Reasons for oil getting into the intake manifold. List and actions

Download PDF

Many drivers are interested in the reasons for oil getting into the intake manifold, because this is not such a common occurrence, but it leads to a number of problems and difficulties. Therefore, if such difficulties arise, you should identify the breakdown as soon as possible and begin to fix it. Some difficulties arise with diagnostics. In case of certain breakdowns, to identify the problem, you will need to partially disassemble the engine; not every driver can do this. In addition, this will require a number of additional tools, which are not available in every garage. But it’s still worth trying to identify and eliminate the cause yourself. The reasons for oil getting into the intake manifold may be different, but in any case it is an engine malfunction. In some cases they are minor, in others such a sign indicates a complex problem that requires immediate attention. Therefore, if you notice oil in the manifold, you should pay attention to diagnostics.

Main signs of oil penetration

The presence of oil in the manifold can be determined by the presence of one or more signs:

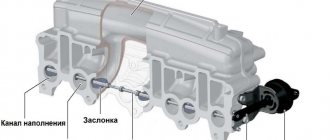

- Oil in the intake manifold or throttle body (the easiest method to detect the problem, but it requires some skill to disassemble the top of the engine).

- Blue smoke from the exhaust pipe. Even novice drivers can see this. It should be noted that very often the presence of this symptom may indicate other problems in the engine.

- Significant increase in oil consumption (check the oil level on the dipstick regularly!).

- A noticeable decrease in engine thrust and an increased noise level during its operation.

- Drops of oil on the air filter (it’s easy to check, because access to this filter is usually very easy).

We've looked at the most common diagnostic options, now it's time to find out the reasons.

Gaskets

The intake manifold is secured to the power unit using gaskets. This avoids possible air leaks. The gasket also helps limit oil from entering the manifold. But over time it can become damaged. In this case, the oil still gets there. The motor may start to fail because of this. If there is a mass air flow sensor, the ECU will generate an error. All this suggests that the gasket under the manifold is damaged.

There can be many reasons for its damage. Most often, these elements fail due to wear and tear. Sometimes the gasket breaks due to overheating. However, modern elements can withstand high-temperature influences. Sometimes the gasket is damaged during engine assembly.

In this case, getting rid of oil in the intake manifold is simple - you just need to replace the gasket. Then the collector is installed back. But you need to observe some nuances. It is recommended to thoroughly clean the surfaces of the engine and manifold. The nuts are pulled with a strictly defined torque.

How to solve the problem permanently

In fact, despite the serious consequences associated with oil getting into the intake manifold, fixing the problem is quite simple. It is enough to install the sensor. This device will monitor the area between the filter and the turbocharger.

If you do not want to spend money on installing a sensor, you can simply follow the manufacturer’s recommendations and change the filter on a schedule. But it is worth making one important note. The rate of contamination depends on operating conditions and loads, so it is not always possible to rely on manufacturers’ manuals.

How can you tell if there is oil in the intake or not?

First of all, I want to note that it is quite difficult to understand whether you have oil in the intake manifold or not, since everything is closed and there may simply be no visual signs.

Signs of lubricant presence are most often the following:

- Traces of engine oil in the throttle valve, as well as the air filter, which I wrote about in my previous article;

- Blue smoke from the exhaust pipe. I think even a complete layman could not notice the thick, bad-smelling, clearly visible smoke;

- "Maslozhor." If the engine starts to eat oil, one of the places where it goes could be the intake manifold. Therefore, do not forget to monitor the oil level!

- A drop in engine power, in other words, the engine does not pull;

- Fuel consumption increases.

