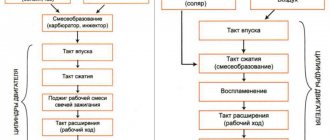

Principle of operation

Do not confuse the anti-roll bar with the stabilizer bars located behind the wheel. The stabilizer is installed below, between the posts. During rotation, the opposite side rises, and the device in this case lowers one side of the stabilizer, the other rises, and the rod begins to twist.

This aligns the vehicle with the plane of the road. The main task is performed by the central rod, the degree of twisting of which depends on the collapse of the body.

Features, design, functions

To understand what

The main

purpose of

suspension

elements such as

struts

, you just need to imagine where they

are installed

in the car, and they are located on

the anti-roll bar

.

Therefore, it can be argued that the stabilizer bar

is one of

the elements of

the vehicle’s chassis system, which

is designed

to

ensure lateral stability of

the car body.

If you imagine that a car

not

with

stabilizer struts

, then while driving when

maneuvering

the car will

listen much worse to the steering wheel

, when

cornering , you will

feel

excessive

vibration of the body body

and possibly even

the appearance of skids

.

If the struts

are in

a faulty condition

, then often

body

simply

loses balance

and

of other

suspension parts

accelerates , and at a rapid pace.

For reference, we note that significant

In recent years, a number of automakers have been trying not only

to improve the car’s suspension system

, but also to make it

easier

to

maintain

.

That is why on a large number of cars in the budget price segment

you can find

installed racks

MCPherson

type of action , which are not only

simple

in their

design

, but also meet many of

the requirements

of manufacturers.

Thus, the vast majority of independent type suspensions

are necessarily

equipped

with stabilizer struts

, which are

part of

a complex

system

.

In addition, the struts

are only

one

of

the elements of stabilization of the

car body; in

combination

with them there are also all kinds of

levers

and

suspension supports

.

As we know the suspension

A car is

a system

consisting of a large number of

individual components

and

mechanisms

that,

working

together,

provide

comfort

,

safety

and the necessary

controllability

while the car is moving .

Among the numerous suspension parts

the stabilizer

stands out separately , which is responsible for

reducing body roll

when the car enters

turns

, as well as

maintaining the trajectory

during

acceleration

and suppressing

skidding

when

braking

the vehicle.

The struts,

in turn, greatly

reduce the swaying

of the car while driving.

These elements are key

parts

of the stabilizer

, which

take

on enormous

loads

.

To some extent, the task of the struts

is to

connect the suspension

and

body

, turning them into

a single

large

mechanism

.

Based on all of the above, it’s difficult to even imagine how the suspension

The car existed

without stabilizer struts

, because even domestic cars had special

elements

that

stabilized the body

while driving.

By the way, in the same Zhiguli

,

the functions of the struts

were performed

by bushings

and

rods

.

On modern cars, if there were no stabilizer struts

, then

the body

and

suspension

own

separate lives,

without communication

each other, which is very

unsafe

, especially when

cornering .

Stabilization of the

car body is needed not only to

combine the body

with

the suspension

, but also, it is necessary to

improve the dynamic performance

and

safety

of the vehicle.

In order to understand what role the racks play

and

front suspension stabilizer

, let's look at simple real-life

examples

.

So,

all the delights

of the absence of struts

and

a stabilizer

during

acceleration

reflected , since if they were

not there

would

very

hard backwards

.

As for the braking

, the situation here

is the opposite

of the previous one, since

body,

on the contrary

would

sharply tilt forward

, and when

turning

,

the body would tilt

to

the left

or

right

side.

In addition, without the same stabilizer struts,

cars would not have

high speeds

,

fly

off

the road

in

turns

, and on

slippery surfaces

, movement would be difficult to imagine in general.

As we see, the need

in

body stabilization

was not created by engineers and designers in one day.

This system

changed

many times , and even now it is still at the

development

.

The suspension

and

body

of any modern vehicle

function

as

a single unit

, evenly

distributing loads

when

body tilts

among themselves.

