Oil pump and its replacement

Due to the oil pump, oil circulates in the engine under a certain pressure. Thus, on VAZ 2109 cars an oil pump is installed to lubricate all moving parts. Then, when the mechanism wears out or does not rotate, the pressure of the composition in the engine decreases, and this can cause damage or breakdown of the engine; urgent replacement is required. On a VAZ 2109, the oil pump can be easily replaced on your own.

Note! The first signs of problems may be a decrease in oil pressure or a knocking sound in the engine.

VAZ 2109 oil pump and its removal

Almost all engines require only 0.7 at/1 thousand revolutions. An increase in pressure will be observed when the engine is cold. The decrease will occur gradually as the engine warms up, then the oil flow becomes significantly thinner. Normal pressure with a warm engine is considered to be 2.1-3.1 at. If signs of malfunction appear, the first thing to do is:

- stop and turn off the engine;

- Check the oil level on the dipstick; at the minimum mark, you need to add the composition, bringing it to the maximum;

- start the engine;

- Continuous lighting of the warning light, the indicator not “sliding” to the normal limit, or continued noise in the engine may indicate problems with the oil pump.

Note! Naturally, there are other reasons, for example, a malfunction of the pressure sensor, oil filter, pressure indicator or oil receiver.

Replacing the oil pump on a VAZ 2109, 2108

October 22nd, 2015 Admin

The power plant of a modern car is equipped with several pumps. They can be called “hearts”, each of which pumps a specific liquid - fuel, antifreeze or oil. Today we will talk about one of them – oil. Since it is impossible to diagnose this unit without partially disassembling the motor, the condition of the pump is determined by indirect signs.

If it malfunctions, events most often unfold as follows: the oil pressure warning light lights up on the instrument panel. The car enthusiast checks its level and sees that it is normal (or adds oil if necessary), but the lamp does not even think of going out, which leads to the need to troubleshoot.

There can be many reasons why the light comes on, but most likely the oil pressure sensor is broken or something is wrong with the pump. In this article we will tell you how to correctly replace this unit on a VAZ-2109 and other cars of this family.

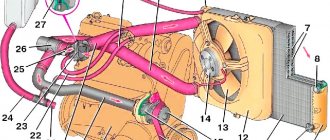

Where is the oil pump on the VAZ 2109

Its location is behind the crankshaft pulley. As a result of this circumstance, it will not be possible to get to it without removing some parts, in particular, the pulley itself and the oil pan. Below is a photo showing the oil pump in its seat.

When to change the oil pump

If the pump fails, the following things happen:

- The oil pressure drops, as a result of which the corresponding control light on the dashboard lights up.

- Oil consumption increases, and it constantly has to be topped up (however, this does not always happen).

How to replace the oil pump on a VAZ 2109, 2108, 21099

Tools:

Before you begin the replacement, prepare all the necessary tools. This is a set of wrenches, a set of sockets, a universal joint and an extension. If the pump is replaced with a new one, then buy the necessary spare part (its catalog number is “2108-1011010″). Also, drive the car into a hole or overpass, otherwise it will be very difficult for you to get to the pump.

Removal:

1) Remove the crankshaft position sensor. It should be noted that this is only relevant for an injection engine; if the engine is carburetor, skip this point.

2) Drain the engine oil.

3) Next, remove the toothed pulley.

4) Now you can remove the oil pan. Then find the oil receiver and unscrew the bolts that secure it, and then remove it.

5) Take the correct size socket and extension and use them to remove the 6 bolts that secure the oil pump to the engine block. Be extremely careful as there are washers under the bolts and it is very important not to lose them.

6) Ideally, after step 6, the pump should be removed, but in practice this does not always happen. If this is your case, take a thicker screwdriver, insert it between the pump and the main bearing and gently wiggle it (remember, do not damage the bearing!).

7) Carefully remove the oil pump.

Installation:

1) Before you install a new unit, follow one very important procedure. You need to find the drive gear and turn it like this... (continued below)

2) So that its position coincides with the special flats located on the crankshaft.

