Characteristics of a metal garage, prefabricated, collapsible, sectional

- Characteristics

- Characteristics

- Home

- gate width: 3000mm

- typical sizes:

- 3780x7400mm

- 3780x6500mm

- 3780x5650mm

- 3400x7400mm

- 3400x6500mm

- 3400x5650mm

- 3000x7400mm

- 3000x6500mm

- 3000x5650mm

- height with ridge: 2600mm

- 3400x6500mm

- gate height: 1930mm

- 3000x5650mm

- Buying a garage. Tips for choosing

- 3000x7400mm

- 3400x7400mm

- Bestseller Metal garage 3000×5650 We sell in Rostov-on-Don and throughout the South of Russia a prefabricated collapsible sectional iron garage.

- 3780x6500mm

- 3780x5650mm

- Construction of a garage: types, choice of location, foundation, walls, roof.

- 3400x5650mm

- walls: sheet steel 1.5mm thick - if desired, it is possible to use sheets 1.2mm thick

- 3780x7400mm

- Metal garage made of corrugated sheets. Construction. Advantages. Flaws

- Comparison. Advantages and disadvantages of a brick and metal garage

- Installation Assembling a metal garage

- 3000x6500mm

Accessories

To make the structure as stable and reliable as possible, special attention must be paid to fastening all parts. Each node performs its own function and carries a certain load. When installing, be sure to take into account all the nuances.

When installing the frame, the vertical posts are secured with profile corners both at the bottom and at the top. Often the frame is welded, but it is also permissible to use special fasteners.

The roof can be either gable or single-pitch. In a collapsible metal structure, a gable roof is often used.

After installing the frame, the structure is sheathed with sheets of metal, which are attached by welding or screwed to the base with self-tapping screws. Despite the fact that all elements are securely fastened, the garage can be disassembled at any time if necessary and transported to another site.

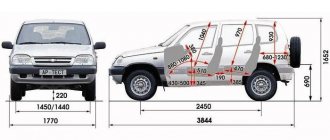

What cars is it designed for?

A metal garage can cover any vehicle: from a passenger car to a truck. The main thing is to maintain the dimensions and draw up the correct drawings of a metal garage in advance to ensure free entry, opening of doors, and closing of gates.

Iron garage dimensions:

- The standard dimensions of a metal garage are 3x6 meters . It will accept both a small car and an SUV into its space, if the owner does not care about additional space for a workbench, storing seasonal tires and household items. All this can be accommodated by increasing the length of the garage by 1 meter. But ideally, for greater comfort, dimensions of 4 x 7 x 3 (height) meters are in demand. You can also park a minivan in such a garage.

- A metal garage for two cars should have a passage between them and the walls of 0.5 meters (preferably 1 m). The total is 5 meters . A space of 1.5 meters is desirable in front of the gate.

- The largest of the jeeps, Hammer, has dimensions of 2.2 x 4.7 x 1.9 (height) meters. Just to without an accident (without a service area!), he needs a room 5.2 x 5.3 x 11 meters.

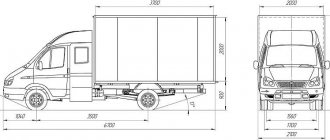

- The Gazelle will fit seamlessly into the garage dimensions of 3.6 x 6 x 2.5 meters, even if it is an awning shelter .

The weight of a metal garage determines the delivery method and the stability of the structure .

Everyone is familiar with the picture of the notorious shell being brought and installed in a city: assembled in the back of a truck. How much does an iron garage shell weigh? Its weight , like the pencil case, is no more than 600 kg . Therefore, such shelter tents often became the subject of thefts .

a metal garage weigh ? The factory-made metal structure will weigh from 1 to 1.2 tons (standard version), and heavyweights of 2-3 tons . It all depends on the thickness and specific gravity of the metal, which allow you to calculate the weight of the finished product. Arithmetic operations are used to calculate the volume of the walls and roof, and then the result is multiplied by the specific gravity of the material.

Izhora garage

The post-war revival of metallurgical and mechanical assembly production in Kolpino was aimed at restoring the country and fulfilling government orders. Among the urgent needs of the population of that time was a garage for private cars, the fleet of which was actively replenished.

Collective parking lots (CAPs) were created on the outskirts of cities, and garages were installed in city courtyards and on personal plots. A reliable, easy-to-transport, collapsible design was preferred everywhere.

Since the 50s of the 20th century, both in the European part of the country and beyond the Urals, many enterprises have appeared that produce garages of this type called “Izhora” , which is now considered as a brand. New manufacturers made their own innovative additions to the design, but the dimensions and set of components remained unchanged.

Peculiarities

- material: cold-rolled steel with a thickness of 1.5 to 3 mm;

- processing of prefabricated elements: stamping with folded edges;

- bolted connection from the inside - 4 M12 bolts for each joint;

- double-sided coating with primer GF-021.

Izhora garage dimensions and weight:

- box dimensions: 3x6x2m (height under the ridge of the gable roof - 2.6m). There are products 3.3 m wide and 7 m long;

- weight - 1200-1300 kg (fits into the Gazelle load capacity standard).

Equipment

Modern manufacturers of this type of garage pack all structural elements in polyethylene and provide assembly instructions . The seven-section garage kit includes:

- Wall sections:

- straight with edges curved on both sides - 13 pcs;

- end (the edge is bent on one side) - 2 pcs.;

- reinforced with a corner and with hinges for gates - 2 pcs.

- Gate sections - 3 pcs.

- Corners for securing gates (50x50) - 2 pcs.

- Gable sections4 pcs.

- Roofing panels - 14 pcs.

Total: 34 metal sheets and fasteners.

