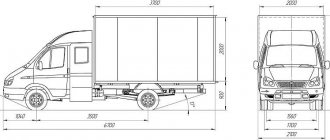

Main components of a car

For normal operation of the engine, it must be constantly cooled, even during the cold winter period.

It is recommended to pay special attention to the serviceability of the pipeline system through which the coolant circulates, as well as to the correct operation of the main part of the liquid cooling system (LCS) - the water pump or, in other words, the water pump of the car.

Due to their design features, the power units of modern cars are operated at high temperature levels. For example, domestic Gazelle cars are designed for a power unit operating temperature range of 92–99 °C.

Domestic Gazelle cars are fairly common budget options for local cargo transportation.

If the machine is used intensively, the engine begins to heat up beyond normal. But thanks to the timely supply of coolant to the engine elements, the operating temperature of the power unit quickly reaches the required values, and significant loads for the car are no longer dangerous. Antifreeze or antifreeze is used as coolant in the cooling systems of various Gazelle models.

Antifreeze is one of the popular options for high-quality coolant

Thus, the ZhSO performs the task of timely cooling of the engine mechanisms. For the system to operate efficiently, constant coolant circulation is essential. During its movement through the pipelines of the liquid coolant, the antifreeze (antifreeze) is significantly cooled, due to which the performance of the internal combustion engine is maintained.

A cheaper option for non-freezing coolant is antifreeze

The liquid used in the liquid liquid circulation circulates in a forced mode. This circulation is ensured by the car's water pump. Thanks to this component of the motor design, the latter does not overheat and its technical and operational parameters are always within the temperature range required for efficient operation.

General pump design for Gazelle

A standard water pump includes the following parts:

The design of the pump for some modifications of the Gazelle provides a special mechanism for automatically turning on the radiator fan. We are talking about an electric coupling. Replacing the pump in these engine models (for example, in the ZMZ 405) is only possible together with the entire mechanism.

One of the successful options for installing an electric coupling is installation in one unit with a pump

The main disadvantages of this design solution include the following points:

Located on the engine block, the pump operates by connecting through a drive belt from the crankshaft.

The best option for ensuring the functioning of the water pump is connection through the drive belt from the crankshaft

The operating principle of the pump is as follows:

To avoid unwanted coolant leakage, a special sealing gasket is installed between the cylinder block and the pump body. In this case, it is necessary to thoroughly clean the contact surfaces on the engine and pump.

During repairs, it is imperative to replace the gasket under the pump.

The pump shaft outlet is equipped with an oil seal capable of sealing due to its design. It consists of a rubber sleeve and a sealing washer. The seal provides the necessary sealing of the product.

The pump seal should not allow air into the pump, ensuring its complete tightness.

The device has a durable metal alloy body, as well as special hinges that ensure proper attachment to the power unit.

Popular water pump model for Gazelle without electric coupling

Signs of a pump malfunction

The pump is a fairly reliable mechanism, but cases of its sudden failure are not uncommon. To avoid this, you need to know the main signs indicating a possible breakdown of this component.

These include:

Repairing the motor pump is considered impractical by experts. Its design features preclude high-quality independent repairs, so it is recommended to replace this component as an assembly.

A design feature of the water pump used on certain engines of Gazelle cars (ZMZ 405 and other modifications) is that the pump is assembled in a single unit with an electric coupling, which ensures timely activation of the radiator cooling fan. The pump is replaced with a new part complete with an electric coupling.

The modern model of water pump for the ZMZ 405 engine is ideal for Gazelle cars

The marking of individual models of water pumps assembled in a single mechanical unit with an electric coupling is as follows:

In other cases, with engine modifications (4216, 406, 421, 402), pumps are used whose designs do not include an electric coupling. This component is mounted separately from the water pump.

The pump for engine 4216 is installed on the latest Gazelle-business cars

Video: signs of a faulty Gazelle pump

Location of the water pump on the car

The pump works synchronously with the machine motor. To ensure rotation of the pump shaft with the impeller, the pulley receives the energy of rotational motion through a belt drive from the crankshaft pulley.

The water pump is located in the front upper part of the Gazelle engine

This is the optimal solution for efficient operation of the engine pump.

