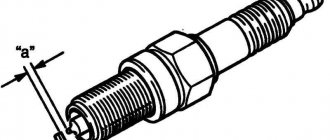

If, when there are interruptions in operation, impossibility of starting, etc., of the UAZ-469B engine, there is a suspicion of a malfunction of the ignition system, then, first of all, it is necessary to check the presence of a spark in the spark plugs.

At the same time, if between the spark plug wires and the engine housing and the high voltage wire of the ignition coil and the housing, a spark breaks through a spark gap of 6-7 mm without interruption, then the ignition system is working.

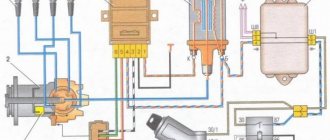

Checking the operation of the ignition system on the UAZ-469B.

If there is no spark between the high voltage wire of the ignition coil and the housing, you need to check the low voltage circuit between the battery and the ignition coil. This can be done with a portable lamp, using it as a control lamp.

If, when switched on between terminal VK-B of the ignition coil and the car body, the light comes on when the ignition is on, then the low voltage circuit is operational. If the light does not light up, you need to check the ignition switch, ammeter and wiring by connecting one wire of the test lamp in series to the ammeter terminals and the AM and KZ terminals of the ignition switch, leaving the second contact of the light bulb connected to the car body.

If the low voltage circuit between the battery and the ignition coil is working, damage should be looked for in the wires connecting the breaker lever with a contact isolated from the breaker body and the movable and fixed panels in the distributor. Breakage of these wires, as a rule, occurs after prolonged use. This malfunction can be identified using the same portable lamp.

To do this, you need to connect one of the legs of the portable lamp plug with a separate wire to the low voltage terminal on the distributor, and the second leg to the car body. Then turn on the ignition and, turning the crankshaft with the starting handle, observe the lamp. When the contacts are opened, the lamp should light up and vice versa. If the lamp does not go out when the contacts are closed, this confirms a break in one of the indicated wires. In this case, it is necessary to remove the distributor from the engine and eliminate the malfunction.

If the low voltage circuit turns out to be serviceable, it is necessary to check the condition of the breaker contacts and, if there is a malfunction, eliminate it. Interruptions in the operation of all spark plugs of the UAZ-469B engine can be caused by wear on the edges of the breaker cam, a reduced or increased gap between the breaker contacts. As well as a break in the wire connecting the movable and stationary plates of the breaker, short circuit of the primary or secondary windings of the ignition coil, a crack in the distributor cap, wear of the distributor cap carbon and a decrease in the capacitance of the capacitor.

Interruptions in engine operation at high crankshaft speeds may be the result of low pressure on the breaker contacts, which is provided by the spring of the moving contact lever. When the tension of the breaker spring is weakened, the force is less than 500 gf, vibration of the contacts occurs, which leads to interruptions in the operation of the ignition system.

If the spark is weak on all spark plugs, then it is necessary to check the fastening of the capacitor to the distributor body. In addition, a weak spark on the spark plugs may occur if, when starting the engine, the starter does not turn off the additional resistor of the ignition coil. This usually occurs as a result of oxidation of the contacts of the starter switch and slip ring.

Checking the technical condition of the UAZ-469B ignition system devices and their repair.

Checking the technical condition and repairing the B7-A ignition coil and additional resistor.

Ignition coil malfunctions include insulation breakdowns and turn-to-turn short circuits of the primary and secondary windings, breaks in the winding wires from the output terminals, cracks in the cover, as well as burnout of the additional resistor.

If the insulation of the windings breaks down, the engine stops and cannot be started. When interturn short circuits and breaks in the wires of the windings from the output terminals occur, interruptions in the operation of the engine occur. When the additional resistor burns out, the engine starts easily with the starter, but when the starter is turned off, it stops immediately.

