Removing and cleaning the carburetor

In order to remove the carburetor from the scooter, the first step is to remove all the plastic that prevents access to the carburetor (usually you have to remove the seat and plastic under the seat). Then we disconnect the fuel and oil hoses (oil hoses are only available on a 2-stroke scooter), and the contacts of the starting enrichment. After this, unscrew the bolts securing the carburetor to the engine.

Now that the carburetor has been removed, it is necessary to clean its outer surface from dirt and dust. You can wash it in gasoline and wipe it with a dry cloth.

The next step is to partially disassemble the carburetor, namely: unscrew the bolts securing the float chamber cover (2 bolts), then carefully remove the float so as not to bend the plate. We wash the float chamber cover itself very thoroughly from the inside. Now you can start cleaning the inside of the scooter carburetor.

2 easy ways to clean your carburetor:

1) Wash it in gasoline, then blow it out using a compressor with a nozzle in the form of a pointed tip (this will allow you to effectively blow through all channels).

2) Buy a can of liquid to clean the carburetor. We thoroughly clean all the channels and jets of the carburetor. The can also replaces the compressor, since the liquid from it is supplied under high pressure, which allows you to effectively clean small channels.

When cleaning, special attention must be paid to all channels and jets (we unscrew the jets when cleaning). We also remove the starting enrichment and clean its channels. There is no need to dry the internal parts of the carburetor. Now we can put on the float and assemble the carburetor in the reverse order.

Carburetor installation

We install the carburetor on the scooter in the following sequence:

- 1) We fix the carburetor in the place where it is attached to the engine, put on the air pipe and secure it with a clamp.

- 2) We put the drainage hose on the fitting (the lower part of the float chamber)

- 3) Install the throttle cable in a special bracket. We check that the protrusion on the cable fastening screw coincides with the groove on the bracket. Fix the cable with nuts

- 4) We put on the gasoline hose and secure it with a spring clamp.

- 5) Connect the contacts of the starting enrichment.

As you can see, the carburetor connection diagram on a scooter is not that complicated. Next you need to adjust the carburetor.

Carburetor adjustment (tuning)

Adjusting the carburetor on a scooter consists of several stages, which include: adjusting the idle speed, adjusting the mixture quality and adjusting the fuel level in the float chamber.

Setting up the carburetor of 2t and 4t scooters has no fundamental differences, except that on some carburetor models there may be no screw for adjusting the mixture quality and therefore the mixture quality has to be adjusted only by adjusting the needle and float in the scooter carburetor

Idle speed adjustment

5 - idle screw on a 4-stroke scooter

Adjusting the mixture quality

The quality of the mixture is a very important point when adjusting the carburetor, since with a lean mixture the engine can overheat and lose power, and with a rich mixture carbon deposits will form in the combustion chamber.

We adjust the quality of the mixture using the adjusting screw. The mixture becomes richer if we turn the screw clockwise and becomes leaner when we turn it counterclockwise.

The adjustment diagram looks like this:

- Warm up the scooter for 10 minutes, turn off the engine;

- Tighten the screw fully clockwise;

- Unscrew 1.5 turns back counterclockwise

- Start the engine and turn the screw back another 1/3 turn. Let the engine run for 2 minutes.

- If the speed increases, then unscrew the screw another 1/4 turn counterclockwise. We also let the engine run for 2 minutes.

- Repeat the previous step until the speed starts to drop (remember to let the engine run for 2 minutes before each change)

- If the speed begins to drop, then screw the screw clockwise 1/4 turn.

This ensures stable engine operation at any permissible speed. Ideally, the engine should work well with the mixture quality adjustment screw unscrewed by 1.5 - 2 turns. However, due to wear and tear of engine parts, this range may change.

If your scooter’s carburetor does not have a screw for adjusting the mixture quality, then the adjustment must be made only by adjusting the position of the carburetor needle. Raise the needle - the mixture becomes richer, lower the needle - the mixture becomes leaner.

You can tell by the carbon deposits on the spark plug that the quality of the mixture has been incorrectly adjusted. If the carbon deposits on the candle are black and there is a lot of it, the mixture is too rich. If the carbon deposits are almost white, the mixture is too white.

Adjusting the fuel level (in the float chamber)

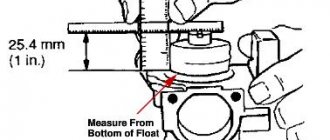

The fuel level in the float chamber can be checked using a transparent tube located at the bottom of the carburetor. In order to do this, you need to unscrew the butter screw and lift the tube towards the top of the carburetor. Now we check the fuel level with the scooter engine running. It should be located just below the protruding skirt at the point where the float chamber cover is attached to the carburetor.

If the level is low or, as is more often the case, too high, then it is necessary to remove the cover and adjust the timing of the locking game by bending the needle holder (a small tendril) in a very small range.

It is worth remembering that if the carburetor malfunctions or its internal elements are dirty, adjusting the carburetor may only temporarily solve the problem.

This is the whole principle of setting up a carburetor on a Chinese and Japanese (Honda, Suzuki, Yamaha, etc.) scooter. Now you can independently repair and adjust the carburetor on 2t and 4t scooter engines with a volume of 50 and 150 cubic meters.

Carburetor setting 139qmb

The mixture prepared by the carburetor, depending on the ratio of gasoline and air, can be rich, enriched, normal, lean and lean. I listed them in descending order of the percentage of gasoline (that is, a lean mixture contains the least gasoline and the most air). The engine cannot operate normally on rich and lean mixtures - they are too far from the optimum. The mixture with the maximum amount of gasoline on which the engine can still operate without interruption is called enriched. Accordingly, with a minimum - depleted. The middle between them is conventionally considered normal. Notice the nuance? The composition of the mixture is not tied to numbers - so many grams of gasoline per liter of air, but to the operation of the engine. That is, this is to some extent a relative parameter. For example, a mixture that is rich for a cold engine will become rich for a hot engine.

The composition of the mixture, logically (well, since it consists of gasoline and air), can be adjusted either by changing the amount of gasoline supplied or the amount of air sucked in. But to achieve maximum power, you need to give the engine the opportunity to suck in as much air as possible, and to match this amount, select such a proportion of gasoline so that the mixture turns out to be normal or slightly enriched.

There is a proboscis on the front of the filter cover through which air is sucked in. And at its end there is a plug with four holes. It was needed for the break-in period, and after the break-in is completed, it can be removed. We pull it out. The next thing that is in the way of air entering the engine is a foam filter. You can't remove it, but you can reduce the resistance. To do this, you need to wash it in a certain way. We prepare a mixture of motor oil and gasoline in a ratio of 1:10, wash the filter in this mixture, then squeeze it forcefully in your fist without twisting it, put it in to dry for about five minutes (not in the sun), then put it back. With this method of washing, the filter has low resistance and at the same time retains sufficient filtering properties. We increased the amount of air. Now we need to increase the amount of gasoline.

