Checking the pressure in the engine power supply system

The pressure in the fuel rail can be checked with a conventional pressure gauge (for example, from a tire pump).

We carry out the work on a cold engine. Relieve the pressure in the engine power supply system (see “Replacing the fuel filter”). Remove the plastic engine screen. We put an oil and petrol resistant reinforced hose (with an internal diameter of 12 mm) onto the threaded fitting of the pressure gauge and secure it with a clamp. Unscrew the plastic cap of the fitting on the fuel rail

Using the wheel valve cap, unscrew the spool valve from the fuel rail fitting. We put the pressure gauge hose on the ramp fitting and secure it with a clamp. We put the wire on the “negative” terminal of the battery. Turn on the ignition. In this case, the fuel pump should turn on, the operation of which can be monitored by ear.

We measure the fuel pressure in the system... ...which should be 3.6–4.0 bar. After stopping the pump, the pressure may decrease slightly and then stabilize for a while. If the pressure in the system is more than 4.0 bar, the fuel pressure regulator is faulty. Low but stable fuel pressure in the power system can be caused by a clogged fuel filter or fuel module strainer, as well as a malfunction of the fuel pump or fuel pressure regulator. To check the fuel filter for contamination, you must remove it (see “Replacing the fuel filter”), drain the remaining fuel from the filter and blow it through a piece of hose (you can use your mouth). The resistance to air passage during purging should be insignificant. Otherwise, we replace the fuel filter with a new one, which we recommend always keeping in stock. We check the condition of the fuel module strainer after removing and disassembling the module (see “Removing and disassembling the fuel module”). If the mesh filter is very dirty, clean and rinse it. If the fuel pressure in the engine power supply system is low and continues to drop after the pump is turned off, this may be due to leaky fuel module connections, a pump malfunction, or leaking injectors. To find the cause of the malfunction, turn on the fuel pump again, and after stopping it, completely pinch the rubber hose supplying fuel to the fuel rail. If the pressure stabilizes, then the fuel module is leaking or the pump is faulty. If the pressure continues to drop, one or more injectors are leaking. A leaking injector can usually be identified by the dark color of its nozzle, which contains coked droplets of fuel. To check the serviceability of the fuel pressure regulator, connect the pressure gauge hose directly to the outlet fitting of the fuel module. Turning on the ignition, measure the fuel pressure. If the fuel pressure in the system is low but stable, the regulator is releasing pressure too quickly and needs to be replaced.

Troubleshooting

No pressure in the fuel rail? Causes:

- Clogged fuel filter;

- Clogged fuel pump filter;

- Fuel pump malfunction;

- Malfunction of the fuel pressure regulator (FPR). And with high blood pressure too.

If the pressure in the fuel rail gradually drops, the cause may be:

- leaking fuel pump connections;

- leaking injectors;

- fuel pump malfunction.

Let's check it like this. We clamp the leading rubber hose of the fuel rail:

- the pressure has become stable - the fuel module is leaking or the pump is faulty;

- the pressure drops - the injector(s) are leaking.

Checking the RTD. Connect the pressure gauge hose to the outlet fitting of the fuel pump and turn on the ignition:

- the pressure is low but stable - this means the RTD is faulty and is releasing pressure too intensely.

If the pressure in the fuel rail is within normal limits, we look for the causes of engine malfunctions elsewhere.

Source

Signs of a malfunctioning fuel pressure regulator

The fuel system of a modern car is a complex mechanism consisting of many parts and is one of the main systems. The fuel system contains many moving parts, one of which is the fuel pressure regulator. The flow of gasoline into the combustion chamber requires constant maintenance of a certain pressure, so this operation requires a special unit that is connected to both the combustion chamber (injectors) and the fuel system (via a valve).

However, over time, with constant and long-term operation of this unit, certain problems arise in the form of malfunctions, which can lead to certain problems in operation.

Signs of a malfunction of the fuel pressure regulator in Priora, VAZ

The fuel system of a modern car is a complex mechanism consisting of many parts and is one of the main systems. The fuel system contains many moving parts, one of which is the fuel pressure regulator. The flow of gasoline into the combustion chamber requires constant maintenance of a certain pressure, so this operation requires a special unit that is connected to both the combustion chamber (injectors) and the fuel system (via a valve).

However, over time, with constant and long-term operation of this unit, certain problems arise in the form of malfunctions, which can lead to certain problems in operation.

Components

This part consists of several main elements:

- The diaphragm valve is the main part of the regulator and is connected to the fuel supply system and the combustion chamber (injector rail). In most domestic models (such as VAZ 2115, 2110, 2114 and Lada Priora) this unit is presented in a similar configuration, since the fuel supply systems of front-wheel drive vehicles of this family have a similar design. Therefore, the quality of breakdowns for these machines is similar;

- Pipes connected to the valves and combustion chamber on one side and, through other valves, to the fuel line on the other. The device in the VAZ 2107 models is somewhat different due to an older and unreliable design. When using equipment for rear-wheel drive, old components of an outdated design are used (the valve may work unstable when operating in a carburetor engine and the wrong choice of fuel mixture enrichment) so its design is somewhat different, although problems arise.

Failure

The design of this unit is quite simple to operate, but the valve can also fail.

