Check Features

You need to know how to check the operation of the generator on a car correctly, otherwise you may encounter the fact that a working part will be completely damaged. By following just a few simple rules, you can avoid unexpected breakdowns.

- Checking should be done using a multimeter.

- When diagnosing the condition of the valves, the current should have a voltage of no higher than 12 V.

- If it is necessary to replace the wiring, you need to select wires with an identical cross-section to the original ones.

- Before you start checking the generator, you need to make sure that all fasteners are connected correctly and that the belt tension is correct (read more about the generator belt tension roller). If necessary, the connections are brought to a working condition, and the belt is tightened or loosened.

The main condition under which it is possible to check a generator at home is to maintain its working condition. If the device is disassembled or has received damage that prevents it from functioning, then diagnostics will not allow us to determine the suitability of the device for further operation.

You may also be interested in our specialist’s article on how to remove a generator on a VAZ-2114.

There is a list of actions that absolutely cannot be performed during verification:

performance testing should not be performed using a short circuit or in other words “spark”; connect terminals of different configurations to each other, as well as connect terminal 30 or B+ to ground; diagnostics and operation of the generator should not begin without connecting consumers

It is especially important to observe this point when the battery is disconnected;

How to test a generator for performance at home

There are two main verification methods. One of them, although very old, allows us to reliably understand the performance of the device. The second works more subtly and is able to respond to minor system flaws. Using the second method, you can identify the slightest deviations in the operation of each element.

How to check a generator on a car without removing it and without having the necessary tools

There is an ancient way to identify a generator malfunction. It is very simple, but the result can only consist of two points:

- works properly;

- there are malfunctions.

Since anyone can check a car generator at home using this method, its popularity is fully justified. You need to start the engine and turn on the low beam. You need to remove the negative terminal from the working engine. If the headlights are on evenly and the engine is not out of sync, then the generator is working properly. If the internal combustion engine operates uncertainly or the brightness of the headlights changes, it is necessary to perform a more in-depth diagnosis, since the device is in a faulty state.

How to test a generator with a multimeter

Measuring with a special device will reveal even a small failure. There are a number of indicators that are considered optimal for all types of machines. The battery without load has a voltage in the range of 12.5 - 12.7 V. Since a load is placed on the battery when the engine starts, the normal readings are 13.8 - 14.8 V. After receiving the maximum load, the voltage reading should drop to 13 ,8. If this does not happen or the voltage drops even lower, then the generator will need to be checked.

Since not all car enthusiasts can ring the generator correctly, if a malfunction is identified, but if it is not possible to carry out diagnostics yourself, it is better to contact a service center. Experienced technicians will be able to suggest the reasons for the breakdown and explain why it was not possible to carry out the research on their own.

How to disassemble a generator

First, make two marks on the metal covers. This will help you later assemble the unit without problems.

- Press out the metal latches and remove the plastic cover.

- Use a Phillips screwdriver to unscrew the voltage regulator mounting screws.

- Unscrew the M10 nut. Then use a screwdriver to remove the screw and remove the capacitor.

- To remove the pulley, clamp the generator housing in a vice. Put a 21 socket on the nut, and through the hole in the head put a 8 hexagon on it. Only after you unscrew the nut can you remove the washer and pulley.

- Remove the four mounting screws to disassemble the generator into two parts.

- From the back of the housing, unscrew the screws securing the stator wire and diode bridge.

- Remove the diode bridge and the oscillator winding.

- Press the rotor out of the cover with your fingers along with the bearing.

- Carefully remove the bearing bushing.

- Take a puller and remove the bearing.

Disassembling the generator itself is much more difficult than removing the entire assembly from the car. To carry out repairs, you will need to diagnose the components of this unit.

First of all, pay attention to the brushes; they need to be changed if this element is visible from the holder by no more than 5 millimeters. If the bearings rotate tightly, then they are the defective element (a hum may be heard during operation)

The breakdown of the starter and rotor windings can be checked with an ohmmeter; the same device determines the performance of the capacitor. If nicks, scratches or burrs appear on the slip rings, they must be carefully sanded to a shine with fine sandpaper.