3) Now take some engine oil and lubricate the front crankshaft oil seal (more precisely, its working edge).

4) Is the oil seal lip lubricated? Install the pump onto the crankshaft. For this you will need an ordinary pencil. It will be needed to tuck the oil seal into its place (this must be done strictly with the unsharpened end of a pencil!). After this, screw back the 6 bolts securing the oil pump, not forgetting the washers.

5) Now reassemble the remaining parts in the reverse order of removal. Archive important!

Since you will have to remove the timing belt to get to the timing pulley (and at the same time the radiator along with a number of other parts), be extremely careful with the crankshaft when changing the pump. It must not be allowed to rotate at a significant angle, otherwise the pistons have every chance of meeting the valves, as a result of which they may become deformed, and this will lead to dire consequences.

Where is the VAZ 2109 pump located?

An automobile pump consists of a metal cast body, which is made of aluminum or cast iron, a moving shaft, bearings and an impeller. The tightness of the unit is ensured by a special seal. Under the action of rotation of the impeller, pressure is created in the mechanism, pushing out the antifreeze, which does its useful work by heating up in the channels of the cooling system and cooling in the radiator to again enter the engine cooling jacket. This process is regulated by a special device - a thermostat.

The pump is located under the timing housing, slightly below the camshaft gear.

Checking the oil receiver

Oil pump VAZ 2109

As a rule, the oil receiver tube is equipped with a screen, at the end of which there is a mesh to prevent the penetration of large debris. Through this element, oil is sucked into the pump from the crankcase. Pump wear can occur due to carbon, contaminants, or other microscopic particles. To check the oil pickup you need:

- remove the oil pan from the engine;

- The element is replaced when it becomes clogged or broken;

- It is quite difficult to clean the oil receiver, since small debris may not be noticed.

Checking the pressure sensor

Oil pump cover VAZ 2109

If there is no unusual noise coming from the engine and the oil level is normal, the warning light may still sound indicating low oil pressure. Then, most likely, the problem will be with the oil pressure sensor. This sensor is usually located on the motor block. Inside the device there is a spring-loaded diaphragm, as well as an automatic switch diaphragm, which is highly sensitive to pressure. This switch is designed to close the low pressure warning light circuit when the pressure drops below a certain level. Reasons for sensor failure:

- if the diaphragm stops moving;

- when the switch is jammed;

- if the hole through which oil gets inside the sensor is clogged;

- in case of unsatisfactory connection, which may be caused by corrosion, connector or wiring failure.

Attention! If the car is equipped with an electronic pressure gauge, a small rheostat will be placed inside the sensor, which, when this diaphragm moves, sends a variable voltage signal.

To check the pressure sensor, you need to connect a mechanical type pressure gauge to the pressure port located on the engine. If the device shows a satisfactory pressure reading, and the sensor gives a corresponding signal, most likely the problem lies in the sensor itself. And, conversely, if the indicators are unsatisfactory, this indicates that the pump is worn out or the oil receiver is clogged.

Disassembly and repair

After completing the dismantling work, you can proceed in two ways:

- Replace the old pump with a new one;

- Repair the old oil pump.

Repair allows you to identify worn elements and replace them with new ones, which will restore functionality. If the breakdown is more serious than simple wear and tear of consumables, the optimal solution would be to completely replace the oil pump.

To disassemble the pump, follow the instructions.

- Divide the pump into two parts. To do this, we have already unscrewed 6 bolts securing the cover to the body and used a screwdriver to pry off this cover. It came out of the pins on the body. So we remove the element and put it aside.

- Inside the pump housing there are driven and drive gears, which need to be removed and placed aside for now. Then we will check their condition.

- Next, the pressure reducing valve is removed. To do this, first unscrew the valve plug and remove the spring from the hole, and then the valve.