It is adjusted by a needle on the air damper (spool). The higher the needle is raised, the more gasoline. The needle rises with the spool, and its position relative to the spool can also be changed. The spool is located under a plastic cover in the center of the carburetor, the needle is inserted into a hole in the bottom of the spool, it can be removed with tweezers. But first, the lid. In its center there is a protrusion (pin) on which the spool spring is fixed. But with such a length (about 20mm), it also makes it difficult to lift the spool all the way up, which is quite justified during break-in and is completely unnecessary after it. To fix the spring, 6 - 7 mm is enough. We bite off the excess. The photo shows the cover with a pin up to

And here she is after:

Now nothing prevents the spool from rising to its maximum limit.

The last object of adjustment is the needle. In the carburetor of GX scooters, it does not have adjusting grooves, so it can be raised by putting on washers of appropriate thickness, for example from M2.5 fasteners. The maximum by how much it makes sense to raise it is 1.5 mm, in increments of approximately 0.25 mm.

The photo shows a needle with two textolite washers of approximately 0.5 mm each:

Now you can move on to fine tuning. To begin with, place a 0.5mm washer under the needle stop, assemble, and close the carburetor

and start it up. Let's warm up. If the engine runs smoothly, but when accelerating it changes its tone to a hoarse tone (dr-dr-dr instead of oo-oo-oo, this is working through a stroke) - the mixture is rich, you need to lower the needle, that is, put a thinner washer. To clarify, insert a plug into the proboscis. It got even worse - as if the mixture was rich. And if the engine operates with dips, especially noticeable at high speeds, and after the dip there is often a jerk (oo-oo-bu-bubu-oo!) - the mixture is poor. Let’s clarify again with the plug: it’s better with her - just like she’s poor. Raise the needle. Finally we find a position in which there are no symptoms of either a rich or lean mixture.

And the last thing is idle speed adjustment. This is done on a warm engine. We start it, release the gas and use the quality screw (it’s on the side, see the last photo of the article) to achieve the maximum increase in speed. Then use the quantity screw to reduce the speed to the minimum stable and again

we use the quality screw to raise them to the limit (in principle, this second iteration may not be needed). That's it, the carburetor adjustment is complete. You can go for a ride. You will see that your dynamics have improved and your maximum speed has increased by 3 or even 5 km/h.

How to adjust the carburetor on a scooter

The first step before starting the procedure for adjusting the scooter carburetor is to study its structure and operating principle. This way you can quickly and accurately adjust the carburetor on your scooter. A correctly configured carburetor makes it possible to obtain lower fuel consumption, improve dynamic characteristics and completely enable the scooter to start and operate normally. Before the procedure itself, it is important to warm up the engine well; also, if possible, thoroughly clean the entire carburetor from dust and dirt.

Standard carburetor adjustment procedures include the following:

- Idle speed adjustment;

- Adjusting the fuel level in the float chamber;

- Adjustment by adjusting the mixture quality screw on the carburetor;

- Adjusting the mixture quality through the needle inside the carburetor.

Adjusting a Chinese carburetor for a 50cc 4t scooter

For the proper operation of any engine based on the principle of internal combustion, optimal dosing of the air-fuel mixture (FA) is important.

If the balance of the ratio is disturbed, the equipment begins to malfunction. Even the most precise mechanisms require periodic adjustments. Adjusting the carburetor on a Chinese scooter is not a frequent procedure, but it is necessary for the proper functioning of the equipment.

The principle of operation of a carburetor on a scooter

The design of a scooter carburetor is quite complex, but most of them have standard elements. The main task of any carburetor is to create a high-quality fuel mixture. Also, most scooters are equipped with a float chamber on the carburetor, so if you do not know how to adjust the carburetor on a 2t or 4t scooter, first study its structure.

The principle of operation of the carburetor is as follows: after pressing the throttle, the valve on the carburetor is activated, it is called a Venturi tube, the needle rises in the valve and the formation of a fuel mixture begins by mixing gasoline and air. An open throttle increases the supply of mixture to the engine, which is why the scooter starts to move.

A faulty carburetor will prevent the engine from starting, so it must be kept in as good condition as possible. Before adjusting the carburetor on a 50cc scooter, identify the main signs of failure. The main consequences may be:

- Inability to start the scooter;

- The engine runs intermittently and often stalls;

- Power is significantly reduced.

Most often, these situations occur when the carburetor is incorrectly adjusted, causing the mixture to become either lean or rich. Checking the characteristics of your mixture is quite simple; just inspect the spark plug for its condition; if the spark plug is flooded and has carbon deposits or other changes, most likely you have an enriched mixture. A spark plug that is too white indicates that there is too much air in the fuel mixture. Keep in mind that if you don’t know how to adjust the carburetor on a scooter, 2t or 4t, the type of engine will not matter; adjustments should be made according to standard recommendations.

Adjusting the fuel level

The float chamber allows you to have a constant flow of fuel in the carburetor, which is always replenished, but it is important to remember that you cannot have an excess of gasoline in the float chamber. Gasoline is drained using a special hose coming from the chamber; you will have to check the amount of fuel with the engine running. Raise the hose above the carburetor as shown in the picture below and check the fuel level. It should not differ much from the mark indicated in the picture. There is a holder antenna located on the needle inside the float chamber; it can be used to regulate the amount of fuel inside the float chamber.

This is interesting: When is it time to change antifreeze

Please also take into account the fact that before adjusting the carburetor, you should only have high-quality gasoline with a normal octane number. Otherwise, you will have to completely drain the bad gasoline not only from the gas tank, but also from the float chamber; it must have a special drain screw.

Setting the mixture quality

The quality of the mixture plays a key role in the operation of the entire scooter, because incorrectly configured parameters will lead to the scooter choking, consuming a lot of fuel and increasing wear on the piston group. That is why the combustible mixture must be in the optimal quantity; a lean mixture indicates a loss of power and frequent overheating of the engine, a rich mixture is characterized by high fuel consumption and the presence of heavy carbon deposits in the combustion chamber.

There are two ways to adjust the quality of the mixture - with an adjusting screw or the needle level in the damper. In some cases, the carburetor design assumes the absence of an adjusting screw, so adjustment is carried out only with a needle. The standard procedure for adjusting the screw is to rotate counterclockwise and clockwise; in the first case, the mixture becomes lean; tightening the screw indicates that the mixture is richer. In the case of a needle, you can enrich the mixture by raising it up; the lean mixture is set on a lowered needle.

