Prerequisites for the creation of K-62

In the USSR, when producing any equipment, unification of components and parts was widely used. Carburetors were no exception. The K-62 carburetor began to be produced in the mid-1970s (Leningrad Carburetor and Valve Plant) named after V.V. Kuibyshev and replaced the K-36 series.

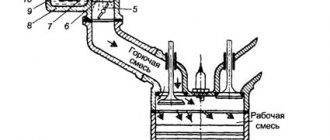

One of the main reasons for the creation of the new model was the increase in engine power. Such engines required enlarged air channels to prepare a larger volume of working mixture. The existing carburetor models did not allow for larger channels, and they also lacked many advanced solutions. The new K-62 carburetor was equipped with a centrally located float chamber, a flat throttle valve, and the float design was changed.

Thanks to such innovations, it was possible to reduce the dimensions of the carburetor and ensure stable engine operation during sudden changes in motorcycle driving conditions.

Adjusting the K62 carburetor:

Hello! Please tell me, I have a Minsk 125, it’s a Pakko (original, new), it’s not in use, it works fine, that is, the idle is normal, it picks up speed briskly, but as soon as you start to move out of place, it doesn’t pull well, or it may even stall, you just need gas open more than halfway. The quality screw is screwed in completely, but if you unscrew it by 1-1.5 rpm, you won’t be able to move it at all - the engine will stall. The spark is normal, the ignition is set correctly, the needle is in the middle position. Please tell me what’s wrong, this is the first time I’ve encountered such a problem?

Did you use the carburetor before or did you just install a new one?

I have an Izh P3 Minsk ignition that runs on a choke and doesn’t hold idle, and when you move from place to place, it’s like a splash, you add half the gas, then it goes, what’s wrong?

started a long time ago? CARBURETOR K 62? HOW DID YOU WORK BEFORE?

Modifications

Various versions of the K-62 carburetor were used on two-stroke motorcycle engines of the Minsk and Izhevsk motorcycle plants, on boat engines of the Neptune series, and on Tulitsa scooters. Since the operating conditions and engine sizes of these machines are different, each carburetor had different diameters of the diffuser and fuel supply nozzles, which was reflected in the model index:

- K-62 with a 30 mm diffuser was used on the Jupiter 4 IZH.

- K-62B with a 32 mm diffuser was used on the Planet 4 IZH.

- K-62V with a 26 mm diffuser was used on Voskhod 3.

- K-62G with a 26 mm diffuser was used on Tulitsa scooters.

- K-62D with a 28 mm diffuser was used on the Jupiter 3 IZH.

- K-62E with a 30 mm diffuser was used on Serpukhov motorized strollers.

- K-62P with a 32 mm diffuser was used on the Planet 3 IZH.

- K-62L with a 26 mm diffuser was used on the Neptune 23 outboard motor.

- K-62M with a 32 mm diffuser was used on IZh PS.

- K-62S with a 26 mm diffuser was used on the Minsk 3.115 motorcycle.

Five random articles about motorcycles:

Java is 60 years old!

Java is sixty!

Is this a lot or a little for a motorcycle brand? If compared with the first Czech motorcycle “Laurin and Klement”, which appeared thirty years earlier, JAVA is not so old. But in this case, it is not the date of birth that should be taken into account. Of the more than 2,500 different brands of motorcycles that have ever been produced in the world and included in the “Illustrated Encyclopedia of Motorcycles” (there is one in the West), there are barely a dozen like YAVA, with such a rich history. It began in 1929, when the owner of the arms factory, Frantisek Janeček, presented at the Prague Motor Show his first motorcycle, built under a German license (from the initial syllables of these surnames, as is known, the name JAVA was born). It was a rather expensive and heavy machine weighing 175 kg, equipped with a single-cylinder four-stroke engine with a displacement of 498.7 cm3 and a power of 18 hp. s./13 kW, which did not have commercial success. Eh... Read more >>

Causes of transmission malfunctions IZh Planet and Jupiter

All Izhevsk motorcycles - single-cylinder "planets" and two-cylinder "Jupiters" - have gearboxes of the same design, but differ in the switching mechanism and gear ratios. The currently produced models IZH-P3, IZH-PS, IZH-Yu4 use standardized gears (see table ), which can also be installed on previous models - IZH-49.

IZH-56, IZH-P, IZH-P2, but only together with the input shaft, clutch drums and shift forks from IZH-P3. During operation, faults in the gearbox most often arise from overloads, rough, forceful gear shifting, untimely oil changes . There are often cases of damage to parts after home repairs of the box, when mistakes are made during its assembly and adjustment. Let's look at the most common malfunctions. Second and third gears do not engage (first and fourth gears do). On “planets” this defect appears due to the loosening of the screws securing the stop mechanism of the re... Read more >>

IZhi for a multi-day race. IZH M12, IZH 64M

Izhevsk Machine-Building Plant is a pioneer of the domestic motorcycle industry.