Fault diagnosis

Now that we have the brush holder with the regulator and the capacitor in our hands, replacing the generator brushes on the VAZ 2112 is carried out together with the brush holder and the relay regulator, but we need to make sure that the cause of the malfunction lies here, so we begin to look for the fault. So:

- It is necessary to clean the contact on the brush holder with sandpaper, they are marked in the photo below; poor contact in this place can also cause poor operation of the electric generator

Clean the contact highlighted in red

- We check the serviceability of the relay - voltage regulator, to do this we connect a 12 Volt light bulb to the brushes

- We apply a voltage of 12 Volts, “+” goes to the terminal, and “–” goes to the ground of the brush holder

- The indicator light should light up

We connect the light bulb to the brushes and apply 12 volts to the contacts of the relay-regulator

- Next, we apply a higher voltage: 15–16 Volts - the light should go out

- When the light is on or does not light up in both cases, this means that the regulator is faulty and needs to be replaced along with the brush holder

- We check the ease of movement of the brushes in the brush holder body and the height of their protrusion

- If they protrude from the body by less than 5 millimeters, replacement is needed; the brushes of the VAZ 2112 generator are changed along with the relay - voltage regulator and brush holder

Required brush height

- If you find chips and cracks on the brushes, then replace the generator brushes on the VAZ 2112

- To change the brushes alone, we pull out the holder from the relay housing - voltage regulator, to do this we press on terminal “B”

- Before installing the voltage regulator with new brushes in place, blow the installation socket on the generator from dust and wipe off oil

This completes the replacement of brushes on the generator for the VAZ 2112; we move on to the last small but important part - the capacitor (see Changing the capacitor (VAZ generator)).

Tip: When there is already wear on the slip rings of the electric generator, it is recommended to slightly grind down the contact corners on the brushes, so that the new brushes will fit more easily into the grooves of the worn slip rings

Capacitor functions and testing

If you have never dealt with capacitors, these instructions will help you:

- The capacitor is designed to protect all electronic equipment of the car from voltage pulses (jumps) appearing in the ignition system; it also reduces radio interference

- If the capacitor is damaged or its fastening on the electric generator is loosened (contact with the housing worsens), it sharply increases the interference of the radio receiver when the engine is running

- We connect the probes of our tester to the terminals of the capacitor

- It should show infinity before connecting

- Resistance decreases only at the moment of connection, and then must return to infinity again

- This means the capacitor is working properly

- Otherwise, the capacitor must be replaced

Attention: The K73-58-4 capacitor is installed on the VAZ2112 electric generator. The marking is located on the side of the case. To avoid problems, it is not recommended to install a different type of capacitor.

- We screw the capacitor back, pay attention that it is important to accurately orient the capacitor relative to the special mounting protrusion located on the cover of the electric generator, otherwise the brush holder will not fall into place

- We connect the connector back to the brush holder (the bend of the output wire faces up), screw it back, and the brushes must fall onto the slip rings

- Snap the plastic cover, insert and screw the wires back

- If there is a spring washer on the “+” bolt under the nut, it must be removed; dirt and moisture often accumulate under it, which often leads to oxidation and deterioration of contacts

- We put the terminals on the battery

How to replace alternator brushes on a VAZ 2110-VAZ 2112?

Note! The brushes can be replaced in two ways, which one you choose is up to you, the first method is to remove the generator from the car and replace the brushes (Convenient, but takes more time), the second method is to simply disconnect the minus terminal from the battery (How to remove the terminal , read in paragraph 1 of the article: “Replacing the battery on a car”) and in doing all the work on the installed generator on the car (It’s not very convenient but it won’t be difficult to remove the brushes, if you do everything correctly, you’ll save a little time, if you use tools there won’t be any short ones suitable for this, then it doesn’t even make sense to undertake such work, it’s better to do everything on a removed generator, and read about how to remove the generator in the article: “Replacing the generator in a car”)!

1. To change the brushes, first press out the three latches on the sides of the generator that secure the cover to it and then disconnect this cover from the generator (see small photo), now you have access to the voltage regulator, it has two screws that it is secured (indicated by blue arrows), you unscrew these screws and then, by pulling the regulator, disconnect it and thereby remove it completely from the generator.

Note! When you have removed the regulator, you can change it entirely with brushes, or if you do not have such an opportunity (it is not sold anywhere or you simply don’t have money for a regulator), then you can find the brushes separately and replace only them, they are soldered to the regulator are attached (or rather, their wires are soldered to the terminals of the regulator), so in this case, take a soldering iron and unsolder the wires coming from the brushes and then remove them from the regulator and new ones in the same way, install them by soldering in the same places, for more details, see the video that is posted below, but there is no sound in it, but in principle everything is perfectly clear from the video!

