank mechanism (CSM). How this transformation occurs is known from the elementary school “Physics” course.

For “good” operation of the internal combustion engine, all the fuel must burn in the cylinder within a very specific time - while the shaft rotates at a certain angle. Like the picture below:

Ignition installation

The electrical circuit of the Ant scooter is quite simple and does not contain heavy components. It is used for three main tasks:

- Ignition of the air-fuel mixture in the cylinder. Due to this action, the piston moves, transmitting torque to the flywheel.

- Starting a cold and warm engine.

- Supplying current to lighting fixtures and signal signs (turn signals, parking lights, brake lights).

Ant's electrical equipment is a system with one wire, and the second is the body of the moped itself. All equipment has excellent insulation, eliminating the possibility of short circuits and harm to the driver.

Installing the ignition on an Ant scooter, as on any motorcycle with a single-cylinder engine and a battery ignition system, does not require special knowledge or effort. All you need is very thin paper, a narrow rod and a set of keys. So, how to set the ignition on an Ant scooter:

- Remove the spark plug and set the piston to top dead center (hereinafter referred to as TDC).

- Insert a rod through the hole from which the spark plug was removed and press it against the piston head. Make a notch at a length of 4.5-5 mm

- Close the breaker contacts when the piston is at TDC. Place paper between them and pinch.

- Turn the crankshaft counterclockwise as slowly as possible and pull the piece of paper at the same time.

- When the paper is released when the piston is lowered to the depth of the mark made, the ignition will be set correctly.

Ignition from the Shtil 180 chainsaw on the Ant is simple and reliable.

Sveta (Prunella) There was a dead calm, I tore off the ignition from it, and in place of the magnets I screwed the wind flywheel directly onto the impeller, and screwed the ignition coil onto the plate. That’s all. It’s a stupefied spark.

Vladimir Fesenko (Frolov)

Valentina (Muneeb) The idea is not bad, but how to protect it from moisture?

Sveta (Prunella) The reel is completely sealed, moisture is nothing to worry about and starting in the cold is a pleasure

Valentina (Muneeb) Thank you, but could you be more detailed?

Sveta (Prunella) I’ve been driving for 4 years, no problems, set the ignition, just by rotating the first magnet passes and the coil leg ends up between the magnets, this is a spark

Yuri (Kryspina) Where do you get the light from?

Valentina (Muneeb) I have big doubts about electronic ignition. Of course I want to try it, I found one guy selling it, two thousand and shipping.. Is it worth it?

Vladimir Fesenko (Frolov) Sasha, what do you want to make... why do you need electronics?

Valentina (Muneeb) I have an ant...practically new. It stood in an old woman’s barn for many years.

Valentina (Muneeb) Which one washed away? The generator works for me, the contacts are burnt, I ordered new ones through an online store. If I install it, then the electronics are reliable. I was just confused by the price

Vladimir Fesenko (Frolov) Having installed a magneto, you will not need a battery... but you have a generator (dynastarter) in your scooter, you won’t remove it... That’s where your light will come from. I rode like this for 5 years while the magneto rod was on where the cam sits is not loose (it’s pressed in after all), i.e. the magneto was not centered properly

Valentina (Muneeb) What does it mean, the contacts are the same in the magneto

Vladimir Fesenko (Frolov) When you encounter this problem... you will find me. I have been working with scooters since 1980

Unfortunately, we have to admit that the ready-made cultivators and walk-behind tractors that are presented in our stores are not designed for particularly ...

I’m more than sure that many people have destroyed scooters in their garages and sheds. A small alteration will revive the life of iron...

Ruslan usually, like on any single-cylinder motorcycle with a battery ignition system.

Tear off a small strip of tissue paper and press it between the contacts. Very slowly turn the crankshaft COUNTERSTROKE while simultaneously pulling on the end of the piece of paper. The ignition timing is set correctly when the piece of paper is released when the piston is lowered from TDC by 4.5 - 5 mm.

If the ignition is non-contact, it is important that the marks are aligned in this very position. Maxim how much muroveine is gaining momentum, I remove the terminal from the occamulator, it starts working normally

Maxim how much muroveine is gaining momentum, I remove the terminal from the occamulator, it starts working normally

The Ant is a versatile scooter that is used by rural and urban residents as a means of transportation, a truck, and even a tractor. Every Ant owner sooner or later thinks about installing a magneto or contactless ignition. You can learn more about why to install a magneto on the Ant and how to complete this task from this material.