He was one of the first in our country to start making sports motorcycles. For all-around competitions, the plant currently produces two main models of special machines. One of them, IZH-64M, is intended mainly for a wide range of athletes. It has the same engine as the popular motorcycle IZH Planet 2, only boosted. This simplifies operation and the supply of spare parts. Rice. IZH M12 Another model, IZH-M12, has higher performance, designed for important competitions such as national championships. The new machine developed the solutions inherent in the design of the IZH-M10, which brought the plant a large FIM gold medal at the international six-day competition in 1967. The IZH-M12 engine (single-cylinder with two-channel purging) is manufactured in three modifications - classes 250, 350 and 500 cm3. They differ in cylinder diameter (corresponding... Read more >>

Electrical circuit diagram of the IZH Planet Sport motorcycle

“Planet-Sport” is the first Izhevsk motorcycle with 12-volt electrical equipment, which meets all modern (as of 1982) requirements for this system.

(click on the picture to enlarge) I— parking light lamp; 2 — main light lamp; 3 — neutral control lamp; 4 - resistor; 5 — oil pressure control lamp; 6 — direction indicator relay; 7 — diode block (isolation); 8 — lamp for illuminating the speedometer scale; 9 — ignition switch; 10 — front direction indicator lights; II— headlight switch and emergency ignition switch; 12 — handbrake brake light switch; 13 — relay-regulator; 14 — neutral lamp switch; 15 — high beam control lamp; 16 — turn signal control lamp; 17 — lamp for monitoring generator operation; 18 — sound signal; 19 - light switch and direction indicators, in... Read more >>

Ural M-67. Electrical diagram

Rice.

Electrical circuit diagram of the Ural M-671 motorcycle - left turn signal lamp 2 - lamp A12-21; 3 - headlight; - 4 - lamp A12-4 side and parking light; 5 — lamp A12-45-40 high and low beam; 6 — right turn signal lamp (not connected on a motorcycle with a sidecar): 7 — speedometer; 8 — lamp A12-1 speedometer lighting; 9 — indicator lamp for direction indicators; 10 — warning lamp for emergency oil pressure; 11 — high beam warning lamp; 12 — generator warning lamp; 13 — neutral sensor warning lamp; 14 — instrument panel; 15 - central switch; 16 — direction indicator switch; 17 — turn signal switch; 18 — contact plug; 19 — emergency oil pressure sensor; 20 - light switch; 21 — front light of the stroller 22 — lamp A12-21 marker... Read more >>

login registration forgot your password?

| Carburetor model | Diffuser diameter, mm | What car is it for? |

| K62 | 30 | Jupiter-4 |

| K62B | 32 | Planet 4 |

| K62V | 26 | Voskhod-3 |

| K62G | 26 | Tulitsa |

| K62D | 28 | Jupiter-3 |

| K62E | 30 | SZD (motorized stroller) |

| K62P | 32 | Planet-3 |

| K62L | 26 | Neptune-23 (boat motor) |

| K62M | 32 | Planet Sports |

| K62S | 26 | MMVZ-3.115 Minsk |

Float chamber

The float chamber is attached from below to the body using screws. The joint of the parts is sealed with a gasket made of special cardboard. The float consists of two elements mounted on a common axis. The fuel supply to the chamber is controlled by a needle. The lower part of the needle is connected to the plate on the float mechanism, and the upper part is connected to the fuel supply channel. The movement of the float is transmitted to the needle, which opens and closes the fuel supply to the float chamber. By changing the degree of bending of the plate, you can change the fuel level in the float chamber.

Additionally, the needle has three fixed positions for different operating conditions. At high ambient temperatures (plus 35 degrees and above) and at altitudes of 2000 meters above sea level, the needle is placed in the lower position. At low temperatures - to the upper.

Carburetor assembly

Set the lock on top of the needle to the middle position; if economical work is required, set it to the lower position. The engine will start poorly, but will become more economical. We insert the throttle valve with the cutout to the air filter. It should move easily and freely along the guide flap.

After preliminary adjustment of the position of all elements, selection of the nozzle, cleaning of all channels, you should screw the carburetor to the engine with a 14 key, attach the hose, cable (from the throttle grip) to the throttle, tighten the mixture quality screw, which is near the gas hose, until it stops, and unscrew it by 2 -3 turns.