2. A few words about checking the brushes: as soon as you remove the regulator, look at the brushes themselves, which should be in good condition and have a length of at least 5 mm (see photo 1), if they are smaller, then either change them separately, or Replace the entire regulator so that you definitely don’t have any problems with it in the future, you can also check the regulator itself as follows, connect a 12-volt test lamp as shown in diagram 2 (that is, to the brushes) and apply the same voltage 12 Volts (the battery can supply it, that is, run some thin wires from it) “+” to the terminal, and “-” to ground, and the lamp should light up and do the same thing, but just apply the current not at 12 V, but at 15-16 V and if the lamp goes out, then everything is fine with the regulator and it does not need to be replaced.

Additional video clip: You can see in more detail and clearly the process of replacing the voltage regulator with a new one in the video located just below:

What kind of crap parts do Russia make here, in general, I bought a new generator and after two weeks the brushes burned out, at least that’s what they told me, I had to remove the generator and go return it under warranty, in the end they didn’t accept it, but at least the brushes were new for that They changed it, installed it again, drove it to 100 and said everything was working, before that the battery died in less than a week and I couldn’t even imagine that the new generator was to blame!

We install the voltage regulator of the VAZ 2110 generator

The voltage regulator on a modern car automatically and continuously adjusts the excitation current of the generator. Moreover, this process proceeds in such a way that when the current load and rotation speed of the generator changes, the value of its voltage remains in a strictly defined range.

Voltage regulator - its main functions

On a VAZ 2110 car, the voltage potential in the generator is formed under the influence of alternating current. This phenomenon becomes possible due to the presence of silicon diodes in the generating device of the vehicle. The generator rotor (the rotating component of the mechanism) operates according to the following diagram:

- First, the crankshaft begins to function, which is affected by the current;

- the crankshaft sets the movement of the rotor;

- After this, the generating device itself begins to work.

All stages of the sounded process are monitored by a voltage regulator, which is also often called a relay. It is this that is considered the main control unit of the generator.

Without a regulator, the current-generating mechanism of the VAZ 2110 will not perform its tasks, which are listed below:

- starting the generator;

- control (in offline mode) of current supply;

- “holding” in a certain voltage range.

The described relay cannot be repaired. In the event of a breakdown, the regulator must be replaced, which is done after checking the functionality of this unit.

Generator brushes, generator brush sizes according to standards

The designers developed the required resource for this part. At the moment, it is approximately fifty thousand kilometers. Some compare this distance to four years of vehicle operation.

In addition, there are certain standards regulating the permissible size of these brushes during operation. Generator brushes are prone to wear because during operation they have constant friction with the commutator and decrease in size. To ensure that they are constantly in contact, springs are provided to ensure their tight contact, even if they are worn out. However, over time, their length is limited, and the springs can no longer provide tight contact.

To diagnose whether the brush needs to be replaced, you should visually assess its length. As a rule, it is considered normal when the brush protrudes from the socket by five millimeters or more. If this parameter is too low, the brush needs to be replaced.

Dismantling the generator with the auxiliary belt

We will talk about removing a generator with a “long” belt. Do everything the same as in step 1 (see above). Then loosen the top screw on the generator housing.

Where is the tension roller located?

Move the generator towards the engine. Loosen the belt tension by unscrewing the screw on the roller by 1-2 turns (see photo).

Before unscrewing the screw, remember what position the roller was in. A “flat” tuning key will help.

Special wrench for tension rollers

The belt must be removed from the pulleys. Then unscrew the fasteners (two screws) and completely remove the generator.

All generator mounting elements

The nuts must be held with a “13” wrench.

During installation, the tension roller is set to its original position. If the belt is not replaced, this option will be correct.

Replacing brushes

Replacing generator brushes on a VAZ 2110

To replace the generator brushes you will need:

Removing the generator

- Place the car in a garage with an inspection hole.

- Place wheel chocks under the rear wheels.

- Raise the hood.

Replacing generator brushes VAZ 2110

- Disconnect the negative cable from the battery terminal.

- Raise the front of the car with a jack and install standard support devices.

- Unscrew the bolts securing the crankcase protection and remove it.

- Loosen the nuts at the top and bottom of the generator mounting points.

- Unscrew the adjustment bolt as far as possible.