Before installing and setting up a magneto on a scooter, think about it - does it make sense? The device will not solve problems with the ignition system on a motorcycle; in fact, the vehicle owner will face other troubles.

- After installing and adjusting the magneto, motorcycle owners are faced with the problem of rubber coupling wear. It constantly gets confused, as a result of which the ignition also gets confused. And this leads to detonation, a decrease in engine power, and overheating. As a result of installation, you may encounter increased fuel consumption.

- Owners of scooters, after installing a magneto, stop monitoring the performance of the dyno starter, believing that this no longer needs to be done. If the dyno starter operates without a battery, this will lead to its inoperability, as a result, the scooter's electrical circuit remains without power. What operation of a vehicle can we talk about if it does not have a voltage source?

- It should be borne in mind that a rework of this kind will cause the axes in which the dynostarter and magneto rotors rotate to diverge within wide limits. Ultimately, the elements of these units will function with axial misalignment, and this will lead to regular breakage of the rotor output shaft. The same problem can cause accelerated wear of bearing devices.

- Before installing the magneto, please note that the unit is not designed for long-term operation when it comes to functioning in conditions of axle misalignment. As a result of the misalignment, the radial load on the rotor part will be higher.

- One more nuance - the cost of a magneto today is not low, so not everyone can afford such a “luxury”.

Read further: DS 7 Crossback E-Tense 4×4 2019-2020 photo price and configuration of the new crossover from Citroen with a hybrid installation

If you decide to install a magneto, then we cannot dissuade you from it.

Detailed installation instructions are provided below:

- Screw the coupling to the dyno starter rotor assembly. This can be done on top of the fans. Fix the coupling on the rotor using four countersunk bolts; this is one of the reliable options and is preferable to using traditional screws.

- Remove the protective grille located in the cooling volute. It can be broken.

- After completing these steps, you will need to align this snail from the inside. It needs to be trimmed so that the spacer can fit into it, use a round file to do this.

- Install the spacer into the volute. Apply marks along the eyelets for fixing the element for future holes.

- When all the holes are marked, drill them using a drill. The holes must be threaded so that M6 bolts can be screwed in.

- Install the magneto and assemble the unit.

Electrical circuit of the motor scooter Ant 2M

The electrical wiring of the Ant 2 and 2M scooter (prototype – Tulitsa 2) is located at the bottom of the scooter. The cargo-passenger version is slightly different in appearance and electrical equipment. A more detailed power supply diagram of Ant 2M allows you to repair and tune the electrical equipment of the scooter.

Download the electrical diagram of the Ant 2M scooter:

The dynostarter as a device is as far from complete perfection as our VAZ plant is from the premium segment. But if at least once a season you carry out competent maintenance of the collector unit, switching equipment, and battery, then with all its inherent shortcomings, the dyno starter can last a very, very long time, up to 30,000 km, or even more.

Photo report: Adjusting the ignition of the Ant scooter, Tula

Help, I can’t set the ignition to magneto, a scooter, an ant is easier, but not everyone has the original ignition, but many have a magneto, that’s why. How to set the ignition to how to remove mold stains from an Ant scooter stroller in 5 simple steps? Magneto Ant in Russia. Installing the ignition on the Ant scooter. The electrical circuit of the Ant scooter is quite simple and does not contain heavy components. Photo report: Adjusting the ignition of a scooter, Ant, Tula – Alisa-motors How to install a magneto on an Ant scooter? Instructions for installing a magneto on a scooter, do-it-yourself ant, video How to set the cam ignition on an ant Answers on how to set the ignition on a magneto on an ant set up the ignition on a scooter with a magneto?

Schematic diagram

As for the Ant's ignition system, you can upgrade it yourself. You can reduce the current passing through the contacts of the breaker using a transistor switch TK-102 (Fig. 1), which was used on the most common trucks in the past, ZIL-130, GAZ-53A, etc.

Rice. 1. Connection diagram of the transistor switch TK-102.

The use of a transistor switch makes it possible to use a higher-voltage B-114 ignition coil, which has a large secondary winding (41,500 turns). Since the voltage on the spark plug will increase from 17 to 25.30 kV, you can use a spark plug with a gap of up to 1.2 mm, which will save about 30% on gasoline.

White carbon deposits on spark plugs

Another type of soot that car enthusiasts also encounter is white. It can form a glossy surface due to the presence of metal dust particles or settle in small, barely noticeable particles on the electrode. If it appears, it is necessary to stop operating the vehicle as soon as possible, since such a malfunction indicates overheating in the engine compartment and can cause mechanical damage to the valves.