- In some cases, problems may arise with removing the valve. If you encounter this situation, gently tap the oil pump body against a piece of wood or use a wooden cone-shaped pin. It is inserted into the valve hole, the valve is hooked and removed.

- After disassembling your oil pump on the VAZ 2109, thoroughly wash all its components using clean kerosene. Don't forget to wipe the parts dry afterwards.

- Check the condition of the cover and body of your pump for mechanical defects, chips, cracks.

- Pay special attention to the landing spots of the gears, where there should be no signs of wear or other mechanical defects. If they are, the pump will have to be replaced.

In many ways, the performance and maintainability of the old oil pump depends on the results of checking the characteristics of the cover and body of the device. It is necessary to take measurements of the gaps.

Check location

Requirements

Driven gear seat diameter

The diameter may increase as the pump operates and friction occurs. The normal diameter of this place for the VAZ 2109 is 75.1 millimeters. If there is a deviation in the direction of increasing diameter, the pump must be replaced.

Thickness of the mating wall

Under normal conditions, this parameter is 3.4 millimeters. If the gap is less than specified, the pump is replaced completely

Drive gear thickness

The normal value is 7.42 millimeters. When the size is reduced, the pump goes to a landfill, and a new one is installed in its place.

Driven gear thickness

For her, the normal parameter is a thickness of 7.35 millimeters. As with the drive gear, deviation from the norm means replacement

Drive gear axial clearance

To measure, take a metal ruler and feelers of 0.12 and 0.15 millimeters. The gap is checked as follows: a gear is placed in the pump housing and a ruler is placed on top with its end. The gap between the end of the ruler and the plane of the feeler gauge is measured. For the drive gear, the gap is 0.12 millimeters

Features of operation and malfunction of oil pumps

In wet sump lubrication systems (the oil is in the engine sump), the oil pump is located between the oil receiver and the filter at the front of the engine. For dry sump systems (the lubricant reserve is in a special tank), the pump is located between the oil tank and the cleaning filter. In some car models, it may also be located near the additional oil cooler of the air cooling system. It is easy to find by focusing on the oil pump drive gear connected to the crankshaft.

The service life of the pumps is quite long - several hundred thousand kilometers. The main requirements for the correct operation of this unit are the use of high-quality oil, regular filter cleaning, as well as timely topping up and replacement. Incorrect engine starting, especially at low temperatures, as well as coolant getting into the oil can have a negative impact.

The most common problems are:

- Wear of gear teeth or rotor surfaces.

- Increasing the gaps between the main working elements and the body.

- Surface corrosion.

- Failure of the pressure reducing valve (jamming, untimely operation).

- Malfunction of the oil pump drive.

Oil pump failures lead to disruption of lubricant supply to the main engine components. At the same time, both too high and low pressure are negative for the motor. If a malfunction is detected in the oil pump, in most cases it is completely replaced with a new one.

What kind of oil should I use and how much?

Often, G8 owners fill in universal 5W-30 and 5W-40. For example, you can buy MOTUL 8100 X-cess 5W40 - a good oil.

When purchasing, focus on the quantity of 4 liters because... the engine immediately consumes about 3.5 liters. You also need to leave at least 0.5 liters for daily monitoring and, if necessary, for topping up the level.

For scrupulous owners, below is a table that will help you choose the viscosity and brand of engine oil. For example, if you live in the middle geographical zone, take a closer look at the universal (all-season) viscosity.

| Year | Viscosity SAE all season from +25 to -25 °C | winter from -35 to 0 °C | summer from 0 to +35 °C |

| 5W-20 5W-30 10W-30 10W-40 | 20W-30 20W-20 20W-40 25W-30 |

SGCD-IImineral, hydrocrackingLukoil, Valvoline, Kixx, G-Energy, Rosneft, CONSOL198515W-20 10W-30 10W-20

| 5W-20 5W-30 10W-30 | 20W-30 20W-20 25W-30 |

SGCD-IImineral, hydrocrackingXado, ZIC, Lukoil, Valvoline, G-Energy, Rosneft198615W-20 10W-30 10W-20

