Motorcycle engine repair Voskhod

The Sunrise is a road bike.

It was very popular in Soviet times, but is no longer produced. The most popular model is considered the Voskhod 3M, an engine whose repair is completely simple and completely easy to maintain. The reliable design and stability of the bike make Voskhod an excellent friend for any motorcycle enthusiast. Since nowadays you can only buy such a motorcycle second-hand, you have to tinker with the technical part of the motorcycle. You will be very lucky if the previous owner kept the bike clean and used it according to recommendations. If not, then frequent repairs of the Voskhod engine will take up your free time.

Voskhod 3M is considered a direct competitor to the YAVA 350 motorcycle. However, Voskhod breakdowns happen an order of magnitude more often. This happens mainly due to the negligence of the owner. Failure to follow operating instructions leads to minor problems that create significant problems. A special feature of 3M is the chassis. The brake pads were equipped with a wear sensor, the shock absorbers were fitted with corrugated rubber covers , and a protective shield was installed on the front wheel. The design of the Voskhod 3M engine also changed slightly after the modification was released. Motor 3M-01 with five-channel cylinder purging and one exhaust window.

External view of the motorcycle sunrise 3m

When compared with other Soviet-era motorcycle models, the Voskhod 3M looks quite attractive and has the outlines of a classic bike. The motorcycle was equipped with a low chrome-plated steering wheel, on which rear-view mirrors and devices that ensure control of the motorcycle (clutch handle, turning on turns and headlights, etc.) were attached. The model is equipped with a large round headlight, which provides diffused light and does not dazzle drivers driving in the oncoming lane. The exhaust pipes are chrome-plated, which adds a certain chic to the motorcycle. The rim of the spoked wheels is also chrome plated. The fuel tank has a rectangular outline.

Particular attention should be paid to the seat, which was of two types, one-piece (one for the passenger and the driver) and separate. If we consider the appearance, it is better to give preference to a solid seat. It makes the motorcycle look somehow more noble. In addition, many models had a small trunk installed in the back (like on a bicycle), which could easily be used to transport small loads.

The last motorcycle in this series rolled off the assembly line in 1992. It was replaced by the modernized Sova motorcycle, more adapted to the realities of the modern market. But for true connoisseurs of Soviet-era motorcycles, the Voskhod 3m will forever be remembered as the most reliable, unpretentious and financially affordable motorcycle. Even now there are motorcycle enthusiasts who prefer to have a trouble-free motorcycle in their arsenal. And probably for many representatives of that generation it will not be a revelation that Voskhod 3M was and is a true friend for motorcyclists.

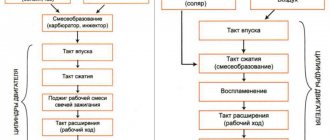

Engine diagram

For Voskhod motorcycles, the engine size was the same. It was 173 cm3. In general, all bikes from this manufacturer had the same single-cylinder engine with two power strokes and an air cooling system. The very small volume of the engine produced 10 horsepower and over time, modifications to the engine began to produce power of 14 hp.

If you discover a malfunction and it is related to the operation of the engine, do not put off repairs for a long time. Exacerbating the problem will result in unexpected costs. There is no need to be afraid to overhaul the engine. Not only disassembly, but also assembly of the Voskhod engine is very simple.

Before repairing, carefully inspect the motorcycle for wear or broken parts. After inspection, clean the engine from dirt. It is better to wash it thoroughly with a cleaning agent. Since the main engine problem is the crankshaft bearings, seals and gaskets, let’s consider the process of repairing them:

At the same time, be careful not to overtighten the crankshaft, otherwise it will move or bend. In this easy way you can replace bearings and gaskets in the engine. As you can see, the work does not require hard-to-find or rare tools.

Ignition and carburetor

It is these two components that, as a rule, determine the stability of the engine. Often, interruptions in the crankshaft rotation speed, loss of traction, and difficulties starting the engine are associated precisely with their malfunctions. Repairing the ignition and carburetor usually comes down to adjusting them. Setting the ignition includes setting the gap between the coil core and the sensor magnet within 0.295...0.305 mm. The piston ignition timing should be 3.5-5 mm to top dead center.

