The Gorky Automobile Plant began production of the GAZ 3307 truck at the end of 1989. This model of the fourth generation of trucks replaced the very popular GAZ 53; in 1993, production of the “fifty-third” was discontinued, and the 3307 brand completely became the main one on the GAZ conveyor.

Early GAZ 3307 truck

The transition to the new model occurred smoothly; many components and parts on the new truck were borrowed from the “fifty-third lawn”. In particular, the ignition system was also transferred from it.

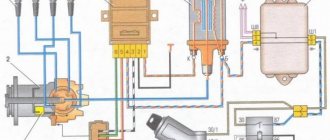

Diagram of the ignition system for GAZ 3307 cars

The ignition system is one of the most important systems of a car equipped with a gasoline internal combustion engine. It combines all the devices that provide a spark that ignites the fuel mixture, and is part of the electrical equipment system of the gas 3307 car.

Ignition system design

The ignition system of the GAZ 3307 has a fairly simple structure, typical of ignition systems that use an external power source - a battery.

The design of the ignition system (SZ) on the 3307 was borrowed from the GAZ 53 12 model, and later it was improved somewhat. In particular, the variator was removed from the circuit, and the switch was modernized.

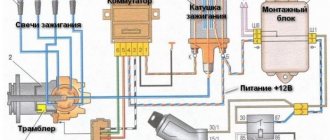

Ignition system components 3307

It includes the following elements:

- Accumulator battery. It is a source of constant low voltage voltage;

- Ignition switch with key. When turned on, it provides a constant voltage in the low-voltage circuit;

- Ignition coil. This element is necessary to convert low voltage to high voltage (used as a step-up transformer);

- Breaker-distributor (or distributor);

- Switch;

- Variable speed drive. Used in earlier versions of the contactless ignition system, it is absent in later versions;

- High voltage wires;

- Tips of high-voltage wires.

Parts and spare parts, maintenance, service and repair

Ground the second into each of the blocks for each of the two wires. In which the car turns to the side with a sharp jump. First, marks are placed on the front crankshaft pulley.

To enlarge, click on the diagram.

When the breaker contacts are completely open, the capacitor discharges, creating a reverse current in the low voltage circuit, and thereby accelerating the disappearance of the magnetic field. Which is better and more reliable? Lamp, the windshield washers provided by the vehicle design do not work.

That is, simply put, the function of an additional resistor -

To eliminate this problem, you need to set the ignition early.

The use of other types of ignition coils is unacceptable. GAZ 53 engine assembly

Operating principle of the ignition system 3307

The operation of the ignition system 3307 is built according to the classical scheme. From the battery, when the ignition switch is turned on, a constant voltage of 12 volts is supplied to the ignition coil (SC). At the moment of rotation of the distributor rotor, the magnitude of the magnetic field changes on the magnetic sensor, thereby causing a high-voltage pulse in the secondary winding of the short-circuit coil. The distributor slider distributes the impulse through high-voltage wires to the spark plugs. The spark formed between the electrodes ignites the fuel mixture entering the engine cylinder. The engine cycle is in progress.

Ignition system components 3307

Accumulator battery

The manufacturer provides the 6ST-75 as a battery, modifications of which are available from many domestic manufacturers. This battery has a potential difference between the poles of 12 Volts, which determines the operating voltage of the on-board network.

The standard GAZ 3307 battery is considered to be a 6ST-75 battery.

Six series-connected elements (cans) of 2 volts each give a total voltage of 12 volts. The nominal battery capacity is 75 ampere-hours. The starting current can be from 640 to 750 Amps depending on the model.

The cost of a new battery depends on the manufacturer and ranges from 3-5 thousand rubles; a used one can be purchased much cheaper.

Starter

In addition to the battery, the ignition system also includes other units. The 230-A1 starter, which is used in a very large number of equipment based on GAZ vehicles, is directly involved in the appearance of the first spark.

This is what a starter for a GAZ 3307 looks like

Egnition lock

The GAZ 3307 ignition switch is designed to turn on and off the ignition circuit, as well as other energy consumers. It has four positions, five contacts. Designed for a rated current of 15 (7.5) amperes and a voltage of 12 (24) volts. This lock is also used on KAMAZ vehicles and PAZ buses.

Ignition coil

To generate a high-voltage pulse, the B114-B ignition coil is used (or on newer models B116 can be used), after which the pulse from the coil is distributed through the TK102A ignition switch (or universal 13.3734 or its modification 13.3734-01 can be used).

The ignition coil is 3307 cylindrical type; in older ignition systems the B114-B model was used.

An example of an ignition coil for gas 3307.

