How to tension the variator belt

Many motorcycle or scooter owners have encountered the problem of replacing the variator belt. After replacing it, the question arises - how to tension the variator belt. The answer to this question is very simple!

Author: Evgeniy Date: February 13, 2013

- Variable speed drive

- Belt variator

- Set of tools

In fact, there is no need to tighten the variator belt. The variator is designed in such a way that it itself tensions the worn belt to the required force. The main thing is to correctly place the belt on the variator pulleys. To do this, it is necessary to remove the protective cover of the variator pulleys. As a rule, they are screwed on with bolts, so there should be no problems with unscrewing them. After removing the casing, you need to unscrew the fastening of one of the pulleys. As a result, the belt tension will disappear and you can remove it without any problems.

After this, you need to put a new belt on the pulleys and tighten the pulley mount. As a result, the belt will tighten a little, but this will not be enough for normal operation of the variator. However, you should not try to tighten it by clamping the fastening of one of the pulleys. After putting on the belt, you need to start the scooter. As a result, the pulleys will begin to rotate. Immediately you need to give a little gas. As a result, the variator will tension the belt on its own. After this, you need to turn off the scooter engine and replace the variator belt protective cover.

Checking and replacing the scooter's variator belt

Many new scooter riders, especially those who are not familiar with technology in general, when buying a scooter, have no idea that such an element as a variator belt will one day/soon become unusable, especially if the scooter is not new. However, it is always important to ascertain the “point of condition” of the belt in time, otherwise there is a danger of getting firmly stuck somewhere.

Generally speaking, a normal variator belt should last at least 6000 km under normal conditions - this is the minimum. Normal conditions here mean, firstly, the correct installation of the belt, with the stated dimensions. Secondly, the riding style of a scooterist, because you can “lose” a new belt in a week, endlessly skidding and accelerating in a childish way. Thirdly, it should be borne in mind that with prolonged inactivity the belt may also become unusable. In this sense, the belt on a new scooter (especially a Chinese one) may not pass the required minimum - a consequence of tedious downtime in damp warehouses.

Although in most cases a worn-out belt begins to slip significantly*, which is noticeable (from the dynamics of the scooter) even without a visual inspection, I would recommend checking the belt every 1500 - 2000 km, but not only for signs of wear. Some belts (again, especially Chinese ones) during their first 1000 - 3000 km begin to “lose” the top layer, which is a fabric braid. The remains of this braid in the form of fluff clog all possible cracks, corners and ventilation holes in the inside of the variator body, which instantly leads to an increase in the operating temperatures of the scooter's variator components. You understand that this is extremely undesirable.

* belt wear is not the only reason for slippage; it could also be, for example, a weak spring stiffness of the driven pulley.

It is quite easy to determine the condition of the belt by eye - the presence of cracks indicates its imminent collapse. The belt can crack both along (delaminate) and across (fall apart). In this case, replacement is necessary without delay.

What are the dangers of a belt breaking on the road? The photo shows a typical case of belt delamination.

Replacing a torn belt is not so difficult; it is not necessary to disassemble part of the variator. But at the moment when the belt fails, the movable cheek of the drive shaft becomes “uncontrollable”, and at this moment it is very easy for the weights to fall apart. My belt broke twice, and both times the weights fell apart, in one case several flew out of my cheek, and in the other they remained inside, but fell out of their tracks. If you can disassemble the variator in the garage - using a gas wrench - then in road conditions it is extremely problematic, almost impossible, to unscrew the variator fastening nut, I was convinced of this. For this case, a special puller is needed:

But the same thing is done using a gas key:

What happens if you install a belt of the wrong size?