| 5W-20 5W-30 10W-30 | 20W-30 20W-20 25W-30 |

SGCD-IImineral, hydrocrackingLukoil, Valvoline, Kixx, G-Energy, Rosneft198715W-30 15W-20 10W-30 10W-20

| 5W-20 5W-30 10W-30 | 20W-30 20W-20 25W-20 25W-30 |

SGCD-IImineral, hydrocrackingG-Energy, Rosneft, Mannol, Lotos, Total, AGA198815W-30 15W-20

| 5W-20 5W-30 10W-30 | 20W-30 25W-20 25W-30 |

SGCD-IImineral, hydrocrackingKixx, G-Energy, Rosneft, Mannol, Lotos, Total, AGA198910W-30 10W-40 15W-30 15W-40

| 5W-30 10W-40 10W-30 | 20W-30 25W-20 25W-30 |

SGCD-IImineral, hydrocrackingMobil, Kixx, G-Energy, Rosneft, Mannol, Lotos, Total, AGA199010W-30 10W-40 15W-30 15W-40

| 5W-30 10W-40 10W-30 | 20W-30 25W-20 25W-30 |

SGCD-IImineral, hydrocrackingGt-Oil, Kixx, G-Energy, Rosneft, Mannol, Lotos, 199110W-30 10W-40 15W-30 15W-40

| 5W-30 5W-40 10W-40 | 20W-30 20W-40 25W-20 25W-30 |

SGCD-IImineral, hydrocrackingGt-Oil, Kixx, G-Energy, Rosneft, Mannol, Lotos199210W-30 10W-40 15W-30 15W-40

| 5W-30 5W-40 10W-40 | 20W-30 20W-40 25W-30 |

SGCEmineral, hydrocrackingMobil, Kixx, G-Energy, Rosneft, Mannol199310W-30 15W-30 15W-40 5W-30

| 5W-30 10W-30 | 20W-30 25W-30 |

SGCEsemi-synthetics, mineral water, hydrocrackingGt-Oil, Kixx, G-Energy, Rosneft, CONSOL199410W-30 10W-40 15W-30

| 5W-30 10W-30 | 20W-30 25W-30 25W-20 |

SGCE semi-synthetics, mineral water, hydrocrackingMobil, Valvoline, Kixx, G-Energy, Rosneft, Mannol199510W-40 15W-30 15W-40

| 5W-20 5W-30 10W-30 10W-40 | 20W-30 25W-30 |

SGCE semi-synthetics, mineral water, hydrocracking Kixx, G-Energy, Rosneft, CONSOL199610W-30 10W-40 15W-30 5W-40

SHCF-4semi-synthetic, mineral waterMobil, Valvoline, Kixx, G-Energy, CONSOL199710W-30 10W-40 15W-30

| 5W-30 5W-40 | 20W-40 20W-30 25W-30 |

SHCFsemi-synthetics, mineral waterValvoline, Kixx, G-Energy, Rosneft, CONSOL199810W-30 10W-40 15W-40 15W-30

| 5W-30 5W-40 | 20W-40 20W-30 25W-30 |

SJCFsemi-synthetics, mineral waterMobil, ZIC, Lukoil, Valvoline, Rosneft, Mannol199910W-30 15W-40 15W-30

| 5W-20 5W-30 5W-40 | 20W-40 20W-30 25W-30 25W-40 |

SJCG semi-synthetic, mineral water Xado, ZIC, Lukoil, Valvoline, Kixx200010W-30 10W-40 15W-40 15W-30

| 5W-20 5W-30 5W-40 | 20W-40 20W-30 25W-30 25W-40 |

SJCG semi-synthetics, mineral water ZIC, Lukoil, Valvoline, Select, Kixx, G-Energy, Rosneft, Mannol, Lotos200110W-30 10W-40 15W-40 15W-30

