What is a motorized dog

Before you figure out how to make a motorized dog with your own hands, you need to take a closer look at this type of device. They are compact snowmobiles or swamp vehicles equipped with an engine. The main elements of a motorized dog are a caterpillar-type towing vehicle, as well as a sled attached to it.

Depending on the specific modification, this type of mechanism may have other components, for example, a loading platform located on the tractor. The power units used in the design of this vehicle are equipped with low-power motors - from 6 to 13 hp, which allows you to move over rough terrain at low speeds, about 30-40 km/h.

The motorized dog has small dimensions

It should be noted that a motorized dog made from a cultivator does not require a braking system; this makes driving at high speed unsafe. The device is in high demand among lovers of fishing, hunting, and outdoor recreation. It is used to perform various household tasks and transport small loads.

It is advisable to include the following features among the characteristic advantages of motorized towing vehicles:

- simplicity of design, allowing you to assemble such a device yourself;

- the highest cross-country ability, due to which it is possible to move even in difficult terrain;

- low cost of operation, maintenance and repair.

In their design, such devices resemble classic snowmobiles, but the driver’s position is located outside the towing vehicle, which can significantly reduce its weight, increasing cross-country ability.

The products are excellent for lovers of winter fishing, since, thanks to their low weight, they can easily move across the surface of frozen lakes without creating the threat of breaking the ice.

Motorized towing vehicle for difficult terrain

When planning to make homemade motorized towing vehicles, you must take into account that their cost will be similar to the most budget models on sale. However, they are mostly made in China, have poor build quality and often break, unlike a homemade unit with increased reliability.

Be sure to read: Classification of plows for plowing

A self-made motorized towing vehicle is perfect for moving and transporting goods in the following conditions:

- marshy areas;

- snow;

- dirt roads;

- uneven terrain, replete with descents and ascents.

The device is small in size and light in weight, which allows it to be transported to the place of operation using standard vehicles without unnecessary inconvenience.

Making an all-terrain vehicle

Other types of machines

You can also assemble an ATV from a walk-behind tractor, although this unit does not develop ultra-high speed, but in terms of maneuverability and cross-country ability it is not inferior to its own. The landing position in a homemade ATV remains traditional, not a motorcycle one. Wheels can be used from any passenger car.

It is worth mentioning an interesting homemade product called karakat. The power of the car lies in its large wheels, which are ordinary inner tubes, tightened with strong belts.

They put homemade wheels on carakat, modifying standard car ones. A very original disk is also installed on a lightweight walk-behind tractor. To do this, two aluminum basins are connected along the contour, having previously cut the bottom to fit the size of the hub, stiffeners and side stops are installed to fix the camera.

Despite its external clumsiness, the caracat has high cross-country ability and stability. Not only can it easily overcome swampy lowlands, but it is capable of transporting significant cargo (up to 100 kg).

Homemade motorized dog

A homemade motorized towing vehicle, made from scrap materials, has a reduced operating cost and more powerful technical characteristics compared to similar purchased models.

Successfully making a motorized dog with your own hands involves several stages at once. Among them:

- Selection of basic structural elements with the necessary parameters.

- Studying drawings, diagrams and video instructions, which allows you to avoid errors during assembly.

- Direct manufacturing followed by testing.

This allows you to make the necessary changes to the design and achieve the desired operating parameters, for example, lower fuel consumption or increased speed. If desired, you can implement additional compartments for various useful tools, gear and other types of equipment.

Manufacturing of basic structural elements

There are several elements that need to be prepared in advance for successful self-assembly of such a mechanism. This is a power unit that has enough power to perform this kind of task. For this purpose, gasoline-type engines equipped with 1 cylinder are used.

Other elements worthy of mention are:

- caterpillar mechanism;

- suspension;

- motorized towing vehicle frame;

- transmission.

Each of these nodes requires careful attention, and therefore it is advisable to study them in more detail. Models from Japanese manufacturers, for example, Yamaha or Honda, as well as budget Chinese analogues, are widely used as engines. In this case, the use of motors from walk-behind tractors, chainsaws and other improvised devices is allowed.

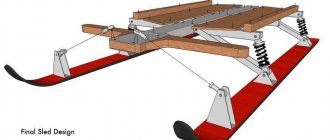

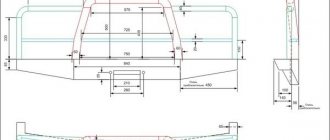

Motorcycle dog frame drawing

The selection of suitable tracks should also be given due attention, since they are not only specialized, but also universal, designed for snowmobiles and other equipment. It is believed that the best option would be tracks at least 50 cm wide, since they will make the device stable and maneuverable.

Be sure to read: DIY blueberry harvester

When planning to implement a transmission, it is necessary to note the possibility of choosing between mechanical, automatic gearbox and variable. Despite the accelerated wear of parts, automatic transmission is considered preferable because it can significantly increase traction force. As a budget option, it is possible to use a gearbox, for example, from a VAZ.