Gazelle pump. Water pump Gazelle. Additional pump Gazelle. Price

+7-916-119-99-08

The PARKMOTORS company sells auto parts from a warehouse in Moscow: pump for Gazelle (water pump).

Pump Gazelle ZMZ 405-406 Euro-2. Water pump

pump for gazelle water pump euro-2

Gazelle pump (water pump with an electromagnetic fan drive clutch) for ZMZ 405th and 406th engines (EURO-2) complete with gasket. The electric pump (electric water pump) on the Gazelle is produced with a pressed-on electromagnetic clutch - when the engine temperature rises, the ECM closes the electromagnetic clutch, and the cooling impeller attached to it begins to rotate along with the rotation of the pump pulley.

Price 4500 rub.

Pump Gazelle ZMZ 405-406 Euro-3. Water pump

pump for gazelle water pump euro-3

Electric pump (water pump with electromagnetic clutch) for Gazelle on ZMZ 405th and 406th engines (EURO-3) complete with gasket.

ATTENTION!

Electric pump of EURO-2 and EURO-3 standards are NON-INTERCHANGEABLE! The Euro-3 electric pump differs from the “regular” Euro-2 electric pump with an electromagnetic coupling in the following:

The pump housing (electric water pump) has been changed - the pipe coming from the thermostat has been reduced in diameter;

The impeller (impeller) of the pump has been changed - the characteristics of the coolant supply have been increased;

The cross-section of the electrical wire has been increased.

Price 4500 rub.

Gazelle Business pump (water pump) for UMZ-4216 EURO-3 engine

pump 4216 umz for gazelle business water pump

pump 4216 umz for gazelle business water pump

Price 2000 rub.

Gazelle Business pump (water pump) for UMZ-4216 EURO-4 engine

pump 4216 umz for gazelle business water pump

pump 4216 umz for gazelle business water pump

Price 2000 rub.

Additional electric pump for Gazelle D-18 mm

Additional pump for Gazelle of a new type (Kaluga), hose diameter 18 mm.

Procedure for replacing the water pump on a Gazelle car

If the water pump malfunctions, it is recommended to immediately replace it with a new part, since ignoring repairs can lead to more serious consequences and, as a result, to significant financial losses. We are talking about the performance of the engine and, in particular, about the money for its overhaul.

When operating the engine, inevitable wear of the part occurs and the pump must be replaced with a new one. The service life of the water pump may vary. For example, the original pump will last more than 80 thousand km under satisfactory operating conditions. When using a mechanism from an unknown manufacturer or a counterfeit, you should not expect even 20 thousand km. In this case, in addition to purchasing a prematurely failed part, you will have to additionally purchase an expensive coolant.

Reasons leading to water pump failure

The design of the pump is very simple and breakdowns are rare, but it is impossible to completely eliminate them. There are several reasons why the pump may fail:

- Natural wear, which primarily concerns the aging of the oil seal;

- Poor manufacturing quality of the pump, which is why it could not work for a long time;

- Unskilled repairs that you may have tried to carry out yourself without having the proper experience.

How to identify nearby pumps

- Replacing a Cummins pump may be necessary in cases where the engine and radiator boil even during short trips. This is indicated by the temperature sensor on the dashboard;

- Leaking pump or antifreeze at its location.

Replacement of a Cummins pump is carried out strictly after diagnosis, so that our service center specialist is confident in the accuracy of the diagnosis.

Replacing the pump on other engine models

For almost all engines of modifications UMZ, ZMZ, which are installed on Gazelle vehicles, the main steps for replacing the water pump will be similar. Only minor differences regarding the structural arrangement of the unit are possible.

When performing work on the power units of the Gazelle Business vehicle, model UMZ-4216, there are some differences in the actions and their sequence:

In all modifications of Gazelle cars, replacing the water pump involves almost the same steps. In any case, the coolant is removed from the motor fluid supply system, and the drive belt is also dismantled. The procedure is not complicated: it is quite feasible for drivers with basic car maintenance skills.

Source

Why do you need a pump in a car?

Any power unit operates at high temperatures. In particular, for Gazelle cars, the operating temperature of a well-heated engine is considered to be 92–99 degrees. Starting to overheat due to increased loads, the engine is immediately cooled by the timely supply of the required amount of coolant (depending on the model, Gazelles are filled with either antifreeze or antifreeze).

