The VAZ 2108 device, like any other vehicle, involves powering electrical circuits from a battery. To ensure that the battery is always in good condition and does not let you down at the most inopportune moment, a generator is always connected to it.

The battery is especially important when the engine is ignited; while driving, when the car develops sufficient speed, the entire electrical circuit is powered by the generator.

When the question arises about connecting additional powerful electrical appliances to the car, it is very important to match their load with the permissible power of the generator. To do this, it is important to know its technical characteristics. And if the battery lack of charge indicator suddenly lights up, it’s better not to even look under the hood without understanding how the electrical charging circuit, voltage regulator and ignition work.

After reading today's article to the end, you will learn about the connection diagram and dimensions of the VAZ 2108 generator, the main reasons for failure and how to check the voltage in the circuit. If trouble happens to the generator, then don’t worry, we will clearly show you the process of removing and installing it.

VAZ 2108 generator circuit

The VAZ-2108 generator has a rather massive stator winding, since it uses a large cross-section wire. It is with its help that electricity is generated. The wire is wound evenly over the entire inner surface of the stator into recesses specially provided for this purpose in the magnetic core.

It’s worth talking about the latter separately. The middle part, the generator stator, consists of a series of thin metal plates pressed tightly together. They are often boiled on the outside to prevent separation.

- Alternator. The 37.3701 or 94.3701 series can be installed.

- Negative diode.

- Additional diode.

- Positive diode.

- Alternator warning lamp, also known as battery discharge lamp.

- Instrument cluster.

- Voltmeter.

- Relay and fuse box located in the engine compartment in the compartment between the engine and the vehicle interior.

- Additional resistors built into the fuse mounting block.

- Ignition relay.

- Egnition lock.

- Accumulator battery.

- Capacitor.

- Rotor winding.

- The voltage relay is located in the engine compartment.

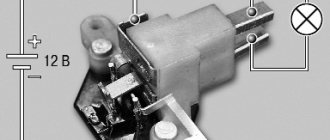

Connection diagram for generator model 37.3701.

When you turn the ignition key, the voltage to turn on the generator is connected to the output through a pilot light and resistors. After the engine is started, voltage is supplied to the field winding from three valves present on the rectifier block. In this case, the control lamp does not light up, since no current passes through it. The main voltage is supplied to the regulator output directly from the generator output.

Since 1996, changes have been made to the model 37.3701 generator, namely, the design of the regulator and brush holder has been changed. From this point on, the voltage regulator is located in a metal case and attached to the brush holder. That is, they have become inseparable.

In addition to the considered generator model on VAZ 2109 cars, you can also see German, Bulgarian and, as mentioned above, Slovenian generators. They can all be replaced with 37.3701. Of course, there are differences, but they are small and related to the design of the generator itself, and in terms of technical data and dimensions they are the same.

- accumulator battery

- generator

- mounting block

- additional resistors 100 Ohm, 2 W

- ignition switch

- ignition relay

- instrument cluster

- battery discharge warning lamp

Technical characteristics of the VAZ 2108 generator

The following generator models are installed on VAZ 2108 cars:

- 3701

- 3701

Technical characteristics of the first:

- The value of the delivered current (at 6000 rpm-1 and a voltage of 13 V) – 55 A — The voltage value – 13.6 – 14.6 V

- Rotor rotation direction – right – Maximum rotor speed – 13000 rpm-1

- Engine/generator gear ratio 1/2.04

Technical characteristics of the second:

- The value of the delivered current (at 6000 rpm-1 and a voltage of 13 V) – 80 A — The voltage value – 13.2 – 14.7 V

- Rotor rotation direction: right

A normally working, serviceable generator of VAZ 2108, 2109, 21099 cars and their modifications produces a voltage in the range of 13.6 V - 14.6 V. This can be visually tracked using a voltmeter on the instrument panel, but it is better to measure the voltage with a voltmeter (multimeter, autotester

What generator is installed on the VAZ 21099, VAZ 2109, VAZ 2108

| Specifications | 37.3701 | 94.3701 |

| Limit current strength at a voltage of 13.5 V and speeds above 5500 rpm | 56 | 81 |

| Adjustable voltage range | 13,5-14,4 | 13,3-14,6 |

| Gear ratio | 01.01.1970 | 01.01.1970 |

| Capacitor capacity | 2,3±15% | 2,1±15% |

Note to the driver!!! If the IP drive belt breaks along the way, and you don’t have a spare one at hand, cut a 25 mm wide ring from the car inner tube.

To significantly reduce current consumption when the power unit is running, it is necessary to turn off the maximum number of current consumers: radio, radio, lighting, cooler, stove heater.

Reasons for failure of the VAZ 2108 generator

Experts believe that the main reasons for the failure of the VAZ 2108 generator are:

- voltage regulator failure;

- damage to the diode bridge (aka rectifier);

- wear of current collecting brushes;

- defects in the charging circuit wires;

- damage or operational wear of the pulley;

- wear of slip rings or commutator;

- short circuit of individual turns on the stator winding;

- bearing failure.