Its reliability directly depends on the strength of the unit’s frame, and therefore it is advisable to make it yourself, using a welding machine. For this purpose, pipes of at least 3 mm thickness are suitable, which avoids deformation under heavy loads.

If you want to make a motorized dog from Buran or other mechanisms, you will need:

- Install the engine onto the frame.

- Install the chassis, making the front and rear axles.

- Connect it to the gearbox.

- Install tracks and controls.

The suspension of the device can be roller or slip, depending on the season of intended use. The first option is suitable for use in summer, autumn or spring, and the second - exclusively for the winter period.

Winter motorized towing vehicle

Guided by diagrams, drawings and video instructions, it is enough to assemble a structure from pre-selected elements, which will allow you to quickly produce a motorized dog. For a winter motorized towing vehicle, it is advisable to use a ski module for the driver’s platform, as well as a roller type of suspension. Otherwise the design is completely identical to the standard one.

How to make a snowmobile from a cultivator with your own hands?

Homemade equipment will consist of two main parts: slave and master. The first part includes the steering column, skids, and shock absorbers.

The snowmobile is assembled in the following order:

- First you need to make a strong supporting structure. Medium-thick water pipes and corners that need to be fastened together by welding are suitable for this. First, the frame parts must be fixed using spot welding. If the structure is created correctly, then its elements must be completely welded to each other. When connecting them, you need to calculate the locations for mounting the engine, as well as other equipment components. The welds will need to be cleaned. The frame parts must be primed. After it dries, all metal elements of the frame must be painted to protect them from rust;

- Then you need to weld the brackets to the painted frame. They are necessary for fixing the engine, seat, runners, steering column, and other parts. The stability of parts in the overall design of the equipment depends on the quality of fastening of the brackets;

- The next step is to make the runners. To do this, take 2 pieces of thick plywood and cut two identical skis from them. They will be installed at the front of the structure and must be connected to the steering via a hinge joint;

- You will need to install 2 track mechanisms at the rear of the snowmobile. You can take them ready-made, or make the elements yourself from a conveyor belt;

- Next you will need to install shock absorbers. Parts from an old motorcycle are suitable for this;

- Then the engine, gearbox and brake system must be installed into the finished structure. You will need to lay a rubber mat between the engine and the frame, which will dampen the vibrations of the internal combustion engine. The engine and transmission should be pre-positioned so that the driver has direct access to the drain and fill holes. The motor and gearbox must be secured to the front of the vehicle. The pipe from the exhaust system will need to be routed away from the driver and passenger;

- Next you need to install the seat. For convenience when using a snowmobile from a cultivator, it is better to take an old sprung seat from an old mini tractor;

- You will need to install gas, brake and clutch pedals under the steering wheel. The video will show the results of assembling the snowmobile.

The finished snowmobile from the cultivator should be tested. To do this, it is necessary to fill the appropriate tanks with fuel and lubricants. Next, you need to start the engine and let it idle for a few minutes. After this, you can start driving the snowmobile. It is important not to start too quickly so as not to burn the engine. It is best to start slowly and gradually pick up speed.

Selection and production of basic elements

The main components, basic components and controls of a motorized towing vehicle should be discussed in more detail.

Engine

The most important component of the equipment is the motor (power unit). As a rule, a single-cylinder carburetor engine is used to manufacture motorized towing vehicles. An equally important element is the caterpillar - suspension and propulsion. With the help of the caterpillar you can move on ice, snow cover, and soft ground in warm weather.

In most cases, motorized towing vehicles use motors from Honda, Yamaha (expensive) or Chinese brands (MTR, Lifan and others, affordable).

These motors vary significantly in cost, although their power is usually equivalent. Lifan engines equipped with a centrifugal clutch performed well.

Some craftsmen use engines from a walk-behind tractor (cultivator) and engines from chainsaws (motor saws) “Ural” and “Druzhba” to make motorized towing vehicles.

The Sh-58 motor from a moped, designed for manual gearbox shifting, is in demand. Scooter motors can be used equally. The main condition is that the units have good traction properties, a power of at least 6 horsepower. This is quite enough to transport one person and 30-50 kilograms of cargo on a motorized towing vehicle. To move 2 people and 150-200 kilograms of cargo, it is advisable to choose a motor with a power of more than 9 horsepower.

Support frame

The quality level of the frame must be high, since during movement it is subject to heavy loads, especially when moving off-road. This structure is constructed entirely on its own, welded from profile pipes with a rectangular cross-section. Basically, a pipe with a wall thickness of 3 mm is sufficient - thinner metal is not suitable, it can quickly deform.

The assembly of the homemade product is carried out according to the previously selected drawing (about the same as ours).

To make the frame, take 2 pipes measuring 20x20 millimeters, add two more with a section of 20x40 millimeters, and form the frame.

2 corners of 40 millimeters each are welded into it, and a safety structure for the engine is welded on top, which will prevent it from being damaged when the equipment turns over. It also doesn’t hurt to “sew” a galvanized sheet to the frame using rivets to cover the track.

