Generator device

Before talking about the symptoms of a breakdown, it would be useful to remember how the alternator works and functions. This part consists of an aluminum housing, inside of which there is a stator coil and a rotor on bearings. The rotor shaft is driven by a drive belt from the engine crankshaft. The alternating current taken from the stator winding is converted into direct current by a powerful diode rectifier. The carbon brushes transmit control current from the voltage regulator to the rotor. Thanks to its operation, the generator constantly produces about 13.8–14.7 volts of output, regardless of engine speed. This current is used to power the vehicle’s on-board network and serves as a source of recharging the battery. A breakdown of the generator or its incorrect operation leads to rapid discharge of the battery or its complete failure, as a result of which the machine is de-energized and is unable to move independently in space.

Common battery problems:

- short circuit of battery electrodes/plates;

- mechanical or chemical damage to the battery plates;

- cracked battery case due to impact or improper installation;

- chemical oxidation of battery terminals. The main reasons for the above malfunctions are:

- gross violations of operating rules;

- expiration of the product;

- Various manufacturing defects.

It is very useful for the driver to know the main causes of generator failures, methods for eliminating them, as well as preventive measures to prevent failures.

Generator faults

All generator malfunctions can be divided into two groups - mechanical and electrical. The first includes destruction of the device body, breakage of fasteners, bearings, brush pressure springs, overrunning clutch or pulley and other parts, and the second includes breaks and short circuits of the winding, breakage of the diode bridge and relay regulator, wear of the carbon brushes. Common signs of impending generator trouble include dim or flickering headlights, trouble starting the engine, and a blinking or persistent warning light on the dashboard.

The car's battery and alternator work in tandem. In this case, it is the generator that is the main source of power for the electrical network, while the battery acts as a backup source of energy and is needed primarily to start the engine and power electronic devices when the engine is not running.

Generator malfunctions manifest themselves in different ways, but in most cases they do not occur suddenly; the driver has time to notice the impending breakdown and minimize troubles.

Difficulty starting the engine

One of the sure signs of a generator breakdown is an uncertain start of the car engine. When the alternator stops working correctly, the battery does not receive enough charge and is unable to crank the starter normally. A discharged battery is usually a direct consequence of a generator failure. In this case, the battery may not only receive less charge, but also, on the contrary, be recharged.

This happens due to a breakdown of the electronic relay-regulator unit: the generator produces more current than required, and this leads to boiling off of the electrolyte and rapid failure of the battery. Note that many modern cars stop starting when the voltage in the on-board network drops below 12 volts. In this case, the battery is able to crank the starter.

Worn or stuck brushes

Brushes are needed to supply power to the constantly rotating generator rotor. As a rule, together with the relay-regulator they are one separate part. The brushes are made of conductive graphite and are spring-loaded to ensure reliable contact with the commutator. If the contact between them and the slip rings is poor (or absent), the generator will not be able to work normally (or will not work at all).

The most common problem with brushes is their natural wear. When the graphite wears away, the brushes are simply not long enough to power the rotor. As a rule, at the initial stage, this malfunction manifests itself in the form of abundant sparking inside the generator. Due to wear, the brushes do not always come into close contact with the commutator, and sparking occurs between these parts.

The second characteristic malfunction of the generator is associated with the so-called freezing or sticking of the brushes. This happens due to graphite dust or other dirt getting into the brush guides. The latter become motionless, and therefore can no longer be pressed by springs to the collector. As a result, increased sparking is first observed, and then the generator stops generating electricity altogether.

Along with sparking, critical wear or sticking of brushes can be detected by voltage drops in the on-board network (if there is a voltmeter in the cabin) or by a warning lamp on the instrument panel. It should also be noted that this malfunction can be identified visually without removing the generator from the car. The brush assembly, as a rule, can be easily removed together with the relay regulator, as it is secured with two screws. If the brushes are worn out, then this is only a replacement. Sticking can be eliminated by cleaning the guides of graphite and other dirt.

Dim or flickering headlights

The second symptom becomes noticeable in the dark. The car's headlights dim or change in brightness depending on engine speed and the load on the electrical system. This behavior of the lighting devices clearly hints that an urgent inspection and diagnosis of the generator and its drive belt is necessary - the device cannot cope with the load placed on it. Problems can also be noticed by the dashboard lighting and interior lighting devices - they all change brightness in the same way.