The prefabricated Izhora metal garage is designed for domestic small cars without servicing the car indoors. An attempt to increase its length is solved by purchasing additional wall and roof sections. Increasing the width will require a radical rework of the entire ceiling and gate frame, which is not economically profitable .

DIY metal garage installation

For people living in the city and having a car, having their own garage is a huge success.

And the owners of country houses, in general, cannot do without a personal house for their car.

It is not always possible to purchase a garage built from cinder block or brick due to financial situation or other reasons.

However, there is an excellent prospect for vehicle owners - metal garages. What are their advantages? What materials should be used for construction?

How much does a metal garage weigh?

installing a frame A metal garage is a convenient option for quickly building a room. Such construction does not require laying a foundation or other work that requires careful and lengthy preparation.

A garage made of metal structures is a frame that is sheathed with a sheet profile.

This is the main characteristic feature of a garage made of metal structures. Therefore, before you finally decide which garage to build, you need to weigh the pros and cons of such a structure.

Among the types of such structures, the following can be distinguished: Factory kit. This metal prefabricated garage can be assembled by two or three people. All potential builders should have is a basic set of tools (which includes a wrench, hammer, etc.). If the product is of high quality, then all components of the structure can be easily assembled, and potential builders will not have the need to use additional equipment.

Garage for one car

» » Having a garage for a car is a prerequisite for increasing its service life.

Before starting construction work, it is necessary not only to decide on the size of the garage for 1 car, but also to resolve several main related issues. Any construction must be carried out taking into account current regulations; it is necessary to familiarize yourself with their provisions before planning the structure. Some local authorities have their own restrictions on the construction of garages, check them before you start planning work.

Ready garage SP 42.13330.2011. The set of rules regulates the distances between rooms depending on their number of storeys, purpose, material of manufacture and seismicity of the region.

Garages are prohibited from being placed above existing utility networks, gas pipelines, electrical cables, etc. The minimum distance between the size of the garage and the boundary of the site must be at least one meter if there are no other buildings in the adjacent area. If there are other structures, the distance increases depending on their purpose.

SNiP 01/21/97. Building codes establish minimum distances between buildings taking into account fire safety.

In order to prevent the spread of fire, the distance between existing buildings cannot be less than six meters. The standards take into account the existing requirements of fire authorities.

Distance from the garage to other buildings

There is a set of rules and regulations (SNIP) numbered 2.07.01-89, which outlines the standards for the location of a garage on the site. This is a legislative act, the provisions of which must be strictly observed. But there is a deviation from the regulatory requirements, which states that regional administrations have the right to introduce their own requirements, which should not contradict the legal ones. That is, the above-mentioned SNiP in each area can be added by other standards.

However, it should be noted that the norms specified in the documents are advisory, because the suburban area is the property of its owner. And on it he can build whatever he wants and wherever he wants. That is, the violator will not bear either administrative or criminal liability for violating building regulations.

But lawyers recommend not to break the rules, because they were written for a reason. Because there will always be a person, for example, your neighbor, who decides to organize a recreation area near the fence, and in this place you have a garage on your property. Here's a conflict for you, because he doesn't want to breathe the exhaust from your car. And if you violated the standards, then the court’s decision, if your neighbor goes there, will not be in your favor.

Diagram of the correct location of a garage on a suburban areaSource bankfs.ru

There is no point in scolding the laws; they have been developed for more than one year. Especially construction ones. Their rules, requirements and technologies are based on the vast experience of mankind, which primarily protects the person himself: his life and health.

So, here are the rules and regulations according to the above-mentioned SNiP, which must be followed when building a garage on a summer cottage, taking into account sanitary and household standards:

- from the garage to the windows of the neighboring house - at least 6 m, this distance was specially chosen in case a fire occurs in the garage and so that the fire does not reach the neighboring building;

- the distance to the boundaries of the dacha plot is 1 m minimum, this is done so that pedestrians can move freely along the pedestrian path near the plot if the car is parked near the garage;

- the same parameter before the fence, here the reasons are different: so that the building does not cast a shadow on the vegetation of the neighboring dacha, so that rain from the roof of the garage also does not flow into the neighboring garden, so that it is possible to repair the walls of the building without climbing into the neighbor’s plot;

- they leave 3 m to the walls of the main house for the same fire safety reasons, it’s just that this distance allows special equipment to pass.

The distance from the garage to the border of the neighboring plot is at least 1 mSource shadowgold.ru

There are standards for the location of a garage in relation to two-story buildings. Here there is 1 m to outbuildings, and 5 m to a residential building. And the last parameter is the distance to the roadway. It should not be less than 3 m, but within 5. This is all for the same case associated with the use of special equipment. If the road is located on the side of the garage, then the distance to its edge should be at least 3 m, and to the center of the roadway within 5 m. This is in case of a safe exit of the car from the garage onto the roadway, so as not to collide with moving traffic.

Please note that according to SNiP, a garage in a dacha must be built taking into account the above standards, starting from the base of the building. If there is no such element in the building, then from the walls

If the garage is covered with a roof with a protruding eaves, then the countdown is from its edge. Or rather, from the projection onto the ground.

Now there is one subtle legal point. Everything that was said above applies only to capital structures. That is, garages built from bricks, blocks and other building materials, laid on a thoroughly poured foundation. And varieties such as a metal garage, frame or concrete portable garage qualify as temporary structures. That is, they can be transferred at any time. This also applies to carports. These buildings do not fall under the requirements specified in SNiPs.

But you still have to adhere to some requirements. For example, if the garage door is level with the fence, then you need to think about the exit of the car, and also maintain the distance to the pedestrian path.