| 5W-20 5W-30 5W-40 | 20W-40 20W-30 25W-30 25W-40 |

SJCG-4semi-synthetic, mineral waterMobil, Rosneft, Select, Mannol, Lotos200210W-30 10W-40 15W-40 15W-30

| 5W-30 5W-40 0W-30 | 20W-40 20W-30 25W-30 25W-40 |

SJCHsemi-synthetic, mineral waterMobil, Select, Mannol, Lotos200310W-40 5W-40

| 5W-40 | 20W-40 25W-30 25W-40 |

SHCH-4 semi-synthetic, mineral water Mobil, ZIC, Lukoil, Valvoline, Rosneft, Select200415W-40 10W-40 5W-40

| 0W-30 5W-40 5W-30 | 20W-30 20W-40 25W-30 |

SJCH-4 semi-synthetic, mineral water Mobil, Lukoil, Valvoline, Rosneft, CONSOL

Oil pump repair

Oil pump VAZ 21093

You can disassemble the mechanism and identify signs of wear or damage yourself. Typically, wear is observed in the pump housing itself, which causes excessive growth of the gaps between the housing and the gears. To eliminate such a defect, you will have to either change the body or weld it, and then adjust the wear area. It's best to change the oil pump.

Replacement

Oil pump for VAZ 2109

Before replacing the pump, you need to make sure that the mechanism you are purchasing is actually suitable for the engine. If there are not enough throughput characteristics, the engine may starve of oil. When the unit is bolted to the bottom area of the block, gaskets or O-rings must be used. If this detail is not provided or the seal is installed incorrectly, an oil leak may occur.

Oil pump for VAZ 2109

Note! It is not recommended to use seals twice, even if the products are made of rubber.

You can identify the malfunction of the mechanism, as well as replace it, based on videos and photos at home with your own hands. This is not a complicated procedure, so the simplest instructions will help. The main thing is to choose the right replacement part; its price must correspond to the quality.

This is interesting: Do-it-yourself auto glass repair

Oil pump wear

Oil pump for VAZ 2109

The oil pump is the only engine element that can be treated with unfiltered oil. Before you understand why an oil pump wears out, you need to know how it works and what it reacts to. So:

- If there are worn mechanisms inside the mechanism or large gaps between the housing and gears, there may be a pressure leak. Thus, the normal operating condition of the engine is not ensured.

- The oil composition from the crankcase is absorbed by gears rotating inside the housing, then it passes into the oil receiver, and only then into the pump itself. Through the pump, the oil enters the oil filter under a certain pressure. If it is cold and the stream is thick, then the bypass valve opens easily and allows the unfiltered mixture to pass through without hitting the filter. Due to this, a cold engine will develop good oil pressure until it warms up and the jet thins out.

What to do if a breakdown occurs?

If such a malfunction occurs to you, then you need to perform the following manipulations:

- Stop and turn off the engine.

- Wait until all the oil that is poured into the engine flows back into the sump. Check the level. If it is below normal, then you need to top it up.

- Start the engine.

- Pay attention to the control lamp - if it still lights up and extraneous noise appears, then this is clearly a breakdown of the oil pump.

In some cases, the oil receiver mesh may become clogged. To be fair, it is worth noting that the pump is a mechanism in which there is nothing to break - it is the body and two steel gears. They will be able to “survive” even a tenfold increase in loads and long-term operation without lubrication. But the oil receiver often gets clogged, and lubricant simply does not flow into the pump.

Design

Oil pump VAZ 2109

Today there are three types of pumps:

- 2-gear pumps, in which one gear is connected to a shaft, which starts working from the intermediate or camshaft of the VAZ. This pump is installed inside a sump located in the lower area of the cylinder block. Typically, the rotation speed of the element is ½ the rotation speed of the motor.

- A gerotor pump has a rotating small gear inside an outer gear. This pump is located in the lower area of the motor in the sump.