- Remove the alternator belt.

- Carefully remove the terminal from output D.

Replacing generator brushes on a VAZ 2110

- Remove the rubber protection cover.

- Unscrew the nut securing the electrical plug.

- Disconnect the electrical wire plug from the contact bolt - output B. Unscrew the nuts at the top and bottom of the generator mounts and remove them.

- Remove the generator tension bar.

- Remove the spacer bushing.

- Hold the generator lightly.

- Remove the mounting bolt.

- Remove the generator (see VAZ 2110 generator repair: we do everything ourselves).

Disassembling the brush installation site

- Use a coarse brush to clean the entire surface of the generator.

- Blow air through the surface of the generator housing from the compressor.

Replacing brushes on a VAZ 2110 generator

Replacing brushes in a VAZ 2110 generator

Carry out work on disassembling the generator on a clean table or workbench. To do this, cover it with clean paper or cloth. Necessary:

Place the generator on it, pulley down. Carefully, using a flathead screwdriver, unclip the three springy metal holders. Remove the plastic cover from the back of the housing. Unscrew the brush holder fastening screws with a Phillips screwdriver. Take it out with caution.

Replacing brushes on a VAZ 2110 generator

- Be careful not to damage the brushes.

- Remove the electrical wire terminal from it.

- Unscrew the nut from the contact bolt.

- Remove the spring washer.

- Remove the second washer.

- Disconnect the capacitor wire from the contact bolt.

- Unscrew the screw securing the capacitor and remove it.

Replacement of generator brushes is necessary when they are completely worn out.

There are many reasons why a car battery may not be charged sufficiently, but the most common is considered to be severe wear or damage to the alternator brushes. It's easy to check their condition - you just need to remove them and inspect them. It is best if the generator brushes are inspected and replaced with the device removed, but if you have enough experience, you don’t have to remove it.

The main signs of excessive brush wear are:

- at night, the headlights are dim or flickering;

- voltage sags;

- The battery is not fully charged;

- The radio, air conditioning, and other electricity consumers turn off.

Quite a lot of car enthusiasts do not pay due attention to small details such as alternator brushes during maintenance at a car service center, so it is not surprising that they are taken by surprise when they fail. But you should not immediately resort to replacement if you discover problems with the generator - you must first make sure that the malfunction did not arise for some other reason, and only then proceed with disassembly.

Possible generator malfunctions

The electrical system of any car is equipped with the ability to indicate faults. In addition, poor operation of the generator can be detected not only with the help of a warning light located on the dashboard, but also during computer diagnostics. This way, you can identify faults in any components at an early stage and replace faulty parts in a timely manner.

Stuck or worn alternator brushes are a fairly common cause of insufficient charging. Car owners who know the principle of operation of the device know that the excitation voltage is supplied to the armature through the brushes, as a result of which the generator starts working. In addition, its output power is adjusted.

In modern cars, the generator brushes are installed in a single unit with a relay regulator (called a brush holder); on earlier models, the relay regulator can be installed separately. When replacing generator brushes , if the relay is in order, its replacement is not necessary.

As a rule, brush wear does not appear immediately, but gradually - at first, short malfunctions of the generator and voltage drops begin, which ultimately leads to failure of operation. Only replacement can help. But in case of freezing, a sudden failure of the generator is possible. If this happens, the brushes do not necessarily need to be replaced - it is enough to lightly treat them with sandpaper and remove burrs and burrs so that they move freely in the brush holder. In addition, you need to check the condition of the spring - maybe it is the cause of the freezing.

Replacing brushes

The replacement procedure itself is not complicated; even a novice car owner can handle it. But if you don’t have any experience, then it’s better to go to a car repair shop - the employees there will do everything efficiently and quickly. In addition, it is not always possible to perform a replacement without removing the generator - in this case, the procedure becomes somewhat more complicated and it is no longer possible to do without special equipment and tools.

Another advantage of visiting a car repair shop is the ability to detect potential generator malfunctions. For example, it may have a worn bearing and you may not even realize it. And if the generator brushes are replaced on a removed device, then the bearings can be changed at the same time. The main reason for their failure is too much belt tension, and not a lack of lubrication. It is recommended to visually inspect the engine compartment while the engine is running and listen to the operation of the generator.

Generator repair for VAZ 2110

To carry out repairs, the generator must be completely disassembled.