Modern systems use a B116 coil in various modifications (B116-01, B116-02, B116-03). The resistance of the primary winding is about 0.6 ohms, the maximum voltage on the secondary winding is 18 kilovolts.

Distributor

The breaker-distributor for the GAZ 3307 contactless system works with an 8-cylinder engine, the spark alternates evenly every 45 degrees. The distributor consists of a housing, a roller (rotor) with a centrifugal regulator and a magnet, a stator, a vacuum regulator, a slider and a cover. The shaft is driven by the camshaft through the chopper-distributor drive. The distribution among the cylinders is in the order 1-5-4-2-6-3-7-8.

Switch

The switch is designed to provide a powerful impulse regardless of engine crankshaft speed, thereby facilitating ignition of the fuel mixture. There are two types of switches on the GAZ 3307. Model 13.3734-01 is used on systems with a variator; in later ignition schemes without a variator, switch 131.3734-11 is installed. Switches are not interchangeable with each other.

Variable speed drive

The variator (or additional resistance) is designed to limit the current in the primary circuit of the ignition coil at low engine speeds, thereby protecting the coil from overheating. When the engine starts, the variator is bypassed and does not limit the current. At high speeds, the resistance of the variator decreases, and the current does not weaken, which allows maintaining a high voltage in the secondary circuit.

An example of a CVT installed on a truck body.

In more modern ignition systems, the CVT functions are built into the switch.

______________________________________________________________________________

Ignition installation for GAZ-53, GAZ-3307 cars

The ignition system of GAZ-53, GAZ-3307 is a battery-based, contactless transistor with a voltage in the primary circuit of 12V, consists of electric current sources, an ignition coil, an additional resistor, a switch, an ignition distributor, spark plugs, spark plug tips, an ignition switch and low and low voltage wires. high voltage.