So, to prevent the motor from overheating and “boiling,” the machine is equipped with a cooling system. In this case, the liquid in the system circulates only forcibly, under the influence of a water pump (or, as drivers often call it, a pump).

The pump ensures stable circulation of antifreeze, thereby always supplying fresh liquid to the engine. It is thanks to its operation that the engine does not have time to warm up to a critical temperature.

The device has a metal case and special hinges for secure fastening in the car body

Replacing the pump on a Gazelle

As soon as problems with the pump begin, the car owner is recommended to immediately replace this device. Firstly, over time, the water pump one way or another begins to wear out - accordingly, it can no longer fulfill its main purpose. And secondly, you cannot risk the performance of the engine - after all, it is easier to replace a cheap pump than to carry out a major overhaul of the internal combustion engine later.

Where is the water pump located?

The pump is switched on together with the motor. Accordingly, in order for the pump shaft with the impeller installed on it to begin to rotate, some action must be applied to it. The energy for rotation is supplied through the pump pulley thanks to the hydraulic timing belt drive.

To make work as convenient as possible, the pump is located in the timing device. On the one hand, this is the most comfortable place to start the pump. But on the other hand, in cases of replacing the mechanism, you will have to remove the timing belt, which makes its subsequent installation difficult.

The pump pulley is one of the most important elements of the timing system.

Preparing the tools

To remove and install the pump you will need the following set of tools:

wrench 12;

open-end wrench 24;

wrench 27;

flat screwdriver with a thin blade;

container for draining coolant.

Experienced drivers always keep such kits on hand, since the tools they contain are needed in all cases of self-repair of the car.

How much antifreeze to drain/fill when changing the pump

If the pump has exhausted its service life, it is recommended to drain all the coolant that is in the system. In this way, the system is cleared of impurities in the antifreeze, which also has a beneficial effect on the performance of the new device.

It is best to drain the antifreeze simultaneously from the expansion tank and from the radiator by disconnecting the pipe from it. You need to place containers under the drainage points. When draining antifreeze, it is necessary to take into account that it will not be possible to completely dry the cooling system using this method. Therefore, when filling in new coolant, it is worth remembering that there is still some amount of antifreeze in the system. It is recommended to first fill the fluid to the MIN mark on the tank, then start the engine and warm up the car. After this, evaluate how much antifreeze has gone through the system. Add the required amount, following the MIN and MAX marks on the tank.

Gazelle pump replacement

The vast majority of modern cars are equipped with a water engine cooling system. Let’s make a reservation right away: the term “water” itself is conditional; it would be more correct to call this system hydraulic, and even then not to the full extent. Cooling of the liquid itself and additional cooling of the engine by air flow through the radiator grille have also not yet been canceled. But, nevertheless, cooling a running engine using continuously circulating coolant is the main element of the system. Hence its name.

Replacing the pump: instructions for various modifications of Gazelle engines

After the coolant has been drained, you can begin to dismantle the device:

The first step is to remove the cooling radiator.

Next, after access to the timing belt is opened, you will need to unscrew the three bolts of the water pump pulley.

It is recommended to keep the pump from turning with a long bolt or a special blade.

Remove the pump drive belt.

Then remove the unscrewed pulley and reflector.

From the pump body, unscrew the fitting of the pipe through which antifreeze is supplied.

Loosen the fastening clamps and disconnect all hoses and pipes from the mechanism.

After this, use a hex key to unscrew the four screws that secure the device to the motor housing.

There is also another fastening bolt under the pump - it needs to be unscrewed last.

Remove the water pump.

Remove the seal from the landing site.

Installation of a new pump is carried out in the reverse order. Moreover, it is necessary to correctly set the marks on the pulley and roller so that the timing belt does not break when the engine is first started.

Pump replacement process

1

. Using a 12mm wrench, unscrew the three bolts securing the pump pulley, if necessary, holding it from turning with a mounting blade.

2

. Remove the coolant pump drive belt. Remove the pulley and pulley reflector.

3

. Using a 27 key, unscrew the fitting of the heater supply pipe.

4

. Use a screwdriver to loosen the clamps.