- Issue a warning

- Information

- Quote

Oil in the EGR valve, intake manifold, intercooler

Message: No. 1 Will » May 20, 2009, 3:02 pm

It all started as usual with “female pads”. I decided to check the glow plugs, because some troubles began to arise with the start-up. I dismantled the entire top and... I saw the connector gasket. covers and intake manifold in Oil. I. let's go. At the moment, the car only has a block with pulleys and an injection pump. Everything else was removed one by one, but the reason for the increased gas pressure in the crankcase was never found (List of what was removed: 1) valve cover, cleaned, the gasket naturally needs to be replaced, there is a possibility that the strainer on the ventilation tube is clogged. But since everything is riveted there, I put this work aside for now. Although I washed it, blew it out, it seems to be blown out 2) The cylinder head has been removed. Took it in today for diagnostics and replacement of everything that was even a little bit wrong. Although, when filling with kerosene, only two valves leaked. And the mechanics asked: why did you change the valves? Because they look like new (Synthetics every 7.5 thousand) 3) the pan was removed, washed, a spring was found there, either from the oil seal or from the oil seal (we are finding out. 4) the oil “swallow” (damn, I forgot the word), clean 5) removed turbine together with the EGR valve. It's all covered in coked oil, the crankcase ventilation tube is all covered in oil, the intake manifold is all covered in oil, the intercooler pipes are all covered in oil. The turbine was taken for “diagnostics” Like the master disassembled it, said that the blades are in order, there are no distortions, everything is okay, like he’ll supply a repair kit (seals, 2 some brass things and that’s it) To my question about the money: like the repair costs 11,000 ooh. This is such a bullshit scam for replacing oil seals for 11,000 thousand. 3.14 gifts, evil takes. In short, the turbine was already the most alive of all living things, but now it just has to be ideal if they haven’t ruined it for me. By the way, they promised to clean the valve. returned dirty. 6) The valve is washed and cleaned, everything works. 7) the oil filter pressure reducing valve was removed. Cleaned/washed everything works. The exhaust manifold and exhaust pipe have been removed. The catalytic converter is fucking knocked out. 9) The vacuum pump has been removed from the generator. Washed and cleaned. Ideally. 10) The pistons are removed. The cylinders are visually perfect. Sounds like new. Ring gaps have been verified. The upper compression is at the limit, but normal, the second is still in the middle of normal. The rings are not stuck. In general, the piston is in order, the liners are almost ideal. The block has been cleaned, wiped, lubricated with solarium, and covered with bags.

I decided to check the glow plugs, because some troubles began to arise with the start-up. I dismantled the entire top and... I saw the connector gasket. covers and intake manifold in Oil. I. let's go. At the moment, the car only has a block with pulleys and an injection pump. Everything else was removed one by one, but the reason for the increased gas pressure in the crankcase was never found (List of what was removed: 1) valve cover, cleaned, the gasket naturally needs to be replaced, there is a possibility that the strainer on the ventilation tube is clogged. But since everything is riveted there, I put this work aside for now. Although I washed it, blew it out, it seems to be blown out 2) The cylinder head has been removed. Took it in today for diagnostics and replacement of everything that was even a little bit wrong. Although, when filling with kerosene, only two valves leaked. And the mechanics asked: why did you change the valves? Because they look like new (Synthetics every 7.5 thousand) 3) the pan was removed, washed, a spring was found there, either from the oil seal or from the oil seal (we are finding out. 4) the oil “swallow” (damn, I forgot the word), clean 5) removed turbine together with the EGR valve. It's all covered in coked oil, the crankcase ventilation tube is all covered in oil, the intake manifold is all covered in oil, the intercooler pipes are all covered in oil. The turbine was taken for “diagnostics” Like the master disassembled it, said that the blades are in order, there are no distortions, everything is okay, like he’ll supply a repair kit (seals, 2 some brass things and that’s it) To my question about the money: like the repair costs 11,000 ooh. This is such a bullshit scam for replacing oil seals for 11,000 thousand. 3.14 gifts, evil takes. In short, the turbine was already the most alive of all living things, but now it just has to be ideal if they haven’t ruined it for me. By the way, they promised to clean the valve. returned dirty. 6) The valve is washed and cleaned, everything works. 7) the oil filter pressure reducing valve was removed. Cleaned/washed everything works. The exhaust manifold and exhaust pipe have been removed. The catalytic converter is fucking knocked out. 9) The vacuum pump has been removed from the generator. Washed and cleaned. Ideally. 10) The pistons are removed. The cylinders are visually perfect. Sounds like new. Ring gaps have been verified. The upper compression is at the limit, but normal, the second is still in the middle of normal. The rings are not stuck. In general, the piston is in order, the liners are almost ideal. The block has been cleaned, wiped, lubricated with solarium, and covered with bags.

So, I still haven’t understood the reason for the increased pressure in the crankcase and such a copious release of oil vapor through the breather tube into the EGR valve. Does anyone have any ideas?

- Issue a warning

- Information

- Quote

Re: Oil in the EGR valve etc. collector

Message: No. 2 Leningradets » May 21, 2009, 10:33

- Issue a warning

- Information

- Quote

Re: Oil in the EGR valve etc. collector

Post: #3 Will » May 21, 2009, 11:12 am

I strongly disagree. That is precisely why oil or oil vapor rushes up the breather tube because there is excess pressure from the crankcase gases. It is the excess pressure of the crankcase gases, not the oil. Oil is ok.