If it is necessary to replace the conductors of the VAZ 2110 generator, the car owner should select only those cables that correspond to the length and cross-section.

Belt adjustment

To adjust the belt, follow these steps:

- Use a wrench to loosen the tightening of the nuts on the lower and upper fastenings of the generator device.

- To perform tension, the assembly is moved away from the internal combustion engine cylinder block; for this, the adjusting screw is turned clockwise. To loosen the strap, the bolt is turned in the opposite direction, only the generator device moves towards the BC. The approximate play between the threaded surface for the adjustment bolt and the black frame should be about 1.3-2 cm.

- Using a key, the crankshaft of the power unit is turned by the screw that secures the pulley two turns. Scrolling is done clockwise. Then the strap is re-diagnosed. If necessary, it is adjusted.

- Upon completion of the work, the nuts securing the assembly are tightened.

The channel “In Sandro’s Garage” showed in detail the process of adjusting the tension of the drive belt on “ten” generators.

Repair of brushes and regulator

The brush assembly repair procedure looks like this:

Using a construction brush, the outer surface of the generator unit is cleaned. If there is a compressor, the housing is purged. If it is not available, a vacuum cleaner may be used. Further steps to disassemble the device are performed on a workbench or clean table

The generator unit is installed on the working surface with the shaft down. Using a flat-head screwdriver, carefully release the three spring-loaded metal clips. The plastic cover located on the back of the device body is removed. Using a Phillips-blade screwdriver, unscrew the bolts securing the brush holder

This element is carefully dismantled. When performing the task, you must be careful not to damage the brush assembly. The central terminal of the electrical circuit is disconnected from the mechanism. The nut is unscrewed from the screw of the contact elements. The spring part is removed. The second washer is being dismantled. The conductor connected to the capacitor device is disconnected from the contact screws. Then the screw that secures the part is unscrewed. The capacitor element is dismantled. Before installing a new brush mechanism, it is necessary to diagnose the main elements of the device. The brushes should be located 0.5 cm from the body of the holder itself. When performing a task, it is recommended to immediately check the capacitor device.

To repair the control device, do the following:

- Three spring elements are disconnected. The protective cover located on the diode bridge is dismantled.

- The two bolts that secure the control device are unscrewed. To complete the task you will need a Phillips head screwdriver.

- The block with the conductor is disconnected from the output of the regulatory device. The part is dismantled and replaced with a new one. Assembly is carried out in reverse order.

The MegaMeyhem channel talked about the procedure for repairing and replacing the regulatory device on domestic “ten” generators.

How to remove the generator on a VAZ-2110 with 8 and 16 valves

The generator is responsible for supplying electricity to the vehicle's engine. On the VAZ-2110 this unit is located in front of the engine, which makes it easier to access. Removing the unit and disassembling it is not difficult even for an inexperienced car enthusiast. Let's look at the main breakdowns that motorists encounter.

Generator operating principle

This unit consists of several parts:

- frame;

- rotor;

- stator;

- rectifier bridge;

- relay-regulator;

- pulley.

Thanks to the generator, the torque from the power plant is converted into electrical energy. During rotation, the rotor creates a magnetic flux, which is regulated by a relay, and the pulley carries out a belt drive. The rotor moves with the help of bearings, and when they work well, the shaft moves easily.

Another purpose of the relay regulator is to limit the output voltage in the range from 13.6 to 14.7 V. The voltage is transmitted through the commutator rings to the brushes, and the rectifier bridge is responsible for ensuring that energy is transferred in one direction.

What types of breakdowns are common?

Most often, the generator for 8 and 16 valve VAZ-2110s fails as a result of moisture and dirt. Another reason is the wear of the components of this assembly, namely the brushes. Most often, the malfunction manifests itself as follows:

- the generator does not produce electricity;

- output current is either too high or low voltage;

- During engine operation, extraneous sounds are heard, most often a squeak or squeal.

The operation of the generator is checked using special stands or a digital voltmeter. If extraneous sounds are heard in the engine compartment area, then first of all you need to check the timing belt tension. Most often this is the reason, but after checking, remove the belt from the pulley and start the engine. The absence of noise is a reason to check the performance of the generator more carefully.

How to properly remove the generator on a VAZ-2110

If you have a power unit with 8 valves, then it is best to work from above. In the sixteen-valve version, the generator must be removed from below. To do this, first unscrew the pan. Before work, prepare several different keys. You can remove this assembly quickly if you follow the following instructions:

- De-energize the vehicle's on-board system - to do this, simply remove the negative terminal from the battery.