Thus, it turns out that the stabilizer struts

seem to

hold the suspension elements

in a certain

balance

, thanks to

the combination of components

into one large

system

.

Just like any other detail

car,

stabilizer struts

have their own specific

service life

.

Wear of the struts

occurs due to

the high loads

that they

withstand

during

vehicle

operation In addition, the service life of the racks

is directly affected

by the quality

of the roads.

Due to the low quality of

domestic

roads

, these

suspension elements break down

and

sometimes

fail 2 times faster

than

the manufacturer’s

intended

life cycle of the part

.

Besides quality

roads, an equally important

reason for rapid breakdowns of racks

is

the quality of the fabric

from which they

are made

.

For reference, we note that warranty

on

chassis components

covers an average

mileage

of

100 thousand kilometers

, including

stabilizer struts

, but this takes into account

the quality of

European roads.

On our roads, most suspension parts

begin to “

fall apart

” already after

a mileage

of

40-50 thousand kilometers

.

In addition, do not forget about

the driving style

of the manager, since this point also has a strong

influence

on

the durability of the stabilizer struts

.

It is not for nothing that many experts

in the field of

vehicle

maintenance the more carefully

the driver drives the car, the

longer the suspension parts

, including

struts

with

stabilizer

, last.

Main signs indicating replacement of stabilizer struts

:

- Most common symptom

To quickly

replace the struts,

there is a distinct

tapping sound

while driving, which comes from

the front suspension

of the car.

The sound

especially clearly when

driving

over

uneven surfaces

or when

entering

turns

;

— Appearance of slip

car

sideways

, that is, the car begins

to pull

to the right or left while driving.

Note that experienced auto mechanics

check

the wear of struts

using

pull

-out

method , that is, while driving,

they release the steering wheel

and watch how

behaves

.

But it is worth understanding that

this

sign

does not always one hundred percent

indicate

excessive wear of the stabilizer

struts .

Sometimes the cause

may be simply

unevenly inflated tires

or

incorrectly adjusted camber

and

toe

.

We recommend: Causes of manual transmission oil seal malfunction and its replacement

— Also indicate increased wear of the struts

maybe the fact that

one side

of the car is slightly

lower

to

the ground

than

the other

.

However, in this case,

the springs

with

shock absorbers

may be the cause of the problems .

Therefore, in order for this sign

certainly

confirm a malfunction of the struts

, the car must be

checked

in

a pit

or on

a lift

.

— The final main feature

,

which may

indicate

breakdown

of the stabilizer struts

is excessive

swaying of the

car body at

speed

, when

braking

or when

entering

turns .

How to check stabilizer links yourself?

a simple method

for this that will most likely

determine the condition

of the parts.

The algorithm

for checking the serviceability of the stabilizer struts consists of

turning the front wheel

to the right or left until

it stops

.

Then we take

our hand to

the rack

, which is located in

the wheel well

and strongly

pull

it from side to side.

For reference, we note that when checking

in this

way

,

there is no need to worry

about the fact that we

will break the stand

, as we said earlier, these parts

can withstand enormous loads

, so they will definitely survive our touches.

If, when the stand swings,

it has a strong

play

, that is,

it moves back and forth

, then with a probability of 99 percent,

the stand needs to replaced

.

This method

applies not only

to the front struts

, but also

to the rear struts

, if the car has them.

In the event that we have a garage

with

a hole

, then you can

check the stabilizer links

for

serviceability

differently.

We unscrew

the bottom nut

from the rack , thereby

freeing

the part and, as with

the method

above,

pull

the element in

different directions

.

If the hinges do not provide

stubborn resistance

to us , and the actions are accompanied

by a

with

play

, then again with a 100% probability, we can say that

the rack is out of order

.

The second stabilizer link

can be

checked without unscrewing

the mounting nut.

To do this, without returning

already partially removed

first part

place

,

we rock

the car

holding

the

stabilizer

and

listen

for

possible

sounds from

the rack

.

If a knock

when

swinging

, then we get ready and go to the auto store for

a set of stabilizer struts

.