It is necessary to maintain the distance to the road, taking into account convenient and safe exit. Source podkova56.ru

Weight of metal garage 6x3

Contents A lightweight and convenient prefabricated garage made from profiled metal sheets or sandwich panels does not require a powerful foundation. The installation of the structure can be done with your own hands, if you have a minimum of necessary tools.

A prefabricated metal garage is not a permanent structure, so its installation does not require special permission from many authorities.

What other advantages does this type of prefabricated structure have:

- relatively low cost compared to brick garages and block buildings;

- opening a metal garage is difficult - you need tools that work with a lot of noise - an angle grinder or welding;

- prefabricated garages made from sandwich panels have good thermal and waterproofing;

- You can install the structure yourself in two days;

- fire resistance;

- a metal garage is lightweight, so its installation does not require a complex, expensive foundation;

- When insulating, heating such a design will also not require much expense.

- it is easy to make simple ventilation in a prefabricated metal garage;

This durable and lightweight design has many advantages.

Of course, a prefabricated garage made of profiled metal sheets cannot be compared with a permanent brick building, but such a structure can protect a car from weather conditions and theft. Metal garages also have disadvantages that must be taken into account:

- because ready

Installation of a prefabricated garage

The prefabricated insulated structure can be installed on any cement base and even on a bed of compacted soil, crushed stone and gravel. Only in this case is it necessary to equip a high-quality drainage system to remove seasonal storm and melt water from the metal walls of the garage.

Without drainage, a prefabricated warm garage is installed on a concrete base (strip or monolithic). The required lifting height from the ground level is at least 20 centimeters. It is safer to install prefabricated frame structures on monolithic reinforced concrete foundations.

Foundation structure

The foundation for an insulated metal garage can be ordered along with installation from our company, because any construction begins with us! Or you can do it yourself, but taking into account the size of the structure. The sequence of work is as follows:

- remove the layer of fertile soil, compact the soil thoroughly;

- According to the dimensions of the frame, it is necessary to dig a trench for a strip shallow foundation. Width 60 cm, depth 50 cm;

- a sand cushion is poured onto the bottom of the trench - a layer of 20 cm and carefully compacted;

- then formwork is placed from boards or plywood, width 40 cm, height 20 cm above the soil level;

- to waterproof the foundation, lay a layer of plastic film on the bottom of the formwork;

- after that the reinforcement is installed, two reinforcement rods (at least tied with knitting wire and secured with transverse rods in increments of 50 cm;

- Concrete mortar for the foundation is prepared in a ratio of 1 part cement, two parts sand and two parts fine crushed stone.

Advice. For regions with low temperatures, it is better to purchase ready-made concrete with anti-frost and strengthening additives for the foundation; it is not much more expensive, but is of better quality than a home-made mixture.

- The hardening time of the concrete tape depends on weather conditions, but until it hardens completely, it is better to cover the poured foundation with roofing felt or film. In hot weather, to avoid cracking, periodically spray the foundation with water;

- When the concrete has hardened, you can remove the formwork and backfill all cracks and gaps in the ground with sand.

Now you can start installing the garage floor.

Floor installation in a warm garage

It’s easy to pour a concrete floor screed:

- cover the floor with a 10 cm layer of sand and compact it thoroughly;

- Be sure to level the surface using a level, taking into account the required slope for water drainage of 2 cm;

- A reinforcing frame is placed on top of the sand layer (8 or 12 mm reinforcement, depending on the weight of the car). The mesh is raised slightly above the sand so that it is completely filled with concrete;

- It is immediately necessary to set the beacons according to the level of the concrete screed, a step of one meter, this will make it more convenient to level the concrete mixture after pouring;

- Next, a rough floor screed is poured - a layer of at least 10 cm.

Using the rough screed, it will then be possible to make a moisture-repellent or anti-dust coating with a special mastic for garage floors.

Exhibiting the frame of a warm garage

The frame can only be installed on a fully matured and frozen foundation. The frame assembly sequence is as follows:

- First, the lower trim is installed, which is firmly fixed to the foundation.

Important. Be sure to correctly align the lower part of the frame horizontally so that there are no distortions; the strength and rigidity of the entire structure depends on this.

- then vertical posts are attached in the corners, in the places where the gates are attached and along the walls, in increments of at least 3 meters;

- depending on the chosen frame design, the frame is assembled using bolts or welding;

- then the roof truss is installed along the vertical posts and the roof covering is mounted;

- For warm garages made of sandwich panels, installation of all extensions and connections that come with the kit is required. This will help prevent moisture from getting inside the panels.

You can assemble the finished structure according to the drawings with your own hands, but it will take a lot of time and you will need helpers. It’s easier to immediately order a warm prefabricated garage with installation. In this case, you receive a guarantee from the manufacturer not only for the components and design, but also for the entire construction as a whole.

Alternative solutions

Structures made from metal profiles have a lot of advantages, but some are not satisfied with their weight, problems with transportation when they need to move often, and some other nuances, so alternative solutions are selected. If you have to move often or go on vacation, then you can use a shell awning.

Essentially, this is the same garage, but instead of sheets of metal, it uses high-strength fabric. It does not allow precipitation, wind or sunlight to pass through. In some cases, a tarpaulin is used for this, but it is better to use polyester fabric, which must be impregnated with special compounds. In addition, such an awning can be a good option for temporary housing on vacation, at the cottage, and so on.

On our website you can get acquainted with the most popular plots in the Moscow region for the construction of a country house. In the filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Video description

What you need to pay attention to when choosing a ready-made used metal garage, watch the video:

On our website you can get acquainted with the most popular projects of garages and other small forms for a private house - from construction companies presented at the exhibition of houses “Low-Rise Country”.

