Design and adjustment of the carburetor on lawn mowers and trimmers

A petrol mower or trimmer with an internal combustion engine requires not only constant refueling of the fuel mixture of gasoline and oil, but also periodic adjustment of the supply of this fuel. The carburetor is responsible for supplying fuel to the cylinder of the lawn mower, and the efficiency and performance of the tool depends on its proper operation. If during operation a faulty (abnormal) engine operation is detected, the first step is to adjust the carburetor of the lawn mower. Before adjusting the carburetor of a gasoline trimmer, let's first understand its design.

The design of a gas trimmer carburetor and its purpose

Petrol mowers are equipped with two-stroke internal combustion engines. A carburetor is used to supply the air-fuel mixture to the engine cylinder. In the design of gasoline units, this is a key element, without which the operation of the internal combustion engine is impossible. Moreover, this carburetor differs from a car device not only in size, but also in its operating principle. In particular, this difference lies in the presence of a membrane, which plays the role of a fuel pump. It is due to the presence of a membrane that the devices under consideration in the design of two-stroke internal combustion engines are called membrane ones.

Structurally, the entire mechanism is a small part, inside of which there are channels, valves and membranes. The carburetor body is made of aluminum, and the internal structure is shown in the photo below.

Before you adjust the carburetor of a lawn mower with your own hands, you need to understand all the components of the device in question. The carburetor of a lawn mower and trimmer consists of the following parts:

Having an idea of how the carburetor works inside, you have to understand the principle of its operation. A detailed description of how a carburetor works on a two-stroke internal combustion engine using the example of a chainsaw is described in this material.

How does a lawn mower carburetor work or its operating principle?

Adjusting the carburetor of a Chinese lawn mower is completely identical to the adjustment of lawn mowers from European, Russian and other manufacturers. To cope with the task of adjusting the carburetor on lawn mowers and gas trimmers, you need to understand the principle of their operation. How a carburetor works on a lawn mower is described step by step and in an accessible manner below.

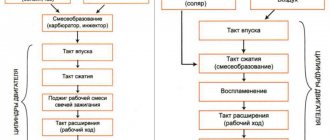

Below is a diagram of the operating principle of a lawn mower carburetor. Based on the diagram, you can not only understand the principle of operation, but also identify breakdowns and other malfunctions of the mechanism.

When operating the tool, it is necessary to take into account the presence of another jet. This jet is located between the idle and full power passages. It is necessary in order to avoid severe leaning of the mixture, which occurs when the engine operates at partial load. In such a situation, the occurrence of a bullying couple cannot be ruled out. Through an additional channel (nozzle), fuel is sucked into the chamber, thereby enriching the fuel-air mixture. The diagram below shows an additional jet, which is designated by the number 1.

Having an idea of the design of the diaphragm carburetor of a brush cutter and the principle of operation, it will not be difficult to configure it yourself. To adjust the carburetor of a lawn mower, adjusting screws are used. The diagram above shows two screws for adjustment, however, most modern models of gasoline trimmers are equipped with three screws. The presence of three adjustment screws allows for more precise adjustment, while achieving stable and uninterrupted operation of the internal combustion engine.

Machining a Honda Dio two-stroke engine

The model is equipped with a 70 cc engine with a basic lubrication and gas distribution system. Buyers are attracted, first of all, by the high power and quick acceleration: the scooter responds to any press of the gas handle, so the sensations are almost the same as when riding a sports bike.

Initially, treatment was carried out on a practically new scooter with a mileage of 1440 km. A third of a can of RVS-Master 2 Strock Engine 2T 200cc was used. After treatment, the noise level of the internal combustion engine decreased slightly, while the traction characteristics significantly improved. If previously the scooter accelerated to a maximum of 46 km/h, then after treatment it easily reached 51 km/h. The average increase in power and traction was 9% (measurements were made over a mileage of 2200 km).

How to find out if your lawn mower's carburetor needs adjustment

Many craftsmen use lawn mowers for a long time, and do not think about the need to adjust the carburetor of the tool. When is it necessary to adjust the carburetor on a lawn mower or brush cutter? If you are asking this question, then you are probably seeing changes in the operation of the engine that are not for the better. In order not to guess and not to miss the moment when it is necessary to adjust the carburetor, you should adhere to the following recommendations on the need for adjustment measures:

As you can see, there are enough reasons to adjust the carburetor of a lawn mower. Typically, craftsmen who have been working with a tool for a long time can hear changes in the operation of the motor, which indicates the need for an adjustment process. Even if you are not sure about the need to carry out adjustment work, then performing it out of turn will definitely not be superfluous.