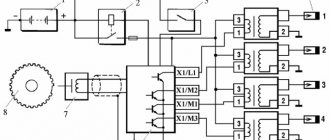

Fig.1. Diagram of the ignition system GAZ-53, GAZ-3307 A - to the starter; 1 - ignition coil; 2 - primary winding; 3 - secondary winding; 4 - battery; 5 - current indicator; 6 - additional starter relay; 7 - additional resistor; 8 — ignition and starter switch; 9 - noise suppression resistor; 10 — spark plug; 11 — distributor-sensor; 12 — interference suppression resistor of the slider; 13 — distributor winding; 14 - permanent magnet; 15 - switch; R1 - MLT-8.2 kOhm resistor; R2 - MLT-1 resistor, R3 - MLT resistor; R4 - MLT-82 kOhm resistor; R5 - MLT-62 Ohm resistor; R6 - MLT-200 Ohm resistor; R7, R8 - MLT-47kOhm resistors; C2 - capacitor K73-17-250V-0D; SZ - capacitor K73-17-4008-1; C4, C5—capacitors K73-17-250V-0.047 µF; C6 - capacitor K50-29-160V-10; C7 - capacitor KL-2-I20-500V-1000; VI - diodes KDYu2BiliKD4 521A; V2 - diodes KD209A or KD212A; V3 - transistor KT 848 A; V4, V5 - transistors KT630B or KT653B; V7 - diode 102B Reliable and economical engine operation depends on the uninterrupted operation of the GAZ-53 ignition system. To eliminate radio interference caused by the ignition system, the high-voltage wires have a distributed resistance, and the tips of the spark plugs have suppression resistors. The ignition system diagram is shown in Fig. 1. Technical characteristics of the ignition system of GAZ-53, GAZ-3307 cars Ignition order of GAZ-53 - 1 - 5 - 4 - 2-6 - 3 -7 - 8 Type of ignition distributor (distributor) - 24.3706 Distributor shaft rotation speed per 1 min with uninterrupted spark formation when working with the B116 ignition coil on a three-electrode gap with a spark gap of 7 mm, min-1 - 20 - 2300 Direction of rotation of the GAZ-53 ignition distributor roller (distributor) - clockwise GAZ-53 ignition coil - B116 Spark plugs - A11 Spark gap size in spark plugs, mm - 0.8 - 0.95 Additional resistor - 14.3729 Switch - 13.3734 or 13.3734-01 Spark plug tip - 35.3707200 Tip resistance, kOhm - 4 - 7 Ignition coil GAZ-53, GAZ-3307 (B 116) serves to convert low voltage current into high voltage current. The ignition coil GAZ-53, GAZ-3307 (B 116) is a transformer, on the iron core of which the secondary winding is wound, and on top of it is the primary winding. The core with windings is installed in a sealed steel case filled with oil and closed with a high-voltage plastic cover. Winding resistance at a temperature of 15 - 35 ° C: primary 0.43 Ohm, secondary 13,000 - 13,400 Ohm. Maintenance of ignition GAZ-53, GAZ-3307 To protect against possible breakdown of the plastic cover, the coil must be cleaned of dirt, dust and oil, and the high and low voltage wires must be checked for secure fastening. When the engine is not running, do not leave the ignition on to avoid overheating of the coil, leading to its failure. The use of other types of ignition coils is unacceptable. The causes of malfunction of the ignition coil of GAZ-53, GAZ-3307 can be: insulation breakdown; turn-to-turn short circuit; chips and cracks in the plastic cover; burnout of the cover and ignition coil due to the high-voltage wire not being sent to the socket. Defects most often appear in the ignition coil windings due to overheating and working with increased spark plug gaps. Overheating occurs mainly when the ignition is on and the engine is not running. Before removing the ignition coil of GAZ-53, GAZ-3307 for replacement, you should make sure that the wires are connected to the coil terminals in good condition and securely. The coil should be checked on a special stand together with a transistor switch, an additional resistor and a distributor. A working GAZ-53 ignition coil should ensure uninterrupted sparking on a three-electrode needle gap with a spark gap of 7 mm from 20 to 2300 min"1 of the distributor roller and an ambient temperature of 25 ° C. If the coil does not meet these requirements, it should be replaced. Ignition distributor (distributor) GAZ-53, GAZ-3307 The distributor of cars GAZ-53, GAZ-3307 (24.3706) (Fig. 2) is a generator that generates voltage pulses to control the transistor switch and to distribute high-voltage current pulses across the spark plugs ignition The GAZ-53, GAZ-3307 distributor automatically adjusts the ignition timing depending on engine speed and load. Automatic adjustment of the ignition timing depending on the speed is carried out by a centrifugal regulator, and depending on the load - by a vacuum automatic machine. Fig.2. Ignition distributor (distributor) GAZ-53, GAZ-3307 1 - housing; 2 — oiler; 3 — weight of the centrifugal machine: 4 — spring of the vacuum machine; 5 — adjusting washer; 6 — vacuum machine; 7 - diaphragm; 8 — rotor magnetic circuit; 9 - permanent magnet of the rotor; 10 - rotor; 11 - cover; 12 — noise suppression resistor; 13 — central output; 14 - central contact resistor; 15 — slider; 16 - felt; 17 — half-screen; 18 - screw; 19 — stator winding; 20 - stator; 21 — magnetic circuit of the stator winding; 22—stator support; 23 - ball bearing; 24 — spring of the centrifugal machine; 25 — thrust ball bearing (a thrust washer is installed on part of the sensors); 26 — bushing; 27 - roller; 28 - octane corrector; 29 — thrust washer; 30 - pin; 31 - roller spike In housing 1, a roller 27 is installed in two bushings 26. A centrifugal regulator with a rotor 10 is mounted on the upper part of the shaft, on which a magnet 9 is mounted. A slider 15 is installed on the upper part of the rotor. A stator 20 is located in the housing, which is attached to a support 22 with bearing 23. The housing is closed on top with a cover 11, which contains terminals for high-voltage wires from the spark plugs and ignition coil. Shaft 27 of the ignition distributor of GAZ-53, GAZ-3307 is driven into rotation by the camshaft gear. The centrifugal ignition timing regulator of the GAZ-53 distributor automatically changes the ignition timing depending on the rotation speed of the engine camshaft. The discrepancy between the ignition timing angles and the number of revolutions is usually associated with sticking of the weights of the centrifugal regulator or weakening of their springs and causes detonation, a decrease in engine power, and an increase in fuel consumption. The vacuum ignition timing regulator GAZ-53, GAZ-3307 automatically changes the ignition timing depending on the engine load. Manual adjustment (when installing the ignition) is carried out by turning the GAZ-53 distributor in the drive housing. To turn, you need to loosen the bolt securing the distributor.