By the way, about the material. Firstly, after the construction of a dacha or country house, a thrifty owner always has metal profile waste that he does not throw away. You can use them too. If the garage will always be under supervision, then for its construction it is recommended to use cladding materials with low strength characteristics. And this will affect the reduction in construction costs. For example, instead of sheet iron with a thickness of 2-3 mm, use corrugated sheeting with a thickness of 0.7-1 mm.

In addition, the owner, together with invited craftsmen, can determine the dimensions of the structure, the type of its roof, the type of thermal insulation material and internal cladding. And all this should be adjusted to the budget allocated for the construction of a metal garage.

Inexpensive garage made of profiled sheets

The correct method for calculating the weight of a 3x6 m metal garage

On average, the weight of a 3x6 metal garage varies between 3-4.5 tons. You may only need information about how much a garage weighs in 2 cases:

- You haven't yet decided which metal garage you're going to buy.

In this case, the weight of the metal garage will affect the cost of delivery and the load that the concrete base will receive.

If you purchase a garage box from a specific manufacturer, then all the necessary information can be found in the delivery note.

- You have decided to move your old metal garage to a new “place of residence”.

In this case, it is quite difficult to know the exact weight of a 3x6 metal garage, since many people cook it themselves. In this case, various material options are used - from various configurations of corners to metal thickness varying around the entire perimeter.

Weight of a metal garage 3x6 Initial data: length 6 meters, width 3 meters and height 2 meters.

If you are faced with the 2nd situation, then using our method you will quickly calculate the approximate weight and be able to choose the right manipulator.

The basis of the design is an all-welded type of garage, in which a layer of sheet steel with a thickness of about 4 mm (the most common option) acts as a cladding. These are the minimum standard garage sizes for any modification of a passenger car. Important: How much an iron garage weighs will mainly depend on the thickness of the sheet covering and the total surface area.

Garage projects

- 26² Total area

- 5 x 4m Building area

- 11.7² Total area

- 3 x 3m Building area

- 24² Total area

- 6 x 4m Construction area

- 30.17² Total area

- 5 x 11m Construction area

- 22² Total area

- 4 x 5m Building area

- 37² Total area

- 9 x 5m Construction area

- 31.8² Total area

- 6 x 5m Construction area

- 31.8² Total area

- 6 x 5m Construction area

- 143² Total area

- 20 x 6m Construction area

- 33² Total area

- 6 x 5m Construction area

- 158² Total area

- 57² Total area

- 8 x 6m Construction area

- 42² Total area

- 6 x 7m Construction area

- 33² Total area

- 6 x 5m Construction area

- 31.8² Total area

- 6 x 5m Construction area

- 40² Total area

- 8 x 5m Construction area

- 32² Total area

- 4 x 8m Construction area

- 58² Total area

- 10 x 6m Construction area

- 2 rooms

- 1 bathroom

- 192.58² Total area

- 18 x 8m Construction area

- 76.95² Total area

- 7 x 11m Construction area

Today we will tell you in this article about such a very necessary structure as a metal garage. Let's look at the selection criteria, how to install and assemble it, and how the garage is sheathed and insulated. Once you understand the information received, you will understand what, how and why the craftsmen who were entrusted with the construction of this structure are doing and will be “in the know” when discussing the details.

Metal garage with gable roof

Design Features

Basically, such garages are made from metal profile sheets, and the reliability of the product is ensured by the thickness of the material. The shape of the building corresponds to the name of the structure - semicircular. But there is another option - a garage pencil case, which is presented in the form of a long metal structure.

The price of this design depends on the materials used and dimensions. These can be standard metal sheets or options with a special polymer plastic coating. They bend easily, acquire the desired shape, but remain quite strong.

Metal collapsible garage: features and advantages

» » » A collapsible garage is a convenient structure for storing a car when its owners frequently move from one place of residence to another.

In this case, the collapsible elements are connected to each other with bolts or screws, which will help, if necessary, quickly dismantle the garage or improve its design.

This article will tell you how to make a collapsible garage with your own hands. The main feature of the design is that a metal profile corner is used for its manufacture, and sheet metal is used for cladding. A metal garage is a lightweight structure that requires only a symbolic foundation around the perimeter.

The base for the garage can be poured with concrete, while a reinforced mesh is laid over the entire area. Such a slab will simultaneously act as the foundation and subfloor of the garage. Factory-made floor slabs can be laid directly on the ground.

But with any foundation, several rules must be followed: The top of the foundation or base slab should be 15-20 centimeters higher than the ground level. This is necessary to protect the garage from water flowing in when snow melts or from rain.

The surface of the foundation is strictly horizontal, which is checked by the building level.

Construction set for adults

A collapsible garage is a functional structure that consists of many parts, assembled together using fasteners. It can have a flat, gable roof, be collapsible or non-removable. A variety of materials are used to make floors: boards, asphalt, paving stones, reinforced concrete slabs. Sometimes a garage is placed directly on the ground if we are talking about a temporary structure.

When transporting disassembled, sometimes a Gazelle with a carrying capacity of 1.5 tons is sufficient. When transporting a huge structure, a more spacious vehicle with a larger body area may be required. Items up to 100 kg can be loaded manually. In other cases, it is better to immediately call a crane.

Materials

You can line the inside of a garage with a variety of materials.

It could be:

- drywall;

- wooden or plastic lining;

- plywood;

- metallic profile.

Before you begin installing a metal garage, you should definitely draw up a plan diagram. It is very important to calculate all the main dimensions in advance, then it will become clear how much material will be required.

A collapsible garage is most often 3.5 m wide and 5.5 m long. The foundation for the structure should be 15 centimeters above ground level so that water does not enter the room during precipitation.

The foundation is poured immediately, this will greatly increase the strength of the floor. Before making a concrete slab, it is definitely recommended to add gravel, thus creating a “cushion”, which will be a slight elevation above the ground level. This will protect the room from moisture in rainy weather and in the spring when the snow melts.