Adjusting the carburetor on lawn mowers and brush cutters - setup instructions with a step-by-step description

The process of adjusting the carburetor of a lawn mower or trimmer is not difficult, however, it must be done step by step, following the recommendations. Before starting work, it is necessary to carry out preparatory actions, namely:

When all the preparation points have been completed, we proceed to the actual process of setting up the carburetor. First, you should start the engine and let it run for 5-10 minutes, depending on the ambient temperature. When starting the motor at XX, the coil or blades on the trimmer should not rotate. If they move, then you need to reduce the idle speed. The photo below shows an example of the location of the adjusting screws used to make adjustments.

Using a slotted or Phillips screwdriver, we proceed to the direct process of adjustment work. First, we identify the number of screws for adjustment, since there can be 2 or 3, which depends on the manufacturer of the tool. Typically, Chinese trimmers are equipped with two screws. Below we will consider the process of setting up a carburetor, which has three adjustment screws:

Outboard motor carburetor. Adjustment

Being a frequent culprit of increased fuel consumption, unstable engine operation, decreased power output, and so on, the carburetor has a rather complex structure and extremely small fuel strokes in critical parts, which tend to become clogged, accumulating sediments, resins and various oxides.

To seriously understand the operation of the carburetor as part of a single engine mechanism, you will have to spend some time. True, we don’t need to delve into the subtle processes, and everyone probably already knows the general principle of operation. Carburetor, in essence, is a regulator of the fuel mixture (air and fuel), which it supplies to the combustion chamber, depending on the operating modes of the engine.

If there is any suspicion of any malfunction of the carburetor, before making any adjustments (do not immediately disassemble it), you should replace the spark plug with a new, original one, of course, with the manufacturer’s markings, set the recommended gap correctly and warm up the engine for 5-10 minutes . Of course, we must use only recommended fuel and oil. Moreover, it is not customary to store fuel for more than three months, but it can retain its characteristics for no more than six months.

Typical idle adjustment using adjusting bolts is carried out according to a fairly well-known general scheme. Two screws: the so-called quality screw and quantity screw .

Using the quantity screw, which slightly opens the throttle valve in idle mode, we set the speed to slightly higher than the minimum stable speed. Following this, with the quality screw we catch the increase in speed and leave it at the highest, and with the quantity screw we reduce them to the previous, slightly higher ones.

You will have to repeat the process several times. After this, we remove the slightly increased speed not with the fuel mixture quantity screw, but with the quality screw, tightening it. The main thing is that we need to achieve a minimum stable idle speed.

If the outboard motor stalls when you engage the gear, you need to slightly increase them with the quantity screw. The same should be done if the engine is ready to stop when putting the hood back on. Before making adjustments, you should check the condition of the screw springs; if they are weakened, you can simply stretch them and put them in place. Otherwise, the adjustments will soon be lost due to vibration. You can check whether we have left the mixture too lean while driving by sharply releasing the gas. The engine should not stall.

A problem with adjusting the fuel level in the float chamber can cause such behavior of the outboard motor as an attempt to stall when revving up, difficulty starting a warm engine, unstable idling, increased fuel consumption - these are signs of an increased level. Unstable idling and worsening acceleration dynamics are signs of a low level.

In most PLMs, the fuel level in the float chamber is adjusted by changing the angle of the float tongue, which is usually made of soft metal and soldered into the float body. The tongue, in turn, interacts with the shut-off needle valve, pressing it when the float rises and the fuel level rises, thereby forcing the needle valve to go back into the seat and shut off further fuel supply. Obviously, the position of the tongue depends on how

he will do it soon. In principle, there can be no exact recommendations for tuning here, because each motor, even from a reputable manufacturer, is individual. Simply, following the logic, you need to bend the tongue with the screwdriver down or up. Of course, the angle should be changed very slightly, using a regular flat-head screwdriver. It is more convenient to remove the float for this, fortunately it is not difficult.

But initially the float was set up at the factory strictly according to the manual. Here, for example, are the standard values for Mercury 9.9:

But for Mercury 5:

Of course, the float itself must be sealed; fuel should not splash inside it. The seal can be corrected by soldering, and in camping conditions you can use soap. Gasoline does not dissolve soap. The needle valve may also have wear or a clogged seat. During severe storage without preservation and, of course, without removing fuel from the carburetor, resins may well be deposited on the valve and it may simply stick in the seat.

Tuning the carburetor of a two-stroke engine

If your carburetor is not set up quite correctly, a situation may occur that the engine will run on a lean mixture. A lean mixture is when there is less gasoline in it and more air. It would seem - well, what’s wrong, well, it will burn more quietly, but it won’t overheat. But in fact, the opposite is true!

A two-stroke engine does not have a separate lubrication system. Oil gets into moving parts (piston and cylinder walls, as well as crankshaft main bearings, connecting rod needle bearing) from the fuel mixture. A lean mixture is not only a lack of gasoline, but also a lack of oil. The crankshaft rotates at enormous speeds - thousands of revolutions per minute, so the bearings must always be well lubricated.

