Every car owner should have at least a general understanding of its structure. No repair can be done without such knowledge, and when it comes to tuning the performance of a car, then it is imperative to know its structure.

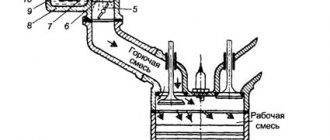

An important part of an internal combustion engine is the carburetor - a device in which air and fuel are mixed. The result is a flammable mixture of the consistency necessary for the operation of the power unit.

When it comes to domestic carburetors, one cannot fail to mention the Solex 21083 - one of the best devices in its class, with excellent performance and high reliability. This model has one undeniable advantage in its arsenal - it can be modified in a wide variety of ways, thereby “tailoring” the carburetor to specific operating conditions.

What are jets

As a rule, modification of the carburetor consists of replacing the jets. Jets are small metering elements with holes of a certain cross-sectional area through which the components of the combustible mixture pass. This article will discuss the jets of the Solex 21083 carburetor.

Types and classification of jets

To create a good lean mixture, fuel jets with a small cross-section of the hole must be installed in the carburetor, and air jets with a larger cross-section. Using this scheme allows the engine to operate stably even with sudden changes in driving mode.

The Solex 21083 carburetor is equipped with two types of jets:

- Fuel. Ensures a uniform flow of fuel into the carburetor chamber.

- Airborne. Dose the air supply to the carburetor.

Car owners for the most part prefer to reduce the appetite of the power unit, so the optimal solution would be to install a combination of jets that reduces fuel consumption (sometimes it is possible to improve this figure by a third). To choose suitable jets, you need to understand their markings, which are not as complicated as they might seem at first glance.

Further maintenance of the carburetor

To prevent the carburetor from seriously malfunctioning in the future, it is necessary to carefully monitor its operation and not run it to a critical state, which precludes independent repairs.

It would be appropriate to purchase the necessary parts of a similar carburetor model, disassembled into parts specifically for these purposes.

For better engine performance, it is recommended to get rid of the forced idle economizer. And timely prevention and precisely selected jets will ensure the most reliable operation of the unit.

The article fully reflects the main goal of adjusting the Solex carburetor starting device, based on many years of practice and consisting in a stable start of the engine at idle, which ensures standard operation of the starting system.

Jet markings

When choosing jets for a carburetor, inexperienced car enthusiasts are often perplexed by the presence of several numbers in the jet markings. These symbols are deciphered as follows:

- The Solex 21083 carburetor as standard is equipped with jets marked 21 (for the first chamber) and 23 (for the second chamber). The numbers indicate the diameter of the dosing elements.

- On the bottom of the “original” fuel jets there are numbers 95 and 97.5 (the first and second chambers, respectively). This data displays the throughput of the jets.

- The air jets are marked in exactly the same way as in the previous example, only in this case they will be marked 155 and 125, indicating the performance of the parts. Naturally, these numbers will change on jets with different throughputs.

The marking of carburetor jets is quite simple, but simply recognizing the numerical values is not enough - you also need to understand how and what these indicators influence.

How to replace the rear wheel hub bearing can be found in our material.

See how to independently adjust the amount of light from your car headlights. Read more here.

An important parameter that affects the operation of the jets is the ratio of the amount of air and fuel in the chamber. The normal ratio is 14.9:1, at which fuel consumption and power are in balance. To determine the combination suitable for a particular driving style, it is enough to understand what the ratio of air and fuel in the combustible mixture will be.

The factory fuel jets of the Solex 21083 carburetor are designed for economical driving and have a fairly small cross-section . The original jets do not need to be changed unless there is a particular need to increase engine power. In addition, as a result of replacing the jets, the mixture may become too lean, and the engine simply will not have enough combustible mixture for normal operation.

If the engine is not running smoothly, and the problem clearly lies in the composition of the fuel mixture, you can think about the options: different configurations of fuel and air jets make it possible to choose the most efficient scheme and use it in your car to achieve suitable results.

Idle speed adjustment

The second setting of the VAZ-2109 carburetor is idle speed, it can be partial or full. The first is for minor speed adjustments, the second is for adjusting the amount of air (setting CO emissions in the exhaust gases).

Partial adjustment is performed using the air-fuel mixture “amount” screw. This screw sets the opening angle of the throttle valves, which ensures that the air-fuel mixture enters the cylinders when the accelerator pedal is released. The “quantity” screw rests on the throttle valve control lever and when screwed in, it pushes the lever, causing the valves to open slightly.

Partial idle adjustment is performed with a warm engine and creating a load on the vehicle's on-board network by turning on the high beam headlights and the interior heater at full power. The adjustment is carried out with the engine running by screwing in/unscrewing the “quantity” screw until the optimal idle speed is established, which for the VAZ-2109 is 800-900 rpm (this can be tracked using a standard or plug-in tachometer).