To install a concrete screed you will need:

- cement grade minimum M 200;

- metal rods 6-8 mm for reinforcement;

- sand and crushed stone.

With no less efficiency, you can install a pile foundation that can withstand heavy loads. A pile foundation costs much less; its strength will not be inferior to a concrete structure.

The main material costs will be for the purchase of material for the frame.

If the garage frame is metal, you will need to buy:

- corners;

- pipes;

- galvanized profiles.

If the frame is wooden, then you will need to purchase:

- beam;

- boards;

- plywood

Most often, pipes are used for construction, which are easy to bend while maintaining strength. To work with such material, you can use both welding and threaded connections. It is best to develop a project for an iron garage on the basis of a modular model, when the frames of all the walls are made separately, and after that all the elements are assembled into one and installed on a prepared area.

To install the frame of a metal structure product you will need:

- metal pipes, their parameters must correspond to the dimensions of the future structure;

- welding equipment or corners - the choice depends on the profile fastening;

- grinder with cutting discs or drill with drills;

- fasteners;

- perforator;

- water level;

- corrugated sheeting

You can also use reinforced concrete elements; they can withstand heavy loads, but are much more expensive. When installing a reinforced concrete product on concrete, a waterproofing layer must be placed between the metal and the screed. Metal profiles must be primed with a primer and then painted.

The best option is to use an alkyd primer; it is relatively inexpensive and effectively protects the metal from corrosion.

Video description

The sequence of assembling the metal frame in the video:

And so, our garage is 4x6 m, so we cut a 50x50 mm corner to fit these dimensions. Four sections of 6 m each, four of 4 m each. Then four racks of 2 m each. These elements are used to assemble a box directly on the slab foundation.

First of all, a 6x4 m rectangle is assembled on a plane. The joints are welded together using electric welding. Let’s make a reservation that we will talk about how non-demountable metal garages are manufactured.

Garage structure assembly diagram

Then racks cut into 2 m lengths are installed in the corners. They are first positioned vertically. They are attached by electric welding to the lower trim. Now an important point: the length of 6 m is significant. If you place a corner of the top trim on two posts, it will sag. Therefore, intermediate posts are also installed along the length of the garage in increments of 1 m. Only for this purpose can you use a smaller corner: 35x35 or 40x40 mm. The same is done with the side of the building 4 m long.

The elements of the upper trim are laid on the installed supports. Welding is in progress. Please note that intermediate support posts are not mounted on the gate installation side. A 50x50 mm corner with a length of 4 m is quite rigid, so it will not sag under its own weight.

Roof formation

The simplest option is a pitched roof. To do this, five sections of a corner are welded vertically on the constructed box above the gate with an installation step of 1 m. The minimum length of the sections is 50 cm. They are connected on top with a horizontal piece of the corner.

Then measure the distance from the laid corner to the rear element of the upper skin. It must be more than 6 m. Another 60 cm is added to the size. This is for overhangs in front and behind the garage of 30 cm. The minimum size.

Metal structure for a garage with a pitched roof

This might be interesting!

In the article at the following link, read about a garage made of sandwich panels.

From a 50x50 mm corner, cut rafters of the estimated length in the amount of 3 pieces. They are laid in place and welded. They are connected to each other in small sections, distributed along the length every 1-2 m.

If the roof is gable, then first assemble the trusses on the ground in the form of an isosceles triangle. To make it clear what we are talking about, look at the photo below. These are complex trusses to make because they use jumpers. For a small garage, these elements are not necessary. The corners are simply welded into a triangle. It is important to take into account here that the trusses should protrude at least 20-30 cm on each side along the edge of the building. If the roof is covered with sheets of steel 2-3 mm thick, then the overhangs are formed with them. Then the trusses are made strictly according to the size of the garage, as shown in the photo.

Truss diagram for a gable roof of a metal garage

So, if the trusses are ready, they are installed on the frame box, welded to the elements of the upper trim. By the way, the optimal installation step is 1 m. That is, they should rest on the vertical support posts of the frame structure. All that remains is to form the crate. It is made from a 35x35 mm corner, laid across the installed trusses. Installation step 1 m.

Now we need to give the assembled structure greater rigidity. To do this, scarves (isosceles triangles with a leg length of 20 cm) are cut out of a sheet of steel, which are welded at the junction of the vertical supports and the elements of the upper and lower trims.

Frame covering

To avoid high costs, you need to select metal sheets exactly to the size of the garage being assembled. In our case, sheets measuring 1x2 m are optimal for walls, and 1x2.5 m for roofs.

The sheets are simply laid on the racks so that adjacent ones are joined on the supports. Laying is carried out from the outside of the garage, welding from the inside. First the walls are sheathed, then the roof. Welding is carried out spotwise with a seam length of up to 5 cm.

Garage wall cladding with sheet metal

This might be interesting!

In the article at the following link, read about organizing a garage.

Manufacturing and installation of gates

They are assembled separately from the general structure. Usually this is a double-leaf model, consisting of two identical rectangular products. The same 50x50 mm corner is used for manufacturing. For our garage we will have to prepare eight 2 m long sections. They are assembled into two squares. Two more segments are needed to create rigidity of the structure. They are welded one into each sash in a vertical direction.

Then the sheathing

gates with sheets of iron, welding them to the corners.

All that remains is to hang it

gates. To do this you will have to buy four loops.

Their upper parts (with a cavity inside) are welded

to the gate leaves.

After which the gate itself is raised and placed

to the garage, aligning it vertically and so that the doors close tightly, but there is a small gap between them. If necessary, small supplies are placed under the doors.

