What is VROZ and how does it work?

VROZ is a device that resembles a stabilizer in its operation, the task of which is to control the operation of the motor. Without VROZ, the engine will definitely not function stably.

If you delve into the functional tasks of the device in more detail, it becomes clear that the VROZ not only controls the operation of the engine, but regulates the ignition system during load on the power plant.

Note. As is known, during a heavy load on an internal combustion engine, its cylinders begin to actively fill with fuel assemblies (fuel mixture), thereby increasing the pressure at the moment of ignition. Conversely, if the load is light, the pressure decreases, which also reduces the combustion rate.

How does a vacuum ignition timing regulator work?

VROZ is able to regulate the points described above. When required, the advance angle or SOP is automatically reduced or increased.

For example, when the load on the power plant decreases, the following happens. The damper closes at the place where the regulator is connected. This correspondingly leads to an increase in the aperture. It moves and is affected by the pressure difference, thereby overcoming the resistance of the spring. Thus, there is an increase in SOP.

As for reducing the SOP, everything happens in a similar way, only in reverse order. The damper opens completely, the diaphragm and rod move, and the plate rotates.

Design and principle of operation

The main task of the vacuum advance regulator is to regulate the ignition during a change in the throttle opening angle, that is, during a change in the load on the engine. During light loads, the filling of the cylinders with the working mixture decreases, and hence the pressure at the moment of direct ignition.

At the same time, contamination of the entire mixture with gases from the residue increases, and this reduces the combustion rate. This, in turn, requires a larger ignition advance angle. That is, the sparking process must occur earlier. An increase in load brings a decrease in residual gases. The air loss coefficient is placed in the range of 0.8–0.9.

In order to correct the exact ignition timing, a regulator is needed. If the load decreases, the shutter closes at the place where it is connected, which leads to an increase in the diaphragm. The pressure difference acts on the diaphragm, which moves, overcoming the force of the spring, and then, with the help of traction, turns the moving plate towards the rotation of the cam. That is, the sensor rotor. In the process, the ignition angle increases.

If the load increases, the throttle valve itself opens, and the vacuum in the regulator drops. In this case, the spring shifts the diaphragm to the left, and does the same with the thrust. The latter rotates the plate, as well as the breaker, in the direction in which the cam rotates. This reduces the ignition angle.

As for the device, the vacuum ignition timing regulator is usually installed on the distributor. It also consists of a static body with a cover that is made of fabric. These two elements are separated by a special diaphragm. Also, the vacuum ignition timing regulator includes a spring of the same diaphragm and a thrust spring. It is clear that it is he who is responsible for vacuum ignition timing.

Where is the VROZ located and what is the danger of its failure?

VROZ is installed on the distributor. The latter consists of a body with a lid made of fabric. The two elements are separated by a special diaphragm. VROZ includes springs and other components.

How to check ignition timing

A malfunctioning regulator can easily result from problematic engine operation. There will be no ignition adjustment.

It is enough to look at how the crank shaft rotates after insulating the hose with VROZ to understand the importance of the operation of the regulator.

The cause of VROZ failure may be jamming of bearings or loosening of fasteners. The tightness of the VROZ is a very important thing, and it can easily be damaged if the tube leaks air somewhere. Also, the loss of tightness will be affected by low tightness of the fitting, critical damage to the diaphragm and much more.

You can clearly see what happens to the engine when the VROZ is damaged or loses its tightness in the table below.