Maybe nothing special, just the dynamics of the scooter will change, perhaps the maximum speed. However, it is not for nothing that each scooter model has its own belt size. And installing a non-standard one can end badly. Here's a good example. After the scheduled replacement of the used belt, the new one (Taiwanese belt, decent quality) traveled only about 1500 km, when suddenly, on the descent from the hill, at high engine speeds, it was torn into pieces. It turned out that the new belt is about 1.5 mm wider than the standard, contrary to the dimensions written on it. As a result, at high speeds, the belt came out of the cheeks higher than necessary, and at one moment it simply caught on the edge of the cheek and came out “outside” (after all, the belt is under constant pressure “on the sides”, due to which it is pushed out by the cheeks larger diameter), where the cheek diameter is much larger. Unable to stretch any longer, the belt gave way at the ends, of which there were as many as 6 pieces - it was torn into 3 parts. So, even when buying a “true” belt, compare it with similar ones, otherwise you never know.

How to replace a scooter's variator belt?

Unless you are an experienced scooter owner, you may not think about how often you need to check your vehicle for proper operation. One of the most important elements of a scooter is the belt.

It is what allows your scooter to move by transferring engine energy to the wheel. Therefore, belts can often break or wear out. Checking the variator belt is necessary in any case, especially if you decide to buy a non-new scooter. Basically, a new belt has a service life of 6,000 km, that is, if you have driven such a period on a new belt, then first check it and, if necessary, replace it.

With new scooters the situation is different, because the belt is selected only for your scooter and only the new one. But there is one minus of new scooters. If the vehicle was released a long time ago, then the scooter has been sitting in the seller’s warehouse for more than one year, and because of this, the belt may crack.

One of the most common belt failures is the abrasion of the base layer. That is, if you heavily load the scooter or drive quickly, the fabric seal located on the inside of the belt will be worn out and the belt will begin to slip. Accordingly, after the top layer has worn off, the belt will begin to wear off in large quantities, leaving abraded material. And it can get into other parts of the scooter.

Another common belt failure is when the belt cracks. Even if you take care of your scooter and try to ride smoothly, after a certain period of use the belt will begin to crack. When you notice this, replace the belt as soon as possible.

To change or not to change?

Suppose you “overhaul” your engine: you change the seals, crankshaft, gaskets and other devices, but you doubt whether to replace the timing chain with a new one or not. If you doubt it in vain, change it for a new one at the first opportunity. And now I will explain why.

See for yourself: a chain has an average service life of approximately 18,000-20,000 km of a scooter (personal experience), approximately the same as the average service life of the engine itself. And for example, after driving 6,000 km, the crankshaft jammed or the engine leaked, or something else happened that requires complete disassembly of the engine. Naturally, you disassemble the engine, replace the crankshaft with a new one, and leave the chain, which by that time has exhausted a third of its service life.

And what happens? The chain, after 12,000 km, will exhaust its service life and become unusable, but the crankshaft and other parts will be in good order and you, like it or not, will have to again, because of the chain alone, half the engine. Is it necessary? The chain is a consumable item. Never skimp on it!

How to tighten a belt on a scooter

Checking and replacing the variator belt

In this article we will look at such an important element as the variator belt. What it is and what it looks like remains a mystery to many. Because Today you can see a large number of scooter riders, among whom there are both experienced drivers and beginners. If an experienced scooter rider knows all the technical features of his scooter and also monitors the condition of the engine, then a beginner can ride for a long time and not suspect that this or that part has a certain lifespan. It is the variator belt that has a certain resource and must be periodically replaced. [adsense id="1"]

In order not to get stuck on the road at the most inopportune moment, we recommend reading this article to the end. In any case, you will at least already have an idea of what a variator belt

scooter, and also learn how to easily replace it yourself and how to determine the condition of the belt.

Let's start with the fact that a normal (high-quality) variator belt should last approximately 4000-5000 km. Less quality and cheap belts last about 2000-3000 km. under normal operating conditions. Most often in the scooter spare parts market, you can find 3-4 manufacturers: China (CN), Taiwan (TW), USA (GATES) and Italy (Malossi). The price range can start from 350 to 3000 rubles.