Since when the starter is turned off, the engine can stop even if the ignition switch is faulty, you need to make sure that after turning off the starter, current is supplied to the VK-B terminal of the ignition coil. A characteristic sign of damage to the additional resistor is also normal sparking when cranking the engine with the starter and the absence of a spark when cranking it with the starting handle.

A burnt-out additional resistor must be replaced. If there is no spare resistor, it can be made from nickel wire NP-2 GOST 2179-59 with a diameter of 0.3 and a length of 740 mm. If the additional resistor comes off at the place where its ends are attached, then it must be soldered using acid-free soldering.

Checking for spark

Let's say your fuel-injected car has stopped responding to the ignition key and refuses to start. It is quite irrational to immediately complain about a malfunction in the ignition system. First of all, you need to make sure that it is the spark that has disappeared and not something else that has broken. To check spark plugs for the presence of the coveted “light”, you can resort to several procedures at once. Perhaps the most effective and simple ones are the following:

- The first method is a mass test. To implement it, you need to turn off the ignition, unscrew each spark plug in turn and, placing its body against ground (the metal body of the engine), try to start the engine;

- The second method is checking with a multimeter or a tester based on a piezoelectric element. This diagnostic option is quite similar to the method described above, except that the spark plug is applied not to ground, but to the contacts of the tester or multimeter. However, in this case there is no need to “turn” the starter; the spark must come from the devices themselves.

If, as a result of the above-mentioned testing methods, sparking on the spark plug is not detected, or there is a spark, but weak (dimmed, dim, dull), it is necessary to identify the cause of the malfunction. Do not forget that operating a car with a poorly functioning ignition negatively affects engine performance and significantly reduces its service life.

Note! Checking the spark on the injector is an extremely important undertaking, since such cars have very sensitive electronics. Considering this particular feature, it is important to carry out diagnostics carefully and as quickly as possible, that is, without numerous repetitions of the test and using only high-quality testers.

Bringing the car back to life

As for why a spark disappears, everything is probably very clear. Now, it would not be amiss to consider the order of her return. The reality is that in most cases, getting the spark back is a simple matter and just involves carefully checking the broken car. To be more precise, to normalize sparking it is required:

- Firstly, check the spark on the injector using the method described above, make sure that it has disappeared, and, at least indirectly, try to determine the cause of the malfunction;

- Next, it is enough to assess the current circumstances and act based on them. As typical situations, we suggest considering solutions to the following problems:

- the spark plug is wet, the presence and strength of the spark are unimportant, the carbon deposits are correct (brick color) - wipe the part and screw it back in;

- the spark plug is wet (not always) and the carbon deposits are incorrect (white or black) - clean, dry the part and try to start the engine, if there is no result, change the spark plug and deal with problems in the fuel system (cleaning the injector, checking the ECU, etc.);

- the spark plug is wet, there is no spark at all, the color of the soot is not important - we try to change the part, if there is no result, we check the ignition system and the operation of the injector.

In principle, in theory there are no particular difficulties in repairs of this kind. Despite this, it often causes difficulties in implementation for inexperienced motorists. To solve these, you need to act in the order described above, but if something doesn’t work out, it’s better to turn to professionals at a service station. This approach to repairs will not only save time, but also guarantee trouble-free operation of the car in the future.

Perhaps this concludes the most important information on today’s issue. We hope that the material presented was useful to you and provided answers to your questions. Good luck in operating and maintaining your car!

No spark on UAZ injector 409 engine reasons

Others, tell me. I changed the main tank, threw out the left tank, connected the hoses of the left one to each other, plugged the hose to the adsorber from the left tank with a bolt. After a month and a half, the UAZ stood for welding and painting. Before this the engine started perfectly.

Now the fuel pump is humming, the starter is turning, but does not engage at all. I rang the wires from the crankshaft sensor to the brains, rang the windings - everything works. I bring the metal to the DCV - when the ignition is on, the fuel pump turns on - that is, the DCV is working.