Insert the bottom parts of the loops

to the top ones and make marks on the corner posts where they need to be welded. Experienced craftsmen do this right there without markings.

All that remains is to weld

loops to the gate for a padlock or install an internal one, and also attach a handle.

Making garage doors

Insulation of the garage

Whether it is worth insulating a metal garage or not, everyone decides for themselves. If such a decision has been made, then here is the easiest and cheapest way. To do this, you will need wooden slats with a cross-section of 50x50 mm, polystyrene foam boards 50 mm thick and wood screws.

The sequence of the thermal insulation process is as follows:

Optimal sizes for a garage

When deciding to take such an important step as building a garage, you simply need to plan everything carefully.

Firstly, it is very important that it is spacious and comfortable enough; on the other hand, a garage that is too large means extra costs for both building materials and its maintenance in the future.

The standard dimensions of a garage for 1 car are 4x6 meters, that is, based on one meter for passage on the sides and ends, plus 1 meter in length for workplace equipment.

Such a room is quite sufficient for maintaining a passenger car and is quite economical in repairs and heating in the winter. But in cases where the garage is planned to be used as a utility room, or a larger car is planned to be purchased, the dimensions may change upward. The plan for building a garage largely depends on the size of the car itself and the available space for construction.

In any case, the internal space should be sufficient not only for the car itself, but also for passage, installation of shelving and storage of necessary components. Agree, it won’t be very pleasant if, after finishing construction and finishing, you find that if you open the door abruptly, you risk scratching it on the walls or shelves. If in the coming years you plan to change your car to a larger one, then the building must be planned taking into account its dimensions.

Today, one of the optimal, one might say spacious, garages for passenger cars is the size of 7x4 and 3 meters high. This is quite enough to maintain and service any modern passenger car.

Metal "Volgovsky" garage

Collapsible metal structures have a number of advantages. The so-called “Volgovsky” garage can be easily disassembled and moved to the desired location near the house. The mobility of the room and small dimensions allow the structure to be installed on personal plots.

Main parameters:

- Length 5.6 m;

- Width 3.45 m;

- Height 1.9 m;

- Gate width 2.6 m.

These sizes are suitable for most domestic cars. However, the room is designed only for parking a car. Storing foreign items is not possible. In winter, the lack of heating is the main disadvantage.

Advantages of metal construction:

- Mobility;

- Easy to install;

- Low cost;

- Durability and strength;

- Does not require pouring a foundation.

A standard metal garage is a low-cost alternative to a brick or concrete structure. The undeniable advantage of stationary premises is the ability to equip and insulate the area, as well as resistance to open fire.

When selecting or building a garage, consider the future. There is a possibility of buying a larger car, so when making calculations it is better to start from the parameters of large cars, for example a jeep. It is necessary to think through all the little things and take into account the nuances. A garage space is a financial investment for many years.

Source

How much does a 3x6 metal garage weigh and how to calculate its weight correctly

› A metal garage is a reliable structure that protects your car from bad weather and thieves. It is easy to build, it is inexpensive and, if necessary, the box can be transported to another place without disassembling it. However, to transport a metal garage, you need to know its weight in order to choose the right crane and van without overpaying.

Let's figure out how much a finished metal garage weighs, and what methods of calculation exist. Information about the weight of a metal garage is required by owners in the following cases:

- There was a need to move the building to a new location.

To lift and transport it, you need to know the initial weight in order to correctly order loading equipment, the rental price of which varies greatly depending on the power. The situation is complicated by the fact that most of the buildings, dismantled or welded, are made by the owners themselves, and no preliminary calculation of their mass was made.

In this case, you need to calculate the weight yourself.

- Construction is just planned; or buy a ready-made design.

You need to know the weight to order a vehicle with adequate power to deliver the cargo to the place.

The foundation for a building is also poured to accommodate a certain load, and if done incorrectly, the reliability of the structure will be significantly reduced.

Calculating the weight in such cases is not particularly difficult, since: companies producing metal garages to order indicate the weight in the technical documentation

Other requirements for garage construction

Building codes and regulations define the following requirements for a garage structure:

- It should not be adjacent to the boundaries of the site closer than a meter if there are no buildings behind them. This space is required so that during repairs it can be freely walked around, the garage does not cast a shadow on the neighboring area, and water from its roof does not fall on it. The rule applies to both gardening cooperatives and individual housing construction.

- The building is being erected no closer than 5 m from the main street and 3 m from the side passage.

- The minimum distance between structures located on an adjacent site and the garage should be 6 m. With this arrangement, the fire will not spread from one building to another in the event of a fire. By agreement with neighbors (documented), it can be reduced.

- The garage should be located no closer than 3 m from a residential building, 8 m from concrete buildings and 10 m from reinforced concrete ones. If the garage itself or the building nearby is made of wood or other flammable materials, the minimum distance between them is 10 m (if both are 15 m).

- The canopy or gate should not interfere with movement along the street.

We recommend: How to level a wooden floor in a private house under laminate without screed (without tearing off the boards)

To build a private non-permanent garage, permission is usually not required, but contacting the local administration and clarifying this point would be the right decision.

For a permanent building with a foundation on a site for individual housing construction or personal subsidiary plots, it is necessary to obtain it - it is subject to tax (the rules for issuing are regulated by Article 51 of the Town Planning Code of the Russian Federation). A permit is also required if the garage will be used for commercial activities.