Oil naturally enters the intake through the turbine. But. if the turbine is dead, then the oil simply flows from the low-flow pipe through the turbine into the inlet. At the same time, there is a huge consumption of oil, wow. A friend of mine got oil through the breather tube into the EGR valve in large quantities and only then drove it through the turbine. When the valve becomes coked, oil begins to ooze from all the cracks

There's a clever device there. There is a breather sticking out outside. But the hole is not visible from the inside. But you can see two thin sheet metal plates riveted (!!) along the entire length and width of the valve cover. Ini and close the breather and. something else. Maybe. I read from the dealers that there is a type of mesh filter there and it can become coked..

- Issue a warning

- Information

- Quote

How to avoid the unpleasant consequences of cleaning the damper?

After removing oil from the throttle valve, another problem may appear - unstable (increased) engine speeds, leading to increased fuel consumption.

The thing is that after removing the layer of dirt, the position of the damper changes (as the gap between it and the body increases). However, the ECU continues to control the fuel supply according to the previous indications (before the cleaning operation).

Adaptation allows you to completely eliminate the problem of high speed and restore engine performance.

As a rule, electronic throttle valves need adjustment, but sometimes difficulties arise with mechanical components.

The easiest way to restore optimal engine speed is to reset the battery terminals. Before carrying out this operation, you should warm up the internal combustion engine well and take a short trip. After the engine is turned off, the negative terminal of the battery is removed for a period of 10 seconds to 20 minutes, depending on the make of the car. During this period, all ECU parameters should return to factory settings, and the speed should return to normal.

Turbine

Another reason is a turbine malfunction. This structural element constantly circulates oil, which performs the function of lubrication and cooling. The turbine is located near the manifold, its task is to pump additional air, and it is due to this that it is possible to achieve an increase in engine power. But in some turbine malfunctions, it is the location that causes oil to appear in the manifold. It is worth noting that this problem is not the most serious, but a lot depends on the specific model, as well as the malfunction itself.

If there are problems with gaskets and seals, oil begins to enter the manifold during turbine operation. Moreover, this happens actively; there is quite a lot of oil. As a result, lubricant begins to spill through the top of the manifold. Actually, this malfunction manifests itself quite clearly. You can see how the oil is driven through the manifold, and the lubricant also appears on the spark plugs. Having seen this, you can safely remove and repair the turbine. Also, in the presence of such a malfunction, you may notice some dips when gaining speed, this affects the poor performance of the turbine.

Repair in this case will have its own characteristics depending on the car model. For some car models you can find repair kits for turbines. This will allow you to avoid unnecessary costs and quickly repair the unit; you can do this work, including yourself. But for some models the manufacturer does not produce repair kits for the turbine, which leads to the need to completely replace the part.

An article on the topic “Which is better - a turbine or a compressor?”

Causes of turbine failures

Do you own a car equipped with a turbocharger? Then you probably asked yourself: “what factors negatively affect the turbocharger mechanisms?” or “why did my turbine fail?” There are quite a few reasons, and we will try to reveal the main ones in this section.

Mechanical damage to the turbine

The most common cause of turbine failure is the entry of foreign bodies into the area of the turbocharger impeller on the intake (intake manifold) and exhaust (exhaust manifold) sides. Nuts, washers, pieces of plastic forgotten in the air filter housing during maintenance can lead to significant damage to the impeller, and the resulting increase in imbalance results in failure of the turbocharger. Even such seemingly harmless materials as rags, cardboard, paper, if they get into the intake system, can cause irreparable harm. The ingress of foreign particles (scale, rust, hard coke, pieces of destroyed engine parts) from the exhaust manifold is fraught with more serious damage, since objects and particles that get into this part of the turbine can damage not only the turbocharger impeller, but also its “geometry” .

Another fairly well-known cause of failure is damage to the turbocharger impeller by abrasive particles such as dust, sand, soot, etc. How can such particles get into the working area of the turbine, you ask? Very simple! This happens for a number of reasons: leakage of the air line from the air filter housing to the turbocharger, leakage of the air filter housing, deformation of the air filter, in which part of the air entering the turbocharger is not filtered properly, failure of the crankcase ventilation system pipe. Pay attention to the condition of the parts associated with the operation of the turbocharger, be careful when replacing them, and you will not soon be faced with such a troublesome and expensive undertaking as turbine repair.