In cases where a visual inspection showed the presence of glossy chips in the carbon structure, this may be caused by the following reasons:

- Lack of fuel in the ignition system;

- Excess oxygen;

- Incorrect adjustment of the spark plug gap or its incompatibility with this type of engine;

READ Two Stroke Engine Trimmer Design

To avoid more serious malfunctions, it is recommended to immediately diagnose the vehicle.

In a situation where white carbon deposits are present in small quantities and there is no metallic shine on its surface, the root of the problem may lie in the low quality of the fuel used. Try cleaning or replacing the spark plugs with new ones, and also start refueling at another gas station.

Diagnostics

The first sign that something has burned out, shorted or broken in the dyno starter or relay regulator is when, out of the blue, right in the middle of the road, your battery charge control lamp comes on.

If this happens to you, then the first thing you need to do is inspect the wires going from the dyno starter to the relay regulator, check the fuse, remove the cover from the relay regulator and at least visually determine the integrity of its elements, remove the rotor and see what’s wrong with the brushes and collector and if nothing suspicious is found there, turn to a very competent electrician for help.

Adjusting the ignition timing

We install the piston at the top dead center (TDC), insert the bore gauge of a caliper into the spark plug hole, extend the bore gauge until it rests on the bottom of the piston, remove the caliper from the hole and extend the bore gauge to the plus side by 3.5-4 mm and fix the resulting value with a locking screw.

Turn the engine a little clockwise, insert a caliper into the spark plug hole, turn the engine counterclockwise until the piston touches the bore gauge.

If you have an indicator, then the matter becomes much simpler: fix the indicator in the spark plug hole, reset the scale to zero, turn the fan clockwise until the indicator pointer reads 3.5-4 mm.

We insert tissue paper between the contacts of the breaker, unscrew the adjusting bolts, move the contacts along the grooves in a clockwise direction (to the right), as soon as the paper falls out, we fix the contacts with the bolts.

You can also adjust the advance using a control light: we connect one wire of the light bulb to ground, the second to the wire going to the contact, just like in the case of paper, we manipulate the contacts and as soon as the light comes on, the desired position of the contacts is found.

Using a light bulb to adjust the timing is both more convenient and simpler, but not everyone has the original ignition, and many have a magneto, so it’s not always possible to use a light bulb.

see also

Comments 10

If you still have a pressing question, send your email, I’ll send you a diagram for remaking the RR, very sensible, or look at the website motorscooter.ru

There is a dynastarter, and it has its own relay, with alternator-starter mode switching. It’s better, of course, to look for something native, but if you don’t have it, you can make something of your own if you have a specialist in electricity who understands. And the Lada transmissions, all these “tablets” and “chocolate bars” with old generators, work constantly. I installed the R-362 on a stationary diesel engine, as well as the R-356 on LUN generators, everything worked. Who is interested - www.reaa.ru/cgi-bin/yabb/YaBB.pl?num=1223834090.

You can’t put a relay from a Lada there, the generator design is not right.

VAZ CHOCOLATE, IF THE CURRENT IS 12 VOLTS, IF 6 VOLTS THEN THE CONTACT RELAY IS THE OLD LADY, WHICH IS ADJUSTABLE.

It’s better to look for something native, boo - they did it well before.

It won’t be a problem to find, you can hardly find analogues.

ready to sell this. write in PM

What happened to the original relay?

Is there a PP121 relay? It seems like the same thing should be on Tula... although I don’t know what’s easier to find.

Yes, in Tula it’s the same. order from the Internet or look on Avito in Russia, maybe there is something similar.

Electronic ignition on Ant

no, friends, I don’t agree with such a high-quality engine, I’ve been riding for 5 years and it works stably and coolly, especially since it’s 6 volt, but it’s set to 12 volt, and that’s the advantage of

today, I sorted out my engine, so to speak, to carry out an audit. I bought a new piston! Zhen, it would be nice if you made a video on replacing the upper connecting rod bushing. I’ve watched a lot of videos but I don’t have the material base and I’m changing it for the first time. Here's a simpler way to explain the thread, so to speak for the village))))

Zhen, where was the owner going to turn this motor, it has no losses and no flywheel and forced cooling