Built-in garages

Based on the type of construction, a distinction is made between built-in and free-standing garages. As a rule, a built-in garage is an extension to the house or part of it. Projects of modern multi-storey buildings have built-in garage parking. This pleases car owners and greatly upsets “horseless” residents. Built-in garages are very convenient to use. Private houses and cottages may have a garage for one or two cars. The main value of such a garage is the economical use of space around the home and good protection of the car. In addition, a built-in garage allows you to save on building materials, since part of its walls are the walls of the house. Closely located house communications allow them to be routed to the garage. In cold or rainy weather, you can get inside without going outside. The obvious disadvantage of this option is the additional noise and the presence of extraneous odors. In addition, to build such a garage, you will need to comply with a lot of technical and regulatory requirements. To prevent the occurrence of negative phenomena at the design stage, you should carefully consider the development of ventilation lines and sound absorption systems. The most common location for a built-in garage is the basement. When building such a garage, you should carefully consider the design and insulation of the foundation. The special design of the descent and ascent must prevent freezing in winter, flooding with water during rain and when snow melts. If the original house plan did not include a garage, but the surrounding area allows it, then you can register a new plan and add a new room to the house. Creating a front door outside the home will eliminate some of the disadvantages.

Frame

Frame garages, like frame houses, have gained popularity in recent years. This is due to the exceptional speed of construction, lower cost and environmental friendliness. In general, the advantages of the frame look like this:

- the ability to quickly build with your own hands;

- use of environmentally friendly materials;

- all-season construction work.

In order to build a garage from wooden slabs, there is no need to build a foundation, which makes the structure extremely cheap. And since this is not a residential building, they save on insulation.

Of course, it was not without its drawbacks. Thus, frames are not well suited for areas with strong winds or exceptionally low temperatures in winter. In the latter case, they will still require insulation.

Brick

Thanks to its stability and reliability, brick still remains the most common building material for the construction of not only private houses, but also garages.

Having chosen a brick, the first thing to do is start building the foundation for the garage. The most suitable one is tape. Since the weight of the brick structure is quite large, the depth is chosen to be at least half a meter. On average - a meter. The width is a little less than half a meter. The foundation is strengthened with reinforcement and rubble stone, after which it is filled with concrete.

After the concrete foundation dries, which happens after two to three weeks, they begin laying the walls. For a garage, a thickness of one and a half bricks is considered sufficient. To calculate the exact number of bricks, they resort to a simple formula: multiply the width of the wall by its thickness and height and divide by the volume of a standard brick product (usually it is equal to 0.00195 cubic meters).

From foam blocks

Construction of a garage from foam blocks is preferred by those who value speed of work and do not have a large enough budget. This material combines lightness with large dimensions. As a result, one block can replace up to six bricks.

In practice, such features of this building material lead to the possibility of saving on the foundation. The light weight of the structure allows the construction of its lightest type. As for the thickness of the masonry, one block is enough.

From aerated concrete

The construction of walls from aerated concrete blocks, in general terms, does not differ from the construction of foam blocks. Only the slightly greater weight of this material is taken into account.

Autonomous garages

Autonomous – detached garage. This option does not have the disadvantages of built-in garages. But the required financial costs significantly exceed those of the first type, especially if it is necessary to create a garage, respecting the style of the main house. Additional costs will be required for communications. No matter what the weather is in the yard, to get to such a garage you will have to cover the distance from the house to it. A detached garage can be designed as a simple shed or as a permanent structure. If possible, it is better to arrange a permanent garage with an additional carport.

Two-car garage options

The length of the garage does not depend on the number of cars if they are placed next to each other and parallel to each other. It would seem that I multiplied it by two and got the required width. In fact, everything is not quite like that. A distance of half a meter between cars is enough if you do not open their doors at the same time.

To calculate the minimum width of a garage for two vehicles, take their width and add one and a half meters to it. If the cars are located behind each other, the increase in length is taken into account in the same way.

All other increases are determined depending on the intended placement of working surfaces, as in the case of a garage for one vehicle.

Find out how to correctly calculate the size for a 2-car garage.

Size matters

Let's start with planning the dimensions. The dimensions of a standard garage are 3 by 6 m. This is the ideal size, suitable for any car. This “house” will comfortably accommodate both Oka and an SUV. There will also be space for shelves on which tools, spare parts, tires and all sorts of necessary little things will be located. If the site allows, it is better to increase the width of the building by 1 meter. Then the household will have a place to park their sleds, bicycles, and strollers. Get convenient storage.

We make an increase

Every inch of space is important in a garage. The aisles between the shelves and the car should not be too narrow. When walking back and forth, you can accidentally scratch the car. Four by six meters is the ideal size for a garage.

Many novice motorists are interested in how to calculate the size of a garage. The width of most cars is 1.8 meters, so if you decide to purchase even the largest vehicle, you can’t go wrong with the size. The material consumption will increase insignificantly from the meter added to the standard, and additional convenience is guaranteed.

One meter on each side is enough to easily get out of the car without staining your clothes or peeling off the paint on the door.

The average length of a car is 4.5 m. So 6 meters is enough to have access to the hood and trunk. But it’s better to make the height a little more than two meters.

Optimal sizes

The everyday principle “the more the better” is not always justified for a garage. Empty space is a sign of wasteful spending of funds. Therefore, you need to clearly determine the optimal dimensions of a garage for 2 cars and adhere to them when drawing up the project and estimate.

A Russian proverb advises starting a dance from the stove. Regarding the garage, this means that all its dimensions must be tied to the dimensions of the stored cars. A preliminary calculation must be made based on the most inconvenient situation: the driver and passengers get into one of the cars.

We recommend: Laminate in use

What is the main problem with ultra-compact floor plans? If you try to get into a car from the right or left side, you simply will not be able to open its doors.

From this situation follows the first rule of garage layout: there must be a “gap” between cars equal to the width of a fully open car door plus 10-15 cm for parking error. You can measure this distance yourself, or you can trust the experience of the owners who have already done this work. They claim that 0.9 meters of distance between the sides of the cars is enough to open the doors without bumps or scratches.