Where to dig next, how to start it?

Others, tell me. I changed the main tank, threw out the left tank, connected the hoses of the left one to each other, plugged the hose to the adsorber from the left tank with a bolt. After a month and a half, the UAZ stood for welding and painting. Before this the engine started perfectly.

Now the fuel pump is humming, the starter is turning, but does not engage at all. I rang the wires from the crankshaft sensor to the brains, rang the windings - everything works. I bring the metal to the DCV - when the ignition is on, the fuel pump turns on - that is, the DCV is working.

I removed the spark plug and there was no spark.

Where to dig next, how to start it?

No. There is not even an ignition switch, everything is direct: a toggle switch for the ignition, a button for the starter.

Injection engines cannot be diagnosed using these methods; this is not a carburetor. There is nothing to do there without a computer. There is no need to bring anything anywhere or call blindly. There is not a dull spark like in a carburetor, you put it on the engine and see if there is fuel flowing or not, the ECU can turn it off separately in each cylinder, as well as the fuel supply in a separate injector, the ECU can understand that some sensor is faulty and just will not allow the engine to start. You need to see the operating parameters of all sensors in the diagnostic program and nothing else. All the described manipulations of you are wasted time, it’s like pointing your finger at the sky. While the car is being repaired for a long time, for example, as luck would have it, some sensors fail, this is inexplicable. The fuel pump can pump and hum, but the pressure is weak. Unfortunately, any part works today but not tomorrow, even if the car is stationary.

Mikas 7. There is no spark when the DPKV is working properly.

No. There is not even an ignition switch, everything is direct: a toggle switch for the ignition, a button for the starter.

There are two pluses for the brain. You need to check both, maybe it’s a bug when remaking the original one.

Source

Fuel injection system failures

For proper fuel injection, the electronic engine control unit has to receive and process a large amount of information. Data comes from several sensors. Problems with any of them lead to the impossibility or complication of starting the engine.

For diagnostics, it is recommended to use a special scanner. In its absence, problems can be indirectly determined by inspecting sensors, contact connections, wiring harnesses and checking the condition of fuses.

Similar:

- Porsche Cayenne will not start In order for the Porsche Cayenne engine, like any other internal combustion engine, to start, several conditions must be met: the starter spins the crankshaft to the required speed, there is a spark in the cylinders.

- Lada Priora will not start Lada Priora is a popular Russian car, which, since its appearance, has been actively popularized among car enthusiasts in our country. It is also important that manufacturers pay close attention.

- Nissan Sunny won't start Almost every car owner, while using a car, is faced with a situation where the Nissan Sunny won't start. Without hearing the treasured sound of a running engine, it is important for the driver not to fall into disarray.

- VAZ 2112 will not start. The inability to start the engine on a VAZ 2112 is a standard problem with this model (especially with a 16-valve engine). The best solution to determine the root problem is to use.

Why does the coil not produce a spark?

Among the reasons that the vehicle does not want to start are:

- fuel does not flow to the carburetor;

- no spark from the coil;

- the current signal does not reach the coil;

- the ignition distributor is broken;

- there is no spark between the spark plug electrodes;

- no current flows to the toggle switch.

In addition, sometimes it happens that the operation of the power unit is blocked by the starter. But, first of all, you should inspect the winding of the electric motor. Perhaps there are cliffs there. If not, then, for the most part, the starter will be fine. In this case, you should inspect the coil.

Checking the spark plugs and coil

Next, it is necessary to evaluate the adequacy of the functioning of the candles. First of all, remove 2 high voltage wires from the distributor. Then we place the wiring so that it is 7 millimeters from the motor. We start the starter. If you see a blue spark, the system is working properly. If the shade is different, or there is no spark at all, it is necessary to repair the system.

Then, in a situation where you have lost the spark from the ignition coil, you need to evaluate the performance of the coil itself. The algorithm here is no different from checking candles. We take the wire that comes from the coil, and then bring it to the motor. If there is no spark when starting the engine, then the element is faulty.