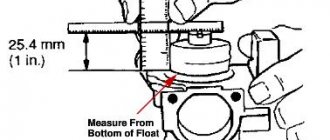

Adjusting the carburetor is somewhat more difficult. If you are repairing a Voskhod-3M motorcycle, then you will have to deal with the K65V carburetor, and the main tools will be the quality and quantity screws included in its design. Using the first, you can lean or enrich the mixture - change the proportion of fuel and air entering the cylinder. The second determines its volume per working cycle. With the standard setting, the quality screw is screwed in completely and then unscrewed half a turn. Then the rotation of the quantity screw achieves the minimum stable speed and the quality of the mixture is re-adjusted. Finding the optimal adjustment balance is a search for maximum traction and stability with minimum fuel consumption.

Source

Force

To increase power on Voskhod 3M, you can do engine tuning yourself. Even simple manipulations like an air filter can increase performance.

For a stronger increase in power, you can replace the intake system. For example, install a new carburetor. Perhaps even from another motorcycle with a similar system. There is an option in which you can install two carburetors, but you will have to connect pipes to it and weld the channels, filling the cracks with epoxy liquid.

Photo report: How to disassemble the Voskhod engine?

It is not clear why Voskhods have gained fame as unreliable and capricious motorcycles. You might think that Jupiter or Ant is much better than Sunrise. However, this opinion still exists in the motorcycle community. Well, okay, if there is such an opinion, then so be it.

Someone had already “overhauled” the engine before us, then we drove it a little, removed the cylinder for boring and rolled it into the garage for the winter. While the motorcycle was standing in the barn, water began to flow into the engine... And when spring came to the yard, the owner wanted some drive... Well, let's give him some drive.

Removing the piston

We unscrew the four nuts on the head, remove the head from the studs, remove the cylinder, remove the retaining ring from the piston boss, push out the piston pin, remove the piston and remove the separator

Disassembling the clutch

Removing the clutch cover

Checking the motor circuit

We put pressure on the motor chain and see how much it has sagged: if the chain sag by more than 15 mm, we immediately throw it in the trash.

In our case, the motor chain is ideal: there is practically no sagging

Removing the clutch basket springs

Remove all discs from the basket. After removal, check the discs for wear and warping.

We take out the clutch rod

We weld a rod or piece of tire to the old unnecessary clutch disc, unbend the lock washer under the nut of the inner drum of the clutch basket, fix the inner drum with a puller and unscrew the nut (left-hand thread)

First joint

Someone put a washer under the inner drum

Place a tin block or stick under the chain and unscrew the nut (right-hand thread)

The sprocket sits on a cone and can only be removed with a puller

Remove the adjusting washers from the shaft and pick out the second key

Disassembling the clutch and kickstarter Voskhod

We repeat all removal work exactly as described below: - remove the ends of the spring from engagement with the pressure plate; — dismantle the pressure disk with the adjusting bolt and lock nut, driven and driven; - remove the squeeze fungus; — bend the lock washer securing the inner drum, use a 22 by 17 socket wrench to unscrew the nut and remove the inner drum.

It is easier and more convenient to unscrew the fastening nut by fixing the drum using a homemade device as in the photo. Don't forget the thread is left-handed.

— Unscrew the nut securing the crankshaft sprocket, remove the washer; - pull off the drive gear from the crankshaft along with the chain and outer drum; — remove the key from the groove of the left crankshaft journal; — remove the spacer sleeve with the washer from the input shaft; — remove the trigger mechanism.

Why put the trigger lever on the splined end of the roller? Slowly turning it clockwise, lift the trigger mechanism upward so that it goes beyond the plane of the crankcase. Then, slowly releasing it, take it out.

Removing the kickstarter

We put the claw on the kickstarter shaft, pull the shaft towards us, unwind the return spring and remove the kickstarter from the shaft

Second jamb

Cracks often appear where the kickstarter shaft enters the crankcase. It is advisable to weld crankcase cracks

Engine disassembly

We unscrew the bolts holding the crankcase together. There should be 14 bolts

We heat the crankcase connector with a hairdryer, apply gentle blows to the protruding shafts through a wooden spacer until the engine is halved

The third jamb

The crankcase gasket was installed crookedly, so much so that it did not even cover the crank chamber connector

Jamb four

The main bearing was closed. He died quickly

Fifth jamb

The gearbox secondary shaft bearing was not assembled correctly: the rollers should be separated by a ring, but on this engine a ring was not installed between the rollers

So much for a major “repair”, the painted oil seals are proof of this. Now think: is it worth buying a motorcycle after a major overhaul or is it better to buy one that has been worn out, but has never been chipped.