Article on the topic: Differences between a diesel engine and a gasoline engine - which is better to choose?

| Causes of malfunction | Remedies |

| Insufficient gap between breaker contacts | It will be enough to adjust the gap |

| Contamination of the distributor slider and cover, the appearance of cracks in them, leading to greater leakage of high voltage current, burning of the sockets in the cover | Wipe the slider and lid. If there are cracks or burnt sockets, the faulty slider or cover must be replaced |

| Burning breaker contacts | Clear contacts |

| Excessive wear of the roller bushings, uneven wear of the distributor cam, severe wear of the moving contact axis | Disassemble the distributor, replace worn parts, assemble and adjust the distributor |

| The engine does not develop full power | |

| Breaker lever spring weakening | Check the pressing force of the breaker contacts and, if it is lower than required, replace the spring |

| Ignition installed incorrectly | Check that the ignition is installed correctly |

| The centrifugal ignition timing regulator is faulty | Disassemble the distributor and fix the problem |

| The vacuum ignition timing regulator is faulty | Check the condition of the vacuum regulator tube and, if damaged, replace the tube. If there is no damage, check the vacuum regulator on the stand and replace if necessary. |

Vacuum ignition accelerator

The vacuum ignition timing regulator is an element of the ignition system of VAZ 2108, 2109, 21099 cars

Purpose of the vacuum ignition timing regulator

The vacuum ignition timing regulator is designed to automatically adjust the ignition timing depending on the load on the car engine (throttle valve opening degree). Changing the ignition timing using a vacuum regulator leads to more efficient combustion of the fuel mixture at different engine operating modes and, accordingly, an increase in its power and throttle response.

Location by car

The vacuum distributor housing is located on the ignition distributor (distributor), and its support plate is located inside the distributor.

Vacuum ignition timing regulator device

The vacuum ignition timing regulator for VAZ 2108, 2109, 21099 cars consists of a housing, inside of which there is a diaphragm with a return spring. A rod is attached to the diaphragm at one end. The other end of the rod is attached to a support plate on the ignition distributor shaft. The vacuum supply tube connects the fitting on the vacuum regulator body and the fitting of the channel exiting above the throttle valve in the carburetor body.

Operating principle of the vacuum ignition timing regulator

— When the engine is idling, the throttle valve is closed, the vacuum in the space above the throttle is low and does not affect the position of the membrane in any way - the vacuum regulator does not work.

— As the throttle valve opens (the driver presses the gas pedal), the vacuum in the carburetor mixing chamber increases and is transmitted through the tube from the carburetor to the vacuum regulator housing, behind the diaphragm. The diaphragm moves against the resistance of the spring. Its rod is pulled into the body and rotates the support plate with the Hall sensor against the rotation of the ignition distributor shaft. This leads to the fact that the slots in the screen on the ignition distributor shaft pass through the gap of the Hall sensor earlier and, accordingly, it begins to produce its impulse to the switch and then to the coil and spark plugs earlier. The ignition timing increases (earlier ignition). The fuel mixture in the cylinders is burned most efficiently.

— As the load on the engine further increases (even more or even completely open the throttle), mixture formation in the engine cylinders improves, and the need for early ignition timing disappears. At large opening angles of the throttle valve, the vacuum in the carburetor mixing chamber drops and the vacuum regulator diaphragm moves back, returning the support plate with the Hall sensor into place. The ignition timing becomes later and returns to normal.

Malfunctions of the vacuum ignition timing regulator

A broken diaphragm, a leaky vacuum supply tube, a stuck base plate, a clogged channel in the carburetor body, or a leaky housing lead to failure of the vacuum ignition timing regulator. And this, in turn, entails a drop in the power and throttle response of the engine, an increase in its fuel appetite, since due to an incorrect ignition timing (not corresponding to the given engine operating mode), afterburning of residual gases and mixture formation in the cylinders worsen.

In some cases, you can check the vacuum regulator to identify the problem.

Applicability of the vacuum ignition timing regulator on VAZ 2108, 2109, 21099 cars

— On engines 21081 of VAZ 21081, 21091 cars, an ignition distributor 40.3706-10 with a red mark on the cover was installed. On engines 2108, 21083, the ignition distributor is 40.3706 or 40.3706-01. They have different characteristics of the vacuum ignition timing regulator (see “Notes and Additions”).

Notes and additions

— Changing the ignition timing angle with a vacuum regulator at different engine crankshaft speeds.

| Distributor 40.3706 | Distributor 40.3706-10 | ||||

| shaft speed | angle change | underpressure | |||

mm r. Art.

mm r. Art.