But the work doesn't end there. Now you should take an ohmmeter. This way it will be possible to detect a break in the circuit. If everything is normal, then, checking the primary winding, we will see 3 Ohms, and the secondary - 7000 Ohms . If the indicators we obtain are below standard values, you should purchase a new coil.

If there is no spark from the ignition coil, you should very carefully check all the wiring and contacts. Inspect the wiring insulation; there is a possibility that there is a certain defect. First of all, it is necessary to untangle the wiring and also lay it out correctly. Then we take an ammeter. To check the system with it, you should connect the wiring of the distributor, and then turn on the ignition.

It is important that the resulting current reading does not exceed the permissible limit for your vehicle.

If the current is more than needed, this indicates a break that occurs in the event of a short circuit. As a rule, such a problem occurs when the ignition is turned on while the engine is off, which leads to a break in the high-voltage wires.

What to do if there is no spark at the injector? Possible problems

One of the most common reasons causing the inability to start a gasoline engine is the banal lack of spark at the spark plugs. Under such circumstances, there is nothing to ignite the combustible mixture on the compression stroke, and as a result, the engine refuses to work. Depending on what kind of power system the car is equipped with, it is determined exactly how to proceed to determine the exact cause of the lack of a spark and measures to return it. We’ll talk in more detail about this problem on injection engines today. Interesting? Then be sure to read the material below to the end.

How to set the ignition

In order to correctly adjust and set the ignition on a UAZ, you must follow the sequence of actions that are given in the user's repair manual.

Before you begin adjusting the ignition system, you must place the vehicle on an inspection pit or a special platform for repair work and apply the hand brake. The wheel mechanisms of the vehicle must be secured with a stopper or stop. The power unit must be turned off.

After this, you can begin installing the ignition. To do this, it is necessary to fix the piston of the first cylindrical element in the position of the highest dead center. In this case, you need to check that the hole on the crankshaft pulley coincides with the pin on the cover of the timing gear block. It is necessary to slightly lower the mounting bolt located on the plate to the distribution equipment sensor housing.

Then remove the cover from the distributor and rotate the crankshaft 180°. The octane corrector must be in the zero position. Then it is necessary to tighten the pointer to the housing of the distribution mechanism sensor with a bolt so that its position coincides with the octane corrector mark.

How to check spark on ignition coil

When you realize that the problem lies in the coil, you should repair it. But you shouldn’t immediately run to the service center if there is no spark from the ignition coil. After all, you will have to pay a lot for such services.

First you need to conduct a visual inspection of the element. Various deformations, mechanical damage, severe dirt and stains can lead to no current flowing to the ignition coil. Dirt must be wiped off with a dry cloth. You also need to pay attention to the wiring.

It is important that there is no moisture or breaks on it.

Then you should move the high-voltage wiring a little. If after this there is still no spark from the ignition coil, then it is necessary to engage in more thorough diagnostics.

Installation of ignition UAZ Bukhanka injector

I decided to name the topic exactly that “No spark after the distributor” because I didn’t find anything on the Internet for such a request, please do not delete it to the admins, please maybe someone will find my experience useful.

And so the story itself, in the middle of the city, the car stopped starting and they pushed and towed, it still won’t start, they checked the spark on the spark plug, there is no spark, they decided to check if there is a spark on the central cable after the coil, there is a fat white spark, they changed the distributor, still no spark, they changed the slider, spark We arrived at the meeting, the car still won’t start, the starter turns like crazy, still nothing, we check the switch, there is no power, there was one dead swollen capacitor in the switch, replaced no, the car started.

Solution to the problem: I replaced the coil, the spark became fat and blue and this is the main thing.

