Where is the camshaft sensor on a VAZ 2114

In order to understand where the faulty part is and what are the signs of a malfunction of the VAZ 2114 camshaft sensor, you first need to answer the question “where is the VAZ 2114 camshaft sensor?” and its location in the design of the car. In model 2114 cars it is located near the power unit, next to the air filter, which is located near the cylinder head.

How to replace a phase sensor with your own hands

If you are absolutely sure that the phase sensor is faulty, you can replace it yourself. It is located at the end of the cylinder head next to the air filter.

Replacing the phase sensor begins by disconnecting the power from the battery. In this case, the control unit memory will be reset.

If this is not done, it will continue to operate in the same mode as with a faulty phase sensor. Normal operation will begin after a few engine starts.

The tool that will be needed is just a ten key and sealant. Next, disconnect the wires from the phase sensor and remove it using a key.

The new sensor needs to be coated with sealant, the layer should be small, and it should be left for about five minutes before installation. We install it on the seat and connect the wires.

Next, connect the battery, start the engine and see if the check engine light comes on. If it no longer lights up, then the sensor is installed correctly.

How to check the camshaft position sensor on a VAZ 2114

The first most obvious cause of device malfunction is the Check error, which may appear after starting the engine. In case of this malfunction, the engine starter will wait for information from the regulator, and if it is absent, a VAZ 2114 camshaft sensor error will appear on the dashboard with the inscription “Check”. If a car enthusiast asks the question “how to check the camshaft position sensor on a VAZ 2114?” – then you can do it yourself using diagnostic equipment. To do this, you can take a multimeter and connect it to the camshaft sensor.

To do this, set the “alternating voltage” mode and turn on the machine for work. If readings appear on the multimeter display, then the regulator is working properly. If there is no hint of current on the multimeter, then the multimeter shows signs of a malfunction of the VAZ 2114 camshaft sensor.

Another sign of a malfunctioning regulator is increased fuel consumption. In order for the car to drive normally, even with a broken controller, it needs to inject much more fuel.

- When you independently diagnose a machine, problems and multiple malfunctions appear;

- The power and dynamics of the motor can be significantly reduced;

- During the trip, the car may stall.

Also, if the VAZ 2114 camshaft sensor does not work correctly, errors of type 0340 or 0343 may appear on the dashboard. That is why, after errors appear, the most correct solution would be to diagnose the regulator, as well as check the device. If a motorist experiences this problem, the best solution would be to start diagnosing the car to fix the problem.

Main symptoms of failure:

- The power unit shows unstable operation at idle speed; the speed can decrease or increase regardless of the driver’s wishes;

- Reduced motor power;

- When you press the gas, dips may appear in which the power does not increase;

- There are difficulties when starting the engine;

- Damage to the case due to vibrations and the influence of moisture on the mechanism.

When visually diagnosing a camshaft, you need to pay attention to the following features:

- Appearance of the device body, whether there is any mechanical damage. If the case has chips, cracks or signs of crushing, then you should think about replacing the device.

- Check contacts for moisture. If moisture gets on the contact pad, oxidation or short circuit may occur as a result of which information from the regulator will not reach the control unit. If the whole point is oxidation of the contacts, a possible disruption of the impulse due to which information will be transmitted with errors. To diagnose the operation of the contacts, it will be enough to use a standard multimeter, which is available from radio amateurs or in electronics stores.

Checking the integrity of the electronic circuit. If the wiring is damaged, it must be replaced. For this operation, you can use a multimeter and test the electrical circuit for breaks.

Determination of DF failure

If it breaks down, minor problems arise with idle stability; when starting to move, a “tweaking” effect is possible, as well as increased fuel consumption. These symptoms are associated with the failure to receive on-board computer data on the ignition angle at a certain point in engine operation. If there is no signal from the sensor, the control unit enters emergency mode, that is, it begins to work on a predetermined program without a sensor and issues an emergency error “0340” or “0343”.