Chinese belts are of lower quality, but very cheap. This is not to say that they are bad and will tear on the first trip. No! This is far from true. It all depends on your driving style, if you like to “drive”, then there can be only one recommendation here, to install expensive belt options, because... their price corresponds to their quality and durability. For some, a Chinese belt can last for more than one season, while for others it can last for one month. Therefore, it’s up to you to choose based on your use.

I would like to say a few words about Taiwanese belts, because... many can compare them in quality with Chinese ones. It is not right. Taiwanese manufacturers have a completely different approach to the manufacture of variator belts, because... More precise equipment and high-quality raw materials are used in production, which undoubtedly affects the quality of the belt.

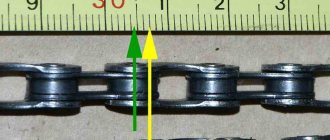

And so... we've sorted it out with the manufacturers, now it's time to learn about the technical side of belts. Each belt has its own dimensions: length and width. Those. Each scooter model has a specific belt size. You can’t take any one you come across and put it on. You need to know the length and width. Otherwise, your scooter will stop developing the required speed or will not move at all. Remember - the belt must be installed in the appropriate size! Slight deviation in length and width is allowed. You can find out the belt size in the operating manual of your scooter, or remove the variator cover and see what is written on the already installed belt. In this example, 788 is the length of the belt, and the number 17 indicates the width.

How to determine the technical condition of a belt? — A heavily worn belt begins to slip, the engine begins to operate more often in the high speed range when starting off; — Dips appear during acceleration, the maximum speed drops; — A whistle is heard from the side of the variator cover;

If you suspect that the belt is worn out or torn, then you need to remove the variator cover by unscrewing it from the engine. In this case, the belt is torn, only small fragments remain. The arrow in the photo shows the nut that should be unscrewed. This nut screws the variator pulley to the crankshaft

. Without removing the pulley, you will not be able to install a new belt.

Before unscrewing the nut, the pulley itself should be firmly secured. This can be done in several ways: 1) Slide a flat file into the “wedge” of the pulley (under the teeth). The method is tough, but if the nut is not too tight or stuck, it will help. CAREFULLY! The most important thing with this method is not to bend the pulley itself, not to break the teeth and not to destroy the engine crankcase. If the nut cannot be unscrewed, then you need to look for another method;

2) By analogy with the first one, we install a wooden block made of durable wood into the “wedge”. The method is also “so-so” but it can work;

3) Use a large grip gas wrench. Throw it on the pulley, but for this you need to use the help of a friend;

4) Purchase or grind yourself a special device with teeth, which will allow you to fix the pulley well. The disadvantage of this method is that it is very difficult to find such a retainer on sale, and grinding it yourself will entail a lot of time. But if you cannot remove the pulley using the first three methods, you will have to grind it out;

5) Another option to unscrew the nut is to use a pneumatic impact wrench, but not everyone has such an exotic thing. One thing is certain: the pneumatic impact wrench must tighten the nut without any fixation of the pulley. Pneumatic impact wrenches should be available in any tire shop or car service center, where you can always ask for one for 3 minutes. The photo below shows some options for unscrewing the pulley.

Option with a block of durable wood.

Option using a special clamp.

Some scooters have pulleys made of aluminum alloy and no teeth are provided there. Therefore, to unscrew these pulleys you will have to use a special clamp, which is shown in the photo below.

You can also find scooter models with pulleys made of aluminum alloy, only with holes provided for the lock.

Making such a puller yourself is not that difficult; you only need 2 steel strips and a few bolts. We insert the clamp into the holes of the pulley, then press the clamp into the ground and try to unscrew the nut.

We talked about the fasteners, it’s time to continue about the belt itself. And so we will continue. In our version, the belt was completely torn into small parts and it is already pointless to determine its condition; a new one needs to be installed. You just need to find the dimension inscription on the remaining pieces. But in your case, the belt may be intact and then you just need to inspect it correctly. The presence of cracks indicates its imminent collapse. The belt may be cracked, both along (delaminate) and across (fall apart). Therefore, be careful when inspecting; if cracks are found, the belt should be replaced.