The instructions for most scooters say that there is a standard setting for the mixture quality, where the screw should be unscrewed only 1.5-2 turns. Therefore, if it is impossible to accurately adjust the mixture, stick to this indicator.

The needle is adjusted by raising or lowering it; it has markings and a special locking ring that sets the current height. Accordingly, if you find a lean mixture, you will have to raise the ring level by 1 notch. Having achieved optimal performance, your scooter will operate smoothly and correctly, it will consume fuel in normal quantities, and the power will correspond to the characteristics.

Adjusting and tuning the scooter carburetor

Carburetor adjustment must be carried out on a warm engine. Before tuning, you should clean and rinse the carburetor if there are signs of clogging.

The following manipulations are understood as setting and adjustment:

1) Idle speed adjustment; 2) Adjusting the quality of the mixture with a special screw on the carburetor; 3) Adjusting the quality of the mixture by moving the needle; 4) Adjusting the fuel level in the float chamber.

Let's look at each of these elements separately.

How to adjust a scooter's carburetor

In order for a scooter engine to operate efficiently and steadily, it needs the correct fuel mixture, which is prepared in the carburetor. Depending on the condition of the engine, cylinder volume, quality of gasoline and other factors individual for each scooter, additional carburetor adjustment may be required.

Before getting down to business, it is strongly recommended to put things in order in the fuel system, namely: clean the carburetor and air filter, and also adjust the fuel level in the float chamber.

The carburetor should only be adjusted on a well-warmed engine. That is, before setting up, you need to drive the scooter for 10-15 minutes.

The carburetor usually has two adjustment screws. The smaller one is the mixture quality screw. The larger one is the idle speed screw. However, there may not be a mixture quality screw - then the quality adjustment is carried out by manipulating the throttle needle.

The factory settings are as follows: the quality screw is unscrewed by 1.5-2 turns, the idle screw is unscrewed by 2.5 turns. What does it mean? This means that the screws must first be tightened clockwise until they stop, and then unscrewed back the appropriate number of turns. It is from these initial settings that you should begin tuning. And in principle, if at the same time the engine runs stably and the scooter accelerates without failure and to maximum speed, you don’t have to adjust anything in particular. But if this is not the case, then adjustments cannot be avoided.

So, put the scooter on the stand. The motor must be running (and it must be warmed up before tuning).

Unscrew the quality screw 2 turns. Now you need to adjust the idle speed. Tighten it slowly (clockwise) - the engine speed will increase. At some point the clutch will engage and the rear wheel will begin to rotate. Then turn the screw back a quarter turn.

Now you need to test how the scooter will behave when riding. Accelerate on a flat road.

- If the scooter accelerates sluggishly, it means the mixture is not rich enough. Then tighten (clockwise) the mixture quality screw a quarter or half a turn. At the same time, the mixture will become richer (there will be less air in it, more gasoline).

- If the scooter accelerates normally, but not to the maximum, then the mixture is over-rich. In this case, you need to unscrew (counterclockwise) the mixture quality screw a quarter or half a turn to lean the mixture.

If you have turned the mixture quality screw, then you need to adjust the idle speed using the method described above.

With an ideal setting, the scooter should accelerate without dips or jerks, stably, and reach maximum speed.

Please note: This article and the images in it are subject to copyright. Partial or complete reproduction on other resources without permission is prohibited.

Source

Idle speed adjustment.

It is carried out on a warm engine. Each carburetor has an idle screw, with which you can ensure stable operation of the scooter during idle time.

Consider the location of the adjusting screws on different carburetors:

Honda carburetor adjustment. 1- idle screw; 2 - mixture quality screw.

Adjusting the idle speed on the carburetor of a Chinese scooter. 1 — idle quality adjustment screw; 2 — fuel inlet fitting; 3 - fitting through which you can drink fuel from the float chamber; 4 — screw-plug of the float chamber.

A type of carburetor. Adjusting idle speed and mixture quality. 1 - ventilation tube; 2 — idle speed adjustment screw; 3 — screw for adjusting the composition of the fuel-air mixture.

Adjusting the carburetor of a 2T scooter

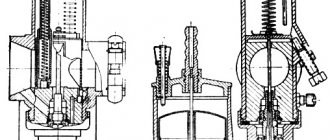

In terms of complexity and abundance of systems, this carburetor can compete with the most sophisticated automobile ones (only those with electronic control are more complex). Hence the advice: if your experience with the motorcycle power system is limited to two or three successful repairs of devices like K-65, do not take risks - contact specialists. And second: work on a table covered with a sheet of clean white paper under the light of a bright lamp - this makes it easier to see the details and harder to lose them. And it is extremely difficult to examine the holes of the jets: they are so small that they can be clogged by the smallest speck of dust. Some channels are comparable in size to them. The outside of the carburetor must be clean before disassembling. The hands are the same as those of a surgeon before an operation. To work, you will need screwdrivers with unworn working surfaces. Most of the screws here are not only tightly tightened, but also secured with thread sealant, so that a screwdriver with a bad tip will only break their slots. Stock up on tweezers to make it easier to “catch” little things. Well, are you scared? If not, let's get started.

You can remove the carburetor through the hatch under the seat, but it will be easier if you first remove the entire trunk.

You can get to it through a hatch in the trunk, under the saddle. But it’s easier to do this if you unscrew five bolts and dismantle the entire trunk along with the saddle, loosening the clamps. Loosen the one on the engine side more firmly so that the flange on the rubber pipe can come out of the deep groove on the carburetor outlet pipe. Usually, when the engine is not running, the gas valve with a pneumatic drive is securely closed, but it is better to be on the safe side - secure the end of the hose removed from the carburetor above the gas tank. Then disconnect the throttle cable and the connector of the wires A going to the carburetor starter. Clean the carburetor from dust with a soft brush, wash your hands and begin disassembling.

Unscrew the three bolts and remove the float chamber cover. The float axis is held in place by a bolt. Unscrew it and remove the float block with the shut-off needle. The needle of this carburetor has a rubber conical part, and a spring-loaded rod rests against the float tongue. This design makes the unit sealed, very durable and resistant to abrasive wear.

Back view

: 1 — starting device; 2 - channel leading into the cavity under the spool membrane; 3 — air channel of the starting device; 4 — air jet of the main dosing system; 5 — accelerator pump nozzle; 6 - channel in which the air jet of the idle system is located; 7 - accelerator pump.

Possible malfunctions. The tide on the side walls of the floats should be parallel to the plane of the upper carburetor connector. If this is not the case, bend the metal tongue to achieve the correct position. Check it by placing the carburetor on its side - the tongue should just touch the needle rod, but not recess it.

Front view

: 1 - channel for the exit of the fuel-air mixture from the starting device; 2 — tube through which excess gasoline is drained if the float mechanism malfunctions; 3 - channel through which vacuum from the intake manifold is supplied to the idle air system shut-off mechanism.