5

. supply hoses and remove the lower hose from the pump nozzle.

6

. Using a 6-point hex key on the pulley side, unscrew the four screws securing the coolant pump housing.

7

. Using a 12mm wrench, unscrew the additional pump mounting bolt.

8

. and remove the pump. A sealing gasket is installed between the pump and the cylinder block.

9

. Using a 24mm wrench, we unscrew the fitting from the housing of the old pump and screw it into the new pump, after first applying sealant to the threads.

10

. Before installing the pump, check the serviceability of the pump bearing; its shaft should rotate without clicks, play or jamming. We install the new pump in the reverse order, replacing the gasket.

How to remove the pump on a gazelle 406

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

First of all, to replace the pump, of course, you need to drain the coolant from the ZMZ 405 engine block. Then, in order to gain more access to the water pump, you will have to remove the upper part of the “TV”, remove the pipes, dismantle the cooling radiator, unscrew the fan from the electric coupling and remove the hanging belt. By the way, to remove the pump you will also have to dismantle the housing with the thermostat, so take this into account and unscrew all the bolts of both the pump and the thermostat (they often forget about one tricky bolt at the back). Along with the pump, do not forget to change the gaskets of both the pump itself and its thermostat, and it is also advisable to replace one short pipe, so that later you do not have to suffer again and dismantle the thermostat housing.

Owners of the ZMZ 406 engine were faced with a water pump leak. This means it's time to change the part. The process itself is quite simple and only requires the necessary tools and minimal design knowledge of the car.

How to remove and replace the pump on a Gazelle 405?

First of all, you need to drain the coolant. To do this, you need to open the tap, which is located directly on the block and connect a hose to it.

It will take some time to drain the cooler. Therefore, you can begin to dismantle individual elements:

- the upper part of the TV, held in place by bolts, is removed;

- the tensioner roller becomes loose;

- The belt becomes loose. To do this, you will need a 10mm wrench. It is recommended to use a special wrench;

- The belt is dismantled, first from the roller, and then from the generator.

Now you need to dismantle the upper pipe. You need to install a container under the radiator, after which you can remove the lower pipe. After this, you can carefully dismantle the radiator and drain the remaining coolant from it.

Particular attention should be paid to the radiator cushions, since sometimes car owners lose these elements.

Before removing the pump on the Gazelle 405 , it is necessary to remove the fan.

At the next stage, you need to disconnect all connectors, remembering the operating sequence.

Pump ZMZ 406: replacement process

On the one hand, the process of changing an element is simple, on the other hand it will take about 2-2.5 hours. In order for the ZMZ 406 pump to be replaced, a significant part of the car parts will have to be dismantled. As practice shows, water pumps are not repaired, although for the 406 it is possible to change the pulley.

First, you should determine the reasons for removing the product from the car:

The reasons have been identified, and you can proceed directly to the replacement process itself. Firstly, it is recommended to consider the detailed disassembly and assembly diagram of the unit, which is provided by the manufacturer. Secondly, we collect the necessary tools (a set of keys and screwdrivers). Thirdly, the ZMZ 406 engine (pump) is quite easy to repair. To do this, you just need to strictly follow the technology.

Replacing the ZMZ 406 pump yourself:

Original

The ZMZ 406 pump, like all automotive parts, has catalog numbers. The original part number of the water pump can be registered in two ways: 4063.1000450-20 or 4061.1307010-21.

When choosing an original part, you should pay attention to whether the car enthusiast is buying an original or a fake. The ZMZ 406 pump is always packed in polyethylene with the ZMZ trademark. All seams are soldered and even. The water pump comes with a sealing gasket. The box always contains the brand name of the Zavolzhsky Motor Plant, as well as a hologram sticker.

In the original product, inside the box, there is always a warranty sheet, which also contains a set of installation rules, addresses of the plant's branches, as well as the terms of warranty, return and replacement. A water pump produced by the Zavolzhsky Motor Plant always has a special mark on the metal part of the housing.

Analogs

In addition to the original ZMZ 406 water pump, you can find quite a lot of analogues on the automotive market. At the same time, the quality indicators of the parts are no worse, but the cost may be lower. But most car enthusiasts, when purchasing, still prefer the original.