Ultimately, an insufficient amount of lubricant will lead to severe heating of engine parts. The bearings will burn out and may fall apart. The piston head will burn out. Broken pieces of parts will damage the inside of the engine.

Of course, it’s not necessary that everything will fall apart at once, but thermal seizure of the piston, one might say, is guaranteed.

Therefore, it is extremely important to control the quality of the mixture. This can be done visually by turning out the candle (I have already written about this more than once). Signs of a lean mixture are a white insulator.

What can cause a lean mixture? First of all, an unadjusted carburetor. You can read how to adjust the carburetor in a separate article.

Another reason is air leaks in the fuel lines. This is usually a bad or missing gasket.

And the third reason is the zero-resistance filters installed instead of the standard foam filter. If you have installed FTS on your scooter, it is necessary to adjust the carburetor, because such a filter, by its design, leans the mixture.

In general, on a two-stroke engine it is better to overdo the mixture than to run it too lean. Although a rich mixture leads to the formation of soot, this soot is not as bad as overheating.

Please note: This article and the images in it are subject to copyright. Partial or complete reproduction on other resources without permission is prohibited.

One of the main components in the fuel mixture supply mechanism in a vehicle such as a scooter is the carburetor. Before moving directly to the description of the adjustment process, let's talk about why it is needed at all.

Carburetor - a device that ensures the formation and supply of a fuel mixture (consisting of air, gasoline and oil) directly to the engine

What exactly is the purpose of a carburetor? In a nutshell, this is a device that ensures the formation and supply of a fuel mixture (consisting of air, gasoline and oil) directly to the engine. That is, the quality of this mixture and, accordingly, the power that the power unit produces depends on it.

Scooters typically use carburetors of a type called “float” carburetors. The main element is a Venturi tube, which houses a damper that regulates the amount of air supplied to the mixture, as well as a needle that supplies gasoline. By unscrewing the throttle, we thereby open the throttle and raise the needle, increasing the amount of air-fuel mixture entering the engine.

Naturally, the movements of the valve and the needle must be clearly synchronized to ensure its (mixture) homogeneity. The float chamber is designed to ensure the constant presence of gasoline in the tube. The principle of its operation is based on the fact that when the fuel level drops, the float lowers and opens a channel for supplying gasoline to the tube. When it is full, the float rises and closes the valve, thereby stopping the flow of fuel.

If the scooter's engine power drops, it is impossible to start the engine or the engine stalls - these are signs of a carburetor failure

Signs that the carburetor is faulty may include:

Another way to assess the quality of the carburetor (more precisely, the correctness of its operation) is as follows - unscrew the spark plug and look at its color. If it is white, it means the fuel mixture is lean, that is, there is too much air in it, and if the spark plugs have a black tint, it means the carburetor is “pouring” too much fuel. With any of these options, one thing is clear - it needs adjustment.

It should be noted that, globally, this process does not depend on the engine stroke, therefore the answer to the question of how to correctly adjust the carburetor on a Chinese 4t scooter and how to correctly adjust the carburetor on a 2t scooter will be the same. Let's now move on to describing the sequence of actions.

Design and principle of operation of a two-stroke engine

In two-stroke engines, all operating cycles (the processes of injecting the fuel mixture, exhausting exhaust gases, purging) occur during one revolution of the crankshaft (and not two, as in four-stroke engines) in two (and not four) main strokes.

Two-stroke engines do not have valves (as in four-stroke internal combustion engines); their role is played by the piston itself, which, in the process of movement, either closes or opens the intake, exhaust and purge windows. Therefore, a two-stroke engine is simpler in design. The power of a two-stroke engine with the same cylinder dimensions and shaft speed is theoretically twice that of a four-stroke engine due to the twice as many power strokes. However, incomplete use of the piston stroke of a two-stroke engine for expansion, poorer release of the cylinder from residual gases and the expenditure of part of the generated power on purging lead to an increase in power by only 60 - 70%.

So, consider the design of a two-stroke internal combustion engine , shown in Figure 1:

A two-stroke engine consists of a crankcase in which a crankshaft and cylinder are mounted on bearings on both sides.

Lubrication of all rubbing surfaces and bearings inside two-stroke engines occurs due to the fuel mixture - a mixture of gasoline and oil in a certain proportion. From Figure 1 it can be seen that the fuel mixture (yellow color) enters both the crank chamber of a two-stroke engine (the cavity where the crankshaft is fixed and rotates) and into the cylinder. There is no lubricant there anywhere, and if there was, it would be washed off with the fuel mixture. This is the reason why oil is added in a certain proportion to gasoline. The type of oil used is special, specifically for two-stroke engines. It must be able to withstand high temperatures and, when burned together with the fuel, leave a minimum of ash deposits, that is, soot.