Turbine oil starvation

Failure as a result of a permanent or temporary lack of lubrication of a turbocharger is probably one of the most common breakdowns. This type of failure can only be identified by disassembling the turbine. Characteristic signs will be a change in the color of the shaft and bushings from steel to yellow, and then blue-black. Operating a turbocharger that is starved of oil will lead to destruction of the shaft (even its fracture). If this happens, you will hear a pop and see a puff of smoke behind the car, and the engine may “go crazy.” In this situation, many people ask the question: What to do? Don’t panic, try to turn off the engine, then under no circumstances continue driving, so as not to encounter such a more serious problem as engine repair, use a towing service or tow the car yourself to the repair site.

The main causes of lubrication deficiency in a turbocharger:

- Malfunction in the engine lubrication system (wear of oil pump elements, failure of the pressure relief valve, clogged oil filter, etc.);

- Severe contamination of the oil pan with various deposits; In this situation, the oil pressure at idle speed will be normal, but with an increase in engine speed (that is, with an increase in oil pump performance), the oil receiver is blocked by debris and a drop in oil pressure in the system is observed, which leads to oil leakage. fasting. You should not rely entirely on electronic warning systems (sensors); they do not always work. It’s better to check the oil level more often and monitor the performance of the lubrication system mechanisms.

- Reduced throughput of the oil supply tube and oil channels of the turbocharger; This reason is a consequence of mechanical damage and coking of the oil line.

Owners of French cars since 2004 with a 1.6 HDI capacity or cars equipped with this engine should pay attention to a little-known, but causing a lot of trouble, “mesh” in the oil supply tube, or rather in the bolt that secures this tube to the engine block. This mesh acts as a filter that cleans the oil from various contaminants, but since many motorists do not change it in a timely manner or use low-quality oil that does not meet the manufacturer’s tolerances, the mesh becomes clogged, the oil pressure to the turbine decreases, which leads to oil starvation and destruction of the turbocharger mechanisms. Pay attention to the presence of this grid in the highway and if it is present there, be sure to remove it.

Contaminated engine oil

Contamination of engine oil with large and small abrasive particles has a detrimental effect on the internal mechanisms of the turbocharger and is accompanied by significant uneven wear with deep scuffing of the shaft journals, radial and thrust bearings and bushings.

The most likely causes of such pollution:

- Poor quality oil filter with leaking safety valve; As a result of a valve malfunction, some of the unfiltered oil enters the engine lubrication system bypassing the filter element, which can result in dirt getting into the engine lubrication system and its elements.

- Excessively contaminated engine oil

- Exceeding the engine oil change interval. As a result, there is a partial loss of the lubricating properties of the oil and its coking.

- Untimely oil change after engine overhaul; During the running-in process, new parts grind in and form small abrasive particles that enter the turbine lubrication system, forming scuffs and roughness, thereby disrupting the correct shape of the parts. The result is failure of the turbocharger!

- Chemical contamination of engine oil; Occurs as a result of fuel and various additives entering the engine oil, which have a negative effect on the oil film in friction zones.

Conclusion: Use only high-quality and proven spare parts, do not add questionable additives to the fuel that guarantee a sharp increase in power, reduced fuel consumption, and if you decide to experiment, then choose only prototypes that have proven their quality and efficiency.

Limit operating modes of the turbine

If you operate a turbine in excess of temperature conditions or at exceeding the maximum permissible speed, be prepared for repairs. Typical signs of turbine failure when temperature conditions are violated are oil deposits on the shaft support journal, coking of the shaft itself, and cracks on the rear surface of the turbocharger impeller.

The causes of such damage are:

- Violation of the temperature regime of engine operation; This violation occurs due to a malfunction of the thermostat, insufficient coolant level in the system, etc.

- Incorrect fuel injection angle and ignition timing;

- Use of fuel with an octane rating that does not comply with the manufacturer’s recommendations; Damage resulting from operation at maximum permissible speeds is characterized by: cracks on the impeller blades, and further operation of the turbine leads to the loss of blades up to the separation of the impeller from the turbocharger shaft.

Why is oil leaking?

Reasons for unstable operation and oil consumption on the Nissan 3.5 V6 VQ35 engine

If something disrupts normal operation - suction (air release), oil supply, shaft rotation, bearing operation - the turbine begins to drive oil. And you know, you first need to figure out why this happens, otherwise after replacing the turbine with a new one, the oil will also leak out! THE REASON IS NOT ALWAYS IN THE UNIT ITSELF!