Main dosing system

Its jet is located in the center of the float chamber. Through it, the fuel enters the emulsion tube, where it mixes with air and forms an emulsion. Air enters through a jet located at the carburetor inlet. The emulsion is dosed with a needle, which is fixed in the spool. A constant vacuum in the sprayer area is ensured by the spool. Next to the metering needle there is a hole through which the vacuum is transmitted to the cavity above the membrane, while the spring is compressed and the spool rises to the desired height.

Right view

: 1 — accelerator pump drive lever; 2 - throttle valve drive sector; 3 — screw for adjusting the amount of fuel-air mixture at idle.

To lean or enrich the combustible mixture, unscrew the screws securing the membrane cover and remove the spool with the membrane. Be very careful - the lid is made of fragile plastic. Remove the needle plug and the needle itself.

The range of adjustments is small - there are only three grooves on the needle; with the factory adjustment, the stopper is in the middle. During engine operation, spool oscillations occur due to air fluctuations in the intake tract. To prevent the stopper from breaking the needle groove, a rubber ring is installed under it. If you damage or lose it, you will not only shorten the service life of the unit, but also impoverish the mixture - the needle will drop lower without this part.

Left view

: 1 — idle quality adjustment screw; 2 — fuel inlet fitting; 3 - fitting through which you can drink fuel from the float chamber; 4 — screw-plug of the float chamber.

When you install the membrane in place, make sure that the protrusion on it fits into the recess on the body.

Possible malfunctions.

There may be two of them. The first is that the fuel nozzle is clogged. Blow it out. Second, the spool membrane is damaged. In this case, you cannot do without replacing the membrane with the spool.

Parts in the float chamber

: 1 — fuel tube of the starting device; 2 — block of floats; 3 - lock bolt; 4 — needle with a rubber tip and a spring-loaded rod; 5 - axis; 6 - tongue; 7 - main fuel jet. 8 - . and its emulsion tube; 9 — idle fuel jet.

The idle speed (XX), as in most carburetors, is adjusted with two screws: mixture quality and quantity. The quality screw is located under the throttle valve axis on the left side of the carburetor, and the quantity screw is located on the axis sector stop. At the factory, quality adjustment is carried out as follows: the screw is tightened until it stops, and then unscrewed 2.5 turns. The XX system fuel nozzle is located next to the main fuel system nozzle; it and the emulsion tube form a single unit. The air jet is pressed into a tube-like boss to the right of the air jet of the main fuel system. The emulsion is supplied to three holes under the throttle valve. Why - by three? As the damper opens, its cut moves from one to the other, and they alternately find themselves in the zone of the highest air flow speed, and therefore in the zone of greatest vacuum. Thanks to this, the operation of the carburetor at the beginning of the throttle valve is improved and “dips” are eliminated.

When installing the spool, make sure that the protrusion on the diaphragm is in the recess of the housing (highlighted in red). The arrow indicates the hole through which additional air enters the idle system to turn it off.

When the damper is open to a large angle, the XX system is turned off by a special device. If the damper is closed, vacuum from the intake manifold enters the cavity above the device membrane and attracts it to the cover, compressing the spring. In this case, the XX system operates normally. When the throttle is open sufficiently, the vacuum in the manifold is too low to compress the spring, and it opens the valve with the diaphragm protrusion. Air from under the main fuel system valve diaphragm enters system XX. The vacuum in the XX system decreases - it becomes insufficient to supply gasoline. Possible malfunctions.

The XX system is one of the most vulnerable in any carburetor. First of all, due to the fact that the flow sections of the jets here are the smallest, which means they easily become clogged. If the diaphragm of the system that turns off XX becomes leaky due to age or for any other reason, the vacuum of the intake manifold will not be able to keep its valve closed, the fuel supply will be disrupted and the engine will stop running on XX. The same will happen if the valve loses its seal. The connector area between the membrane cover and the carburetor body (it contains the channel through which vacuum is supplied) is sealed with a rubber ring. The tightness of the seal will deteriorate - the operation of the membrane mechanism will be disrupted, and in addition, air will be sucked into the intake manifold, thereby making the mixture leaner. And it will become impossible to adjust the engine operation at XX.

When the throttle valve is opened sharply, the vacuum near the nozzle decreases, there is not enough of it to suck in a sufficient amount of gasoline - and a “failure” occurs in the engine’s operation. The purpose of the accelerator pump, as its name suggests, is to help the engine accelerate the scooter during this carburetor confusion.

Adjusting the quality of the mixture.

It is very important that the fuel mixture on which the scooter operates corresponds to the proportions specified by the engineers. If the mixture is too lean, the scooter does not work properly, overheats, and loses power. With a rich mixture, there is increased fuel consumption, the formation of soot in the combustion chamber, and the carburetor is usually wet.

The quality of the mixture can be adjusted either by adjusting the screw or by moving the needle in the throttle valve. In the photos above you can see the location of the mixture quality screw. If it is absent, adjustment is carried out only with a needle.

By turning the screw clockwise, we enrich the mixture, and by unscrewing it counterclockwise, we lean it. It’s the same with a needle, raising the needle makes you rich, lowering it makes you poorer. The combination of both methods allows us to achieve the most acceptable results when tuning, however, in the absence of the first, as for example on Suzuki Sepia and Suzuki Assress carburetors, we will be content with only moving the needle. And thanks for that.

Adjusting the fuel level in the float chamber.

You can check the fuel level in the float chamber using a transparent tube located at the very bottom of the carburetor. Unscrew the butter screw,

lift the tube up opposite the carburetor and check the fuel level. Please note that the fuel level must be checked with the scooter engine running, and the tube should always be located above the carburetor. The fuel level should be just below the cap curb.

If there is little, or usually a lot, remove the cover and adjust the moment of operation of the locking needle by bending the needle holder in very small ranges.

It should be noted if the carburetor has not been washed for a long time and there are signs of contamination of its channels and jets, if gasoline has been or is being filled with an octane rating lower than that recommended by the manufacturer (for example, A-80), if the installed jets and other parts do not correspond to those recommended by the factory parameters, then before adjusting the carburetor you need to eliminate all this, since further adjustment will only be temporary and you will not achieve the desired result.

You can also read other articles on the topic:

Setting the gasoline level and the correct position of the float in the chamber

A correctly adjusted fuel level in the float chamber does not allow the spark plugs to get wet and the engine to stall. In the chamber where the floats and jets are located, there is a valve that provides fuel supply. The correct position of the floats determines the closing or opening phase of the valve and prevents fuel overflow in the carburetor. The position of the floats is changed by slightly bending the fastening bar.