Suspension

Suspension (suspension system) is an important factor in the functioning of the chassis. The size and speed of movement will depend on the type of system chosen.

The structure of the suspension system comes in several varieties:

The fastest is a slip suspension, since the gap during movement is clogged with a minimum amount of debris, snow and other foreign objects. As a result, the engine will function with minimal disruptions, without overloads and excessive heating, however, slides are used exclusively in winter: they require snow, which serves as cooling for the ski module.

For traveling at any time of the year, you should choose a modern roller-type suspension system, but not with rigid ones, but with spring roller supports.

Such a motorized towing vehicle will move more smoothly on frozen roads. The roller behaves worse on snow cover (when moving, it is advisable to avoid too loose, deep snow), but is ideal for moving in the summer months.

Combined types of suspension combine both the advantages and disadvantages of slides and rollers.

Transmission

The transmission (power train) is responsible for transmitting the rotation of the shaft to the drive sprocket (profiled wheel) of the track. The power transmission can be automatic gearbox, mechanical, CVT; some varieties, for example, are equipped with a reverse gearbox from “Ant” (for reverse gear). The advantage of an automatic power transmission is the large horizontal traction force, the disadvantage is the rapid operation of some elements and the need for regular maintenance.

As a mechanical one, you can use a box from a VAZ or another old car. Its advantages are ease of maintenance and no need for frequent adjustments, but the operation of such a power transmission is less comfortable.

The CVT provides a smooth transmission of force from the engine to the track, which makes it possible to reduce the wear rate of elements and save on fuel. The disadvantage is the weak belt of the units, which needs to be changed regularly.

Caterpillar

Such devices are available for snowmobiles and special ones, designed specifically for motorized towing vehicles. They differ in width, height, length.

There are replacement snowmobile tracks on the market that can be practiced when creating motorized dogs.

Caterpillar tracks from “Buran” are in demand, but they are not characterized by increased cross-country ability ; it will be possible to use a motorized towing vehicle on a Buranovskaya caterpillar exclusively on an ice-bound body of water, a well-rolled track.

You need to buy tracks that are not very narrow. A 50-centimeter product is suitable, as it makes the motorized towing vehicle stable, passable, and agile.

There are also “aggressive” caterpillar tracks on the market that provide increased cross-country ability , with a width of 550 millimeters and with a non-standard tread pattern. They have an increased lug height - it is 32 millimeters (the normal height is 21 millimeters).

Tracks for a motorized towing vehicle can also be made on your own. You can practice using a variety of materials: conveyor belts, motorcycle chains, water pipes, etc. The main thing is to make them of high quality, lightweight and reliable, so that there is a balanced grip of the tracks with the road surface.

Electrical equipment and control systems

To control a motorized dog, they use a steering wheel connected to the gearbox, gas, and clutch handle, which must be borrowed from any suitable old motor vehicle. As a rule, the basic configurations of motorized towing vehicles are equipped with a manual start, but at the client’s request it can be replaced with an electric starter or supplemented with a lighting coil.

All this can be built without much effort on your own, but the cost of manufacturing a motorized towing vehicle will increase.

You can easily do without an electric starter; in addition, manual starting is the most trouble-free in terms of failure. Nevertheless, it will definitely be difficult to drive a motorized towing vehicle without light at night; this system must be taken into account without fail. The vehicle should be equipped with a 7 A coil so that there are no difficulties with powering the headlights.

Pros and cons of a homemade snowmobile

You can buy snowmobile equipment in a store, but many continue to create such machines with their own hands. This is due to the fact that homemade vehicles have some advantages over finished products.

Main advantages:

- Low cost. It is precisely because of the price that many do not buy ready-made models, but create snowmobiles themselves from a motor unit. If we compare the cost of ready-made devices, their price can be 10 times more expensive than a home-made design.

- Ability to select parameters. Some homemade designs are more powerful than popular branded snowmobiles.

- Reliability. Snowmobiles, even from branded manufacturers, often break down during use. For their own all-terrain vehicle, people choose only high-quality materials.

Features of converting a cultivator into a snowmobile

Almost every farmer has a cultivator at his disposal.

In winter, it essentially sits idle, so for the winter you can equip it with a motor for a homemade snowmobile. To manufacture the vehicle, as a rule, engines from middle-class cultivators are used. The motor must be equipped with a towing device and manual control. For example, the Neva cultivator is equipped with such elements. It is made from high-quality Japanese parts, and costs relatively little money. The engines of these cultivators are equipped with a forced air cooling system, which is sure to come in handy during regular use of the snowmobile. As a result of the work done, you will receive a passable snowmobile or snowplow with a capacity of approximately 7 hp. With. It can support no more than two people, or one driver and a small load.

To make a snowmobile you will need the following elements:

- Motor;

- Welding machine;

- Pipe bender;

- Some purchased items.

Below we will look at step-by-step instructions for making a snowmobile from a motor cultivator.