Today’s review of mine will be devoted to a Chinese-made two-stroke scooter that has probably been out of production for a long time, and is therefore better known among the people under the nickname “chain”. He received this nickname not by chance, but because of the presence of a drive chain in the transmission instead of the usual belt. This scooter has different trade names and even different designs, but the essence and its design do not change from the name of the model.

I would not advise you to buy this scooter even if the price seems very attractive to you, even if they give it to you for free and with a bunch of spare parts - avoid this Chinese scab like hell. Avoid, ignore and put the thought of buying it out of your head.

I agree with you - the appearance of this Chinese scab is attractive, even by the standards of the “Chinese”, but the essence and internal filling are complete darkness!

Ergonomics

The controls are standard. The only thing you have to get used to is the enrichment lever, which is located on the right handle of the steering wheel. Everything else is standard. The instrument panel is somewhat old-fashioned, but quite informative and easy to read even in sunny weather. The seat is quite roomy, but sitting behind the wheel, let alone driving this Chinese stick, is not very comfortable. This scooter is equipped with an underseat container, a front glove compartment and a small rear luggage rack.

Variations on the handle

So, with the general principles of changing the gear ratio everything should be clear, now it’s time to proceed to the mechanism of this change, that is, how to make the scooter’s variator pulleys move and move apart exactly when required. To do this, let’s immediately make a reservation that in a scooter variator it is customary to distinguish the driving pulley (located on the crankshaft) and the driven pulley (located on the clutch shaft). In the bowels of the drive pulley there are special cylindrical weights (sometimes also called rollers). These plastic-coated metal bushings are placed in special grooves in which they can move radially. If you move the weights in the drive pulley from the center outward, they will inevitably move the pulley cheeks together. In fact, of course, only one cheek of the variator pulley moves, but this is not important. When the pulley rotates, the weights, under the influence of centrifugal force, tend outward and, shifting the pulley cheeks, push the belt outward. The faster the pulley rotates, the stronger the centrifugal force acting on the weights, and the further outward the compressing pulley cheeks will push the belt. The driven pulley has no weights, but has a large spring that constantly tries to squeeze its jaws together and push the belt out. Like the driving pulley, the driven one has only one moving part - the external one (referred to in foreign literature as the torque driver). It is the torque driver that moves either outward, overcoming the resistance of the spring and allowing the belt to “fall” inside the pulley, or, conversely, inward, closer to the fixed part of the pulley. Thus, the change in the working radii of the scooter's variator pulleys always occurs synchronously. When the belt goes out in the driving pulley, then in the driven pulley, overcoming the resistance of the spring, the belt, on the contrary, moves inward, closer to the axis of the variator pulley.

For a more complete understanding of the process, let's see how the scooter's variator behaves under different engine operating modes . At idle, the rotation speed of the variator drive pulley is minimal. Although a certain centrifugal force acts on the weights, it is not enough to pull the belt out. After all, this requires overcoming the resistance of the large spring of the driven pulley! But now the gas is open, the crankshaft speed jumps, and now the centrifugal force acting on the weights is already enough to push the variator belt in the drive pulley a little outward.

Drive pulley coupling: cover; guide plate; coupling body; rollers.

The gear ratio changes. The rotation speed of the driven pulley of the variator increases significantly, which forces the centrifugal clutch to operate. The scooter starts moving. The engine speed reaches its operating level, meanwhile the belt continues to move further and further outward in the drive pulley of the variator, and deeper in the driven pulley. That is, the speed remains unchanged, but the gear ratio gradually changes, making the scooter go faster and faster. This, by the way, hides one of the great advantages of the variator - acceleration occurs at constant speeds, so you can configure the entire system so that during acceleration the engine will operate at its maximum power (for example, this is impossible to achieve with a manual transmission). Finally, the belt reaches its maximum design radius in the drive pulley of the variator, and its minimum in the driven pulley. However, as a rule, it is possible to accelerate a little faster, but by increasing the speed of the scooter's engine, and not by increasing the transmission.

When the throttle is closed while driving, the engine brakes the scooter for some time until the centrifugal clutch disengages. As soon as it is turned off, under the action of the large spring of the driven pulley, the belt returns to its original position, as when idling a scooter. But as a rule, the scooter’s clutch disengages only when it comes to an almost complete stop (10 - 25 km/h).