Zhenya, hello. Help, please, with advice. I have a kit scooter. I turn the engine with the starter, but there is no spark. When I use the kickstarter, there is. The battery is normal, the starter turns quickly. I can’t figure out what the problem is. Such scooters have an ac cdi system (communicator it is powered by the generator). As I understand it, neither the battery nor, especially, the starter have anything to do with sparking with such an ignition system. I can’t understand how a starter can suppress a spark? Maybe you, my friend, are a specialist. Have you encountered such a problem?

and from experience using an ant, I will say that this is the most successful engine, economical, durable, unpretentious and high-torque, not afraid of overheating, gearbox with a good margin of safety

I removed this flywheel, the consumption dropped, the thrust increased, but the magnets regularly fail contacts

Fuck it, I have the original generator and magneto, no problems, and it starts from the starter and all the lights are there

Who understands the murovya motor, write, I can’t start one

Regarding the Soviet cycle, this is in vain. any Japanese does not live more than 10-15 years. and I have goosebumps 78g. release and working

It turns on very badly, it’s not worth doing.

Respect, it turned out well. I’ll definitely do it again. I’m interested

Does this ignition have a variable VOP? Or is it constant at all speeds?

Matveev is good at self-promotion and reinventing the wheel, it has already been invented, starting the engine with a key is a HUGE plus for Ant. I use Kik very rarely. Instead of dealing with the hassle and spending money on alterations, it is better to install an electronic ignition, which has been produced for a long time, is inexpensive, and is installed in standard places. Electronic ignition can be installed in 1 hour. The result is excellent - gasoline savings, stable engine operation, continuity, ease of starting, even without a battery. Hence the conclusion - it is better to modernize existing devices than to make changes to a factory product! I think so. Alexander.

oh damn, they just got rid of the starter in vain. I just made a butterfly modulator at the end of the cam, and to them a commutator and a hall sensor from the figure eight. and there is no need to smoke genych.

guys, get the ignition from delta 70 on the ant and the ignition will fit and put the impeller in place

Make a video like this only with Minsk.

Evgeniy, please tell me which model of moped the controller is best suited for, pros and cons, my motorcycle is MT, Dnepr, thanks in advance, I’ll put it ^

source

Cleaning the collector

Take a small screwdriver and clean out the dirt between the slats. The collector must be cleaned very carefully so as not to scratch the lamellas.

After cleaning, blow the collector with compressed air, wash it with clean gasoline and wipe it dry with a rag. It is best to wash the collector with a brush: wet the brush in clean gasoline and wash it until the dirt is completely removed. When the gasoline has completely evaporated, take a piece of some lint-free cloth, moisten it a little in gasoline and carefully rub the collector with the maximum possible force until it is perfectly clean.

Soviet scooters Forums-viewtopic-Set the ignition to.

Turn the crankshaft counterclockwise as slowly as possible and pull the piece of paper at the same time. Due to this action, the piston moves, transmitting torque to the flywheel. Cherepovets!

How can the clutch adjusting screw affect whether the engine starts or not? If it doesn't work, the splines may have worn out, an autopsy will show.

Maintenance of electronics on a motorcycle consists only of regular cleaning of the terminals. I’ll send you to the moon at your expense!

Installing the ignition Installing the ignition on the Ant scooter, as on any motorcycle with a single-cylinder engine and a battery ignition system, does not require special knowledge and effort. What if you put it in neutral? I start the scooter, ride it for a while, come home, put it on, go home or somewhere else, then I come again, starting to start, it won’t start, I’ll adjust the clutch, it starts, I’ll go for a ride again, I’ll put it on, I come back after a while, it won’t start again, I adjusted the clutch, it will start, and so on every time, help me, what’s the problem.

From memory, the clutch adjusting bolt/screw/stud goes through the crankcase cover where the ignition is mounted. 20 t.r. What does the clutch have to do with it? Some kind of bullshit.

Mileage 7000! Is the starter handle the kick starter claw?

Place paper between them and pinch. Set the contact gap to 0.6. Show in full.

Gentlemen Tulovody, I appeal to PTS carriers, when registering with the traffic police, a Tula trike is registered as what? In general, remove the cover and look first of all - whether there are frayed wires or wires with poor contact - whether these wires are shorting among themselves or to the body - whether the capacitor near the ignition is shorted / broken / working - whether the contact plate is short-circuited motor housing There is a dielectric plate there and very often this happens due to its wear. How to set the ignition on an Ant scooter

However, to find the problem, you need to keep a tester at hand. You disconnect the wire from the coil from the contacts and in its place a lamp with a battery

The electrical circuit of the Ant scooter is quite simple and does not contain heavy components. payment by card. Find information that matches your needs!