The situation when a car does not want to start, although quite common, is still very unpleasant. Especially considering the fact that it always happens precisely at the time when we are in a hurry to get somewhere. There are many reasons why the engine does not want to work, but the most common of them is due to the fact that there is no spark from the ignition coil.

Checking the operation of the ignition coil

First of all, you should make sure whether the ignition coil sparks at all. To do this, you need to remove the distributor cap and turn the crankshaft so that the contacts close, and then bring the end of the central wire going to the coil to the ground (engine cylinder block) at a distance of 5-6 mm, and then turn on the ignition.

If it is working properly, a bright spark will be observed. If the spark is weak or not observed at all, the problem is in the coil (or in the central high-voltage wire). In some cases, a situation is possible when, due to poor insulation, sparking of the ignition coil itself is observed, right along its surface.

The next step is to check its low-voltage and high-voltage circuits. To diagnose the primary winding, you need to use an ohmmeter to measure the resistance on the coil between the positive and negative contacts. It should be about 3-5 ohms. To check the secondary winding, the resistance between the positive contact and the central terminal of the coil is measured.

Here the readings should be about 6-7 kOhm. These values are indicative and may vary depending on the specific vehicle model. If the winding is broken, the ohmmeter will show zero; if there is a short circuit, the readings will tend to infinity. In this case, replacement is indicated, since, most likely, its body is leaking. On an injection engine, the coils are measured individually.

Checking the spark plugs and coil

Next, it is necessary to evaluate the adequacy of the functioning of the candles. First of all, remove 2 high voltage wires from the distributor. Then we place the wiring so that it is 7 millimeters from the motor. We start the starter. If you see a blue spark, the system is working properly. If the shade is different, or there is no spark at all, it is necessary to repair the system.

Then, in a situation where you have lost the spark from the ignition coil, you need to evaluate the performance of the coil itself. The algorithm here is no different from checking candles. We take the wire that comes from the coil, and then bring it to the motor. If there is no spark when starting the engine, then the element is faulty.

But the work doesn't end there. Now you should take an ohmmeter. This way it will be possible to detect a break in the circuit. If everything is normal, then, checking the primary winding, we will see 3 Ohms, and the secondary - 7000 Ohms . If the indicators we obtain are below standard values, you should purchase a new coil.

If there is no spark from the ignition coil, you should very carefully check all the wiring and contacts. Inspect the wiring insulation; there is a possibility that there is a certain defect. First of all, it is necessary to untangle the wiring and also lay it out correctly. Then we take an ammeter. To check the system with it, you should connect the wiring of the distributor, and then turn on the ignition.

It is important that the resulting current reading does not exceed the permissible limit for your vehicle.

If the current is more than needed, this indicates a break that occurs in the event of a short circuit. As a rule, such a problem occurs when the ignition is turned on while the engine is off, which leads to a break in the high-voltage wires.

Available in the following modifications

ZMZ 409.10 - meets the requirements for the EURO 2 environmental class. Power 142.8 hp. ZMZ 4091.10 - produced since 2007. Meets the requirements for the EURO 3 environmental class. Designed for installation on UAZ vehicles with a carriage layout (in common parlance “Loaf”). Power 125 hp. ZMZ 4911.10 - produced since 2012. Designed for the same “Loaves” and “Tadpoles”. The design includes an absolute pressure sensor and timing chains. Power 125 hp. ZMZ 40904.10 - installed on Patriot, Hunter, Pickup and Cargo. It is distinguished by the use of an absolute pressure sensor. Double-flow nozzles are mounted on the ramp. The timing belt is driven by toothed chains. Crankcase gases are sucked into the receiver cavity. The cylinder head cover has been changed; on this engine it is made of plastic. Power 142.8 hp. ZMZ 40905.10 - meets the requirements for the EURO 4 environmental class. Otherwise similar to ZMZ 40904.10

Tags: UAZ

Comments 54

Above it was suggested to unhook the wiring from the switch from terminal D from the distributor and connect it to ground (previously, instead of the explosive wire, insert a piece of wire into the coil and place it 5-7 mm from ground) with the ignition on - is there a spark? It always makes sense to have a _tested_ distributor cap, slider, distributor sensor, switch and coil with you.