Every self-respecting car enthusiast should understand what causes generator malfunctions most often and how they can be dealt with. It is also necessary not to forget that timely prevention helps to avoid serious problems. Towards the end of the article, we will look at some tips that will help you learn how to test the generator yourself. But let's first learn about the internal structure of the node.

How to check the voltage of the VAZ 2108 generator

In order to check the performance of the VAZ 2108 generator, you need to perform the following steps:

- Using a voltmeter, diagnose the voltage at the battery terminals. When the engine is running and the generator unit is operating normally, this parameter should be around 13.8-14.5 volts.

- Try placing your palm on the unit body with the engine running, you need to feel the vibration. If there is vibration, you will notice it immediately. Moreover, it may be due to wear of bearing parts.

- It is also necessary to diagnose the tension of the device strap, while the motor must be turned off. Press the strap with your finger - the deflection should be no more than 1.5 cm

Interchangeability of the VAZ 2108 and VAZ 2106 generator

The idea of replacing a generator on a classic is as old as the history of the car itself, because everyone who installs more bells and whistles on their own car than a weak Chinese radio, the native 42A G-221 is no longer enough for everyone.

True, even those who neglect the hassle of installing a more powerful generator are annoyed by the weak low beam at idle and poor battery charge. Once, an acquaintance fitted me with a 55A generator on a ball and the idea arose about telling you how to install it in our classic.

Having scoured the Internet to find at least something about installing and connecting it to a car, I didn’t find anything useful, a lot of comments like “Plug it in and forget it” or long discussions of professional electricians, but they spoke in a language that would suit a simple Russian to a person, it’s like a Chinese song, nothing is clear.

In this regard, it was decided to write an understandable article for ordinary people in order to help them do this simple procedure of replacing the generator themselves, without any problems and special skills in working with electricity, but with their hands. It is important to know: There are many alternatives to a standard generator, since with the appropriate skills, means and desire it is possible to install any generator. In the provided article I examine only “economical” VAZ generators from other models, because:

- They are cheaper.

- They are more common.

- They are easier to change - you don’t need to find or make any special fasteners and completely change the electrical system.

How to remove the generator on a VAZ 2108 yourself step by step instructions

In order to remove the VAZ 2108 generator with your own hands, you must perform the following procedure:

- In order to easily remove the VAZ 2108 generator, it is necessary to remove the engine protection.

- During the dismantling process, the VAZ generator must be removed together with the bracket, since its fastening bolt will be impossible to pull out due to the position of the body side member.

- Now disconnect all electrical terminals from the generator

- Then you need to loosen the adjusting nut and the generator mounting nut from below.

- Move the generator forward and remove the loose belt

- Unscrew the bolt and remove the adjusting bar

- We find it at the bottom of the engine compartment (shown in the photo) and unscrew the two bolts securing the bracket.

- Then, carefully pushing down, remove the VAZ 2108 generator

- After repairing or purchasing a new generator, we install it in the reverse order, taking into account the fact that the long bolt securing the bracket should be closer to the generator drive.

- After completing the installation of the VAZ 2108 generator, tension the drive belt

We begin to remove the unit from the engine

Let's start removing the VAZ 2108 generator, repairs will be the next step:

- We disconnect the wires from the unit - they are usually red and come in two groups

- The first group of two wires is attached with a nut to a bolt located on the back cover

- The second group is made of one wire, connected to the unit terminal via “mother-father” contacts, on the same back cover of the generator.

To remove the generator from the engine, we need to unscrew a couple of nuts and one bolt in a certain sequence:

- First, unscrew the nut that is attached to the drive belt tensioner bar (located at the top of the power source)

- Then unscrew the bolt securing the tensioner bar to the motor housing and remove it

- The third step is to unscrew the nut from the bolt that secures the generator bracket to the engine block

Useful recommendations for withdrawal

Some nuances that will make it easier for beginners to remove the unit with their own hands:

- The bracket securing the generator is located at the bottom of the engine housing, under the generator. After unscrewing its nut, you must immediately remove the drive belt from the pulley of the unit itself.

- The bolt securing the generator should be pushed to the left from its bracket until it rests against the body or to protect the unit.

- It is necessary to unscrew the two screws located on the wheel side (right), which secure the mud protection to the body

- If the bolt holding the generator still rests on some body parts, you should press the engine with one hand and simultaneously pull out the bolt using the other hand.

Now that the generator has been completely removed from the engine, we can begin disassembly.

Let's move on to disassembly

To disassemble an electric generator, you just need to have two important tools:

- Bearing puller

- Vise

They will greatly facilitate and also speed up your work. In addition to these, it will be useful:

- Hammer

- Set of keys (or heads)

- Screwdriver Set

Now that we have stocked up on the necessary tools, let's start disassembling:

- Using a 19mm wrench, unscrew the nut that secures the impeller to the shaft

Unscrew the impeller fastening nut with a 19 wrench

- To do this, you need to hold the impeller with one hand, and with the other hand remove the nut, rotating it counterclockwise

- It will take some effort, but this nut must be unscrewed

- The impeller is locked on the shaft with a pin, after removing the impeller from the shaft we need to remove this pin

Attention: You should remember and even write down the location of the spacer washers on the rotor shaft and the nuts when removing them. Since each type of generator device has its own unique characteristics in their immediate location, which does not depend on the instructions in the instructions or repair books. Remember right away, or better yet, sketch out the order of arrangement of such washers installed on your existing unit.