Checking the combined relay-regulator

Checking the VAZ 2110 voltage regulator

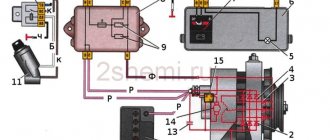

To perform the corresponding check, it is necessary to assemble the circuit shown in the figure. To do this, use a charger or power supply with an adjustable load (it is important that it be used to regulate the voltage value in the circuit), a 12 V light bulb (for example, from a turn signal or headlight, with a power of 3.4 W), a multimeter, and the regulator itself voltage (this can be from a Bosch, Valeo or other generator). It is advisable to have the wires used for switching with “crocodiles”.

Checking the voltage regulator of the generator 37.3701: 1 - battery; 2 — ground terminal of the voltage regulator; 3 - voltage regulator; 4 – terminal “Ш” of the regulator; 5 — output “B” of the regulator; 6 — control lamp; 7 — terminal “B” of the voltage regulator.

If you assemble a circuit in which the voltage is at a standard value of 12.7 V, then the light bulb will simply glow. But if you use a voltage regulator to raise its value to 14.14.5 V, then if the relay is working, the light should go out. Otherwise the regulator is faulty. That is, when the voltage reaches 14.14.5 V (depending on the model of the machine and, accordingly, the regulator) and above, the light goes out, and when it drops to the same level, it lights up again.

Checking the VAZ 2107 voltage regulator

Checking the voltage regulator on VAZ 2108/2109 cars

Until 1996, a VAZ 2107 with a 37.3701 generator was equipped with an old-style voltage regulator (17.3702). The verification procedure is given above. After 1996, a more modern generator of the G-222 brand was used (integrated regulator RN Ya112V (V1).

Read also: Boiler piping with natural circulation

As you can see, the verification algorithm for all regulators is almost the same. The only difference is the cutoff values when the relay is activated.

The icon on the dashboard is lit

A lit or flickering battery icon on the dashboard indicates that your car has serious problems - the battery is not charging properly. The on-board system independently warns the driver that the car will not drive for a long time. As a rule, we are talking about several tens of kilometers - the car will be able to drive exactly until the battery is completely discharged and stops producing a spark on the spark plugs. In such a situation, much depends on the condition of the battery itself, as well as on the number and power of the consumers involved. Try to turn off everything unnecessary, including music, headlights, electric heating and even interior ventilation, and go to the nearest car service center or turn off the engine and call a tow truck. Many modern batteries become completely unusable after the first deep discharge, which means that the services of a tow truck can pay off.

How to check the generator voltage regulator

A modern regulator, combined with a brush assembly, is used on most foreign and domestic cars. First, let's evaluate access to the generator. If it is difficult to access and inconvenient, then it would be better to remove it from the car. If access is free, then remove the relay from it without removing the generator. But before this, you must remove the negative terminal from the battery.

The regulator is attached to the generator from the rear cover side, usually with two bolts. We unscrew them and carefully, so as not to damage the brushes, remove it, having first disconnected the wires from it.

For further testing, we will need either a power supply or a charger, a 12-volt calvania lamp. The main thing is that you can increase and decrease the voltage from 10 to 16 volts. If you use a charger for testing, you will also need a battery. The fact is that many chargers do not work without it.

We connect the charger to the battery in normal mode. Additionally, we connect a multimeter and two wires to the battery terminals. One is positive, the other is negative. And we connect them to the relay regulator. The positive terminal of the regulator is a plug. The downside is a metal plate under one of the mounting holes. We connect the light bulb to the brushes with wires. The stand is ready, you can start testing. The power supply is connected in the same way, only without the battery.

We connect the charger to an external network and turn it on. The load regulator knob should be at the minimum level. We begin to slowly increase the tension. At the same time, the intensity of the light bulb should gradually increase. With a load of 12 volts or more, it should burn at full heat. We continue to gradually increase the voltage until the light goes out or the load reaches 15 volts. If the regulator is working properly, the light should go out at a voltage value of 14.2 -14.5. When the load decreases, the light will light up again.

If the light bulb goes out to 14 volts, or a voltage of more than 14.8 volts is reached, and the light bulb is still on, then such a regulator must be changed.