- Find the M10 nut on the positive stud of the autogenerator and unscrew it.

- There are wires connected to the generator on the back of the device, which must be disconnected before the next stage of disassembly.

- Using a 13mm wrench, loosen the upper and lower nuts.

- Unscrew the tension bolt with a 10mm wrench to loosen the belt tension and remove it.

- Then completely remove both nuts (upper and lower) and remove the tension bar.

- Carefully rotate the generator at a right angle and remove it from the engine compartment.

If you want to repair this unit, you should thoroughly wipe it with a rag to remove all dirt.

How to disassemble a generator

First, make two marks on the metal covers. This will help you later assemble the unit without problems.

- Press out the metal latches and remove the plastic cover.

- Use a Phillips screwdriver to unscrew the voltage regulator mounting screws.

- Unscrew the M10 nut. Then use a screwdriver to remove the screw and remove the capacitor.

- To remove the pulley, clamp the generator housing in a vice. Put a 21 socket on the nut, and through the hole in the head put a 8 hexagon on it. Only after you unscrew the nut can you remove the washer and pulley.

- Remove the four mounting screws to disassemble the generator into two parts.

- From the back of the housing, unscrew the screws securing the stator wire and diode bridge.

- Remove the diode bridge and the oscillator winding.

- Press the rotor out of the cover with your fingers along with the bearing.

- Carefully remove the bearing bushing.

- Take a puller and remove the bearing.

Disassembling the generator itself is much more difficult than removing the entire assembly from the car. To carry out repairs, you will need to diagnose the components of this unit.

First of all, pay attention to the brushes; they need to be changed if this element is visible from the holder by no more than 5 millimeters. If the bearings rotate tightly, then they are the defective element (a hum may be heard during operation)

The breakdown of the starter and rotor windings can be checked with an ohmmeter; the same device determines the performance of the capacitor. If nicks, scratches or burrs appear on the slip rings, they must be carefully sanded to a shine with fine sandpaper.

checking and repairing voltage regulator VAZ 2110 | VAZ 2111 | VAZ 2112

The operation of the voltage regulator is to continuously and automatically change the generator excitation current so that the generator voltage is maintained within specified limits when the generator speed and load current changes. Checking the voltage regulator on cars of the VAZ 2110 family

To check, you must have a DC voltmeter with a scale of up to 15-30 V, accuracy class no worse than 1.0.

After 15 minutes of engine operation at medium speed with the headlights on, measure the voltage between the “B+” terminal and the “ground” of the generator. The voltage should be within the range of 13.2-14.7 V. If there is a systematic undercharging or overcharging of the battery and the regulated voltage does not fall within the specified limits, the voltage regulator must be replaced. Checking the removed regulator of a VAZ 2110, VAZ 2111, VAZ 2112.

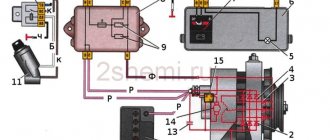

The regulator assembled with a brush holder, removed from the generator, is checked according to the diagram shown in Fig.

7-12. Between the brushes, turn on a 1-3 W, 12 V lamp. Connect a power source to the “D+” and “ground” terminals of the regulator, first with a voltage of 12 V, and then with a voltage of 15-16 V. If the voltage regulator is working properly, then in the first case the lamp should be on , and in the second - go out. If the lamp lights up in both cases, then there is a breakdown in the regulator, and if it doesn’t light up in both cases, then either there is a break in the voltage regulator, or there is no contact between the brushes and the terminals of the voltage regulator. The latter can be checked by connecting the wires from the lamp not to the brushes, but directly to the “D+” and “DF” terminals of the voltage regulator. Checking the capacitor

The capacitor is used to protect the electronic equipment of VAZ 2110, VAZ 2111, VAZ 2112 cars from voltage pulses in the ignition system, as well as to reduce interference with radio reception. Damage to the capacitor or loosening of its mounting on the generator (deterioration of contact with ground) is detected by an increase in interference to radio reception when the engine is running. Approximately the serviceability of the capacitor can be checked with a megger or tester (on a scale of 1-10 MOhm). If there is no break in the capacitor, then at the moment the probes of the device are connected to the terminals of the capacitor, the arrow should deviate in the direction of decreasing resistance, and then gradually return back. The capacitance of the capacitor, measured with a special device, should be 2.2 μF ± 20%.

rice. 7-12. Circuit for checking the voltage regulator: 1 - test lamp; 2 — output (ground) of the voltage regulator; 3 — terminal “DF” of the voltage regulator; 4 - voltage regulator; 5 — terminal “D+” of the voltage regulator; A - to the power source

When using site materials, an active link to car-exotic.com is required!