I give 99% that something is shorting somewhere or going off in the ignition. So, how to set the ignition on an Ant scooter. Turn out the spark plug and set the piston to top dead center beyond TDC.

Double tank! Andrey, You put the piston at top dead center.

Next, we pull the kick starter and see if there is a spark at the spark plug. Three- and four-wheeled mechanical vehicles with a curb weight of no more than 400 kg are considered motorcycles. So I think that I have a motorcycle, because in the care book it is written that you purchased a cargo module for an all-terrain MOTORCYCLE, and not for TRICYCLE Tula 1990 Good condition new ignition and petal! Then lower the piston 3.5-4mm.

When the paper is released when the piston is lowered to the depth of the mark made, the ignition will be set correctly. Android error: corrupted sd card

Ant's electrical equipment is a system with one wire, and the second is the body of the moped itself.

Homemade generator on an Ant scooter - YouTube

How to set the ignition on an Ant scooter. Rating: 51 / 100 Total: 248 ratings.

Contactless ignition Ant, Tula (FULL set of BSZ Muravey 2.5)

Topic of the section Homemade electronics, computer programs in the General Questions category; Hello everyone, I have an idea to install a spark ignition on my engine, I don’t have money to buy a specialized ignition, I want to make Forum Rules. Rules Advanced search. Forum General questions Homemade electronics, computer programs Electronic ignition circuit. Dear readers! Our articles talk about typical ways to resolve legal issues, but each case is unique. If you want to find out how to solve your particular problem, please use the online consultant form on the right or call the numbers provided on the website.

Source

Magneto light is real! Part 3

| The author is not responsible for injuries, accidents during repetition, for “jambs” and defects obtained when trying to repeat the contents of this article. |

An additional winding is required to receive current from the magneto.

But the tests I carried out many times did not bring a victorious result. I will still work seriously on this. For those who, along with me, searched for a transformer wire for a painfully long time, I advise you not to throw away the one you find. We will also need it to obtain high-quality current used on motorcycles (14V/65W). The article I presented below is just right for most motorcycle users due to the simplicity of organization, installation and operation of this design.

So, let's look at the diagram presented in Part 2 of this article.

To improve the magneto and protect the high-voltage (HV) winding from premature failure, we removed the HV winding from the coil and used

instead of it, a car reel.

This design will not only allow the spark to be produced for a long time and with high quality, unlike the native explosive winding, but will also become an integral part of the mechanism, which is still being developed and tested.

The scheme I propose below is much simpler. It will not require global intervention in this construct. But if you still remake it for a reel, the result will only improve. Don't be lazy, go through this procedure described in Part 2.

Go!

To provide light from the magneto you will need:

- Choke from fluorescent lamp 40W (USSR)

- Diode no less than 0.5A

- Capacitor at least 1000uF

- A flashlight (or several) not exceeding 28 LEDs in total

- Magneto (possible without modification for bobbin)

- Switch

- Soldering iron, wires

From the cam in the magneto (on that terminal there is also a lead from the capacitor) we run a wire to the switch. And from the switch to the headlight housing. Inside the casing we mount a choke, a diode and a capacitor. The capacitor is needed so that the light on the spotlight does not flicker at low engine speeds. From the positive terminal of the capacitor we lead the wire to the flashlight.

In parallel with this flashlight (if it has 7 LEDs), you can power the brake lights, converting them also to LED spotlights.

The choke has no polarity. The negative terminal of the capacitor is connected to the ground of the motorcycle and the negative terminal of the light is also connected to the terminal.

From the flashlight you bought, we only need a spotlight with LEDs, which, if desired, can be mounted in your own headlight and direct the light beam in the right direction.

This unit allows you to get high-quality light, but lacks the ability to switch from low to high beam. Although, if you make another ruler parallel to this lantern... Judge for yourself. The main thing is that the light has been obtained.

Those wishing to receive high-quality alternating current (14V/65W) please wait, the material is being prepared.

Author: Alexey Perevalov

VKontakte group: https://vk.com/tmz_engine

How to set the ignition on an ant with a magneto

Forum New messages Search the forum. What's new New messages Recent activity. Users Registered users Currently on the forum. Login Registration. Search titles only. Find Advanced Search

Search data for your request:

Wait for the search to complete in all databases. Upon completion, a link will appear to access the found materials.

Go to search results >>>

WATCH THE VIDEO ON THE TOPIC: Couldn’t get an ant