Troubleshooting the camshaft sensor VAZ 2114

If the motorist decides to change the part with his own hands, he needs to perform these operations:

- Turn off the ignition and open the hood of the car.

- Find the installation location of the controller; it should be located near the oil pump, as well as near the crankshaft pulley.

- Check the seat for contamination. If there is dirt, it should be removed.

- Then you should wipe the area near the part clean. For this, it is best to use a soft brush or a rag soaked in a special cleaning solution.

- Then you should disconnect the connector with the wires that are connected to the regulator and unscrew the fixing screws. Use a visual inspection to inspect the part for damage.

- Before installing a new DPKV, you should clean the seat, and only then install the controller and secure it under the hood. When tightening the bolts, the most important thing is not to overdo it, so as not to break the part itself.

- After installation, you should also check the clearance from the pulley to the controller core. It should be no more than 1 mm. If there is a gap that is larger, the position regulator will not be able to perform its functions of transmitting data to the machine computer.

- When the DPKV is installed, you should start the power unit and check the operation of the machine.

- If the engine starts quickly and quickly, it means the parent has made a high-quality replacement of the controller.

Instructions for checking and replacing

If the above methods failed to normalize its condition, then this part must be replaced. There is nothing complicated in replacing, as well as in checking, since their camshaft is mounted without adjusting the gap. Thanks to this function, you can avoid mistakes when installing a new device. If the gap is adjusted, certain standards must be observed.

If you are not sure that replacing the camshaft sensor yourself will be successful, take it to a special service center. There the replacement is made using an oscilloscope. When starting the oscilloscope, stability of data reading is observed at different engine speeds.

If you have an oscilloscope and you are confident that you can do such a procedure, do it. Just pay close attention to the changing data that the oscilloscope will show. If it shows straight stripes and there are no gaps, that's good. Because you just have to remove the old one and install a new one.

In principle, if you use this method, you need to take into account many points and features that the tester provides in order for the replacement of this camshaft part to be successful. Since, if the indicator does not work, then, logically, the engine should not work. But technology is a delicate matter, and sometimes it malfunctions. If the sensor and built-in electrical devices do not know the location, they go into an emergency state. And, being in this state for a long time, the sensor fails.

We recommend: Computer engine diagnostics - what errors can be identified?

Replacing the camshaft sensor on 8-valve engines

- The sensor is attached with one bolt and a 10mm nut; by unscrewing the first two parts, you can painlessly dismantle the spare part.

- After removing the spare part, it is necessary to close the open part with the component in order to prevent dirt and dust from entering.

- If the device did not work properly due to dirt and moisture getting on the main components of the mechanism, you must remove them with a brush or rag and put them back in their place for further work. You can also use a special compressor that will supply pressurized air to remove particularly difficult clogs and components. If the camshaft malfunctions when removing the blockages, then it is worth replacing it with a working component.

- Sometimes it happens that even after replacing the camshaft, problems do not disappear. These types of problems are very rare, but it could be a sign that the gear has moved out of place and is not working properly. It will be quite difficult to eliminate this defect yourself, which is why you should seek the help of specialists.

Replacing the camshaft sensor on 16-valve engines

- For easy installation, you will need to remove the radiator grille. To remove the radiator grille, it will be enough to lift the hood and unscrew the mounting bolts. Once the bolts are removed, the grille can be easily removed.

- Using a special wrench, you need to unscrew the two fixing bolts. When dismantling, it is advisable to unscrew the bolts gradually so that there are no distortions when removing the part. First you need to tighten one screw a couple of turns, and then another, and so on until the very end.

- Check the DPRV for deficiencies, clean all components, and then install it again. If these frauds do not help, you should start replacing parts.

- To install a new DF, do not use sealant, because during operation of the cylinder head, the temperature regime of the area may change. If there are signs of a faulty VAZ camshaft sensor, replacing the part on VAZ 2114 cars with a 16-valve engine will be more difficult, but the dismantling mechanism itself is similar to an 8-valve internal combustion engine.