Source

Moto / Plant named after V.A. Degtyarev and his brainchildren, which are so close to us / ZDK 4.105 - Owl / Overhaul of the SOVA motorcycle. Part two.

After a short break, I continue work on assembling the motorcycle. Part one is here. It took some time to find the parts and put them in order.

Air filtration and preparation system. Filter assembly diagram.

In the niche of the upper part of the mud shield I install a filter system and a switch.

Before installing the air filtration system housings, the central wiring harness must be installed. After laying the electrical wiring, the lower part of the filter housing and the switch are installed:

Next, I install the filter element and lay the mesh on top.

Now I carefully install the upper part of the filter housing and screw it on. You need to make sure that the mesh does not move out and gets into the right grooves, otherwise it can be deformed.

After assembling the filter and connecting it to the electrical circuit of the switch, screw on the protective plate. The first versions of the plates were made without stiffeners (flat).

Steering wheel assembly diagram.

Installed: steering wheel, clutch release handle, front brake handle, left remote control and instrument panel wiring.

Next in line are the central stand and side support.

The center stand and side support are installed, and the coupling to the intake muffler is also installed.

Instrument panel assembly diagram.

The instrument panel housing, ignition switch, indicator lamps and speedometer illumination are installed.

Some manipulations were carried out with the speed control and mileage monitoring device.

A speedometer, right remote control, left rubber grip, headlight optics and front direction indicators are installed.

Now we move from the front to the rear of the motorcycle. Rear wheel assembly diagram.

Driven star assembly with casing, chain tensioners, bushings and rear wheel axle.

The driven star is installed. Rear brake assembly and torque rod.

Since the rear tire required replacement, and there was no new one in stock, then I simply installed the brake mechanism (so that what I found and assembled would not be lost in the chaos of full-scale work).

Front wheel assembly diagram.

Front brake parts.

The mechanism is assembled.

Next, a drive lever is installed on the pad release shaft.

I don't have tires for the front wheel yet, so I'm installing a brake mechanism without a wheel.

Checking the wiring to ensure the lighting equipment is working properly.

The tires have arrived, I'm collecting the wheels.

The tire work has been completed, the wheel hubs have been assembled and the tires are inflated.

I'm starting to install the wheels.

The rear wheel is installed. Now you can use the center stand.

Preparing to install the front wheel.

Well, now you can ride the motorcycle.

I turn the vehicle around to carry out work on the right side.

Exhaust gas system assembly diagram.

The muffler is ready for installation. It is attached at two points. In one, using a special bracket with a silent block through the passenger footrest. The second is about using a bolt and nut to the frame.

Brake rod drive assembly diagram.

The muffler, brake foot with shaft and rod are installed.

Seat design.

The seat, fairing and rear view mirror are installed.

Most of the work appears to be completed.

The next stage will be working on the engine, and finally painting the tank and motorcycle trim.

Continuation of work on assembling the motorcycle SOON in the next part: Mounting screws for the ZID 200, Owl, Voskhod 3M-01 engine.

Photo report: Motorcycle engine repair "Voskhod-3m"

Before any repair or assembly of the engine, we carefully inspect all parts for wear or damage, paying special attention to the condition of the engine crankcase and threaded connections. You will find all the answers on crankcase repair in the article: Photo report: Repairing the crankcase of a scooter engine

Next, we carefully wash the engine parts, clean all the oil channels (marked with an arrow in the first photo, the second channel is located there only in the other half of the crankcase), buy a new set of gaskets and oil seals (a prerequisite for a quality repair), lay the engine on planks so that the shafts hang in the air and do not interfere with work.

The engine that we will be repairing today was initially in good condition, only the crankshaft bearings were badly worn and the return spring of the gear shift shaft was broken. Therefore, the entire repair will consist of installing new bearings, seals and gaskets with subsequent engine assembly. You will find all the details on disassembling this engine in the article: Photo report: Disassembling the engine of the Voskhod-3M motorcycle

We begin repairing the Voskhod-3M motorcycle engine by installing the crankshaft main bearings into the crankcase.

We install retaining rings in both halves of the crankcase, then install the main bearings there using a mandrel.

So that the crankshaft “stands” exactly in the center of the crank chamber, that is, the distance between the cheek and the wall of the crank chamber is the same on both sides. We need to take some measurements with a caliper before installing it in the engine.