Old style oil pump

- The internal pump is often installed on the front cover of the engine. It begins to function from the crankshaft. Structurally, such a mechanism is similar to a gerotor mechanism, but in this situation it replaces the front damper of the engine. As a result, it is possible to generate higher oil flow with higher pressure.

Dismantling

Removing the pump yourself is easy. Well, you are completely capable of doing your own repairs.

- De-energize the car by removing the negative terminal from the battery.

- Loosen the generator mounting bolts and remove the belt.

- Prepare a clean container by draining the oil from the crankcase into it. Next you will need to remove the engine protection and the oil pan.

- Remove the camshaft drive timing belt.

- Now that the belt is removed, do not, under any circumstances, turn the crankshaft and camshaft. The role of the oil pump in the design of the VAZ 2109 is difficult to overestimate. Replacing the engine oil and oil filter on a VAZ 2110. If it fails, the operation of the vehicle must stop completely. Otherwise, you will damage the valves by hitting them with the pistons.

- Remove the crankshaft pulley by using 2 flathead screwdrivers and pulling it off the shaft. If the key does not hold well in its seat, it is better to remove it too.

- Next in line for dismantling is the oil receiver. To remove it, you need to unscrew two fastening bolts located on the main bearing , as well as one fastening bolt connecting the oil receiver to the pump (oil).

- Remove the pump, held in place by 6 bolts.

- After unscrewing all the bolts, carefully move the oil pump away from the main bearing , then, with a measured soul, remove the oil pump.

Read:

Dismantling the device

Types and design of pumps

The basic operating principle of all engine oil pumps is the same: suction of engine oil from the oil pan (oil tank) and injection into the lubrication system lines. Structurally, these can be gear, rotary and vane pumps with or without the possibility of forced adjustment of the pressure level. The way they are activated also differs.

Gear pumps

This type of mechanism is unregulated. This oil pump is driven from the engine crankshaft. In practice, this means that the pressure level directly depends on the engine speed. To ensure that the oil pressure in the discharge line of the lubrication system remains constant and does not exceed critical values, such oil pumps are always supplemented with a pressure reducing valve.

External Gear Oil Pump

Structurally, a gear pump consists of the following elements:

- Drive gear connected to the crankshaft.

- A driven gear driven by a drive gear.

- Sealed housing with discharge and suction channels.

- Oil pump pressure reducing valve - it is a plunger with a spring, which, when the pressure increases, is pressed out, opening the oil discharge channel.

- Seals (oil seals).

Gear pumps can be:

- With external gearing - the gears are located side by side and have external teeth. The disadvantage of this type is the difficulty of achieving a high level of compression, since this provokes an increase in specific pressures in the tooth engagement zone. And although the problem can be solved by using a special relief groove, pumps with such a groove are ineffective for a wide range of rotation speeds and at low speeds the performance will be very low.

- Internally geared - the drive gear has external teeth and is located inside the driven gear, the teeth of which are directed inward. The gears do not have a common axis and form a semicircular gap (cavity). This oil pump has a more compact size.

The principle of operation of a gear pump is very simple: lubricant enters through the suction channel, where it is compressed by gears and pushed out under pressure into the discharge channel. Internal gear oil pumps can also be equipped with a crescent baffle. It is installed between the rotor teeth in the area of maximum distance from each other. Thanks to this, the injection cavities are sealed and a higher operating pressure is ensured.

Rotary pumps for pumping motor oil

Rotary type oil pumps are similar to internal gear ones. However, instead of gears, oil compression is carried out using a stationary stator (larger diameter) and a movable rotor (located inside the stator). Such pumps can be unregulated (with a pressure reducing valve) or adjustable.

ICE rotary oil pump

Fixed rotary oil pumps are driven by the crankshaft and produce a level of pressure proportional to its rotation. Excess pressure, as in gear oil pumps, is relieved by a pressure reducing valve.

The difference between adjustable rotary pumps is the presence of a movable stator and a special adjustment spring. The adjustment process itself is based on the principle of changing the volume of the working cavity (the gap between the rotors), which is carried out by turning the stator. So, if the crankshaft speed increases, the engine consumes more oil, which leads to a decrease in pressure.