First, indirect reasons that you can eliminate yourself

After all, it is important to understand that often the “rush” of oil occurs due to a violation of pressure, that is, the locking rings do not cope with the task, the pressure from the impellers is disrupted, and the oil flows much “easier”. This indicates increased pressure at the turbine outlet, which needs to be removed

SO:

1) Check the air filter, it should be clean, in general I recommend changing the air filter 10% more often than expected. If it is clogged, replace or clean it

IT IS IMPORTANT!

2) If the filter itself is fine, look at the box and the intake pipe, it may be the problem with them. For example, there was fluff (from poplar trees).

3) We check the tightness of the housing (cover) of the filter; if there is no tightness, then sand, dust, etc. getting into the turbine is almost 100% guaranteed, and this in turn works as a “disruptor” - it will kill the unit very quickly.

4) If you notice that the seal has been broken

It is IMPORTANT, remove all the pipes and clean them - wash them up to the turbine, and you also need to remove and wash them, clean them from the turbine to the intake manifold, the manifold itself also needs to be cleaned, most likely there is dirt there - 100%

The air filter for the turbine is a very important component, because basically it drives oil only because the pressure is broken due to a clogged filter or pipes! Therefore, make a rule for yourself: change the filter every 8,000 km, and also check the condition of the housing for cracks, dirt, etc. Remember a clean filter, this already adds life to your unit.

Oil

The second most common reason is the oil itself - if it is of poor quality, or you change it rarely, a breakdown is “just around the corner.” Why does this happen?

1) The oil must be heat-resistant, it is specially sold for turbines, it should not burn, because while lubricating the bearings, it encounters high temperatures. If you fill it with regular oil, it will “coke” all the lubrication channels of the bearings, and they will simply fail. RESULT – we choose correctly!

2) Replacement interval. Even the best oil wears out and begins to lose its properties - to burn. Therefore, replacing it frequently will also protect you from “coking” of the oil passages. If your manufacturer specifies an interval of 10–12,000, then change it at least 10% more often, for example, at 9–10 thousand; believe me, the turbine’s life will increase.

3) Branch pipes. Often the cause is underwater oil pipes; if you have not changed the lubricant for a long time, they also become clogged

Even if you then change the turbine, the pipes must also be changed or cleaned, this is important!

If there is oil in the intercooler (in the intake manifold), the air filter (its adjacent structures) is most likely clogged, or the oil pipes are clogged. There is a difference in pressure.

If there is oil in the muffler - essentially the same problems, first of all, the oil pipes and the oil itself are “aired”! I would even remove the turbo and clean it and all the surrounding oil and air lines.

Of course, the above reasons are not a panacea; perhaps your unit itself has already worn out.

Complex reasons:

Needless to say, if you violate the operating rules, your turbine will fail very quickly.

1) The impeller is broken, indicating a large play on the shaft.

2) Oil flows more than normal, indicating bearing wear.

3) The shaft is jammed and the impeller does not rotate at all.

For all these reasons it changes. But these are already complex cases, some can only arise when it has really worn out, it’s just time.

In conclusion, to summarize, if the oil is leaking, this does not mean it has failed; we check the air filters, oil, and pipes. Now a short video for understanding.

I’ll end here, there will be more useful articles.

Whiteness of smoke

After warming up the engine in warm weather, a thick white cloud may appear from the exhaust pipe. It indicates that coolant has entered the cylinders. This happens due to a leak in the gasket between the cylinder block and the head, or cracks in the coolant passages.

It is worth paying attention to other possible causes of white smoke. With the engine turned off, check for exhaust gases entering the cooling system. To do this, remove the expansion tank cap or unscrew the radiator cap. This determines:

- presence of exhaust odors; is there an oily film in the liquid itself; Is the coolant level low?

The entry of gases into the cooling system leads to an increase in pressure. After the engine stops, the coolant partially goes into the cylinders. Its level in the tank decreases. Antifreeze (antifreeze) seeps through the piston rings into the oil pan. There it mixes with motor lubricant, diluting it. A kind of emulsion is formed. Motor oil changes color, becomes cloudy, and loses its working properties.

Experienced technicians advise flushing the inside of the engine with diesel fuel before repairing such damage. This saves nerves and time during repairs. A cleaned motor will make it easier to locate the fault.

Additionally, diagnosing the condition of the oil filler plug and cylinder head cover helps ensure that coolant penetrates into the lubrication system. A light foam with a yellowish tint forms on their inner side. A similar sign can be recorded on the oil dipstick.