Meter design and location

The operating principle of the DPRV is based on the Hall effect - the sensor reacts to the approach of a metal mass by changing the voltage on the signal wire. The design of the device is similar to another element - the crankshaft position detector. Inside the plastic case there is a coil where the 12 V on-board voltage is constantly supplied.

The meter is installed on the engine cylinder head in close proximity to the camshaft. The latter is equipped with a special plate or gear, whose rotation affects the DPRV. The work algorithm looks like this:

- After turning on the ignition and starting the engine, a 12 V supply voltage is supplied to the sensor. Through the third signal wire, the element supplies the controller with a voltage of 90–95% of the original one.

- When the protrusion on the rotating part of the camshaft passes next to the DPRV housing, the voltage at the signal contact drops to 0.2–0.4 volts, depending on the design of the device and the vehicle model.

- When the voltage drops, the electronic unit clearly “sees” the valve timing, promptly supplies the fuel mixture to the engine cylinders and directs the spark discharge to the desired spark plug.

Note. On cars with 16-valve engines, 2 sensors are installed - one for each camshaft.

When the meter is faulty, the electronics are unable to control the operation of the gas distribution mechanism. In such cases, the control unit goes into error and is guided by the signals of other meters. Spark generation and fuel supply are adjusted according to the programmed program, which affects the operation of the power unit.

We recommend: The most reliable and durable engines

Repair price

If you check and remove the DF yourself, under such conditions the motorist will only have to spend money on purchasing a new DFSV. This device, namely the camshaft position sensor for the VAZ 2114, will cost around 300 rubles. When purchasing a position regulator, pay attention to the quality, because parts from certified stores for VAZ are best suited. If the driver wants to entrust his car to service station specialists, such repairs will cost at least twice as much. In any case, the decision will be made by the owner of the car.

Thus, if the driver has skills in working with hand and power tools, and also knows the design features of the VAZ 2114, he can painlessly dismantle and repair the camshaft sensor. Despite its modest size and ease of operation, the DPRV is an important component of the machine, which affects its power and driving performance. If the driver wanted to make the repairs himself, he should stock up on the necessary tools.

Operating principle of the sensor

General view of the camshaft sensor

The camshaft sensor or phase sensor is a part of the main power unit of the car, which is responsible for reading information about the location of the camshaft and is also involved in adjusting the ignition angle.

This meter is similar in principle to a Hall sensor .

Reading occurs using a special camshaft gear that has no teeth. The missing elements are located in such a way that when this gap hits the sensor, the first piston is at the dead center, at the top or bottom.

Phase sensor operation diagram

A signal is triggered and transmitted to the engine's electronic control unit when the sensor hits the missing teeth. In turn, depending on the received indicator, the ECU adjusts the ignition angle. Thanks to the installation of such a system, Samara-2 engines have become more efficient and popular.

Location of the sensor under the hood of the VAZ-2114

The camshaft sensor on the VAZ-2114 is located near the air filter, at a very close distance from the cylinder head. This meter location is almost always standard for other cars in the injection group.

Camshaft sensor location

The main reasons for sensor failure

Before proceeding directly to the diagnostic process, it is necessary to find out the causes of the malfunction of the VAZ-2114 phase sensor.

So, let's move directly to the most direct and indirect indicators:

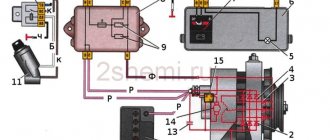

Electrical circuit of the sensor

- Check Engine on the dashboard indicates that a malfunction has occurred. In this case, the engine starts without waiting for a response from the camshaft sensor, and the ignition system works based on the latest indicators.

- Increased consumption of the fuel mixture can also serve as an indirect indicator of a malfunction of the air flow control valve.

- The car begins to lose power and dynamics as a whole.

The combination of these reasons can serve as an indirect indicator of a malfunction of the camshaft sensor.