So, we take a caliper and, using a bore gauge, measure the depth of the crank chamber one by one.

We look at what happened and write down the value in a notebook.

We measure the second chamber in exactly the same way and write down the value in a notebook, after all the measurements taken, we add up both values and add to it the thickness of the gasket, my gasket will be homemade from paronite with a thickness of 0.6 mm, therefore, to the sum of the depth values of the crank chambers we add another value equal to: 0 ,6mm.

Photo report: Assembly of the gearbox (box) of the Voskhod-3M motorcycle

Before assembling the gearbox of the Voskhod-3M motorcycle, we thoroughly wash all engine and gearbox parts and check their condition, replace worn and damaged parts with new ones. We pay special attention to the condition of the gear teeth and cam clutches; we also check the performance of the gear shift mechanism sector; there should be no increased backlash or jamming in its operation. The gearbox that we will be assembling today was in very good condition and did not raise any complaints about the condition of the parts, only the return spring of the gear shift shaft and heavily worn bearings were broken, all the details on disassembling the gearbox can be found in the article: Photo report: Disassembling the Voskhod motorcycle engine -3M Therefore, we will replace only the bearings and the spring, we could not find the original spring, I did not get upset about this, but simply took another spring from the “ant scooter”, bent it a little, cut it to length “antennae”, in the end the spring turned out no worse original (still works to this day).

We begin assembling the gearbox by installing the bearings.

We insert the retaining ring into the mounting hole of the secondary shaft bearing, then insert the support washer from the inside of the crankcase and, using a mandrel, install the outer race of the secondary shaft bearing into the crankcase (with the grooves inside the crankcase, marked by arrows).

Before installing the secondary shaft race, carefully inspect its working surface, which should be free of: cracks, chips, shells, burrs and signs of excessive wear.

An example of an ideal working surface, even traces of factory processing remain.

In the same way, we install retaining rings in the other half of the crankcase, place adjusting washers on the inside of the crankcase, and use a mandrel to install the bearings in place.

We carefully inspect the working surface (“treadmill”) of the secondary shaft; there should be no cracks, chips, burrs, cavities or signs of excessive wear, the surface should be smooth and shiny.

An example of the output shaft "treadmill" in perfect condition.

We apply some kind of grease to the “treadmill” of the secondary shaft and place the rollers on it. The rollers here are laid in two rows; to separate the rows from each other, there are special thrust washers on the shaft. First we lay the bottom row of rollers, then we separate the bottom row with a washer and lay the top row.

As a result, you should get something like in the photo.

Carefully so that the rollers do not fall out, insert the secondary shaft into place. To prevent the secondary shaft from falling out during the assembly process, it must be fixed; to do this: turn over half of the crankcase, support the shaft from the inside with something, install the oil seal, put a spacer sleeve on the shaft (groove towards the shaft, marked with an arrow), install the drive sprocket and tighten the nut.

We place some planks under the left half of the crankcase so that the shafts hang freely in the air and do not interfere with work. We take the gear shift shaft bracket and install it in place.

We install the pre-aligned lock washers into place.

Apply blue thread locker to the mounting bolts, tighten the bolts and bend the lock washers with pliers.

We install the gear shift shaft, input shaft and first gear gear in place.

We insert the spring into the hole of the latch, then the latch rod itself, after installation we be sure to check its functionality. The latch should “walk” in its “socket” without jamming or excessive play.

We put the gear of the second and fourth gears on the corresponding fork of the sector of the gear shift mechanism.

We slightly pull out the shaft of the gear shift mechanism, insert its driver into the groove on the sector of the gear shift mechanism, put the gear of the second and fourth gears on the input shaft and at the same time with both hands install the sector of the gear shift mechanism in its place.

After preliminary installation of the gear shift mechanism sector, we press the lock inward with a screwdriver and finally install the gear shift mechanism sector.

In the same way, we take the pre-aligned lock washers, install them in their places, apply thread locker to the bolts and finally tighten everything. After tightening the bolts, do not forget to bend the lock washers.

Reinstall the intermediate shaft.

After everything has been done, we check the ease and correctness of gear shifting and prepare the engine for final assembly. The assembly of the engine of the Voskhod-ZM motorcycle is described in detail in the article: Photo report: Repair of the engine of the Voskhod-3M motorcycle