About adjusting the ignition of a 4t scooter

Knowing how to set up the ignition of a 4T scooter on your own, you can save time and money, since you will not need to contact a motorcycle repair shop. The procedure is simple, even if you have no experience it takes a little time, but you will need to be patient. Regardless of the type of ignition, an important role is played by how the marks are set.

Correct adjustment is a guarantee of stable and smooth engine operation even in cold weather conditions. Often, in used vehicles, the ignition is broken: this can happen for various reasons, ranging from elementary shaking when driving to improper handling of the equipment. In order for the scooter not to let you down and for you to be able to start it whenever you want, you will need to learn how to carry out this procedure yourself. To do this, you will need to have several keys that allow you to remove the valve cover if the engine is four-stroke.

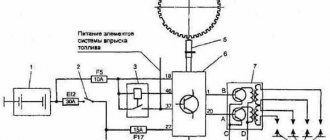

Setting up the Vision scooter ignition system

If the ignition is knocked out, this may be the reason the scooter does not work. Restoring it is not difficult if you understand how it is done.

Advice: before starting work, carefully check and clean the carburetor: this may be the reason. Adjust the quality of the mixture. In addition, it doesn't hurt to check the spark plugs.

You need to start adjusting by setting the timing belt in the desired position. As a rule, there are marks on it for this purpose; they are set at the factory. The cylinder must be installed at dead center. The mark may be indicated by the letter T or another symbol. Now make sure that the mark installed on the rotor matches the mark found on the magneto. To do this, you need to gently press the kickstarter. The rotor can also be turned using your hands, but this is more difficult.

There are also marks on the timing star in the form of holes or dots; they must be set so that the largest hole is on top and located exactly in the center. The remaining points should be below and located horizontally opposite each other. Setting the ignition advance makes sense if you want to increase the engine's power a little and make it start easily. The adjustment will help make the spark plug produce a spark earlier than the standard time. That is, a spark will appear even before the piston reaches the dead center. In cold weather, a moped configured in this way will start better.

In order to configure the scooter in this way, you will need to repeat the procedure described above. However, there is a difference: the marks should not coincide clearly, and not reach each other by about 0.5 cm. The main difficulty lies in connecting the marks.

Don't be afraid of the ignition system. It’s easy to set up, the main thing is to check the entire circuit; much more often the switch fails, there is no gasoline or the spark plug needs to be replaced. Only after making sure that there are no physical malfunctions should you start setting up the ignition. If it is set correctly, you will hear and notice, as the engine will start easily and run smoothly.

Scooter variator device

A variator is a part responsible for a smooth change in speed. It is a unit of two pulleys (driver and driven) connected to a belt. The degree of load on the main variator depends on the intensity of engine rotation. When driving at high speed, the number of rotations is maximum, which is why the variator parts wear out faster.

The belt is attached to the pulley at the sides. If the CVT bushing wears, the belt cuts deeper into the pulley. When the drive pulley operates, the belt smoothly compresses and unclenches. A sports CVT on a scooter makes more revolutions. The belt may need to be replaced sooner.

Even a new scooter can fail over time due to improper use.

Symptoms of wear

The failure of a circuit can be determined by the following signs:

If you ignore such signals, the valves may bend, and in the worst case scenario, the cylinder block will completely fail.

Therefore, during each scheduled inspection of the car, this timing element should be checked. When purchasing a used car, this element should be given sufficient attention.

5 engines on modern production cars that can withstand 300 thousand km without capital

How to replace a belt

The scooter's variator can withstand a mileage of up to 6 thousand km. The belt lasts the same amount of time. The part may last longer, but you still need to regularly diagnose it. You can do it yourself if you have special knowledge in this area.