Also using a pit

You can use another

way to check the stabilizer struts

.

True, he will need the help of a friend who will rock

the car, and thereby we will go down into the hole under

the bottom of the body

in the area of

the front suspension

.

To establish the condition of the struts

, you need to

place

several fingers on

the hinge

while

is rocking horizontally

.

In the event that the rack

needs to be

replaced

, then the hand on

the hinge

will feel

a vibration

that cannot be confused with anything else.

Thus, when we imagine what tasks

perform and

why stabilizer struts are needed

, then we are unlikely to

ignore the suspicious sounds

coming from them while driving.

After all, stabilizer struts

are primarily about

safety

while

driving

, since they

directly affect

the

handling

of the vehicle.

In details

During a turn, thanks to physics, the body shifts relative to the turning axis, trying to fly off it. That is, the outer wheels try to slip out when the inner ones lift up, losing traction.

In this case, the stabilizer, with the compressed suspension of the outer wheel, compresses the rod, which twists and pulls down the other end of the beam. Thus, the inner wheel begins to be attracted to the ground. As a result, the load is redistributed, and the car is aligned relative to the asphalt plane.

Stabilizer device

It has a U-shape with left and right arms, which are attached to the rods, and they in turn are connected to the shock absorber struts.

Full set:

- main steel pipe;

- traction;

- fastenings;

- bushings.

The central rod is an elastic strut made of spring steel, which is most often not of an even shape, since the other suspension elements get in the way.

The posts provide mobility so that the central rod can be lowered and raised. The racks are a rod with hinged elements at the ends, protected by a boot. They bear the main load when cornering, so it is often necessary to replace the stabilizer rods, rather than the entire mechanism.

On average, traction rods last 30 thousand kilometers, despite the material. Yes, most often the pillars are metal, but sometimes durable plastic is used, for example, in the Chevrolet Cruze. They are not particularly inferior in reliability.

The best premium stabilizer links

This category is filled by German and American manufacturers. Their products are of the highest quality and have a long service life. Due to the reliability of the products, many concerns initially agree to install these elements on the production line on their cars.

TRW is one of the most expensive brands

Racks from this German manufacturer are produced for a wide range of European, Korean and Japanese cars, including BMW, VW, Toyota, Mazda.

The connecting rods have different lengths from 50 to 241 mm, which allows you to select a part for a car of any generation and year of manufacture. The products are suitable for both right-hand and left-hand drive models.

Pros:

- the thread diameter on the ball pin M10 ensures strong fastening in the suspension;

- solidly turned fingers are not welded, so they last longer and withstand sharp jerks;

- the overhead boot tightly compresses the rod, so the ball joint is better protected from dust, moisture and destruction;

- complete with self-tightening nuts and washers.

Minuses:

- cost from 1100 rubles;

- there are many fakes on the market;

- It is not always possible to find the part (only from official dealers or large suppliers).

Lemforder - in the best German traditions

These stabilizer links are the best in quality as there is a lot of control in their manufacturing. The German industry leader has deployed production plants not only in Europe. Now Lemforder products can be found assembled in Taiwan, which is also an original.

Pros:

- neat casting;

- smooth movement of the ball pin;

- in a triangle on the side of the rack indicates originality;

- the thickness of the connecting rod is 10.13 mm, which indicates high strength;

- are delivered in cardboard boxes, and inside there is still polyethylene, which protects the racks from drying out or getting moisture;

- The kit already includes nuts;

- the finger is equipped with a protective anti-corrosion coating;

- the back cover is completely made of metal and convex so as not to collect water;

- there is a hexagon inside the finger to hold it with a key;

- soft rubber boot.

Minuses:

- no o-ring;

- on short stands of rods with a diameter of 8 mm;

- cost from 1500 rubles;

- sometimes the package may contain stands from CTR.

Various types

Essentially there are two of them: normal and active. Active is often used in modern sports cars, its task is to change the stiffness depending on different conditions. There are several types of active stabilizers:

- with hydraulic cylinders;

- with active drive;

- with hydraulic cylinders instead of bushings.