Gasoline level is monitored with the engine running using a tube made of transparent material attached to the drain point and raised up. The gasoline level should be a few millimeters below the flange mounting of the cover. If the level is insufficient, remove the cover and adjust the needle firing phase by slightly bending the metal antennae.

on “Adjusting and tuning the scooter carburetor”

How to clean the injector on a Suzuki V50g? I started eating 1 liter per 25 km. Against 70 km half a year ago. Where do they clean them? Or can I do it manually?

The administrator replied: March 25th, 2012 at 12:17

In your case, it is better to contact a service center, since the work is quite delicate.

Roman replied: May 23rd, 2021 at 11:38 am

Good afternoon, there is a problem with the carburetor on stroke 16, air leakage through the carburetor overflow fitting

Sergey replied: March 12th, 2021 at 08:31

Good afternoon. I have a Honda 34 at medium speeds that loses speed until it stops at high speeds and it works fine, what’s the reason?

San-sanych replied: March 15th, 2021 at 11:19

The reason is the carburetor. At a certain throttle position, the required amount of mixture is not prepared. It needs to be removed, washed, and looked at.

Denis replied: May 2nd, 2012 at 21:19

what could this be when you fill up, let’s say, 2 liters, the gasoline level shows 2 times less gasoline? ? Honda 35 moped, Thank you!

The administrator replied: May 3rd, 2012 at 21:38

35 Dio doesn't eat much on his own. A clogged muffler can easily cause excessive consumption. The fuel sensor is responsible for the gasoline level. Most likely, the problem with the incorrect display is there.

Vitya replied: May 6th, 2012 at 12:57 pm

Gasoline is pouring out of my carburetor from a small slag and the scooter immediately stalls! What should I do? I cleaned the carburetor and the tank too!

Vitya replied: May 6th, 2012 at 02:51 pm

I have a storm 50

Vitya replied: May 6th, 2012 at 03:12 pm

Vitya replied: May 6th, 2012 at 03:16 pm

what to do? maybe the needle is bad or! I don’t know!

Vitya replied: May 6th, 2012 at 07:27 pm

The carburetor is filled with gasoline! The needle is bad or the carb needs to be cleaned!

The administrator replied: May 8th, 2012 at 21:10

Second option. Moreover, much attention should be paid to the float chamber.

The administrator replied: May 8th, 2012 at 21:00

It's flooding. You need to remove the carburetor and thoroughly rinse everything again, check the condition of the float chamber shut-off needle.

Vitya replied: May 9th, 2012 at 12:00

Vitya replied: May 9th, 2012 at 12:43

But how to check whether it is good or not!

Vitya replied: May 10th, 2012 at 21:31

How much does a new carb cost for a Storm L?

The administrator replied: May 10th, 2012 at 21:35

No more than 30 dollars. Although the rest is up to the seller.

Vitya replied: May 11th, 2012 at 02:12 pm

what needs to be done to prevent the needle from sticking!

The administrator replied: May 13th, 2012 at 21:28

What kind of needle are we talking about? Throttle valve or float chamber shut-off needle?

Vitya replied: May 14th, 2012 at 08:29 pm

like a throttle! I forget these names!

Nikita replied: March 7th, 2021 at 07:52 pm

Tighten the bolt on the sump

Alexander replied: July 8th, 2012 at 18:10

The administrator replied: July 10th, 2012 at 20:58

It's all about the fuel level in the carburetor. You need to raise the level a little, yours is too low. After this the problem will be solved. Remove the carburetor, unscrew the float chamber cap, turn the carburetor over and note the location of the float. When upside down, it should be parallel to the carburetor. Yours is most likely a little higher. Bend the tendril so that the float is level or falls a couple of mm below the parallel level. Every mm matters there.

Alexander replied: July 11th, 2012 at 07:05

Hello. Thank you for your answer. I was convinced of your competence. Yesterday, before your answer arrived, I set the fuel level higher and the scooter drove. But it feels like the level is a little higher. According to the method you recommended for determining using a transparent tube, it turned out that the level is higher by about 5- 7 mm of the bottom cover. But I was afraid to touch it, and I was glad about it. And my wife had to travel for work. The spark plug became a normal color. I didn’t know about this method that you answered me - turning the carb cap over. It feels like you have a lot of practice. We have All masters set it this way: they bend the tendril, then pump up the fuel and look at the level. It should be a little larger than the bend in the float chamber. I can’t post a photo, but I think you understand what I’m talking about. It didn’t work out for me - it was always low because the scooter stalled ..And I thought that this was normal. So I fiddled with it for 3 days. I set it up according to your recommendations and at the same time put the original float in place. It has a recess for the needle. The craftsmen told me that this was a product and installed a Chinese float. But as I understand this recess there should be. Answer about this. And another question: With great difficulty I got a new float valve. It worked for about a month and eventually the scooter stalled. During disassembly it turned out that the rubber tip remained in the channel and the needle itself was on the float. I got a defective one, simply Chinese .I had to put the original one in place. But from time to time it leaked fuel and flooded the carb. What kind of glue can I use to glue the rubber tip to the needle? I was leaning toward super glue or epoxy, but I doubted that it wouldn’t clog the channels if gasoline dissolved the glue. Or maybe there is another way ?Or just throw it away? Thanks again for the prompt response and correct practical advice - everything was confirmed. Guys. I recommend this site to everyone. A really knowledgeable person with a lot of practical experience.

This is interesting: How to safely transport things in the trunk?

Adjusting the Carburetor Honda Dio 35

Content

Scooter service and repair

regulation and settings of the carburetor scooter

carburetor regulation

You should definitely spend it on a warm engine. Before installation, the carburetor should be cleaned and flushed if there is any sign of clogging.

When installing and adjusting, understand the following procedures:

1) idle speed control 2) regulating

the quality of the mixture with a special screw on the carburetor; 3) regulating the quality of the mixture

by moving the needle; 4) Adjusting the fuel level in the float chamber.

Let's look at any of these parts separately.

idle control.

It is made to heat the engine. Each carburetor has a tension screw that allows the scooter to perform measuredly when not in use.

Consider the placement of adjusting screws on different carburetors:

carburetor regulation

Honda 1. Screw Screw;

2 screws mix quality

.

regulation

idle time on the carburetor of a Chinese scooter. 1. idle speed control screw; 2. fuel fitting; 3. a nozzle through which fuel can be released from the float chamber; 4. float chamber screw plug.

variety carburetor

.

regulation

of downtime and

mixture quality

. 1. ventilation pipe; 2. idle speed control screw; 3. screw that regulates the composition of the gasoline mixture.

The speed of rotation of the screw increases. Unscrewing. reduces the speed accordingly. Warm up the scooter for 10-15 minutes and let it idle using this screw.

Adjusting the quality of the mixture.