Symptoms of a problem

- When the speed increases, the engine rotates quickly, but the clutch does not work. In this case, the transport does not budge. This means the belt has broken.

- The carburetor is normal, but it is still impossible to reach the maximum speed. The reason is that the variator does not reach its maximum radius due to damage.

- The belt lasts very little if it is a cheap fake. You need to disassemble the device and evaluate the appearance of the belt. If it is stretched, then it's time to change it. Due to deviation from the desired value, the transmission stops working as it should.

Main causes of failure

The main causes of CVT malfunctions are violation of operating rules:

- rare oil changes;

- use of low-quality oils;

- aggressive driving;

- sudden braking;

- long trips at top speed.

Mileage up to 6 thousand km.

withstands the scooter's variator. The reasons for the breakdown may be other. One of them is a faulty bearing in the variator, which manifests itself in the appearance of a hum. Noise is often attributed to worn wheel bearings, making it difficult for a beginner to identify the real cause of the problem. The difficulty is that the bearings can be damaged even with low mileage due to aggressive driving.

Another cause of damage is metal dust. The chain and variator pulleys rub against each other, so they gradually wear down.

Dust gets into the oil and then to the bearings. To find this dust, oil filters are present in the design. But neither they nor regular oil changes prevent the appearance of dust.

Another reason for variator failure is the accumulation of metal dust in the oil pump. It penetrates the valves and disrupts their operation, and also leads to pressure surges in the pump. The pulleys move chaotically, causing the belt to wear off. As a result, the vehicle jerks while driving. If you don't fix the variator, you'll have to replace the gearbox.

The variator may fail due to belt damage. This part is a device consisting of many plates located on a bundle of metal strips. Due to the uneven surface, they are better attached to the pulleys. They gradually wear out, and accumulated dust prevents the device from working properly. Because of this, the variator belt slips, jerking the vehicle. In this case, repairs are required immediately.

The most harmless malfunction is that when driving fast, a sign flashes on the panel, indicating that the transmission is overheating. The vehicle stops abruptly to cool down. This indicates that the oil pump cooling system is clogged and has stopped working normally. For preventive purposes, it is necessary to clean radiators twice a year.

How to choose a new one

Scooter belts vary in size and markings. The characteristics are indicated in the transport passport. You cannot fit a larger belt size. Because of this, the dynamics of the vehicle may be disrupted.

Example. The driver changed the belt, after which the variator began to operate in normal mode. But, when squeezing the maximum speed, the belt tore into pieces. The reason is the incorrect choice of belt size. It is necessary to follow the characteristics in the passport. It is allowed to install a belt 1.5 mm larger than necessary. When the maximum radius of the variator was reached, the belt slipped out and caught on the edge of the pulley.

The principle of operation of ignition in a 4-stroke scooter engine

Modern scooters are equipped with contactless systems. They are considered the most reliable and easy to use, do not require complex connections, and provide a constant good spark on time. However, the setting is still important; even the presence of a spark does not always allow the fuel mixture to ignite, since its power also plays a role.

The main reasons for the operation of the ignition system are quite simple: its task is to create a spark to detonate the fuel mixture. If this does not happen, you need to carefully examine each node and find out why the spark disappeared.

- In order to check whether there is a spark at all, you need to unscrew the spark plug and apply it to the engine ground; this can be done using metal objects that are not covered with paint. You cannot hold it with your hand: if there is a spark, it can give you an electric shock, and the discharge reaches 40,000 volts, which the coil creates.

Broken ignition is the cause of engine failure

An incorrectly configured or faulty ignition often causes engine failure. It would be wrong to immediately climb into the cylinder and examine the insides of the scooter, especially since this will not solve the problem. Before touching the ignition system, you need to check for other reasons why the scooter may not work.