Now about the principle of operation. The entire working cycle in two-stroke engines is carried out in two strokes.

A few words about the required frequency of adjustments

Of course, it is better to perform such maintenance more often, without waiting until the engine begins to stall or simply does not start. It is recommended, as a preventative measure, to perform this procedure approximately once every six months.

adjusting the carburetor 2T scooter

Having bought a motorcycle, scooter or other motorized equipment, owners have to become familiar with the operation and adjustment of their main components. One of the important elements of a two-stroke or four-stroke power unit is the carburetor, which is responsible for supplying fuel to the combustion chamber and mixing gasoline with air in the required ratio. Many people do not know how to adjust the carburetor on a scooter using the adjusting screw. This need arises if the device does not start well, shows increased appetite, or the tachometer needle indicates unstable speed.

Troubleshooting in the fuel system of two-stroke engines.

What engines consume how much fuel?

As is usual throughout the world of motors, including boats, consumption directly depends on power. Modern engines, thanks to the introduction of new technologies, can consume slightly less fuel compared to older ones, but with the same power. But this difference will not be so noticeable.

It is generally accepted that two-stroke outboard motors consume up to 350 ml. gasoline per hour per horsepower. For example: a Yamaha 5 CMHS engine will consume no more than 1.75 liters/hour. (5*350=1750ml). Of course, consumption can be significantly reduced if you control the engine more gently and do not “twist” it. Or, for example, go more often at cruising speed, at which the consumption will generally be scanty.

Four-stroke engines are more economical, as you know. Their consumption is calculated using the following formula: 250 ml. gasoline per hour per horsepower. And again, for example: the Yamaha F9.9FMHS outboard motor should consume no more than 2.5 liters per hour. (10*250=2500 ml.) If you take Honda engines, then their consumption will be even lower, because Honda engineers pay great attention to this indicator when developing their outboard engines.

Technical advice Carburetor.

1. idle jet (idling and light loads).

When the engine is running at low speeds and the throttle valve is almost closed and the vacuum in the diffuser is not large, the fuel-air mixture does not exit the main jet. At idle, fuel is supplied through the idle air jet, mixed with air from the idle air jet. Fuel and air, in a proportion determined by the position of the idle speed adjustment screw, enters the engine through an opening located above the throttle valve. When, at low speed, the throttle valve opens so much that it extends beyond the bypass holes, the air-fuel mixture begins to flow through them.

2. Medium speed.

When the throttle valve is still slightly open and the engine is operating in the medium speed range, the fuel-air mixture is supplied from both the auxiliary passage and the bypass holes. Also, depending on the opening angle of the throttle valve, the fuel-air mixture begins to pass through the main nozzle.

3. High speed.

At high speeds, with the throttle valve fully open, fuel mixed with air coming from the main air jet flows through the main atomizer into the diffuser.

Purpose and principle of operation of the carburetor

The carburetor is an important component of an internal combustion engine, responsible for preparing the air-fuel mixture and supplying it to the working cylinder in the required ratio. A scooter engine with an unadjusted carburetor cannot function properly. The stability of speed, the power developed by the engine, gasoline consumption, response to turning the throttle, as well as ease of starting in the cold season depend on the correct settings of the engine power supply.

This unit is responsible for preparing the air-gasoline mixture, the concentration of the components of which affects the nature of the operation of the power plant. The standard ratio is 1:15. Leaning the mixture to a ratio of 1:13 ensures stable engine operation at idle. Sometimes it also becomes necessary to enrich the mixture by maintaining a ratio of 1:17.

Knowing the structure of the carburetor and knowing how to adjust it, you can ensure stable operation of the engine on two-stroke and four-stroke scooters.

Thanks to a properly configured carburetor, easy and quick starting of the vehicle engine is ensured, as well as stable operation of the engine, regardless of the ambient temperature. Any carburetor is equipped with jets with calibrated holes, a float chamber, a needle that regulates the cross-section of the fuel channel, as well as special adjusting screws.

The adjustment process involves specially rotating the screw in a clockwise direction or in the opposite direction, which causes, respectively, the enrichment or depletion of the working mixture. Adjustment measures are carried out on a warmed-up engine. In this case, the carburetor unit must first be thoroughly washed and cleared of blockages.

Principle of operation

One revolution of the crankshaft is one cycle of the operating process of an internal combustion engine.

Fuel (gasoline + oil) with air is supplied to the working combustion chamber of the cylinder, after which, due to the formation of a spark from the spark plug, an explosion of the combustible mixture occurs, the energy of which sharply pushes the piston down.

When the piston moves down, the outlet window opens and a little later the transition window opens, through which a new portion of fuel is injected.