We should try this

How are you doing, comrade? got out? what happened?

they dragged me)))) after that and I can’t get to it because work keeps me late

How are you doing, comrade? got out? what happened?

I'm blaming the switch, although it's new

Now I’ll say bullshit, but sometimes we don’t even notice the obvious... in the manner of a sudden death. Circuit breakers. Weight. HV wires. Filled it up.

I checked the fuses are intact

Don't you carry a spare switch with you? They sometimes get covered, especially if the mass is bad.

That’s what I don’t drive, now I’ll take half the garage with me for spare parts))))

I still have a Zhiguli, on December 31, when leaving the store, right at the turn the switch burns out, as a surprise. I've been driving ever since.

Do you have a sample? I'll tell you everything point by point

Pull out the central wire from the distributor, lean it against the engine 0.5 cm, turn it with the starter, if there is a spark, check the slider, if not, try to bridge the resistance

The first thing I did was try the central wire to ground and there was no wire. But to bridge the resistance, I’m not very good at electrics.

The box in the photo, the spiral inside, when you start the engine, power goes to the coil from the lock, you release the starter, power goes through the resistance, which reduces the load on the coil.

This happened recently. Cause 100%: the contacts on the contact group were burnt. Those. when you remove the distributor cover you will see contacts (2 pcs). So they got burnt. Cleaning cannot fix it, only replacement (tested).

Do you hear any popping noises when you turn the starter? Is there a spark? Does it catch on? Or completely deaf?

Insert the spark plug wire into the coil and check if there is a spark. If there is one, look at the distributor slider.

no spark, I tried that

Check the distributor. The wiring is attached to it on the side, sometimes unscrewed.

Stands in place and is screwed

He may be standing, but there is no contact. Hanging on one insulation.

Check the plus on the coil, if not, then the variator, whether there is a plus on it from the ignition, check the plus on the switch, if there is, then take terminal D and poke it to ground, while bringing the high-voltage one from the coil to ground, pulling it out of the distributor. If there is, then the sensor in the distributor has run out, if not, then the switch. PS in practice, when there are breakdowns, most often the variator, then the switch, less often the distributor, and even less often the coil.

+ there is both here and there

Check the plus on the coil, if not, then the variator, whether there is a plus on it from the ignition, check the plus on the switch, if there is, then take terminal D and poke it to ground, while bringing the high-voltage one from the coil to ground, pulling it out of the distributor. If there is, then the sensor in the distributor has run out, if not, then the switch. PS in practice, when there are breakdowns, most often the variator, then the switch, less often the distributor, and even less often the coil.

Which sensor is the sensor in the distributor running out?

a thin wire goes to the distributor, it is screwed on the side, unscrew it and poke it to ground, if there is a spark from the central coil, then the sensor has ended in the distributor.

Which sensor is the sensor in the distributor running out?

pull the central one out of the distributor and keep it at a distance of 1-2 mm from the mass

Which sensor is the sensor in the distributor running out?

If there is only one wire coming off the distributor, then it is a contact distributor. The pin on the contact has worn off and it won’t press out. See contact. It was so.

UAZ Hunter won't start

#1 askar12v

- Users

- 221 messages

- City: Kazan

- Gender: Man

Post edited by askar12v: 31 October 2011 — 13:36

- Top

- Nickname or quote

#2 samo123

- Sochi city

- Gender: Man

- Top

- Nickname or quote

#3 089

- City: Pereslavl Zalessky

- Gender: Man

Attached files

- re_Hunter.rar 5.8MB 68 Number of downloads:

- Top

- Nickname or quote

#4 Alexander72

- City: IVANOVO

- Gender: Man

Go to the lambda probe and look at the wires, by any chance, not on the muffler? Smell the block and if it smells, buy a new one along with untrained keys and throttle valve.