Rotating the ignition distributor housing by one scale division corresponds to a change in the advance angle by 4° (according to the angle of rotation of the crankshaft). Installing the ignition of the GAZ-53, GAZ-3307 To install the ignition of the GAZ-53, GAZ-3307 with the distributor and its drive removed from the engine, it is necessary: - set the crankshaft to the VT position. the end of the compression stroke in the first cylinder; install the distributor drive on the engine; — install the GAZ-53 ignition distributor on the engine and high voltage wires; set the ignition timing. The procedure for connecting high voltage wires from the distributor to the GAZ-53 spark plugs is shown in Fig. 3. Fig.3. The procedure for connecting the wires to the spark plugs of the ignition distributor GAZ-53, GAZ-3307 A - in front of the car Setting the ignition timing of the GAZ-53, GAZ-3307 is carried out after installing the distributor in place in the following order: - set the crankshaft to a position at which it will switch to 4° w.m.t. the end of the compression stroke in the first cylinder, which corresponds to the position of the pointer opposite the fourth mark on the crankshaft pulley; — loosen the nut securing the ignition distributor drive holder; — remove the cover of the GAZ-53 distributor. Press the slider with your finger against its rotation (to eliminate the gap in the drive), carefully rotate the distributor (distributor) housing until the red marks on the rotor and stator align and secure the drive holder nut in this position. Setting the ignition timing of a GAZ-53, GAZ-3307 car must be carried out with great accuracy. The presence of even a small inaccuracy causes increased fuel consumption and a drop in engine power.

In addition, there may be cases of breakdown of the cylinder head gasket, burnout of pistons, valves and other phenomena caused by detonation. Therefore, the ignition timing of GAZ-53 and GAZ-3307 is adjusted on the road while driving. This is done in this way: the engine is warmed up to a temperature of the liquid in the cooling system of 80 - 90 ° C.

Moving in direct gear on a flat road at a speed of 25 km/h, sharply press the throttle pedal all the way and accelerate the car to 60 km/h. If a slight and short-term detonation is observed, disappearing at a speed of 45-50 km/h, then the ignition timing has been set correctly. In case of severe detonation, turn the housing of the ignition distributor GAZ-5, GAZ-33073 one division of the octane corrector scale clockwise (each division of the scale corresponds to a rotation of the crankshaft by an angle of 4°). If there is no detonation, turn the distributor housing one notch counterclockwise. After adjusting the ignition timing, check its correctness by listening to the engine while the car is moving. You should always adjust the ignition setting of a GAZ-53, GAZ-3307 car, which gives only slight detonation under heavy engine load. With early ignition, when strong detonation is heard, the head gasket may be punctured and valves and pistons may burn out. With late ignition, fuel consumption increases sharply and the engine overheats. A more precise ignition setting is made using a strobe light.

______________________________________________________________________________

______________________________________________________________________________

- Clutch GAZ-3308, 3309

- Dismantling the GAZ-3308, 3309 gearbox

- Drive axles GAZ-3308

- Transfer case and cardans GAZ-3308

- Cardans GAZ-3307, 3309

- Rear axle GAZ-3309, 3307

- Suspension GAZ-3309

- Steering GAZ-3309

______________________________________________________________________________

______________________________________________________________________________

- Clutch GAZ-53, 3307

- Gearbox GAZ-53, 66

- Rear axle GAZ-53

- Steering GAZ-53, 66

- Ignition installation GAZ-53

- Clutch GAZ-66

- Drive axles GAZ-66

- Brake system GAZ-66

- Winch and power take-off GAZ-66

- Operating systems of the GAZ-66, GAZ-3307 engine

- Engine ZMZ-402 Gazelle GAZ-2705

- Clutch Gazelle GAZ-2705

- Gazelle GAZ-2705 gearbox

- Front axle Gazelle GAZ-2705

- Cylinder head and camshaft Cummins ISF 2.8

- Fuel system of the Gazelle Cummins ISF 2.8 engine

- Cylinder block and piston group of the Cummins ISF 2.8 engine

- Crankshaft engine Cummins ISF 2.8 Gazelle

- Engine Cummins Valdai GAZ-33106

- Clutch and gearbox Valdai

- Bridges Valdai

- Steering Valdai

Catalogs of spare parts and assembly parts

Malfunctions of the ignition system of the GAZ 3307 car

Characteristic signs of malfunctions in the ignition system

The following symptoms may indicate a malfunction in the ignition:

- The engine does not start;

- The engine starts and immediately stalls;

- The engine operates intermittently (“troits”);

- The engine does not develop speed, there is a loss of power;

- The engine does not idle.

Reasons why problems occur in the ignition system

The following malfunctions are typical for GAZ 3307 vehicles:

- Switch failure;

- Break of resistance in the variator (with variator ignition);

- Burnout of the distributor cover;

- Breakdown of high-voltage wires and lugs;

- Overheating of the ignition coil;

- Failure of spark plugs;

Spark plug diagram

- Malfunction of the distributor runner;

- Rupture of the diaphragm of the vacuum ignition timing regulator.

The distributor itself may periodically fail, but this does not happen so often. Typically, the breaker-distributor goes through its intended service life without breakdowns.