Replacing the variator yourself

At this stage, it is important to remember about the calculation of the variator. Installing an incorrectly sized belt will cause the device to quickly fail. To maintain the durability of the variator, the belt must be secured in the drive pulley. Then rotate it until it is positioned properly. Next, you need to check the quality of the fastening of the nuts, since they could have become loose during operation. Finally, you need to test the belt. To do this, rotate the crankshaft, after which it will become clear whether the belt is positioned correctly. If yes, all that remains is to return the variator cover to its place.

Replacing the variator yourself

There is a second way to replace the variator chain. Removing the old belt is done in the same way. Next, you need to disassemble the variator and install a pulley on which the new belt will be mounted. To push the belt in, move the pulley halves apart. The belt will take the required position after turning the variator at maximum speed for several seconds. If everything is normal, then the last task remains: how to assemble the variator cover? Everything is very simple. You need to screw it to the workplace and check the quality of the bolts.

Examination

Personally, I never check timing chains. I simply throw them in the trash, no matter how awesome they seem to me. For me, a chain is a consumable, just like a spark plug, oil or oil seal. But if you are important, or money is tight, you can use the old fashioned way.

We stretch the chain along its length, hold it with our fingers and try to position it in a horizontal position

For clarity, I took a new and heavily worn chain, put them together and checked for horizontal deflection. As you can see: the new chain (above) described a barely noticeable arc, while the worn and useless chain sagged like snot, almost at an angle of 90 degrees.

The worn chain turned out to be almost a centimeter longer compared to the new one.

CVT tuning

There are several options for tuning a scooter's CVT. The simplest is the installation of lightweight rollers. Manufacturers install heavier rollers based on engine power and vehicle weight. You can install rollers that are smaller than the factory ones, no more than 1.5 grams. In this case, the diameter must correspond to the factory parameter.

To make the unit last longer, the variator cones need to be polished

How to replace rollers:

- unscrew the variator cover;

- remove the belt;

- disassemble the variator and change the rollers.

Another way is to grind the variator cone. When performed correctly, the procedure extends the life of the variator. If the work is done poorly, the cones will eventually need to be replaced.

Tuning is performed when the cones are slightly worn and involves grinding a thin layer. The work is done on a lathe or with sandpaper.

Grinding the variator cones is necessary to ensure that the unit lasts longer. If the procedure is not done, belt wear increases due to overheating. As the cones wear out, metal dust is formed, which clogs the gaps between the bushing and the variator shaft. As a result, the variator is compressed as the speed increases.

Other tuning options should be treated with caution. For example, to the variator boring. It helps to increase the maximum speed of the scooter, but can weaken the variator housing.

How to bore a variator on a scooter:

- disassemble the variator and remove the belt from the gear;

- remove the restrictive ring, on some models - the plate;

- put the remaining parts in place.

Which method is preferable?

It is logical that the first option with complete disassembly of the scooter engine is more complicated and takes more time and effort. But, as you can see, it is more reliable. Firstly, the factory integrity of the circuit is not compromised; secondly, when disassembling the scooter engine, you can see any defects, such as cracks, wear, change the seals, clean the parts.

The second option is more simplified and can be used when you only need to replace the chain. And you are confident in the quality of your work.

Final word

The scooter is a fairly popular vehicle and is in increasing demand. Because it leaves traffic jams behind, has low operating costs and is economical in terms of fuel and lubricants. Many people prefer to do scooter repairs on their own, especially since four-stroke engines are simple and reliable to use. Timely technical inspections, careful operation and the above article will allow you to enjoy riding this miracle of the Asian motorcycle industry for a long time.

ProVariator.RU

In this review, I will talk about the variator belt that I chose for my Chinese scooter, I will look at issues such as price, quality, belt sizes and at the same time I will show you how to change it.

Actually, this is how we became acquainted with the variator belt.

Which variator belt to choose for a Chinese scooter?

As with most Chinese scooters, the dimensions for mine will be 729×17.5

If in doubt, just take your broken belt and look at the dimensions on us.