The fuel mixture enters the engine crankcase through a window that opens due to vacuum as the piston moves upward from bottom dead center (BDC) to top dead center (TDC). This movement also opens a window for the release of gases from the burnt mixture. After milliseconds, the purge window opens. A new portion of fuel is supplied through the purge window.

Why do you need to regulate?

During the adjustment process, the scooter carburetor needle is adjusted, the position of which affects the proportions of the air-fuel mixture, as well as a number of other adjustments.

Adjusting the scooter carburetor needle is done during the adjustment process

Each tuning operation has a different effect on engine operation and fuel preparation:

A power unit with an adjusted carburetor operates stably in any conditions, is economical, throttle response, develops rated power and maintains speed, and does not cause problems for its owner.

Signs that adjustment is needed

Based on certain signs that appear in abnormal engine operation, we can conclude that the carburetor needs adjustment.

The list of deviations is quite wide:

The carburetor should be adjusted if there are signs that adjustment is necessary.

If one or more of these symptoms is present, you should adjust the carburetor, and then diagnose its condition and check the operation of the engine.

How to adjust engine idle speed

Work on setting up the power system is carried out after the engine has warmed up to operating temperature. All types of carburetors installed on scooters are equipped with a screw designed to regulate idle speed. Changing the position of the adjusting element allows you to ensure that the engine operates at stable speeds during idling.

Depending on the vehicle model, the adjusting elements are located in different places, so you need to carefully study the instructions and determine where the idle speed adjustment screw is located on the scooter.

Rotating the screw in a clockwise direction allows you to increase the crankshaft speed. Turning in the opposite direction, accordingly, ensures a decrease in speed. To perform adjustment operations, it is necessary to warm up the power unit of the scooter for a quarter of an hour.

Setting the engine idle

Then the screw is screwed in or unscrewed until a stable and precise speed of rotation of the vehicle engine is achieved. The adjustment is made in small increments by smooth rotation. After each manipulation, the engine should be run for several minutes to stabilize the speed.

Yamaha carburetor adjustment and analogues

Yamaha two-stroke outboard motors with a power of 9.9-30 hp. carburetor adjustment

In order to achieve a soft idle and quick response to turns of the throttle handle, it is necessary to correctly configure the carburetor and synchronize it with the ignition system. Fuel system settings include adjustments to the mixture screw, idle speed, drive lever (angular shape), throttle control system (starting system), and throttle cable.

This is interesting: Replacing rear shock absorbers for Ford Focus 2

All adjustments, regardless of the two-stroke engine model, must be performed in cases where the carburetor has been repaired or has been removed, as well as when the control cables have been disconnected from the carburetor.

Table1 Setting the mixture quality screw

Number of screw turns (from the stop with the screw fully screwed in)

Adjusting the mixture quality screw allows you to achieve the optimal fuel-air mixture ratio for efficient engine operation and easy starting.

Selecting the quality of the mixture

Use a screwdriver to adjust. Screw the screw in clockwise, being careful not to damage the threads. You need to tighten it carefully until it stops lightly. Currently, there are specifications for various motor models, in accordance with which the quality screw must be adjusted (Table 1).

Prepare the motor for tuning work: lower the sternwood into the water (either into the barrel, or, if the boat is on the water, set the motor to the running position). Start it and let it run at low speed for about 10 minutes until it warms up to operating temperature. After the engine warms up, quickly increase the gas to medium speed and see how quickly the engine responds to this action. Release the gas and repeat the operation. If the engine increases speed slowly or with a delay, then it is necessary to select the quality of the mixture with the screw.

When you turn the mixture quality screw clockwise (to the right), the mixture becomes leaner; when you turn the screw counterclockwise, the mixture becomes richer. The adjustment must be continued (repeated) if, when turning the throttle handle, or the engine’s response to an increase in gas is in doubt.

The screw turns should be small, about 1/8 of a turn, and each time it is necessary to check the engine's response to an increase in gas. On engines with two or three carburetors, all carburetors must be adjusted in accordance with the recommendations given.

The mixture quality screws on all carburetors must be in positions corresponding to the data in Table 1. Be careful when working with the engine running. Do not forget about the cooling system, since if the motor cooling is disrupted, then breakdowns or poor adjustment are possible.

Idle adjustment

Remember that only after correctly setting the quality of the mixture does it make sense to adjust the idle speed.

Install the tachometer by connecting its sensor to one of the spark plug wires (caps), following the instructions

Tachometer manufacturer. Warm up the engine for 1O min. to operating temperature. Check the position of the throttle levers and the magnetosis (ignition) mechanism. Place the throttle handle in idle mode. To correctly set the idle speed, follow the recommendations in table. 2.

How to change the quality of the fuel mixture

For all scooter engines, it is important to receive fuel with an adjusted ratio of gasoline to air. A lean mixture leads to improper operation of the engine, a drop in power and overheating of the engine, while a rich mixture leads to an increase in consumption and the formation of soot.