Low-quality antifreeze can provoke internal corrosion of metal engine parts. Sometimes the damage becomes through, and rust particles get into the expansion tank. Significant funds will be required to restore such an engine.

Engine overheating is a prerequisite for the appearance of white smoke.

The reasons for the appearance of abundant white smoke often lie in engine overheating. Ineffective operation of the system responsible for cooling the engine leads not only to overheating of the power unit, but also to deformation of the piston rings. The consequences require an immediate response and immediate troubleshooting.

If there is white smoke, you will definitely need to check the condition:

- problem cylinder;

- thermostat;

- fan and sensor for turning it on;

- expansion tank plugs;

- intake manifold gaskets;

- cooling system hoses;

- radiator tightness.

Liquid may enter the combustion chamber. This leads to the formation of air pockets and a large amount of liquid entering the cylinders. The consequence may be water hammer. Then pressure surges lead to the formation of cracks in the body of certain parts and damage to various equipment elements.

Having established the specific reasons for the appearance of white smoke from the exhaust pipe, repairs should be started immediately. The consequences of malfunctions will have to be eliminated in the operation of the entire cooling system.

Reasons for oil getting into the intake manifold. List and actions

The turbine drives oil into the intake or exhaust system. Oil flows into the intake system from the compressor side. To eliminate the problem, you must perform the following steps: 1. Leak into the intake system Loss of pumped air leads to loss of boost pressure, and this, in turn, can cause oil leakage . Leak into the engine intake or exhaust system Due to the fact that oil enters the turbocharger under pressure and leaves by gravity, due to the large pressure difference, even slight clogging of the oil drainage paths can provoke very serious oil leaks from both the compressor and turbines, and sometimes even on both sides at the same time.

Leak exclusively into the intake system. Pay attention to the manifold; if you find oil particles there, then the problem is most likely in the engine, and not in the turbine. If you have problems determining the cause of the leak, we advise you to contact a specialist. Similar problems: Increased oil consumption Oil leaks outside the turbine Engine power has decreased Oil leaks in the compressor part of the turbocharger Oil leaks in the turbine part of the turbocharger.

Is it dangerous for oil to get into the intercooler?

The intercooler of a diesel engine with a mileage of over 100 thousand kilometers almost always contains a small amount of oil (20–50 grams). This is caused by the higher pressure generated during combustion of the air-fuel mixture. As long as the oil is below the level of the cooling cells, it does not affect the operation of the engine. When the intercooler radiator is filled with oil to the level of the lower cells, carburetion occurs.

The temperature of an overheated exhaust manifold reaches 700 degrees, which negatively affects the engine. After all, the temperature of the cylinder block begins to increase, the cooling system cannot cope with heat removal, which leads to overheating of the engine and a decrease in its service life.

Dirty filter

An air filter is often called an element of a car's breathing system. When the PCV valve fails, it can become contaminated with hydrocarbons and oil. This is also due to the increase in crankcase pressure, which forces water vapor through the breather element. Water mixes with gasoline, causing buildup and increasing fuel consumption. One way to check this component is to directly inspect the filter for build-up. Another way is to measure the car's fuel consumption. If it starts to increase for seemingly no reason, the PCV valve may fail.

Pipes

This is another reason. If the oil has not been changed for a long time, the pipes tend to become clogged. Even if the turbine is repaired, the pipes are cleaned. It is very important. If the oil is under the intake manifold, then a pressure difference occurs due to the pipes or filter. It is also important to monitor the tightness of the air elements; if the pipes have cracks or other signs of deformation, they should be replaced with new ones.

Otherwise there will be excessive air leaks. This is harmful for both turbocharged and naturally aspirated engines. The problem is further aggravated by the fact that unpurified, dirty air gets through these cracks, bypassing the filter. And the presence of dust in the cylinders of internal combustion engines leads to premature wear of the piston group.

Air filter dirty

Complicated air intake for the turbine is one of the causes of the malfunction. The air filter is often to blame for this - people forget to change it. The air intake pipes may also be partially blocked. It may get pinched or break.

During turbine operation, a vacuum is generated. If there is not enough air, the pressure increases significantly, oil is drawn out of the turbocharger.

For a turbine, the air filter is very important. Basically, the lubricant is driven away due to the fact that the pressure is broken precisely because of the clogged filter. On turbocharged engines, the cleaning element must be changed every 8 thousand kilometers.