There should also be free space from the side walls of the garage to the driver's and passenger's doors, sufficient to get out of the car (0.6-0.8 meters).

The third point: between the front and rear parts of the car you need to leave a passage sufficient for a person to move to any point in the garage without wiping the wall and dust from the car. This distance is from 0.5 to 0.6 meters.

So, the cars are placed in their places, but what about the entry? If you don't want to dent the car body on the gate frame, spend a few minutes on this issue. Knowing the width of your car, add 40 cm to it on each side and you won’t have any problems when entering (in a sober mind and with a clear memory).

Gate height is another stumbling block for beginners. Here the main canon of ergonomics is the average height of a person (1 meter 75 cm) plus 20 cm of reserve for “basketball player friends”. However, we will act smarter and look at the future. If you are going to update your vehicle fleet with the purchase of a minibus in the coming years, then plan a gate height sufficient for its entry. An extra row of masonry walls has not yet ruined anyone, but it has eliminated the need to install a tall car in the open air.

Let's say a few words about parking in the yard. If you intend to acquire a permanent garage for two cars, then adding a covered shed near one of its walls will not be superfluous.

This will solve two problems at once:

- Parking for oversized vehicles for garage doors;

- Optimal protection of the car from the sun and precipitation without entering the garage.

The height of the garage box can be chosen arbitrarily, but preferably at least 2.5 meters. This will allow you to place shelves for storing winter tires and provide enough space for installing shelving.

Summing up the internal layout of a garage space for two cars, let’s name its optimal dimensions:

- Width 5 meters and depth at least 5.5 meters (for two small cars);

- Width 7 meters and depth 6.8 meters (for minibus and SUV);

- Gate height is 2.1 meters (for passenger vehicles) and 2.5 meters for tall minibuses and SUVs;

- Gate width (minimum 2.3 and maximum 2.5 meters).

Those who want to install up-and-over or roller gates should consult with the suppliers of these structures before starting the construction of walls. A certain amount of space under the ceiling is required to install the guides and lifting mechanism. Its dimensions need to be known in advance and adjustments made to the project.

When thinking about whether to build a garage with one gate or two, you need to carefully weigh the pros and cons of each option:

General entrance gates of the up-and-over type allow you to get by with one set of automation. Despite this, the final cost will be quite high (manufacturers classify them as non-standard designs and increase the price by 20-30% per 1 m2). Swing gates are simpler in design and cheaper, but less convenient to use. Therefore, we advise car owners who are not short of funds to install two standard sets of automatic overhead gates in their garage.

When planning the internal dimensions of the garage, we must not forget about the type of floor that will be used. For hollow reinforced concrete slabs and wooden beams, a box depth of 5.5 meters is optimal, as it leaves enough space for them to rest on the wall. If you need a room with dimensions of 7x7 meters, then you will have to abandon the beams (the standard for cutting wood is a maximum of 6 meters). Prefabricated reinforced concrete panels are also suitable in this case, since they are produced in lengths of more than 6 meters.

You can use the option of supporting the slabs on beams mounted on internal columns. However, in this case, the overlap will be more expensive, and the useful height of the room will decrease.

Metal garage - size matters

Contents of the article Dimensions for drawing up a project The construction of any object, regardless of purpose and complexity, begins with the determination of all its main parameters: overall and other dimensions, usable area, type of foundation, if necessary, materials for the construction of the structure. The article examines the questions of how to build a metal garage, its dimensions for different types of cars.

A metal garage is a building that can be used for:

- Vehicle placement.

Garage for one car

- Storage of necessary equipment.

Placing items in the garage

- Performing minor repairs and car maintenance (see).

Minor auto repairs Garages made of metal structures can be:

- Tents-shelters: and.

Metal pencil case

- Garage boxes, which are three-wall structures that are assembled into a linear complex.

Shell garage

- Prefabricated garages on a frame.

Frame for garage assembly

- Prefabricated garages from ready-made structures.

Assembling a garage from ready-made panels

- Fully welded.

The size of an iron garage depends on its design and the selected metal.

Examples of manufacturing metal garages from different materials and their photos: The table shows the main advantages and disadvantages of metal garages: Advantages Disadvantages

- Relatively small mass.

- Possibility of transportation.

Combination options

If there is no utility block and bathhouse on the estate, then the functions of the garage can be expanded by providing space for these premises. This achieves savings in materials and working time and creates a compact functional area for men’s recreation and household work.

There are no particular difficulties in building a garage for 2 cars with a utility block. By expanding the box by only 2-2.5 meters, we will have space for a storage room, a pumping station, a mini-sauna or a bathroom with a shower. This last convenience is especially important if the garage is far from the house.

Another popular combination option is a house with a garage for 2 cars. If the soil conditions of the site allow, the autobox can be placed entirely in the basement. If the groundwater level is high, the best option is to add a garage to the house.

In this case, it is necessary to provide a doorway in the common wall and calculate the floor level in the extension so that the height difference between the house and the garage is minimal.

A garage roof is another structure that can be adapted for a variety of needs, from temporary living to storing household items. The materials for an attic roof will not be required much more than for the construction of a pitched roof. A spacious attic is a useful “bonus” that will cover all costs.

We recommend: Minimum and maximum slope of a flat roof - what SNiP say

Regarding wall insulation, I would like to say the following. If you don’t need to do repair work in your garage in the winter, then don’t spend extra money on thermal insulation and heating. Entering a warm garage from cold air negatively affects the condition of the car (condensation falls in the internal cavities of the body, sharply activating corrosion processes). Long-term observations have shown that one year of storing a car in a warm box (with frequent visits) is equivalent to three years of keeping it in a cold garage. As they say, draw your own conclusions.