Let's look at what pump analogues can be found:

Internal combustion engines (ICE) of cars must be properly cooled during operation so as not to fail before the time guaranteed by the manufacturer. Motor cooling in modern cars is based on the use of various types of liquids. Therefore, the name is used - liquid cooling system.

Main components of a car

For normal operation of the engine, it must be constantly cooled, even during the cold winter period.

It is recommended to pay special attention to the serviceability of the pipeline system through which the coolant circulates, as well as to the correct operation of the main part of the liquid cooling system (LCS) - the water pump or, in other words, the water pump of the car.

The water pump for the engine is the main component of the water pump in any modern car.

Due to their design features, the power units of modern cars are operated at high temperature levels. For example, domestic Gazelle cars are designed for a power unit operating temperature range of 92–99 °C.

Domestic Gazelle cars are fairly common budget options for local cargo transportation.

If the machine is used intensively, the engine begins to heat up beyond normal. But thanks to the timely supply of coolant to the engine elements, the operating temperature of the power unit quickly reaches the required values, and significant loads for the car are no longer dangerous. Antifreeze or antifreeze is used as coolant in the cooling systems of various Gazelle models.

Antifreeze is one of the popular options for high-quality coolant

Thus, the ZhSO performs the task of timely cooling of the engine mechanisms. For the system to operate efficiently, constant coolant circulation is essential. During its movement through the pipelines of the liquid coolant, the antifreeze (antifreeze) is significantly cooled, due to which the performance of the internal combustion engine is maintained.

A cheaper option for non-freezing coolant is antifreeze

The liquid used in the liquid liquid circulation circulates in a forced mode. This circulation is ensured by the car's water pump. Thanks to this component of the motor design, the latter does not overheat and its technical and operational parameters are always within the temperature range required for efficient operation.

General pump design for Gazelle

A standard water pump includes the following parts:

The pump body is always made of durable alloys

The shaft and impeller are the main working element of the pump

The pump bearing ensures free rotation of the shaft, and the oil seal ensures the tightness of the device

The design of the pump for some modifications of the Gazelle provides a special mechanism for automatically turning on the radiator fan. We are talking about an electric coupling. Replacing the pump in these engine models (for example, in the ZMZ 405) is only possible together with the entire mechanism.

One of the successful options for installing an electric coupling is installation in one unit with a pump

The main disadvantages of this design solution include the following points:

Located on the engine block, the pump operates by connecting through a drive belt from the crankshaft.

The best option for ensuring the functioning of the water pump is connection through the drive belt from the crankshaft

The operating principle of the pump is as follows:

To avoid unwanted coolant leakage, a special sealing gasket is installed between the cylinder block and the pump body. In this case, it is necessary to thoroughly clean the contact surfaces on the engine and pump.

During repairs, it is imperative to replace the gasket under the pump.

The pump shaft outlet is equipped with an oil seal capable of sealing due to its design. It consists of a rubber sleeve and a sealing washer. The seal provides the necessary sealing of the product.

Services list:

| GAZelle shock absorber replacement | 500 rub. |

| replacement ball GAZelle NEXT | 1500 rub. |

| replacing a GAZelle wheel bearing | 2200 rub. |

| replacing the silent blocks of the front levers GAZelle NEXT | 1500 rub. |

| replacing GAZelle spring bushings | 1600 rub. |

| GAZelle internal combustion engine diagnostics | 500 rub. |

| GAZelle generator replacement | 1500 rub. |

| GAZelle starter replacement | 1400 rub. |

| replacing GAZelle headlight bulbs | 200 rub. |

| GAZelle timing chain replacement | 6000 rub. |

| GAZelle gearbox removal | 3500 rub. |

| GAZelle gearbox oil change | 600 rub. |

| replacement of GZS GAZelle | 1000 rub. |

| GAZelle gearbox repair | 3500 rub. |

| Removing (installing) the GAZelle fuel pump | 1800 rub. |

| replacing the GAZelle fuel filter | 400 rub. |

| replacement of fuel injection pump GAZelle (Cummins) | 3500 rub. |

| replacing GAZelle injector (Cummins) | 500 rub. |

| GAZelle brake fluid replacement | 600 rub. |

| replacing GAZelle disc pads | 600 rub. |

| GAZelle handbrake adjustment | 300 rub. |

| replacing the handbrake cable (short) GAZelle | 500 rub. |

| replacing handbrake cable (long) GAZelle | 2500 rub. |

| replacing GAZelle brake discs | 1500 rub. |

| replacing GAZelle brake hoses | 500 rub. |

| GAZelle pump replacement | 3500 rub. |

| replacing glow plugs GAZelle (Cummins) | 2000 rub. |

| replacing the front crankshaft oil seal GAZelle | 2500 rub. |

| Webasto diagnostics | from 500 rub. |

| Webasto repair | from 2500 rub. |

| re-equipment of the afterheater into a pre-heater | from 4000 rub. |

Procedure for replacing the water pump on a Gazelle car

If the water pump malfunctions, it is recommended to immediately replace it with a new part, since ignoring repairs can lead to more serious consequences and, as a result, to significant financial losses. We are talking about the performance of the engine and, in particular, about the money for its overhaul.

When operating the engine, inevitable wear of the part occurs and the pump must be replaced with a new one. The service life of the water pump may vary. For example, the original pump will last more than 80 thousand km under satisfactory operating conditions. When using a mechanism from an unknown manufacturer or a counterfeit, you should not expect even 20 thousand km. In this case, in addition to purchasing a prematurely failed part, you will have to additionally purchase an expensive coolant.

The main differences between the original design and the fake:

The original pump differs from fakes by high-quality cast markings of the body and the dim color tone of the alloy

Preparing tools for replacing the water pump yourself

When dismantling the mechanism, as well as when subsequently installing a new part, the following tools and materials will be needed:

The best solution for carrying out a complete repair is a set of high-quality tools.

Prudent drivers always have tools with them, since for any independent car repair they are simply irreplaceable

The procedure for replacing the pump and the volume of coolant drained

In the event that the pump has exhausted its entire service life, experts recommend draining the maximum possible amount of coolant located in the liquid fluid of the car. In a similar way, the cooling system is cleaned of all kinds of impurities contained in the coolant. This circumstance has a beneficial effect on the performance of the new mechanism being installed.

Coolant is drained, as a rule, from the following components:

The radiator provides coolant cooling during vehicle operation

The expansion tank is used to fill coolant, as well as to hold it when heating (increasing volume)

The car heater allows you to heat the car interior, as well as the windows during cold weather.

The cylinder block is one of the main parts of the engine

To do this you need:

- Open the lid from the expansion tank of liquid liquid waste.

Engine cooling system pipes provide circulation and supply of coolant to various engine systems and parts

If the coolant is in normal condition (no sedimentary compounds), then it can be reused. It should be taken into account that it will not be possible to completely rid the system of coolant. Residual volume in various components is inevitable, which is taken into account when filling in new coolant. The total volume of coolant in various models can reach up to 11.5–12 liters. When replacing the coolant or during repairs, about 8.5 liters are drained from the system.

Video: self-replacement of coolant in the ZMZ 405 engine of the Gazelle car

Step-by-step steps to independently replace the water pump on various Gazelle engines

After freeing the cooling system from coolant, you can begin dismantling the mechanism:

- De-energize the vehicle's electrical system by disconnecting the battery.

Removing the negative terminal from the battery is necessary when carrying out any type of car repair, as it ensures safety during operation

The “TV” in the Gazelle is the front upper part of the car body with a lock and a hood lock cable

Underwater hoses to the ZMZ 405 engine pump provide coolant supply/discharge to the cooling system

Before removing the drive belt, the roller is brought into a position that allows the belt to be easily removed

To ensure easy access to the pump, you need to remove the drive belt from the roller and pulleys.

Removing the pump is impossible without dismantling the engine cooling radiator

The engine cooling fan is removed during self-repair of the car.

In some cases, the electric coupling of the engine is dismantled along with the pump; the need for this depends on the power unit installed on the car

The engine thermostat housing is removed from the engine to provide access to the pump mounts

To ensure proper sealing, the housing installation site is thoroughly cleaned with sandpaper and treated with lithol before installation

Installing a new pump

Reinstallation of the new mechanism is carried out step by step, starting from the end of the step-by-step list for removing the pump.