- Top

- Nickname or quote

Site about off-road vehicles, SUVs, off-road vehicles

The procedure and methods for starting an injection engine are the same at any outside temperature, but they have some differences depending on the temperature state of the engine itself. Problems with starting the ZMZ-409 engine may occur in the event of a malfunction or interruption in the operation of the following systems: starting system, ignition system or fuel injection system.

The procedure for starting the ZMZ-409 engine at an outside temperature of minus 20 degrees and above.

It is described in detail in the operating manual for the corresponding UAZ car model. When starting the engine, the control system will independently set the fuel supply and ignition parameters necessary for starting, and after it starts, it will automatically set high idle speeds and will gradually, as the engine warms up, reduce them to minimum. It is not advisable to start the engine if the electric fuel pump has not yet turned off or if the engine fault diagnostic lamp is on.

The procedure for starting the ZMZ-409 engine at an outside temperature of minus 20 degrees and below.

If the ambient temperature is below minus 20 degrees, then starting the ZMZ-409 engine without preliminary preheating of the crankcase oil and coolant is not recommended. As a last resort, before starting you need to at least warm up the engine intake receiver with warm steam or water. The starter cranking time should be no more than 10 seconds, and re-cranking is allowed no earlier than after one minute.

In addition, on a ZMZ-409 engine of Euro-2 environmental class, before starting it in cold weather or if two or three preliminary attempts to start the engine were unsuccessful, the cylinders can be purged with air. To do this, you need to press the gas pedal all the way and turn on the starter for 2-3 seconds.

The electronic engine control unit performs the “Engine cylinder purge mode” function. In this mode, there is no fuel supply and excess gasoline is removed from the cylinders by a stream of fresh air, and the spark plugs are dried. After purging, you must try to start again as usual.

If two or three starting attempts are unsuccessful, then in order to save the battery life, you must immediately proceed to analyze and search, and then eliminate problems with starting the engine or general malfunctions in the operation of its systems.

Problems with starting the ZMZ-409 engine due to a malfunction of the starting system, abnormal operation of the starter.

Malfunctions in the ZMZ-409 engine starting system usually manifest themselves in abnormal operation of the starter, and the following main malfunctions can be roughly identified:

The starter does not turn on.

In most cases, the cause is irregularities in the contact connections, an open or short circuit in the starter activation circuits, a malfunction of the additional starter activation relay, or a malfunction of the traction relay.

When the starter is turned on, repeated clicking noises are heard.

This is most likely a malfunction of the holding winding of the traction relay, the battery is severely discharged, or the contact connections in the starter circuit are loose.

The starter turns on, but its armature either does not rotate or rotates slowly.

In most cases, the reason lies in a discharged battery, broken contact connections of the circuits, burnt contacts of the traction relay, contamination of the commutator or wear of the brush, interturn or short circuit in the starter windings.

The starter turns on, its armature rotates, but the engine flywheel is stationary.

The reason is the weakening of the starter's attachment to the clutch housing, damage to the teeth of the flywheel or drive gear, slipping of the freewheel of the drive, breakage of the lever, drive ring or buffer spring of the starter drive.

The starter does not turn off after starting the engine.

The reason is a malfunction of the starter freewheel clutch or baked contacts of the traction relay. In the event of such a malfunction, the engine must be stopped immediately.

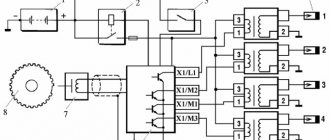

Problems with starting the ZMZ-409 engine due to a malfunction of the ignition system.

In most cases, the on-board self-diagnosis system immediately detects faults in the ignition system and displays them in the form of appropriate error codes. If no codes are recorded, then after checking, with the ignition off, the strength of the individual ignition coils and wiring harness contacts, or the integrity and fit of high-voltage wires in the two-terminal ignition coils, you need to check for the presence of a spark on the spark plugs.