The spring reacts to this and moves the stator, changing the position of the driven rotor and changing the working cavity of the pump. The performance of the oil pump increases. An adjustable oil pump allows you to maintain a stable pressure level regardless of engine operating mode.

Vane or vane oil pumps

For some engine types, a vane or vane oil pump may be used. This design allows you to adjust performance based on engine speed.

A vane pump consists of a housing, inside of which there is a rotor and a stator. Their axes are shifted, due to which a crescent-shaped gap is formed in the lower part. The rotor is also equipped with movable plates inserted into special grooves. Under the influence of centrifugal force in the gap between the rotor and stator, they move out and form separate oil compression chambers. As the rotor rotates, the volume of the chambers constantly changes. When the volume increases, a vacuum is created and oil is sucked in. As the chamber decreases, the pressure increases and pumping occurs.

For what reasons does the pump break?

There are several reasons why the pressure reducing valve and oil pump on a VAZ-2109 fail:

- Excessively low oil pressure.

- Pressure sensor faulty.

- Low quality motor oil.

- Using a lubricant whose characteristics are not suitable for this vehicle.

- The safety or lubrication valve is faulty.

- The oil filter is dirty.

- Clogged oil receiver mesh.

Please note that it is necessary to remove and clean the pan - this will avoid blockages. Malfunction of the pump can be caused by the following breakdowns:

- If the rubber gasket is damaged.

- If the oil filter is not securely fastened.

- In case of excessive wear of parts of the VAZ-2109 oil pump.

- If a pressure reducing valve breaks down.

Possible malfunctions and their symptoms

The resource of the unit is quite large and is about 100,000 kilometers.

How can you ensure that the oil pump does not fail prematurely? The condition for it to last the allotted time is regular replacement and topping up of oil, and periodic cleaning. In this case, only high-quality oil mixtures should be used. However, the device may fail. The following may be “symptoms” of a breakdown.

- Decrease or increase in operating oil pressure. This is indicated by a corresponding light on the vehicle’s dashboard.

- Increased oil consumption.

The following malfunctions may be the causes of such manifestations.

Similar articles

How to correctly measure the oil level in a car engine: instructions, tips

- The oil receiver screen is clogged. If dirt gets in there, it prevents the normal passage of fluid, resulting in the failure to provide the required pressure. The problem is solved by cleaning.

- Valve failure. If the pressure relief valve fails, no relief occurs when the pressure increases significantly. Eliminate the malfunction by replacing the failed part.

- Mechanical wear. Both the internal surface of the housing and the moving elements (gears, rotor, stator) are susceptible to it. If there is minor wear, you can replace the part that has become unusable. If it is significant, the only way to solve the problem is to completely replace the device with a new one.

- Poor quality oil. Some brands of lubricants do not have sufficient fluidity. As a result, problems may arise. The solution is to drain the old one and pump in new lubricant.

- Leak in the crankcase. Due to mechanical damage to the crankcase, lubricant may leak. In this case, the pressure drops and the oil pump begins to work more intensely. Solve the problem by eliminating the cause of the leak.

Device

The device in question may schematically look like this:

Main elements of the oil pressure sensor:

- frame;

- wire connection location;

- thread for fixation in the cylinder block;

- diaphragm;

- a spring that resists deformation of the diaphragm;

- positive and negative contacts.

The oil pressure sensor is located on the left side on the back of the engine. This makes it fairly easy to diagnose or replace.

Where is the oil pump located?

The oil pump is located behind the crankshaft pulley, and therefore can only be clearly seen after removing the pulley from the engine.

The pump is attached to the cylinder block with six bolts, which ensure reliable fixation of the parts. When the oil pump fails, the following problems arise:

- the oil pressure level in the system drops sharply, which will be signaled by the sensor on the panel;

- Oil consumption will begin to increase significantly, which will entail the need to regularly add oil.