The generator voltage regulator (RN) cannot be repaired; it can only be replaced with a new one. However, before replacing it, you should make sure that it is the one that has failed. We are studying the question “ how to check the voltage regulator of a VAZ 2110 ”.

Checking the voltage regulator on a car

To check the pH you will need a DC voltmeter with a scale of up to 15.30 volts. We check this way: with the engine running at medium speed and the headlights on, we measure the voltage at the battery terminals. It should be within 13.5. 14.2 V.

If the regulated voltage does not fall within the specified limits, and there is a systematic undercharging or overcharging of the battery, then it is possible that the voltage regulator is faulty and needs to be replaced.

Checking the voltage regulator after dismantling it

The removed generator voltage regulator is checked according to the following diagrams: (the first diagram for the old-style LV): It is better to check the relay-regulator assembled with the brush holder, since in this case you can immediately detect breaks in the brush leads and poor contact between the terminals of the voltage regulator and the brush holder. You need to turn on the lamp 1. 3 W, 12V between the brushes. To terminals “B”, “C” and to the regulator ground, connect a power source first with a voltage of 12.14V, and then with a voltage of 16.22V. (a 12V power source can be a battery, and a 16. 18V power source can be the same battery, but with 2..4 of the cheapest AA batteries connected to it in series.)

If the voltage regulator is working properly, then

- in the first case, the lamp should be on,

- in the second - go out.

If the lamp lights up in both cases, then there is a breakdown in the regulator, and if it doesn’t light up in both cases, then there is a break in the regulator or there is no contact between the brushes and the terminals of the voltage regulator.

An example of a practical test of the voltage regulator 54.3702 using a 21W lamp: By the way, a three-level voltage regulator can also be installed on the “ten”.

Replacing the generator: removal and installation

Often, many VAZ 2110-2112 car owners are in too much of a hurry at the first generator malfunction and prefer to replace it with a new one, instead of simply finding out the cause of the breakdown and eliminating it. In this case, we will not consider repairing this device, but will only look at the procedure that must be performed to remove and install the unit.

So, to dismantle it without problems, we will need a tool such as:

- Socket heads for 10 and 13

- Ratchet handles or cranks

Before starting repairs, be sure to disconnect the car’s battery by removing the negative terminal. Otherwise, you risk getting a short circuit when disconnecting the positive wires of the generator.

Especially for this post, I decided to make a video instruction to explain everything clearly and clearly.

If you have any questions about the video review, you can ask them on my YouTube channel. Below will be presented everything in the usual format.

Photo report on repairs

I would like to warn you right away that in this example of my VAZ 2110, the generator is slightly clamped by the mounting bracket, since it broke off during the accident, so I cannot show you the removal procedure in all its details. But still, the main points will be shown quite clearly in the photo.

Unscrew the tensioner nut, which is shown by the arrow below:

After this, move the generator back (towards the car interior) and remove the belt from the pulleys. Now you can disconnect all power wires. One “bundle” is secured with a stud and nut, and another plug is simply fixed with a connector:

Then you can unscrew the lower nut securing the generator, first crawl under the car and remove the engine protection (if installed):

Usually the bolt fits tightly, so it can be knocked out carefully and without excessive force with the handle of a hammer:

Then from the reverse side we try to remove this very bolt to the end:

Next, unscrew the tensioner nut from top to bottom and you can carefully move the VAZ 2110 generator to the side in order to remove it later:

If you are replacing the complete device, install it in the reverse order.

But please note that the generator model, if possible, should be the same as the one installed by the factory. That is, first of all, look at the applicability specifically to your car, and then at the current rating in Amperes. As for the price of generators for VAZ 2110-2112, it may vary depending on the type and manufacturer

But if you take the KZATE model, which in most cases is installed by the factory, then the cost can be about 3,500 rubles. Although, Chinese options can be obtained at almost half the price. True, you should not chase low cost, since the service life of these parts can be quite short

As for the price of generators for VAZ 2110-2112, it may vary depending on the type and manufacturer. But if you take the KZATE model, which in most cases is installed by the factory, then the cost can be about 3,500 rubles. Although, Chinese options can be obtained at almost half the price. True, you should not chase low cost, since the service life of these parts can be quite short.