Adjustment operations are performed by changing the position of the quality screw and moving the throttle needle.

Turning the screw to the right causes the mixture to become richer, and unscrewing in the opposite direction causes it to become leaner. The same happens with the needle: when the needle is raised, the mixture becomes richer, and when lowered, it becomes poorer. The integrated use of both methods allows you to achieve optimal results during setup. However, not all carburetors have this feature, so, as a rule, one of two options is used.

A simple and effective way to adjust the carburetor (Views: 1)

Alexander Kr.

Can you give an example? It seems like this has never happened.

And further. A feature of adjusting the carburetor at XX (in carburetors only XX is adjusted with screws) is the dependence of the mixture composition on both the position of the quality screw and the position of the quantity screw. Therefore, the adjustment technique is not the same.

Attachments

Alexander Kr.

Thank you for enlightening me about ejection. The instructions in the attachment are as incomprehensible as most service manuals for some reason. First, the need for adjustment is assessed and the adjustment itself is made in response to a sudden release of gas. But this is true if the mixture was lean. What if you're rich? The engine will respond normally to gas. So, is everything okay? Secondly, it is not clear which way to turn and what should happen. If you don't understand how to adjust, you can wind it in the wrong place. I suggest turning it so as to create a deliberately lean mixture, so that it is clear that it is lean (the revolutions have dropped, the engine stalls). Then create a rich one, and so that the person understands that it is now rich (the revs have dropped again, now from excess fuel). Then it will be clear at what position of the screw the mixture is optimal.

Alexander Kr.

afgan-nsk

Here is a very clear description of the adjustment.

Author fanatic At Yura's request, I share my own experience in adjusting the mixture for idle speed without the use of special equipment, using the speed drop method.

Now more specific. Since the optimal ratio releases maximum energy, it means that the engine running on such a mixture will produce maximum revolutions for the current throttle position. And accordingly, deviation from the optimal settings will cause a drop in speed. Which is what we will use.

Before adjusting, you need to make sure that the engine is absolutely in good working order and that the difference in compression of the cylinders (if you have a lot of them) is small. Otherwise, with a noticeable difference in compression, the idle will be unstable and will float, which will not allow us to adjust the mixture by ear. Moreover, attempts to tune such an engine by ear usually lead to a significant enrichment of the mixture at idle, because Such an engine will only run smoothly on a very rich mixture. Well, in the case of multi-cylinder engines, you also need to synchronize the carburetors.

Stage one is a rough check. It consists of twisting the needle half a turn, and then unscrewing it one turn. This is needed to roughly assess the validity of the current setup. If, when tightening the needle, the speed dropped, and then increased when unscrewing, then the current setting is poor. If it’s the other way around, it makes you rich. If the behavior of the motor has not changed much, then most likely we are close to the optimal setting.

Setting the gasoline level and the correct position of the float in the chamber

A correctly adjusted fuel level in the float chamber does not allow the spark plugs to get wet and the engine to stall. In the chamber where the floats and jets are located, there is a valve that provides fuel supply. The correct position of the floats determines the closing or opening phase of the valve and prevents fuel overflow in the carburetor. The position of the floats is changed by slightly bending the fastening bar.

Gasoline level is monitored with the engine running using a tube made of transparent material attached to the drain point and raised up. The gasoline level should be a few millimeters below the flange mounting of the cover. If the level is insufficient, remove the cover and adjust the needle firing phase by slightly bending the metal antennae.

Setting up a boat motor carburetor

If your outboard motor experiences increased fuel consumption, unstable operation, or decreased power, then the carburetor is most likely to blame. This is a complex engine part that tends to become clogged and accumulate various types of sediment. We will not delve into the intricacies of its operation, but I think everyone knows that it is responsible for the fuel mixture that is supplied to the combustion chamber. If you suspect that the carburetor is to blame for the not-so-good behavior of your engine, do not immediately look for information on it disassembly and setup. The first step is to change the spark plug and install the original one recommended by the manufacturer. The same applies to fuels and lubricants; if possible, pour oil and gasoline as written in your instruction manual. We would like to note that after 3 months the fuel begins to lose its properties, and after half a year it is better to simply pour it out and not pour it into the engine, because it will already lose its characteristics

. The main points of adjusting the engine carburetor.

If none of this helps, then you can try adjusting the idle speed using the two adjusting bolts. One of them is responsible for the quality of the mixture, the other for the quantity. Warm up the engine for 10 minutes, then use the quantity screw to set the idle speed a little higher than stable. Then, using the mixture quality screw, we set the highest speeds, and at the end, again, using the quantity screw, we set the idle speed to slightly higher and stable speeds. This sequence must be completed several times until we obtain a stable minimum idle speed. And attention! At the very end, the increased speed must be removed with a quality screw, and not a quantity screw, as we did before.