It is very important that the fuel mixture on which the scooter operates corresponds to the proportions established by the engineers. When the mixture is too lean, the scooter does not work properly, overheats, and loses power. The main part of the carburetor adjustment of the Honda Dio 35 scooter has also been modernized. With a rich mixture, fuel consumption increases, soot forms in the combustion chamber, and the carbohydrate is usually wet.

adjusting mixture quality

This can be done using the adjustment screw or by moving the needle into the throttle.

The photo above shows the location of the mixture quality .

If it is absent, adjustment is made only with a needle. By turning the screw clockwise, we enrich the mixture by unscrewing the arrows counterclockwise. impoverished. Thus, as the needle rises, the needle becomes richer, and as it descends. impoverishment. The combination of both methods allows us to achieve the most favorable results during tuning, however, in the absence of the former, such as Suzuki Sepia and Suzuki Assress carburetors, we will be satisfied with the needle movement only. And thank you for that.

Before setting up the carburetor

, Warm up the scooter for 10-15 minutes, the carburetor should be clean (inside).

Ideally, the engine operation is considered to be high-quality placement of the screws in the unscrewed position for 1.5. 2 turns. Depending on engine wear and other problems, this range may vary. The scooter should accelerate smoothly, without failures, and there should be no jerks when moving. If you cannot get an acceptable scooter, remove the gas from the carburetor and raise or lower the needle.

To do this, remove it from the valve and insert the retaining ring down the grooves. You can find out the quality of your mixture and therefore in which direction it should be adjusted by the spark plug, more precisely. color and application to its electrodes. Adjusting the carburetor hose level on a Honda Dio Me Honda Dio 35. If it is black, with a lot of soot, the mixture is saturated. If the spark plug is almost white, the electrodes overheat and melt. the mixture is bad. READ Spacers to increase the ground clearance of LADA Granta

regulation of the fuel level in the float chamber.

You can check the fuel level in the float chamber using the clear tube located at the bottom. carburetor

. Loosen the cream screw,

lift the tube opposite the carburetor and check the fuel level. Please note that the fuel level must be checked with the motor running on the scooter, the pipe should always be higher than the carburetor . The fuel level should be just below the edge of the cap.

If it is small or large, generally remove the cap and adjust the torque of the locking needle by bending the (narrow) needle holder within very small limits.

Pit_Stop Workshop: Carburetor settings.

Blog link: Personal page on LCD: Scooter repair team, help.

Honda DIO AF 34. p6 tuning review carburetor

Playlist of action camera EKEN h9r ultra hd 4k Honda DIO

AF 34.

It should be noted that if the carburetor has not been flushed for a long time and there are signs of contamination of its channels and injectors, if the gasoline is full or octane lower than the manufacturer recommends (for example, A-80), if the installed injectors and other parts do not meet the recommended factory parameters, then before installing the carburetor

all of this must be addressed as this

adjustment

. It will only be temporary and you will not achieve the desired result.

You can also read other related articles:

on “adjusting and adjusting the scooter carburetor”

how to clean the injector for suzuki v50g? I started eating 1 liter out of 25 km. 70 km six months ago. where are they collected? can this be done manually?

admin replied: March 25, 2012 at 12:17 pm

In your case, it is better to contact a service center, because the work is quite delicate.

Roman replied: May 23, 2021 at 11:38 am

Good afternoon, I have a problem with stroke 16 with air inlet into the carburetor through a filter for overflowing the carburetor

Sergiy replied: March 12, 2021 at 8:31 am

Good afternoon. I have a Honda

34 at medium speed, it loses speed ahead until it stops at high speed. It works fine, what's the reason?

San Sanich replied: March 15, 2021 at 11:19 am

The reason is the carburetor. At a certain throttle position, the required amount of mixture is not prepared. It needs to be removed, washed, and looked at.

Dennis replied: May 2, 2012 at 9:19 pm

what could happen when we fill up, say, 2 liters, the gasoline level shows 2 times less gasoline?? and I started eating a lot of gas without observing any gas leakage, but there is a lot, how to reduce gasoline consumption? and can a forgotten muffler cause high consumption? Honda moped

35, thank you!

READ Which Carburetor is Better to Install on a Moskvich 2140

administrator replied: May 3, 2012 at 9:38 pm

35 Dio himself doesn't eat much. A clogged muffler can easily lead to cost overruns. The fuel level sensor is responsible for the gasoline level. Honda Af-35 carburetor. Honda Dio and AF-35. And now the carburetor is configured itself. Most likely a display issue is the problem.

Victor replied: May 6, 2012 at 12:57 pm

carburetor from me

gasoline is poured from a small slag and the scooter immediately eats! What should I do? I cleaned the carburetor and the tank too!

Victor replied: May 6, 2012 at 2:51 pm

I have a storm 50

Victor replied: May 6, 2012 at 3:12 pm

Victor replied: May 6, 2012 at 3:16 pm

What should I do? Maybe the needle is bad or! Don't know!

Victor replied: May 6, 2012 at 07:27 pm

The carburetor is filled with gas! Bad or the carburetor needs to be cleaned!

administrator replied: May 8, 2012 at 9:10 pm

Second option. And much attention should be paid to the float chamber.

administrator replied: May 8, 2012 at 21:00

It's flooding. It is necessary to remove the carburetor and rinse thoroughly again, check the condition of the locking needle of the float chamber.

Victor replied: May 9, 2012 at 12:00

Victor replied: May 9, 2012 at 12:43 pm

but how to check whether it is good or not!

Victor replied: May 10, 2012 at 9:31 pm

But how much does a new carburetor cost on a Storm L?

admin replied: May 10, 2012 at 9:35 pm

No more than 30 dollars. Adjusting the carburetor Honda Dio 35 ZX. Everything related to scooter repair. NECESSARILY. Although the rest is up to the seller.

Victor replied: May 11, 2012 at 2:12 pm

what needs to be done to prevent the needle from sticking!

admin replied: May 13, 2012 at 9:28 pm

What needle are you talking about? Needle for shut-off choke or float chamber?

Victor replied: May 14, 2012 at 8:29 pm

throttle how! I forgot these names!

Nikita replied: March 7, 2021 at 07:52 pm

Tighten the screw on the pallet

Alexander replied: July 8, 2012 at 6:10 pm

Guys, I need some advice. Nonda PART 27. Starts off normally. Acceleration is good. Run 500-600 meters. He starts twitching and dies. The fuel level is set according to your site's recommendations. When it can't be stopped, you just need to remove the air and cover the carb with your hand. It will start again. He goes through these 500 meters and stands. What to look for. The piston is normal, changed 2 months ago. Is compression good? Are the crankshaft seals to blame? There is no crankshaft in the crankshaft. There is no clean smoke from the exhaust. I was fine until yesterday. I would be very grateful for your help. Sincerely, Alexander.