By the way, about the scooter’s clutch. This device, although it performs independent functions, is very closely connected with the scooter’s variator itself: if the clutch does not work correctly, the variator will not work correctly, and vice versa. A scooter's centrifugal clutch is almost always three drum-type brake pads that are pushed outward by centrifugal force and engage the clutch drum. The clutch assembly itself is mounted on the driven pulley of the variator and rotates, but the clutch drum is on a shaft, which transmits torque to the rear wheel through a simple gearbox. Thus, in order to make the scooter move, you need to make the clutch drum rotate. This happens as soon as the driven pulley of the scooter's variator gains sufficient rotation speed so that the centrifugal force becomes large enough for the pads to overcome the elastic force of the clutch springs, which prevents their free movement outward. These same springs will “disengage” the clutch, squeezing the pads together when the rotation speed of the driven pulley drops below the critical level for the clutch to operate. As you can see, the system is simple. And it works almost flawlessly, reducing control of the power unit to twisting the throttle (hence, by the way, the name of one popular scooter magazine: Twist'n'go - “Twist and Ride!”). Which not least determined the current wave of popularity of scooters.

This video shows the CVT in action. Shown in the best possible way.

There are several parameters that determine the correct operation of the variator and indicate its good tuning. Firstly, the belt should not slip in the pulleys. Minimal slippage there, of course, is inevitable, but it should be such that the scooter owner does not notice it. Slipping of the variator belt is doubly harmful to the scooter transmission. This includes a decrease in efficiency and increased wear of parts (belt slippage in the drive pulley can also lead to the plastic shell of the variator weights melting due to overheating). A characteristic symptom of slippage is a rise in engine speed when starting from a standstill, which is not accompanied by the expected acceleration (“roars, but does not go”). What determines the slippage of the variator belt? First of all, from the stiffness of the large spring of the driven pulley. The stiffer the spring, the more tension the belt will have before it moves outward in the drive pulley of the variator, and therefore the less it will slip. However, the spring stiffness should not be excessive, otherwise the maximum speed will drop. There are other factors that also affect belt slippage. This is, for example, its wear and tear. Here, of course, there is only one method of struggle - timely replacement.

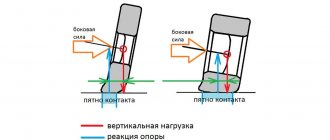

Controllability

What can you say about the handling of this Chinese beast? Only that she kind of even exists, but the whole question is what is she like? And now I’ll tell you what...

Yes, there is a steering wheel here and you can even turn the front wheel with it. But I wouldn’t recommend entering a turn at medium speed, or God forbid you even think about it at maximum speed. At the very least, put it into the ditch. What about the brakes? I'll tell you about them too. They exist - that's a fact. But they practically don't work. Of course, you can press the levers, but it’s almost impossible to stop this clunker. Why not ABS? There's not much to say about the suspension - it's there, but it works disgustingly. To be honest, I have never seen such terrible handling as that of this scooter.

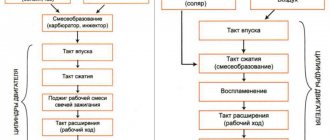

Working principle of automatic centrifugal clutch

As you know, the clutch is designed to connect and disconnect the engine and the drive wheels. When the clutch is engaged, the engine and wheels are connected, and the engine transmits torque through the transmission to the wheels. When the clutch is disengaged, the engine and wheels are disconnected, the engine continues to operate, but no torque is transmitted to the wheels. To connect the engine and wheels (via a gearbox), the clutch uses friction. Clutch discs or pads, rigidly attached to the engine shaft, are pressed against the gear disc and begin to rotate it using friction. In a mechanical (manual) clutch, powerful springs are used to press and create friction force.

This clutch is normally always engaged. To release the springs and disengage the clutch, you need to press the hand lever.

An automatic transmission uses centrifugal forces to press the pads down and create friction. When the engine is idling, the automatic clutch is always disengaged. The pads, rigidly mounted on the engine shaft, simply slide along the transmission disk, because the friction force is too small. Moreover, they are kept from contact with the disk and springs. As the engine speed increases, the centrifugal force increases, the pads begin to press harder against the transmission disc, the friction force increases, and torque begins to be transmitted from the engine to the transmission and further to the wheels. At the same time, the friction force increases smoothly, therefore the torque also increases smoothly. This explains the soft operation of the automatic clutch, because it is a kind of shock absorber for transmitting torque.