If after these carburetor adjustments the engine stalls in gear or when closing the hood, then try increasing the speed with the speed screw. We also recommend checking the springs of these screws. If they are weak, then all your settings will very soon be lost due to vibration. Simply remove the screws, stretch the spring a little, and screw the screws into place. The richness of the mixture can be checked by sharply releasing the gas while driving; the engine should not stall.

Go ahead. If the engine has symptoms such as:

- the engine stalls when revving up

- hard to start when warm

- unstable idle speed

- increased fuel consumption

The reason should be sought in the float chamber, or rather, this indicates an increased level of fuel in it.

If your acceleration dynamics have noticeably decreased and you also have problems idling, then you may have a low fuel level in the float chamber.

By changing the angle of the float tongue, you can adjust the fuel level in the chamber. As the fuel level increases, the tongue pushes the shut-off valve and it, in turn, shuts off the fuel supply. The tongue is built into the float body and it (the tongue) is most often made of soft metal, and just by changing the angle of the tongue a little, you can force the valve to shut off the fuel supply earlier or later. But don’t rush to immediately bend it by 45%; you need to change the angle just a little. A flathead screwdriver works well for this. After changes, check the operation of the motor. We cannot give any more specific recommendations, because... All models are different in this regard. You can look in the manual of your engine and see the factory carburetor settings and compare them with the current ones and try to adjust them if there are discrepancies.

Medium and high speed tuning

Using the quality adjustment screw, the fuel proportions at idle speed are ensured. For medium and high rotation speeds, the engine operating mode is adjusted using a different method. After turning the gas handle, the fuel nozzle starts working, supplying gasoline to the diffuser. An incorrectly selected jet cross-section causes a deviation in the fuel composition, and the engine may stall when gaining power.

To ensure uninterrupted operation of the motor at a higher frequency, it is necessary to perform a number of operations:

The correct operation of the engine is indicated by its quick response when turning the throttle.

Murzilka5d › Blog › Adjusting the quality of the mixture in the carburetor of HDX T 2.6 CBMS engines and similar

Hi all. I got the instructions here... Maybe it will be useful to someone.

For clarity, I am attaching a picture of the carburetor structure, which I took from the spare parts catalog for the PARSUN T2C T2.6CBMS engine. So, you need to regulate the quality of the mixture in these engines by rearranging the lock on the throttle needle, raising (making the mixture richer) or lowering (leaning the mixture) the needle: 1) Remove the throttle cable with the throttle needle from the carburetor (the carburetor itself does not need to be removed). To do this, unscrew the nut (pos. 5) and remove the cable assembly with the needle (pos. 9), lock (pos. 8), C-shaped washer (pos. 7), spring (pos. 6) and plastic cylinder ( pos. 10). 2) Remove the needle from the cable. To do this, press the spring (pos. 6) and remove the gas cable from the cylinder (pos. 10). Here you need to be careful and not lose the C-shaped washer (pos. 7)! It is located inside the cylinder above the needle lock and is pressed by a spring (item 6), which must be released. This washer is needed to ensure that the needle with the lock does not fall inside the spring (since the needle lock has a small diameter, smaller than the diameter of the spring). 3) We look at what position the lock is in (position on the needle (item 9). The needle has 4 marks/divisions. If you need to make the mixture leaner, then move the lock to a higher division, thereby lowering the needle. Accordingly, if you need to make the mixture richer , then we move the needle lock to a lower division, thereby raising the needle. 4) Reassemble everything in the reverse order. When we insert everything back into the carburetor, you need to make sure that the plastic cylinder (pos. 10) is oriented with its bevel towards the XX adjusting screw (pos. 11). Nothing complicated, just disassemble/assemble once and everything becomes clear. A few words about how this unit works, for a general understanding of the operating principle. When we add gas on the tiller, the cable tightens, lifting the throttle needle (pos. 9) assembled with the cylinder (pos. 10). At the same time, by rising, the needle frees the cross-section of the fuel channel (item 24), increasing the flow of gasoline from the float chamber, and the plastic cylinder, rising, frees the air channel, increasing the flow of air (the cylinder is, in fact, a throttle valve). By returning the gas handle to its original position, the needle lowers back into the fuel channel (pos. 24), reducing the flow of gasoline from the float chamber, and the cylinder lowers into the air channel, blocking its cross-section and reducing the flow of air. At the same time, the fuel and air channels are not completely blocked for the engine to operate at idle speed. This is ensured by the adjusting screw xx (pos. 11), which affects the bevel of the cylinder (pos. 10). By tightening the screw (clockwise), we raise the cylinder assembly with the needle, the gasoline and air channels open slightly - the speed xx increases. By unscrewing the screw (counterclockwise), the cylinder assembly with the needle is lowered, blocking the gasoline and air channels - the speed xx decreases. As for adjusting the quality of the mixture. By moving the needle lock to another division, we only change the position of the needle relative to the cylinder. At the same time, in the same position of the cylinder, the amount of incoming air does not change, and the amount of gasoline enters is either more (if the needle is raised) or less (if the needle is lowered).