READ Replacing the air filter Honda CR-V 3

admin replied: July 10, 2012 at 8:58 pm

And it's all about the fuel level in the carburetor. You need to raise your level a little, your level is too low. The problem will be solved. Remove the carburetor, unscrew the float chamber cap, turn the carburetor over and note the location of the float. When inverted, it should be parallel to the carburetor. You're probably a little taller. Bend the antennas so that the float is level or drops a couple of mm below the parallel level. Every mm matters there.

Alexander replied: July 11, 2012 at 7:05 am

Hi all. Thanks for the answer. I was confident in your competence. Yesterday, before your reply arrived, I set the fuel level higher and the scooter started moving. But I feel the level is a little higher. According to your recommended method of detecting the clear tube, it turned out that the level is somewhere above 5-7 mm of the bottom cap. But I was afraid to touch him, it was joy. And my wife had to go to work. The candle returned to its normal color. I didn't know how you answered. I didn't turn the carburetor cap. Your great practice is felt. We have all the craftsmen, they fill it like this: they bend the antennas, and then they pump the fuel and look at the level. This should be slightly larger than the bend in the float chamber. I can't mention it, but I think you know what I'm talking about. It didn't work for me, it was always small because the scooter was dumb, which is normal. And it took me 3 days. I installed it according to your recommendations and put the original float in place. It has a notch under the needle. The craftsmen told me that this was a development and installed a Chinese float. But as far as I understand, this should be a break. Answer. And another question: with great difficulty I got a new float valve. This worked for about a month and eventually the scooter got stuck. During disassembly, it turned out that the rubber tip remained in the channel, and the needle was on the float. It was just wrong that I had to put my family through. But every now and then I would fill up with fuel and load up on carbs. What kind of glue can stick the rubber tip to the needle? I was leaning towards super glue or epoxy, but doubted the channels would clog if the gas dissolved the glue. Or is there another way? Or just throw it away? Thanks again for the quick response and correct good advice, everything was confirmed. Guys, I recommend this site to everyone. A person who is truly knowledgeable and has a lot of practical experience.

Tuning the carburetor of a two-stroke engine

One of the main components in the fuel mixture supply mechanism in a vehicle such as a scooter is the carburetor. Before moving directly to the description of the adjustment process, let's talk about why it is needed at all.

Carburetor - a device that ensures the formation and supply of a fuel mixture (consisting of air, gasoline and oil) directly to the engine

What exactly is the purpose of a carburetor? In a nutshell, this is a device that ensures the formation and supply of a fuel mixture (consisting of air, gasoline and oil) directly to the engine. That is, the quality of this mixture and, accordingly, the power that the power unit produces depends on it.

Scooters typically use carburetors of a type called “float” carburetors. The main element is a Venturi tube, which houses a damper that regulates the amount of air supplied to the mixture, as well as a needle that supplies gasoline. By unscrewing the throttle, we thereby open the throttle and raise the needle, increasing the amount of air-fuel mixture entering the engine.

Naturally, the movements of the valve and the needle must be clearly synchronized to ensure its (mixture) homogeneity. The float chamber is designed to ensure the constant presence of gasoline in the tube. The principle of its operation is based on the fact that when the fuel level drops, the float lowers and opens a channel for supplying gasoline to the tube. When it is full, the float rises and closes the valve, thereby stopping the flow of fuel.

If the scooter's engine power drops, it is impossible to start the engine or the engine stalls - these are signs of a carburetor failure

Signs that the carburetor is faulty may include:

- Engine power drop

- Inability to start the engine

- The engine stalls.

Another way to assess the quality of the carburetor (more precisely, the correctness of its operation) is as follows - unscrew the spark plug and look at its color. If it is white, it means the fuel mixture is lean, that is, there is too much air in it, and if the spark plugs have a black tint, it means the carburetor is “pouring” too much fuel. With any of these options, one thing is clear - it needs adjustment.

It should be noted that, globally, this process does not depend on the engine stroke, therefore the answer to the question of how to correctly adjust the carburetor on a Chinese 4t scooter and how to correctly adjust the carburetor on a 2t scooter will be the same. Let's now move on to describing the sequence of actions.

How to adjust the carburetor on a scooter

This procedure can be conditionally divided into two parts - adjusting the idle speed and adjusting the quality of the carburetor mixture. However, first, the carburetor must be removed and cleaned.

Refer to your vehicle's manual to ensure proper disassembly. Thoroughly clean all its channels, as well as the jets. Unscrew the spark plug - even if it does not have the visual defects described above, it is better to replace it. Fortunately, their price is usually not high. On the fuel metering needle, find the locking ring and install it in the middle groove. After all these steps, install the carburetor back.

After checking and cleaning, which we have just completed, we proceed directly to the adjustment. You will need to find elements such as the screw that regulates the quality of the fuel mixture (hereinafter referred to as the KTS screw), as well as the idle screw. Screw the KTS screw all the way (this is done clockwise), and then unscrew it one and a half turns, and then start the engine.

Using your scooter's tachometer reading, adjust the idle speed screw so that the engine speed is at 1800 rpm. Go back to the KTS screw and, by rotating it, achieve maximum engine speed, then tighten the screw half a turn. Find the idle screw again and return the speed to 1800 rpm, while not forgetting to check the operation of the engine by ear - there should be no failures or extraneous sounds.

When the specified value is set, you need to check the operation of the power unit. Turn the lever that controls the throttle a couple of times, adding gas and releasing it.

If you don’t hear any extraneous noise in the sound of the engine and it doesn’t stall, the carburetor adjustment has been made correctly, that is, you can safely get on the scooter and go about your business.

If the problem is not resolved, then it is necessary to look for the cause in other components of the vehicle.

It is worth noting that sometimes adjustment is not enough - it is also necessary to check and, in some cases, adjust the fuel level in the float chamber.

Locate and unscrew the butter screw, which is located at the very bottom of the device. Next, you should lift the tube and check the fuel level. It is necessary to carry out these actions with the engine running, and keep the upper edge of the tube slightly above the carburetor itself. The fuel level should be slightly lower than the junction of the lower and upper parts of the carburetor.

Video tutorial on adjusting the carburetor on a scooter:

If the level is lower than required, you will need to remove the cover and adjust the timing of the valve by carefully bending its holder (this should be done in very small ranges). You can perform this entire procedure at the very beginning, so if you don’t want to remove the part once again, start the process of servicing the fuel system by adjusting the fuel level in the scooter’s carburetor.