In the case of an individual ignition coil, first, before checking the presence of a spark, it is worth inspecting the surface of its tip for breakdown of the insulator. Upon careful examination, the breakdown site is clearly visible and stands out in the form of characteristic black dots or dashes. If a breakdown is detected, the coil must be replaced with a new one.

Check for spark on spark plugs.

The procedure for checking the spark on spark plugs is quite simple and does not require any special comments. If there is no spark, then the individual ignition coil must be replaced with a new one, and in the case of two-terminal ignition coils, it is also necessary to additionally check the serviceability of the high-voltage wires, replacing them with known good ones. The procedure for checking the serviceability of a two-terminal ignition coil is described in detail in a separate material.

If no malfunctions are detected in the engine ignition system, then most likely problems with starting the ZMZ-409 engine are associated with malfunctions in the fuel supply system or fuel supply control system, or with incorrect operation of one or more control system sensors, for example, a crankshaft position sensor.

Problems with starting the ZMZ-409 engine due to malfunctions in the fuel injection system.

The vast majority of malfunctions of the fuel injection system, which directly affect the ability to start the ZMZ-409 engine in any thermal state and at any ambient temperature, are caused by a failure of the crankshaft position sensor or mass air flow sensor.

In addition, problems with starting the ZMZ-409 engine at negative ambient temperatures may arise due to a malfunction or incorrect operation of the coolant temperature sensor and the air temperature sensor entering the cylinders, on those engines in which it is installed separately in the receiver.

After turning on the ignition, the on-board self-diagnosis system of the electronic engine control unit usually informs about malfunctions or problems in the operation of all these sensors, issuing the corresponding error codes.

The warmed-up ZMZ-409 engine starts and stalls.

The reasons for this engine behavior may be increased or decreased fuel pressure. Increased fuel pressure may occur due to:

- clogged pipelines, hoses and drain circuit elements - faulty or leaky fuel injectors - faulty fuel pressure regulator

Low fuel pressure may be due to:

- leakage or clogging of pipelines and filters - malfunction, coking or clogging of fuel injectors - insufficient performance of the electric fuel pump or its malfunction - malfunction of the fuel pressure regulator

The ZMZ-409 engine starts only when the gas pedal is pressed.

If the ZMZ-409 engine starts only with the gas pedal partially pressed, and the self-diagnosis system of the electronic control unit does not record any fault codes, then most likely the reason is contamination of the bypass channel of the idle speed regulator or its malfunction.

Source

Additional recommendations

If there are signs of engine failure, immediately check the serviceability of the spark plugs. When disconnecting wires, mark them “-” and “+” (this will help you not to confuse the polarity when connecting).

If you encounter difficulties with diagnosing, repairing or replacing elements of your car’s ignition system and the car has a very weak spark on the spark plugs, you will find a suitable auto service center at Uremont.com. Advantages of our aggregator site:

- works for Russia, Kazakhstan and Belarus;

- interactive map with partner service stations;

- you can always request information in the “live” chat;

- portal maintenance is carried out around the clock;

- For ease of selection, the site has user ratings and ratings.

What to do next

So, the reason why there is no spark from the coil has been discovered. Now we need to decide what to do next. There are two main options:

- repair the faulty element;

- purchase a new coil, and then replace it.

Repairing a unit is a rather complex process. Here it is necessary to disassemble the mechanism into its component elements, then check them for various chips, scratches and other defects, and then clean up the damage. Then you need to restore the shell using glue or a special composition.

To replace the coil, you need to select a model with similar parameters.

It is important to connect the connecting wires correctly, otherwise there is a high risk of overheating and a short circuit. If a spark appears during the test, and the data obtained by the ohmmeter and ammeter are within normal limits, then you should look for a problem in the remaining elements of the ignition system.