There were three options for the Chinese scooter:

No thanks, even for sale, I'll buy something better. Last time I pushed the scooter for 20 kilometers. I feel sorry for the people. ))))

My clutch was so loose that it was shaking, and since I didn’t know about it, the belts had to be changed 3 times. And three times I chose this one. In a situation in which it could break on the first day, I skated for half a year.

And the third option is really cool, it costs one and a half thousand. Is it needed? Well, if you are going to go to Crimea on a scooter, then why not?

How to change the variator belt?

It's called a pneumatic impact wrench.

Unscrew a few bolts. And we see:

This is how the belt should be. It will hang around, torn, or even crumble into crumbs.

Yes, yes, that’s what this wonderful tool is for.

Don’t put pry bar keys and other nonsense in there, otherwise you’ll just ruin the gear and cost yourself an extra thousand rubles.

“Guys, do you have a pneumatic impact wrench? Can you unscrew two nuts?

When they are removed, we check the videos:

Then we take the clutch and try to squeeze it:

If it moves tight and smoothly, you're in luck! If it's loose, you'll have to buy a new one.

Well, the easy part remains. We tighten the belt and assemble our scooter.

NO NEED TO LUBRICATE ANYTHING!

Yes, if you bought a new clutch, it will not be easy to tighten the belt. We'll have to do it together. One pulls the clutch by hand, as shown in the previous photo, and the other pulls the belt onto the shaft.

How to tighten a belt on a scooter

Chinese scooters are undoubtedly one of the most popular forms of cheap transportation to hit our market.

Over time, some elements are subject to wear and tear. One thing that can happen at some point with your 139QMB 50cc Chinese scooter is a broken belt. But for many people, replacing a worn drive belt will seem like quite a daunting task. But don't be alarmed, the process itself is much simpler than it seems and often takes less than half an hour.

Place your scooter on the center stand. First of all, you will need to remove the engine variator cover using a wrench. This cover is held in place with just a few bolts. When you remove the cover, there will most likely be a frayed belt as well as black debris or dust that needs to be thoroughly cleaned before installing a new one.

Find the rear wheel "steer" pulley and pull the outer half towards you. This will separate the pulley and relieve tension on the drive belt. Pull the belt completely out of both pulleys.

At the same time, check the inside of the rollers; if they have large flat surfaces or are damaged, replace them with new ones.

When to change the belt on a scooter

When purchasing a new belt for your 50cc 139QMB Chinese based scooter, keep in mind that your riding habits will affect the life of the belt. Typically, belts can last between 3,200 and 12,800 kilometers under standard use.

How to tell if replacement is needed

It is clear that the circuit must be changed when there is obvious dysfunction. When the chain wears out a lot, it makes a loud noise. Well, or jumped over the tooth of a star. Or it fell off, which indicates its stretching and wear.

Standard chain lifespans should be close to the lifespan of the scooter engine itself. It's logical. Each owner operates the vehicle differently, but the average chain lifespan is somewhere between 15,000-18,000 km. In a situation where the engine was halved to eliminate other faults, and the chain was immediately replaced after using it for, for example, 9000 km, everything is clear.

There are options for shortening the chain when stretched. But there are some caveats: if the step does not match, the star begins to erase, i.e. the stretched chain eats the camshaft sprocket. If the wear on the star is small, you can isolate the link and ride it a little. You need to do this correctly, adjusting the chain tension with a tensioner, and not forcibly. Otherwise, you will completely damage the chain.

What is typical for a worn chain: A small point: to check, you need to remove it. The degree of wear can be assessed by the angle of horizontal deflection. If it sags downwards, going almost vertically, change it 100%. The new chain deviates approximately 45 degrees from horizontal. And by laying out the old and new chains on the surface, you will see that the first one will be longer. Also, the wear of the scooter's timing chain can be indirectly judged by the level of extension of the tensioner rod. Critical wear is when the rod extends completely.