Most scooters have a chain drive from the gearbox to the drive wheel

This is how the clutch on a scooter works. But the transmission consists of more than just the clutch. Not a single engine in the world is capable of turning the drive wheel in one rotation of the crankshaft. In order for the wheel to make one revolution, the engine rotates the crankshaft several times. To ensure this, a gearbox is used in the scooter's transmission. Usually this is a pair of gears. The small one is rotated by the engine and turns the large gear, which transmits torque to the wheel. That is, for the large gear to turn once, the small one will turn along it several times. The ratio of the diameters of these gears is called the gear ratio of the scooter.

Most scooters have a chain drive from the gearbox to the drive wheel. The chain fits on two sprockets. The drive sprocket is located in the engine. The driven sprocket is located on the wheel. In this case, the gear ratio is the ratio of the diameter of these sprockets.

However, some manufacturers or tuning enthusiasts install a rear axle on a scooter. In this case, the gearbox is not located in the engine, but in the rear axle.

The gear ratio is changed not only by gearboxes, but also by the gearbox. In modern engines, a variator is used for this. It allows you to smoothly change the gear ratio smoothly and without jerking. It is this part of the transmission (variator) that the electric starter rotates when starting. However, electrics may not always work. The wiring or generator may fail, and the electric start will be unavailable. Then Kickstarter will help. The kickstarter device on a scooter is based on the use of muscle force. The kickstarter lever is connected to a gear sector, which, when you sharply press the lever with your foot, rotates the variator, and through it the engine.

The transmission is not only made up of the clutch.

Engine

- The engine is two-stroke, a copy of some ancient Suzuki scooter. The service life of this engine does not exceed several thousand kilometers, some have more, some have less - it varies. The engine itself is dead, forget about dynamics and power right away, as well as about tuning. There are practically no tuning parts for this engine; you can, of course, install a piston with a slightly larger volume, but in terms of power and increasing the maximum speed, this does not give anything.

- For beginners or those who like to repair their scooter themselves, I strongly advise against buying a scooter equipped with such an engine: in terms of repair, this engine is very complicated. In addition, to repair it you will need a bunch of hair dryer pullers and other tools that, as you understand, are not lying around on the road and you need to buy them or make them yourself.

- Also, due to the design features of the lubrication system, this engine is very inconvenient to operate. The lubrication system of this engine is driven directly from the rear wheel and while the rear wheel is rotating, the lubrication system supplies oil to the parts. As soon as the wheel stops, the lubrication system stops working. To be honest, only a moron could come up with such a drive. Imagine what awaits you: to avoid engine wedge, you will have to turn off the engine at every traffic light...

Design and principle of operation

The fundamental elements are two pulleys and, accordingly, a belt. The cut belt has a trapezoidal shape. The name of the belt (V-belt) comes from the principle of its operation. The transition of the belt to the maximum radius is similar to a wedge. As the pulleys wear out, the radius becomes smaller and the scooter loses speed.

The main condition for stable operation of the variator is its tightness on the pulleys and the absence of slippage. Experienced users of this type of technology claim that 100% absence of slippage cannot be avoided. But it is necessary to minimize it as much as possible. In case of severe slippage, the operation of the entire transmission is at risk. Breakdowns and replacement of parts cannot be avoided. In addition, efficiency is significantly reduced. A striking example of slippage is the drop in engine speed at the very start (the engine seems to be running, but the movement of the equipment is not significant).

Also, straight belt slippage depends on the pulley spring. If it has lost its rigidity, it must be replaced. In addition, unstable, deteriorated performance may be due to wear of the belt itself.

High-quality famous belts from 6000 km.

How else can you determine the correct operation of the variator? – when starting to move, the engine speed is the same until the start of acceleration. At maximum throttle, the engine speed should approximately correspond to the engine power. “People’s” craftsmen sometimes do some “alterations” so that the dynamic qualities of the scooter increase. Also, to speed up the scooter, there is an option to completely replace the variator. For example, you can buy a sports variator for a 50 or 150 cc scooter.

Summary

This garbage disposal costs less than all other Chinese-made garbage disposals. This particular copy was bought for 15,000... I don’t know how you manage to give your hard-earned money to hucksters for such bullshit, but you do and I see it. I wouldn't give even three rubles for this scab.

Before you get involved with this Chinese-made “masterpiece,” think carefully: do you need it? They practically no longer sell spare parts for them, and what they sell can be safely thrown into the trash. Engine tuning is basically impossible, complex and very labor-intensive engine repairs for which you will be asked to pay more than for repairing an ordinary “Chinese” - do you need it?