Conventional linkages are most often located at the front, sometimes found on the rear axle with a slightly different shape.

There are also tripping stabilizers that are physically disconnected and stop working. This type is installed on the Jeep Wrangler SUV so that off-road it will greatly increase the suspension travel and, accordingly, cross-country ability.

Signs of faulty parts

It is not enough to understand what stabilizer struts are; you also need to detect their malfunction in time, because inoperative elements negatively affect the controllability of the car. Worn parts can be determined by the following signs:

- The car body begins to roll more when cornering.

- It becomes noticeable that the car describes a large arc when going around an obstacle.

- During intense acceleration or sharp braking, a slight skid of the body is felt.

- When the steering wheel is turned sharply or speed bumps pass, a dull knock is heard from the front part of the suspension.

One of the most reliable ways to diagnose struts is to conduct a “moose” test.

. The point is to go around an unexpectedly appeared obstacle at a speed of 40-50 km/h - the so-called “moose”. You need to choose a traffic-free area and place a couple of plastic bottles in a convenient place. Then accelerate to the specified speed and try to quickly drive around them.

Beam design. Anti-rental works in a similar way. He connects both levers and moves it from one side to the other. This means that if the left control arm rises during a turn, the right control arm also rises. The extent to which this movement moves is controlled by the diameter of the torsion thread in the stabilizing bar. The stiffer it is, the more the force moves.

We recommend: What kind of oil to pour into the engine

The real role of anti-bars

This will essentially cause the car to understeer, but it will also cause the car to behave very naturally once it turns. This is due to the increased clearance left on the rear axles. When driving slowly, the stabilizer bar will cause the steering wheel to respond correctly.

If during the maneuver the front part of the vehicle rolls heavily and “yaws” to the sides, and a distinct knock is heard from the chassis, then the struts must be replaced immediately. In some cases, the car describes such a wide arc while driving around that it can go into a skid.

However, this will be different when designing a car designed to turn at higher speeds. In such cases, such as on motorsport vehicles, such vehicle will be equipped with a rear crash bar. This will increase the movement of the front wheels of the "accelerating" car during a turn, when the weight transfer moves mass to the rear wheels.

How does it all work

The rigidity of the car body also plays an important role in the mass anti-bar movement. It transfers the balance of mass from the front of the car to the back, and vice versa. This is one reason why automotive designers and construction specialists strive to create more rigid structures.

You can make sure that stabilizer links are needed for replacement using the traditional diagnostic method - manually rocking the parts. To do this you need to do the following:

- Secure the car with the handbrake.

- Turn the front wheels all the way so that you can reach the right or left pillar with your hand.

- Grasp the rod near the ball pin and actively swing it in different directions. To be sure, you should pry the hinge with a mounting spatula, this will reveal the play inside the bushing.

If noticeable play is detected, the element must be replaced

. Due to poor roads in the post-Soviet countries, the racks constantly experience high loads and rarely last more than 20 thousand km. Fortunately, these parts are inexpensive and change quite quickly. If you wish, you can install new parts yourself, having the usual set of metalwork tools, a jack and a puller for pressing out the ball pins.

Worn stabilizer links do not prevent further movement, but only worsen the vehicle's handling. Even a finger that has jumped out of the sleeve allows you to move on under your own power. This is taken advantage of by careless motorists who do not pay attention to the suspicious behavior of the car and the knocking of the suspension. Such driving is dangerous and at high speed can lead to loss of control and an accident with unpredictable consequences.

Disadvantages and tuning

There are practically no shortcomings, unless you consider an SUV. The stabilizer greatly reduces the suspension travel, which is extremely important for SUVs. To solve such problems, there are active stabilizers. Passenger cars benefit on all fronts from this design.

A simple tuning is to install an STC if your car did not have one, the benefits of which you will immediately feel. If you are thinking about installing a thicker and stiffer rod, then it is better to reconsider.

Due to the strong compression of the rigid stabilizer, you will turn your independent suspension into a dependent one, thereby completely killing the car's handling. The manufacturer has calculated everything for you.