Scooter carburetor. Correct adjustment

The carburetor is a unit whose importance cannot be overestimated. Since it is in the carburetor that gasoline is mixed with air and, thus, a fuel mixture is formed before it is directly supplied to the scooter cylinder. The quality and correct composition of the fuel mixture determines fuel consumption, wear of the cylinder-piston group and spark plugs, maximum speed and dynamics of the scooter, and much more. This is why it is so important to take a responsible and comprehensive approach to setting up the carburetor. A properly adjusted carburetor will ensure stable, reliable and productive engine operation, as well as make driving comfortable and safe.

This is interesting: Car diagnostic equipment

Unfortunately, scooter riders often, due to ignorance or lack of experience, underestimate the importance of comprehensive carburetor tuning. For example, there is an extremely widespread misconception that adjusting the degree of richness of the mixture only means adjusting the quality screw on the carburetor. In fact, this setting allows you to achieve the correct mixture only at idle and low speeds. At the same time, at medium and high speeds the proportions of the fuel mixture can be completely disrupted. Let's figure out how to properly configure the carburetor.

Before proceeding directly to adjusting the carburetor, you need to make sure that such adjustment is necessary. There are several sure signs that will help you understand whether the mixture is over-rich or, on the contrary, it is too lean. For different engine operating modes, these signs are slightly different.

Carburetor adjustment at idle and low speed

You can determine a lean mixture at low and idle speeds by the following signs:

- The scooter is hard to start and keeps trying to stall.

- Turning the throttle does not lead to the expected level of increase in speed. Information content is extremely low

- When the throttle valve is opened very sharply, the carburetor begins to make characteristic popping noises.

- The surest and most reliable sign: with a lean mixture, the spark plug will remain white, even after prolonged operation.

A too rich mixture at low speeds also has several characteristic signs:

- Rough, floating engine idle

- Significant increase in fuel consumption compared to the parameters specified by the manufacturer

- The spark plug will be a pronounced black color with noticeable carbon deposits, since the fuel mixture simply does not burn out in the cylinder.

If you notice the presence of one of these groups of symptoms on your scooter, then the quality of the mixture and idle speed need to be adjusted. This is done quite simply, using adjustment screws.

The vast majority of scooter carburetors have two of these screws. One is responsible for the quality of the mixture, and the other for the number of crankshaft revolutions at idle. When the quality screw is tightened, more gasoline is added to the fuel mixture and, accordingly, it is enriched. And, conversely, when this screw is unscrewed, the mixture becomes leaner. As for the quantity screw, by tightening it you increase the idle speed, and by unscrewing it, on the contrary, you decrease it.

Correct carburetor tuning at idle is achieved by setting the optimal ratio between the quality of the fuel mixture and the number of revolutions. In order for the scooter engine to work correctly, you must first tighten the quality screw as much as possible with the engine turned off, and then turn it one and a half to two turns. This value is considered the best for most types of engines, although it should be said that the optimal value may vary depending on the degree of engine wear and other factors.

After you have set the quality screw to the desired position, you need to start the scooter and use the speed screw to find the point at which the idle speed will be the smoothest.

Adjusting the carburetor at medium speeds

Having achieved normal engine operation at low and idle speeds, proceed to adjusting the carburetor at medium engine speeds. In general, the signs of a too lean and too rich mixture for medium and low speeds are the same, so we will not list them again.

It is important to understand that the quality screw has virtually no effect on the fuel mixture in the average engine operating mode. Here, the throttle needle located in the throttle valve is used for adjustment. Usually it can be moved up and down. Most scooters have five needle positions. In the stock version, the needle is at a medium value. When the needle is raised up, the mixture at medium speeds becomes richer, and vice versa, if the needle is lowered, the mixture becomes poorer.

Carburetor adjustment at high speeds

Adjusting the quality of the mixture at high engine speeds (with the throttle fully open) is possible only by selecting the size of the main jet. If the engine does not have enough fuel (lean mixture), then a larger nozzle should be installed, and vice versa, if the mixture is too rich, a smaller nozzle should be installed. The size of the jet is usually stamped right on it. Of course, replacing the jet is a procedure that requires certain labor costs, and therefore it is worth doing it only if it is really necessary. Here are the signs to look out for.

Signs of a lean mixture:

- When the scooter reaches maximum speed, you can hear popping sounds from the carburetor

- The spark plug is completely white. Sometimes the electrodes also melt from too high a temperature

- Poor acceleration and poor response when turning the throttle at the upper limits

Signs of a rich mixture:

- Significant excess consumption of gasoline

- Black carbon deposits on spark plugs

- Black smoke and popping noises from the muffler (if the mixture is already burning out there).

- In especially severe cases, after the throttle is removed from the maximum position, this is accompanied not by a decrease, but, on the contrary, by an increase in speed.

Signs of a properly tuned carburetor

How do you know that you have set the carburetor correctly and no further adjustment is required? An optimally tuned carburetor can be determined by the following characteristics:

- No popping noises in the carburetor or muffler

- The engine behaves smoothly throughout the entire rev range. The dynamics of the scooter are also smooth, there are no jumps

- There is no excess consumption of gasoline. Consumption does not exceed the limits specified by the manufacturer.

- The throttle grip is informative at any speed

- The spark plug color is slightly brown. No carbon deposits or melted electrodes.

Instead of a conclusion

Carburetor adjustments should only be made on a warm engine. Before adjusting, it is advisable to clean the carburetor well. Dirt and other unwanted particles will prevent the adjustment from being carried out correctly. Also check the condition of the air filter. It shouldn't be clogged. A clogged air filter will disrupt the normal proportion of the fuel mixture. It is also advisable to make sure that the compression in the cylinder is not lower than normal. When setting up, you must be sure that there are no influences of any other factors and the scooter is in normal working condition, otherwise you will simply be wasting your time.

How to adjust the carburetor on a scooter

Nowadays almost every teenager has a scooter, because it is easy to ride and is small in size. But with a scooter, like with all equipment, some parts may become unusable. The carburetor is one of the main parts of any vehicle. How to adjust the carburetor on a scooter so that it continues to work? In order to get down to business, it is best to familiarize yourself with the principle of operation of the carburetor so that it will be easier for you to cope. The operation of the carburetor is also affected by: fuel quality, atmospheric pressure, air temperature.

Features of tuning the carburetor of a 4-stroke scooter

Adjusting the carburetor of a 4t scooter is quite possible with your own hands and should not cause any difficulties, the main thing is to act according to the instructions described above. It’s not always possible to adjust; the carburetor on a 4t scooter works right away. You will have to be patient: you may have to repeat the procedure several times until you get a result that suits you. The smooth operation of the engine, the ability of the vehicle to start in cold weather, and what kind of piston wear will depend on how to correctly configure the carburetor in a 4t scooter.

4T scooters are usually equipped with similar carburetor models, so the VLC carburetor adjustment scheme described above is also applicable to other types of devices.