So, you need to regulate the quality of the mixture in these engines by rearranging the lock on the throttle needle, raising (making the mixture richer) or lowering (leaning the mixture) the needle: 1) Remove the throttle cable with the throttle needle from the carburetor (the carburetor itself does not need to be removed). To do this, unscrew the nut (pos. 5) and remove the cable assembly with the needle (pos. 9), lock (pos. 8), C-shaped washer (pos. 7), spring (pos. 6) and plastic cylinder ( pos. 10). 2) Remove the needle from the cable. To do this, press the spring (pos. 6) and remove the gas cable from the cylinder (pos. 10). Here you need to be careful and not lose the C-shaped washer (pos. 7)! It is located inside the cylinder above the needle lock and is pressed by a spring (item 6), which must be released. This washer is needed to ensure that the needle with the lock does not fall inside the spring (since the needle lock has a small diameter, smaller than the diameter of the spring). 3) We look at what position the lock is in (position on the needle (item 9). The needle has 4 marks/divisions. If you need to make the mixture leaner, then move the lock to a higher division, thereby lowering the needle. Accordingly, if you need to make the mixture richer , then we move the needle lock to a lower division, thereby raising the needle. 4) Reassemble everything in the reverse order. When we insert everything back into the carburetor, you need to make sure that the plastic cylinder (pos. 10) is oriented with its bevel towards the XX adjusting screw (pos. 11). Nothing complicated, just disassemble/assemble once and everything becomes clear. A few words about how this unit works, for a general understanding of the operating principle. When we add gas on the tiller, the cable tightens, lifting the throttle needle (pos. 9) assembled with the cylinder (pos. 10). At the same time, by rising, the needle frees the cross-section of the fuel channel (item 24), increasing the flow of gasoline from the float chamber, and the plastic cylinder, rising, frees the air channel, increasing the flow of air (the cylinder is, in fact, a throttle valve). By returning the gas handle to its original position, the needle lowers back into the fuel channel (pos. 24), reducing the flow of gasoline from the float chamber, and the cylinder lowers into the air channel, blocking its cross-section and reducing the flow of air. At the same time, the fuel and air channels are not completely blocked for the engine to operate at idle speed. This is ensured by the adjusting screw xx (pos. 11), which affects the bevel of the cylinder (pos. 10). By tightening the screw (clockwise), we raise the cylinder assembly with the needle, the gasoline and air channels open slightly - the speed xx increases. By unscrewing the screw (counterclockwise), the cylinder assembly with the needle is lowered, blocking the gasoline and air channels - the speed xx decreases. As for adjusting the quality of the mixture. By moving the needle lock to another division, we only change the position of the needle relative to the cylinder. At the same time, in the same position of the cylinder, the amount of incoming air does not change, and the amount of gasoline enters is either more (if the needle is raised) or less (if the needle is lowered).

How to set up a carburetor on a scooter - features for the 2t model

Adjusting the carburetor of a two-stroke scooter differs from adjusting the power system of four-stroke engines. Most two-stroke engines are equipped with a simple carburetor with a mechanical enricher, the trigger of which is pulled before starting the device. Scooter owners call the starting enrichment a choke; it is closed after the engine warms up. To adjust, the power system is disassembled, the needle is pulled out and mechanical intervention is carried out in the fuel chamber. Further adjustment is carried out in the same way as for four-stroke engines.

Setting up the carburetor on a 4t scooter - important points

Setting up the carburetor on a four-stroke scooter is easy to do on your own and is not difficult for motorcyclists. Setting up the carburetor of a 4t 50cc scooter (China) requires certain skills and patience and is performed according to the above algorithm. It is possible that the manipulations will have to be repeated many times until the desired result is achieved. If the carburetor setting on a 4t 139 qmb scooter or a similar model with a different engine is done correctly, the engine will operate stably.

It will be able to start regardless of the ambient temperature and the piston group in the engine will wear out less.

Tips and tricks

Setting up the carburetor on a 4t 50cc scooter is an important and responsible procedure for servicing motorcycle equipment.

When performing adjustment operations, it is important to follow a number of rules:

Before starting work on setting up the carburetor, you must study the operating instructions and clearly determine the location of the quality and idle screws. If you have a 150cc scooter, the carburetor adjustment is done in a similar way. After all, the process of regulating the fuel system is the same for engines of different powers.

Source