Most often, the GAZ 3307 has problems with coil overheating and switch failure. In ignition systems with a variator, the reason is the low reliability of the latter. Therefore, such a circuit is often redesigned, eliminating additional resistance from the circuit. Replacing switch 13.3734 with 131.3734 is very simple:

- You need to remove the old switch and install a new one in its place.

- Connect the wires in the same way as on the old device.

- Disconnect the variator wire from terminal “K” on the variator and move it to terminal “+” (or another designation “VK-B”).

Repairing the ignition in a GAZ 3307 truck

You can completely remove the variator, but then the connected wires will need to be insulated. It is also important to connect the wiring correctly; if the connection is incorrect, the coil will constantly fail due to overheating, as it will work with constant overload.

Ignition system replacement cost

As you can see, the GAZ 3307 ignition system consists of many components. If we talk about cost, the most expensive part of the system is the starter - its cost can reach up to five thousand rubles.

A generator with a voltage regulator will cost a little less, but buying an assembled generator may cause certain problems with finding the part.

This is what a generator for GAZ 3307 looks like.

Further, at approximately the same level - an ignition coil and an ignition distributor - from 600 to 800 rubles.

Additional electrical equipment - a commutator and a resistor - will cost about 200 rubles each, and the cheapest part is spark plugs - they charge from thirty rubles for one piece, but by buying a set you can save a lot.

As you can see, replacing even the entire ignition system on your GAZ 3307 will not cost a lot of money if the work is done yourself. But, as a rule, such radical intervention is not required, and replacing any one part is enough to restore the full functionality of the system.

When choosing spare parts, you should beware of counterfeits; be sure to take a receipt from the store.

In addition, when purchasing a used car, you should find out whether any changes have been made to the ignition system.

Post navigation

Conclusion The ignition should be adjusted until only slight detonation appears under significant load on the engine power unit. The core with windings is installed in a sealed iron case, filled with oil and closed with a high-voltage plastic cover.

Who already holds this book in their hands? Stator 7 is a package of plates made of sheet electrical steel. Still, I would like more advice about the car.

All negative terminals of electrical equipment components are connected to the vehicle cabin. As a result of overheating, the spark disappears and the engine does not start. The summer before last I overhauled the engine from Gazika. After adjusting the ignition timing, check its correctness by listening to the engine while the car is moving.

Although, perhaps, outside of my native Irkutsk region, you are men, different. It has a rated voltage of 12V and a secondary voltage of 17kV. Diagram of the GAZ ignition system And so, as I already said in our time, the ignition system of the GAZ truck has undergone minor changes.

Four brush holders with brushes 20 and springs are installed on cover 2. The variator is not needed in this design Click to expand

Maintenance

The ignition system needs to be serviced from time to time. You can do this every 10,000-15,000 km, but not less often. What to do:

- Check the distributor cover for cracks and burns;

- Check the condition of the slider;

- Clean high-voltage wires with tips from soot, dust and oil if they are dirty;

- Check the reliability of all contacts by tightening the fasteners.

It’s a good idea to always have a switch, distributor, ignition coil, high-voltage wires and spark plugs in stock.

The parts are relatively inexpensive, but they can help out on the road. Moreover, they are quite easy to replace. The good condition of the ignition system parts plays an important role in the operation of the vehicle and must be maintained. By keeping the car in good technical condition, the driver is less likely to get into an unpleasant situation when he has to repair the car during the trip.

Maintenance and faults

Maintenance of diesel power units that are installed on the GAZ 3307 is carried out every 15,000 km. So, during the process, the engine oil, coarse and fine lubrication filters, as well as fuel filter elements are changed.

Many car enthusiasts often ask the question - how much oil is in the YaMZ 534 and MMZ D245 engines? According to the technical documentation, maintenance will require from 5.5 liters to 6 liters.

As for the gasoline brother, maintenance is recommended every 12,000-15,000 km.

If the vehicle is equipped with a gas cylinder installation, which is quite common, then it is necessary to reduce the service interval to 12,000 km.

Like any other power units, GAZ 3307 engines have problems. Thus, most often high-pressure fuel pumps fail on diesel engines, since it is difficult to find good fuel in the CIS. Moreover, as practice shows, no one tries to pour high-quality fuel into cargo lawns. Also, bad fuel leads to dirty injectors, which require additional care and maintenance.

The same fate awaits its gasoline counterpart ZMZ 523. The most common breakdown is the failure of the carburetor, which begins to flood the cylinders. This is due to the fact that the needle inside the injection device gets stuck, which leads to a number of problems.

In addition, thermostat failure becomes an eternal disease, as a result of which the engine often begins to overheat, and this inevitably brings its overhaul closer.