- Now we turn the unit upside down with the back cover, unscrew it using a wrench with 8 nuts (there are four of them)

- We take out the four pins that have become free and release the front part of the case

- In this part of the cover there is a “front” bearing, which is secured by plates (this bearing on the drive side fails more often; the cause of its failure may be overtightening of the drive belt)

- We remove the plates by unscrewing the nuts, then knock the bearing out of its seat using the adapter

- A wooden board, which is the same size as the diameter of the bearing to be knocked out, is ideal for this (you can use a soft metal attachment of a suitable size)

Covers removed from the unit

- Now we need a vice: screw the nut onto the rotor shaft, clamp the unit, or more precisely, what has not yet been disassembled in the vice

- We tear off its back cover with a sharp upward movement from its seat

- Now that we have removed the generator covers, we have the rotor shaft itself, on which the “rear” bearing is located in the upper part, clamped in a vice, as we see in the photo below.

The rotor shaft is clamped in a vice, the “rear” bearing can be removed

- To remove the bearing from the shaft, we need a special puller

- We put the puller on the bearing and pull the bearing off the shaft

Special bearing puller

- Now we have two bearings in our hands: “front” (small) and “rear” (larger) - look carefully at their markings, buy the same ones exactly

Rear and front bearings

Important: As practice shows, when purchasing new bearings, it is necessary to remove the old ones. And then buy new similar ones in the store. And such tips from sellers like: “they are all the same” or “if you have an old-style generator, definitely take these” - are often erroneous. Or rather, almost always. We recommend that, in order to save your time, money and nerves, it is easier to remove the bearings and select similar ones based on their factory markings.

- This advice applies to the rectifier unit (diode bridge), which is installed in the back cover

- If damage or metal oxide is visible on the block, we recommend that you remove it without further hesitation (it is secured with four nuts to the inside of the cover) and immediately purchase and install a new one

How to install and connect a VAZ 2108 generator - step-by-step instructions

Installation of a new generator is carried out in the reverse order. Take a close look at the condition of the bottom bolt. If there is damage to the threads, it is better to replace it.

It will be easier for you to repair the generator later. When installing, pay special attention to belt tension. If it is not tensioned enough, your battery will not charge well. But if you tighten the belt too much, the bearing in the front cover will be destroyed. As a result, you will get an unpleasant whistle when the engine is running. And the reason for this is the appearance of play in the bearing.

The installation of the generator on the VAZ 2108 must be carried out in such a way that even the slightest distortion does not occur.

Assembling the unit

We are starting to assemble a generator for the VAZ 2108, the repair has reached its final stage:

- Assembly begins by pressing the rear bearing back onto the shaft. We perform this action using a small board and a hammer.

- Place the bearing on the shaft with two or three strong blows

- If you removed the rectifier unit, return it to the same four studs for securing the rectifier unit, located in the back cover

- Now we install the back cover itself back on the rotor so that the bearing completely “sits” into the intended seat located in the back cover

- To simplify the procedure, you can use a hammer and hit the cover with gentle blows through a wooden block to “plant” it completely on the shaft

- In our front cover we replace the small (front) bearing and secure it with plates

- We take the unit out of the vice and before putting on the front cover, put a spacer ring on the shaft, which should be located between the front ball bearing and the thrust recess located on the shaft

- We put the front cover on, tighten the nuts on the studs “crosswise” so that they are tightened evenly

- We install the key into the recess of the rotor shaft, then insert the impeller and tighten it with a nut

Now the generator is assembled, now it’s convenient to install the relay with brushes in place.

Returning the unit to its place

The installation procedure is the reverse process of removal:

- We insert it into the mounting bracket

- With one hand we press on the motor from above, and with the other hand, from the side of the front right wheel, we insert the bracket mounting bolt into place

- Screw on the bolt nut, but do not tighten it

- Then we secure the dust protection using self-tapping screws.

- Now we put the drive belt on the unit pulley and install the belt tensioner bar

- We tighten the drive belt to the desired deflection value (1 - 1.5 centimeters) and at the same time tighten the nut located on the tensioner plate

- Now we tighten the nut located on the mounting bracket of our generator.

That's it, the unit has been installed successfully. For VAZ, the generator repair has been completed. Make sure once again that the minus terminal is removed from the battery and connect all the wires back to the generator. Remember that: paired wires are attached with a nut to a stud located on the back cover of the generator, and a single wire is connected using female-male connectors. Now you can connect the negative terminal to the battery and start the engine. If the work was done correctly, then the repair of electrical equipment (generator in particular) on the VAZ 2108 is completed and is no longer a problem for you. The power source began to produce the required voltage for the vehicle to operate. To be completely sure of proper operation, you can check the voltage it produces with a voltmeter. If not everything is clear about the design of the generator, then look for repairs of the VAZ 2108 in the electrical equipment section or use the training video.