Source: autoprivat.ru

Generator brushes.

Generator brushes are a part that is found in almost every generator.

The more modern the car, especially a foreign car, the more electrical consumers it has, which in one way or another make life easier for the car owner. Accordingly, an increasingly important role among automobile units is played by the autogenerator, which supplies electricity to all consumers in the car.

What are generator brushes used for?

Using the generator brushes, the voltage from the regulator relay is supplied to the excitation winding - the rotor. The rotor has commutator rings attached to it - the rotor commutator to which the brushes fit tightly. To transfer current from the voltage relay to the rotor winding, the brushes must be in a certain position and pressed against the commutator rings with a certain force. To do this, they are installed in the seats of the brush holder and are pressed by a spring on the reverse side.

The material from which the brushes of foreign manufacturers' generators are made - a mixture of copper and graphite - differs from domestic ones in better wear resistance and conductivity. For this reason, it is not recommended to install this element on foreign cars from domestic cars.

How do you know when you need to replace your generator brushes?

- Car mileage, 150-200 thousand km. is the period when the part is worn out.

- The battery charging indicator light comes on and goes off again. This may continue for several days until the icon lights up completely.

- Loss of power or voltage drop due to a loose fit of a worn part.

- Voltage surges in the vehicle's on-board network may indicate a faulty part.

- If a lot of motor oil or other technical fluid gets on the generator, then the part is subject to increased wear.

How to check whether replacing the generator brushes is really necessary?

To determine the causes of the malfunction, it is necessary to disassemble the generator and inspect the generator brushes - they must be long enough and in contact with the slip rings.

If the remaining length of at least one element is less than 3 mm, replacement is necessary in any case. Also, the generator brushes must be well movable in their seats, have approximately equal residual length, must not be dirty, and the springs must press with the same force.

How to replace brushes on a generator? Procedure.

On many modern autogenerators, the brushes are integral with the voltage regulator relay, for example, this is true for Valeo, Bosch, Mitsubishi, Magneti Marelli; for Denso, the relay regulator is made separately from the brush assembly.

To replace the generator brushes , if they are built into the regulator relay, the tools you will need are a 40-100 W soldering iron, solder, flux, a 1.5-3 mm drill, a drill or screwdriver, as well as a tool for removing the regulator.

- Remove the protective cover

- Remove the voltage regulator relay (or brush assembly)

- From the side where the brush harness is attached, we drill out the contact so that the remaining parts come out. We try not to damage the spring, which is located inside the brush assembly.

- We take new brushes and check whether they move freely in their seats

- We insert the spring and insert the harness into the hole so that the required working length remains.

- We solder the contact point and cut off the remaining strands.

- We assemble everything in reverse order.

Correct indicators

When checking with a multimeter (it has a special function for measuring volts). When the car engine is started, a volt is connected to the battery - the meter should show approximate readings of 13-14.5 W, but if they are less, it is possible that the battery is almost discharged or the whole issue is a faulty generator. In such a situation, you can try to gas the car and to do this you need to hold your foot on the gas pedal and then remove it from the pedal; if during this the current supply increases, it means the battery is discharged. But if after 1 check nothing has changed, then the procedure should be repeated. If the current readings are less than 12 W, then after a short time the battery will be completely discharged and a new attempt to start the car will fail.

How to check the pH on a VAZ-2110 without removing it

If you find at least one of the listed signs, do not be lazy to check the voltage regulator on your VAZ-2110. This procedure will not take more than 10 minutes. To do this, you will need a voltmeter or multimeter turned on in its mode, as well as an assistant. The verification procedure is as follows:

- We start the car engine and warm it up to operating temperature.

- Without turning off the engine, we connect one voltage probe of the generator, and the second to the “ground” of the device.

- We ask the assistant to turn on the low beam headlights and press the accelerator pedal, keeping the speed at 2000-2500 thousand rpm.

- We measure the voltage with the device.

For the VAZ-2110, the voltage regulator should produce 13.2-14.7 V. This is the norm. If the voltmeter readings differ from those shown, diagnostic measures should be continued.