Tighten the mixture quantity screw to the maximum; the damper rests on it when raised; it must be inserted into the groove next to the throttle cable. There is also an adjustment with the enricher; it can either be attached to the carburetor, or a cable from it can go to the steering wheel. The enricher is a needle that opens an additional channel with fuel.

Throttle valve

The throttle valve is stamped from brass, installed in the carburetor body and has a U-shaped cross-section. On the air intake side, the damper has a cutout designed to direct the air flow into the engine cylinder. The upper part of the damper is equipped with a rod with a limiter, with the help of which the degree of overlap of the diffuser is limited (to adjust the idle speed). A cable is connected to the damper and goes to the gas handle on the handlebars of the motorcycle. When the gas is released, the damper is returned by a spring.

Starting device

Almost all versions of the K-62 carburetor were equipped with a starting device. It was cable driven from a rotary lever on the motorcycle handlebar. Additionally, for starting at temperatures below minus 15 degrees, there is a push-button float suppressor. With its help, additional enrichment of the mixture is achieved, which is very important when starting cold two-stroke engines. Such a device was not installed on outboard motor carburetors.

To prevent the engine crankcase from being filled with fuel and getting it in liquid form into the cylinders, there is a drainage channel in the float chamber.

To limit the speed during the break-in period of the motorcycle, a throttle limiter is used in the carburetor. After running in it is removed. The landing flange of the K-62 carburetor is identical to previous models, which allows it to be installed instead of older models without modifications.

Trigger

Almost all models were equipped with a starting device, which was driven by a lever on the steering wheel. To start it when the temperature drops from -15 C, a float sink is designed. It serves to enhance the enrichment of the mixture when starting cold two-stroke engines.

When setting up the trigger mechanism, to check the correct alignment of the needle, it is first placed on the lower border. Then you need to check how easily the lever rotates and the degree of elasticity of the cable. These parts must be free of corrosion and lubricated.

General recommendations for adjustment

Correct operation of the device is one of the conditions for engine performance. Before adjusting the carburetor, it is necessary to check the correct operation of the ignition system and assess the degree of wear of the cylinder and piston group. Before setting up the K-62 carburetor (like any other), it is advisable to wash the spark plugs or install new ones.

When performing work, cleaning the jets with wire or other metal objects is prohibited. It is not recommended to use solvents or acetone for cleaning. Carburetors are cleaned with clean gasoline and blown with compressed air.

It is necessary to check for gaps and damaged gaskets between the parts of the carburetor, since air may leak through them. The carburetor flange must fit snugly against the engine cylinder. The gasket and flange must not be damaged. It is advisable to check all mating planes of the carburetor against a surface plate and grind them in.

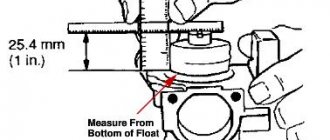

Before making adjustments, it is advisable to check the fuel level in the float chamber and the tightness of the floats themselves. It is important to check the installation of both floats in the same plane; a misalignment of no more than 0.5 mm is acceptable. The distance from the float to the junction of the chamber and the body should not exceed 26.5 mm - this distance ensures a normal fuel level in the chamber at standard atmospheric pressure. When riding a motorcycle at altitudes above 2000 meters above sea level, this distance must be increased to 28 mm.

It must be remembered that if the non-removable idle jet is clogged, the working mixture will become depleted in all operating modes (due to the design features of K-62 carburetors).

Carburetor Inspection

Before removing a mechanism such as the K-62 carburetor from the engine, you should press the float release button and make sure that fuel enters the carburetor (gasoline should exit through the hole under the button), and the cause of poor performance is precisely in the carburetor.

If gasoline flows slowly into the float chamber, then the cause of poor carburetor performance may be a clogged filter in the gas tap. It is enough to unscrew the sump cup (a cylindrical container with a screw at the bottom), it is clearly visible on all gas taps on motorcycles, and clean the filter.

The K-62 carburetor may not work well due to untimely addition of fluid to the oil air filter or its clogging. You should try to start the engine without a filter; if the performance improves, then it should be cleaned and rinsed in kerosene.

Carburetors of motorcycles "Minsk" and IZH

Various models of carburetors were installed on the Minsk motorcycle. Until 1978, K-Z6M and K-Z6S carburetors were used. Since 1978, motorcycles began to be equipped with a K-62S carburetor with a diffuser diameter reduced to 26 mm. The main fuel jet has a capacity of 165 ml of fuel per minute.

The IZH carburetor has a jet with increased capacity to 260-270 ml. This is due to the large engine displacement. The first releases of IZh PS had a Japanese Mikuni carburetor, which was replaced in 1983 by the domestic K62M.

Adjusting the fuel level

Adjusting the K 65 carburetor begins with setting the fuel level. To do this, turn the device over and remove the bottom of the float chamber. Next, replace the distance from the connector to the line that divides the float into two parts.