Features of installing a new pump:

- When installing sealing gaskets under the pump and under the thermostat cover, their seats must first be treated with a thin layer of lithol to obtain a certain protection against corrosion and the necessary sealing.

Litol is used to process pipes and parts where they fit, which are subsequently secured with screws or bolts

Video: step-by-step instructions for replacing the water pump yourself

Design, replacement of the water pump of the ZMZ-40524 engine

The water pump is a centrifugal type, with an electromagnetic clutch for the fan drive, installed on the chain cover, the pump supplies coolant to the cylinder block

The tightness of the pump is ensured by a self-clamping mechanical seal 7, which is pressed into the housing 6 of the water pump and onto the bearing shaft 11.

The coolant penetrating through the seal does not enter the bearing, but flows through the hole into the drainage cavity 9, closed with a plug.

The liquid accumulating in the drainage cavity during engine operation gradually evaporates through holes 10 and 4. The steam penetrating through the seal evaporates into the atmosphere through hole 4.

During operation, it is necessary to monitor the cleanliness of holes 4 and 10, and, in order to prevent premature failure of the bearing, when carrying out maintenance-2, the holes must be cleared of contamination.

The presence of a constant leak from the control hole 10 of the drainage cavity indicates a loss of seal tightness and the need to replace the water pump.

Bearing 11 is kept from moving in the water pump housing by clamp 3, which is screwed in until it stops and is cored.

The bearing with two protective seals is filled with lubricant at the manufacturer and does not require the addition of lubricant during operation.

A stamped steel impeller 8 is pressed onto the bearing shaft.

At the front end of the water pump housing, an electromagnet coil 12 of the electromagnetic clutch is fixedly mounted on a holder.

Hub 1 of the fan mount is mounted on the water pump bearing shaft on a ball bearing.

In the absence of voltage on the electromagnet, hub 1, together with the driven disk 13, is disconnected from pulley 2 and rotates freely at a low angular velocity.

When voltage is applied to the clutch electromagnet, the driven disk 13, overcoming the force of the leaf springs 14, is attracted to the pulley 2 and the fan hub begins to rotate together with the pulley and the water pump bearing roller.

When the voltage is removed from the clutch electromagnet, leaf springs 14 move disk 13 away from pulley 2, separating the hub and pulley.

The electromagnetic clutch is connected to the vehicle's electrical system using connector 5.

Voltage is supplied to the clutch electromagnet according to a signal from the control unit through a relay when the coolant temperature rises above plus 93 ± 2 °C, and it is switched off when it drops below plus 91 ± 2 °C.

Main parameters of the electromagnetic clutch:

1. Supply voltage—10.8…15V.

2. Electrical power consumption - no more than 50 W.

3. Transmitted torque at a voltage of 12 V is at least 20 Nm (2 kgf m).

4. The minimum response voltage is 10 V.

5. Transmitted torque at minimum voltage is not less than 11 Nm (1.1 kgf m).

6. The gap between the driven disk and the pulley is 0.2. . .0.5 mm.

A water pump with an electromagnetic clutch is a non-repairable product. If the water pump or electromagnetic clutch fails, the entire assembly must be replaced.

The water pump and generator (without the power steering pump) are driven by a 6RK 1275 poly V-belt from the crankshaft pulley.

The gear ratio of the water pump drive is 1.11.

The belt tension is carried out by an automatic tensioning device, which provides the necessary tension of the belt when it is stretched and damping (damping) vibrations occurring in the drive.

Replacing the pump on other engine models

For almost all engines of modifications UMZ, ZMZ, which are installed on Gazelle vehicles, the main steps for replacing the water pump will be similar. Only minor differences regarding the structural arrangement of the unit are possible.

When performing work on the power units of the Gazelle Business vehicle, model UMZ-4216, there are some differences in the actions and their sequence:

On Gazelle-Business UMZ-4216 engines, it is not necessary to remove the radiator, since access to the pump is through the lower right part of the car

In all modifications of Gazelle cars, replacing the water pump involves almost the same steps. In any case, the coolant is removed from the motor fluid supply system, and the drive belt is also dismantled. The procedure is not complicated: it is quite feasible for drivers with basic car maintenance skills.

Source