Checking a separate generator voltage regulator

A free-standing stabilizer is checked in the same way. Basically it is mounted on the body in the engine compartment. But sometimes on the generator cover. In any case, unscrew it and connect it to the stand. Let, for example, it be a Y112 V type stabilizer.

the positive wire to terminals “B” and “C”, and feed the negative wire to the housing. We connect the control lamp to terminals “B” and “W”. Next, we do everything exactly the same as with the combined stabilizer. We gradually raise the load; when it reaches 14.5 volts, a cutoff should occur. If there is no cutoff, then change the regulator.

Checking the outdated 591.3702−01

This obsolete type of relay was installed on almost all rear wheel drive vehicles. It is classified as free-standing. Always attached to the body of the engine compartment. The connection diagram for testing is slightly different from that described above. The actions and essence of the check remain the same.

There are only two contacts here. The markings are made with the numbers “67” and “15”. Contact numbered “67” is the negative terminal. Accordingly, “15” is a plus. We fix the negative wire from the charger to the device body. We attach the positive one to terminal 15. We connect the wires of the control light: one on the body, the second to terminal “67”. Our stand is ready for testing.

How to check the k1216en1 regulator with a multimeter

And finally, a few words about the k1216en1 relay. This regulator was installed on rear-wheel drive and front-wheel drive VAZs with injection engines. If we take into account the fact that there are many such cars in use throughout the post-Soviet space, we cannot ignore it.

This regulator belongs to a combined relay with a brush assembly . Its preliminary and main verification is carried out according to the method described above. There are no special differences.

Drive belt whistles

An unpleasant whistle is often heard from under the hood of a cold car. It occurs when the drive belt driving the generator rotor is loose. It is necessary to establish the cause of low belt tension and eliminate the problem. Otherwise, the generator will not rotate at the proper speed and charge the battery properly. On many modern cars, the same belt drives other devices, such as the power steering pump and air conditioning compressor, and is tensioned automatically. On simpler models, an auto-tensioner is not provided by the design - over time, the belt stretches and requires manual tension adjustment.

The belt overheats or breaks

The characteristic smoke and unpleasant odor emanating from the drive belt, or the peeling of tracks and pieces of rubber from it, is a sign of jamming of some kind of attached unit (including a generator) or idler rollers. On some models, a broken drive belt not only leads to the generator turning off, but also causes much more serious troubles (the broken pieces can get under the timing belt, which will lead to irregular valve timing or engine failure). If the belt overheats or spontaneously breaks, check the alternator pulley - it should rotate easily and not warp under load.

Types of existing relay regulators

A century has passed since the advent of automobiles. During this time, the regulators changed their filling and appearance more than once. Let us first consider modern stabilizers, and then outdated ones.

There are two types of regulators today:

built-in - these are attached directly to the generator housing and are produced combined with the brush assembly;

- separately fixed - attached to the car body.

Both types have non-separable housings and cannot be repaired. If the output voltage on the generator deviates from normal, and there is confidence that the stabilizer is to blame, then in this case we simply replace it with a new one.

Ringing or rustling sound from under the hood

Rolling bearings are installed inside the generator. These parts experience high loads and operate at elevated temperatures. Their resource is relatively small. After some time, these parts wear out heavily and lose lubrication, which leads to noise, misalignment and jamming of the rotor, or complete destruction of the bearings. Another cause of noise may be a worn overrunning or damper clutch. It also works for a relatively short time and can become deformed and stop performing its function. Both faults cannot be eliminated without removing and disassembling the generator.

Electric hum

The nature of extraneous sounds becomes somewhat different in the event of a short circuit in the stator winding. It manifests itself with a characteristic electric howl, similar to that which comes from the electric motors of public transport - trolleybuses, trams or electric trains.

When going on a long trip, especially to sparsely populated and hard-to-reach places, make sure that your car’s generator is in good working order. Its breakdown is no less insidious than a gearbox malfunction or a broken timing belt. You simply won’t be able to solve the problem on your own without special tools, spare parts and experience. Therefore, make it a rule to troubleshoot and repair the generator at least once every 100 thousand kilometers and remove it from the car. You can do this yourself, but it is much more convenient and faster to use the services of special companies. The help of professionals in this matter will not be superfluous.