— Fine tuning and adjustment of the centrifugal regulator is carried out on special stands. It is not practical to produce it at home.

More articles on the ignition system of VAZ 2108, 2109, 21099 cars

Vacuum ignition timing regulator

- a mechanism designed to change the ignition timing depending on the engine speed (crankshaft speed) and the load on the engine, which depend on the degree of throttle opening. It is an integral part of the breaker-distributor.

It is a membrane mechanism that uses the difference between atmospheric pressure and pressure in the near-throttle space of the intake tract. A rod is attached to the spring-loaded membrane of the machine, moving the plate with the breaker contacts attached to it. On one side of the membrane there is a cavity of atmospheric pressure, on the other side a vacuum is supplied from the space around the throttle. As the throttle valve is opened slightly and the engine speed increases, the speed of the air flow flowing around the throttle valve and the wall of the first chamber of the carburetor increases, in which, in front of the throttle valve and in its immediate vicinity, there is a channel opening connected to the vacuum ignition timing regulator. Thus, a vacuum is created in the channel due to Bernoulli’s law and the vacuum regulator comes into operation. The higher the crankshaft rotation speed, the more the plate moves against the rotation of the chopper shaft, thereby increasing the ignition timing. When the engine is running under load, the engine speed drops, thereby reducing the air flow speed in the throttle area and the vacuum in the vacuum channel decreases. In response to this, the vacuum regulator comes into operation again and the ignition timing decreases. However, the vacuum regulator operates only at low engine speeds, when the gap between the edge of the slightly open throttle valve and the wall of the first chamber of the carburetor is relatively small and even at low engine speeds there is a fairly intense air flow in the gap. This is a consequence of the same Bernoulli law and creates a vacuum in the vacuum ignition timing channel. At higher speeds and greater throttle opening, the centrifugal ignition timing regulator comes into operation.

How to check VROZ

To check the VROZ, you must first turn off the engine to avoid various critical situations.

Next, the distributor is disassembled:

- You need to remove the distributor cover and the slider itself;

- Next, remove the plastic protection, which is located after the slider;

- Remove the tube through which the vacuum flows.

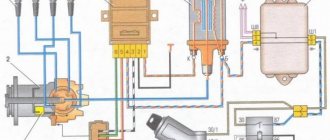

Vacuum ignition distributor regulator and its connection diagram

Then you need to create an artificial vacuum:

- He sucks in air through his mouth;

- At the same time, you need to watch the movement of the diaphragm.

During normal operation of the VROZ, the diaphragm must be retracted into the housing during vacuum, thereby moving the DH plate (Hall sensor). Otherwise, if the diaphragm remains stationary, the VROZ must be replaced.

Here's how the replacement is done:

- The stop washer is dismantled;

- The diaphragm rod is disconnected from the plate;

- The fixing screws of the VROZ housing are unscrewed;

- The regulator is removed from the distributor;

- A new VROZ is installed.

Pump test

Obviously, it will not be possible to thoroughly check the operation of the VROZ by checking the vacuum alone. Or rather, you should also check the tightness. This can only be done after removing the mechanism from the car.

So, the VROZ has been removed, now it needs to be checked. The main tool in this case is a pump. VROZ is lowered into water poured into some container. Next, the pump is connected to the regulator. Air is pumped inside the mechanism chamber. If bubbles are noticeable in the water, it means there is damage, right in the place where the air comes out.

Checking the vacuum regulator pump

This often happens - air comes out directly at the fitting. In this case, there is no need to replace the VROZ. It will be enough to tighten the fitting. The same can be said if air escapes at the rolling point. Here it is advisable to seal the joint using a hammer. In addition, you can coat the damaged areas with epoxy, first thoroughly drying and cleaning the regulator.

Article on the topic: Rules for transporting children under 12 years of age in a car

If the diaphragm is damaged, it is impossible to do without a full replacement of the VROZ.