This distance is usually 13 mm with a possible deviation of 1.5 mm in both directions.

If the size on the carburetor does not fit into these frames, you should bend the float tongue in the desired direction.

It happens that the K 65 carburetor is configured correctly, but it begins to “overflow.” This means that the float has leaked.

Testing this theory is easy. You need to fill the bath with warm water and immerse the float in it for a minute or longer. If bubbles appear, the float is faulty.

How to adjust the K-62 carburetor on Minsk and IZh motorcycles?

What do you need to know? Carburetor adjustment is carried out with the engine warmed up to operating temperature. The K-62S carburetor has two screws (one screw closes the channel - the quality screw, the second screw regulates the position of the damper - the damper screw) with the help of which the idle speed and the needle, which is responsible for the quality of the mixture, are regulated. When the needle is raised, the mixture becomes richer; when lowered, it becomes leaner. The quality of the mixture can be easily determined by the carbon deposits on the spark plug.

Before warming up the engine, use the damper screw to set the gap between the lowered damper and the nozzle within 2-2.5 mm. The damper itself should move easily along the guides - without jamming and without play. There is a second adjustment screw on the top of the housing - the quality screw. This screw closes the channel, which provides additional air supply in all operating modes, including when the throttle is closed. When the screw is lowered, the channel closes and the mixture becomes richer. The cross-section of this channel has a major influence on engine idle speed. In other operating modes, the channel cross-section affects engine operation, but only slightly.

Before you start adjusting the K-62 carburetor on the Minsk, you need to tighten the quality screw all the way, and then release it one turn. After this, you need to start and warm up the engine. Then you need to find the throttle position corresponding to the minimum stable speed (using the throttle screw). Then they begin to lean the mixture by unscrewing the quality screw. The screw must be unscrewed until interruptions in engine operation occur. Then you should tighten the quality screw until the motor runs stable. In this way, a stable mixture composition is set for the given minimum idle speed.

Since the idle speed will be clearly high, therefore, by rotating the damper screw, the speed is lowered. The moment the damper stops lowering will be an interruption in the operation of the motor. After this, the channel cross-section is adjusted using the quality screw. Such operations sometimes have to be repeated several times.

Adjusting the K-62 carburetor on the IZh "Planet" does not differ from the adjustment on the "Minsk". The only difference is the need to remove the protective cover from the carburetor.

Adjusting the K-36B carburetor

Adjustment at idle speed is carried out as follows: 1 - before starting the adjustment, you need to start and warm up the engine. 2 — set the fuel corrector coin to the farthest position from you; 3 — by turning out or screwing in screw 14, set the minimum possible engine speed; 4 - tighten screw 13 until it stops, gradually unscrew it, achieve clear, stable operation of the engine; 5 - set screw 14, lower or raise the throttle to the minimum stable idle speed.

The quality of the mixture is adjusted in operating modes by moving the metering needle 6 in the throttle valve to one of the five annular grooves, while raising the metering needle ensures enrichment of the working mixture, lowering ensures depletion.

Return to content

Checking the settings

After setting the minimum idle speed, you can check how the K-62 carburetor is configured. To do this, the speed is sharply increased and decreased by opening and closing the damper. A properly adjusted carburetor should react sharply to changes in the position of the throttle handle. If there are failures in operation or the engine stalls, then adjustments to the settings are required.

The first method of adjustment is to tighten or loosen the quality screw by one quarter or half a turn. In case of problems with gas supply, tighten the screw. If there are malfunctions in the engine when releasing gas, the screw is unscrewed. If this method does not help, then it is necessary to re-adjust the carburetor from the very beginning.

We examined the design of the K-62 carburetor and the main points regarding its adjustment. We hope this information was useful to you.

Adjusting the K-62V and K65P carburetor

Adjust the idle speed in the following sequence: 1 – screw screw 18 until it stops, which regulates the air supply for idle speed. Then unscrew one turn. 2 – Open the throttle slightly using the throttle. 3 – Start the engine and warm it up. 4 – Using bolt 16, lowering the throttle valve, achieve minimal stable engine operation. 5 – Unscrew screw 18 to set the maximum speed. 6 – Using bolt 16, lower the damper again to minimum speed. 7 – Check the adjustment. Sharply open the throttle with the throttle. If the engine stalls or there is a failure in operation. When switching from idle to main working. The adjustment is incorrect. Screw 18 needs to be used to enrich the fuel mixture - tighten it by a quarter. Or repeat the entire adjustment. 8 – Adjusted correctly, if there is no dip and the motor does not stall. And it continues to gain momentum.

Return to content