If it is not possible to set the required speed or the motor operates unstably at it, a complete adjustment is made, which is made by two screws - “quantity” and “quality”.

The algorithm for this adjustment consists of the following stages:

- Warm up the engine and then turn it off;

- We find the quality screw (it may be closed with a plug that will have to be removed), screw it in until it stops, and then unscrew it 3-4 full turns;

- We start the engine, turn on electrical consumers (lighting and stove) to create a load in the on-board network;

- By rotating the “quantity” screw, we achieve 700-800 rpm on the tachometer;

- By turning the “quality” screw, we set the maximum possible speed (they will increase to a certain level, and then stop. The moment the speed increase stops is considered the maximum);

- We set the “quantity” screw to 900 rpm;

- Using the “quality” screw we lower them to 800 rpm;

- We slowly tighten the “quality” screw until interruptions appear in the operation of the power plant, after which we unscrew it back 1 turn;

- We adjust the speed with the “quantity” screw, bringing it to a normal value - 800-900 rpm;

After the adjustment operations, we check that they were carried out correctly. This is done by sharply pressing the gas pedal and then quickly releasing it. With a properly configured carburetor, the engine should respond quickly to pressure, without any failures or hesitations. And after releasing the pedal, the speed will drop to the idle level, without sags or instability of the engine.

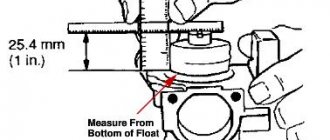

Video: HOW TO CORRECTLY ADJUST THE FUEL LEVEL

Cars of models 2108-09 are truly legendary developments of the Volga Automobile Plant; it was with them that the production of front-wheel drive passenger cars began in the USSR. Also for these cars, a VAZ-2109 Solex carburetor was created and put into production, providing economical fuel consumption and excellent dynamic characteristics.

The carburetor unit (CU) is quite simple to set up and has a generally simple design compared to other similar devices, but it has its own characteristics and characteristic “diseases”. Here we will look at the structure of the carburetor, its dismantling and installation, the specifics of adjustment, adjusting the gasoline level, and debugging the starting mechanism.

Jet selection

When choosing a set of new jets for modifying a carburetor, it is worthwhile to thoroughly study this issue: Solex 21083 is modified very often, and a couple of additional tips from experienced drivers will not hurt. Recommendations for choosing most often sound like this:

- it is very important to take into account the engine volume: with a large displacement, it is better to choose air jets with a small cross-section in order to improve the combustible mixture;

- First of all, you should choose fuel jets, and only then look for air ones;

- The sequence is also important when installing jets: first they are installed in the first chamber, and only then in the second - this step-by-step approach will allow you to choose the most suitable scheme.

As an example of selecting jets for a 1.5-liter engine, you can consider the following combination:

- in the first chamber a fuel jet of 102.5 is installed, and the air jet has a cross-section of 155;

- For the second chamber, a fuel jet of 110 is selected, and an air jet is marked 125 or 135.

It is worth paying attention to the fact that Solex 21083 was originally designed for 1.5-liter engines , and its installation on a power unit with a large displacement is not recommended: due to the design features of this carburetor, an engine that is too “voluminous” will not receive sufficient quality flammable mixture.

It is also worth remembering that all Solex carburetors have a similar design, which ensures the interchangeability of their elements. This rule also applies to jets: if necessary, you can select jets from another carburetor that have a different cross-section for your version.

And the last recommendation: when selecting jets with a large cross-section, sometimes there is a desire to bore them yourself. This should not be done, since the operation of the jets requires the correct ratio, which cannot be achieved in “garage” conditions even with the appropriate equipment.

Idle speed adjustment

The most common problem with a Solex carburetor is the disappearance of normal idle speed; the engine begins to operate intermittently at low speeds. Very often, the cause of such a malfunction is either a clogged EMG jet or the solenoid valve itself. It is very easy to check this - while the engine is running at idle, we disconnect the wiring from the EMG; if the nature of the internal combustion engine does not change at all, and when the valve is unscrewed, the speed increases noticeably, then the defect is present.

Tags: Solex, factory data, calibrations, 21041, 21073, 21053, 21051, 2108

Comments 39

For UZAM 2.0 in Solex-21041, what jets should I choose?

for starters (without knowing the engine compression, camshaft model) something like this: GTZh1=105-107.5 GVZh1=150ZD GTZh2=115-117.5-120 GVZh2=135ZC UN atomizer 40*40 (make it yourself from two 2108) or 45*40 (from 2108 and 21073) Cam UN No. 5, if not, then use No. 7. No. 4 as a last resort. TJ EMR=60 TJ XX 42.43 and further “to taste”