This will entail certain negative consequences and the main signs will be:

- Increased fuel consumption due to partial failure of the element. When the valve unstably performs its functionality, the pressure in the rail and the fuel system drops, there is an excess supply of gasoline to the combustion chambers, which causes significant fuel consumption. This also entails, in addition to increased gasoline consumption, increased wear of the element, which will ultimately lead to complete failure of the part;

- Unstable engine operation at idle speed. If the fuel supply is poor, the engine cannot reach its optimal level of operation, so the idle air regulator operates unstably. If there is insufficient pressure and the fuel pressure regulator fails, its supply either stops or fuel flows freely through the system. This can also cause the engine to start poorly, which requires increasing the load on the starter, also causing wear. This effect manifests itself during mechanical wear of the valve, when the failure of one part of it ensures poor pressure balancing between the fuel and air;

- The crankshaft cannot maintain a constant speed level. This effect is dangerous because this malfunction can involve many elements of the system, and the malfunction of this regulator is an indirect cause of such a breakdown. Unstable operation of the crankshaft not only disorganizes the driver, but also reduces engine life (albeit slightly);

- Deterioration of engine power qualities. If the fuel supply is poor, the engine cannot fully realize its potential when moving, so its performance decreases. This causes a deterioration in the dynamic qualities of the motor and affects its service life;

The video shows signs of a malfunctioning fuel pressure regulator:

Diesel engine problems

For diesel engines, the situation is generally similar, but it can also lead to the inability to start the engine, since if the regulator in the diesel unit is completely faulty, fuel supply is impossible.

The video shows signs of a malfunction of the diesel fuel pressure regulator:

In order to eliminate this malfunction, it is necessary to completely replace the faulty element with a new one. The average cost for domestic cars is about 400 rubles.

Components

This part consists of several main elements:

- Diaphragm valve is the main part of the regulator and is connected to the fuel supply system and combustion chamber (injector rail). In most domestic models (such as VAZ 2115, 2110, 2114 and Lada Priora) this unit is presented in a similar configuration, since the fuel supply systems of front-wheel drive vehicles of this family have a similar design. Therefore, the quality of breakdowns for these machines is similar;

- Pipes connected to the valves and combustion chamber on one side and, through other valves, to the fuel line on the other. The device in the VAZ 2107 models is somewhat different due to an older and unreliable design. When using equipment for rear-wheel drive, old components of an outdated design are used (the valve may work unstable when operating in a carburetor engine and the wrong choice of fuel mixture enrichment) so its design is somewhat different, although problems arise.

How often should the Priora fuel filter be replaced and why?

A worn element has less capacity and can lead to engine failure and premature wear of fuel system components.

You can install a fuel filter on a Lada Priora within 15-20 minutes. The expenditure of time and money will be minimal, and transport will begin to operate as normal. Therefore, it is not recommended to neglect repairs.

Failure

The design of this unit is quite simple to operate, but the valve can also fail.

This will entail certain negative consequences and the main signs will be:

- Increased fuel consumption due to partial failure of the element . When the valve unstably performs its functionality, the pressure in the rail and the fuel system drops, there is an excess supply of gasoline to the combustion chambers, which causes significant fuel consumption. This also entails, in addition to increased gasoline consumption, increased wear of the element, which will ultimately lead to complete failure of the part;

- Unstable engine operation at idle speed . If the fuel supply is poor, the engine cannot reach its optimal level of operation, so the idle air regulator operates unstably. If there is insufficient pressure and the fuel pressure regulator fails, its supply either stops or fuel flows freely through the system. This can also cause the engine to start poorly, which requires increasing the load on the starter, also causing wear. This effect manifests itself during mechanical wear of the valve, when the failure of one part of it ensures poor pressure balancing between the fuel and air;

- The crankshaft cannot maintain a constant speed level. This effect is dangerous because this malfunction can involve many elements of the system, and the malfunction of this regulator is an indirect cause of such a breakdown. Unstable operation of the crankshaft not only disorganizes the driver, but also reduces engine life (albeit slightly);

- Deterioration of engine power qualities . If the fuel supply is poor, the engine cannot fully realize its potential when moving, so its performance decreases. This causes a deterioration in the dynamic qualities of the motor and affects its service life;

The video shows signs of a malfunctioning fuel pressure regulator:

Symptoms of breakdowns

Knowing the signs of a malfunction of the DT regulator, you can immediately determine the level of the problem - whether the unit, mechanical or electronic, has completely failed or partially. But all the “symptoms” listed below do not differentiate a regulator breakdown from other faults - they may also indicate a breakdown of the fuel pump or a clogged filter.

Signs of RTD failure are the same for gasoline and diesel engines:

- The engine does not start. The starter spins for a long time when the clutch pedal is pressed.

- The engine stalled at idle. To keep it running you have to press the gas pedal all the time. The second option is instability of speed, leading to engine shutdown.

- Power is lost. The car cannot drive up the mountain and cannot cope with the load. Simply put, “it doesn’t work.”

- Fuel is consumed more than normal. Losses depend on the nuances of the malfunction.

- Fuel is leaking from the hoses. Moreover, replacing hoses or clamps, as well as other closely located elements, does not help.

If at least one symptom appears, a diagnosis is needed.

In new cars, the regulator is the fuel pressure sensor in the rail. If it fails, an error occurs in the ECU memory and the LED lights up, signaling a motor failure.

On a note! Errors regarding the RTD are listed under numbers p2293 and p0089 - “mechanical fault” and “controller faulty”, respectively.

How does the fuel pressure regulator work?

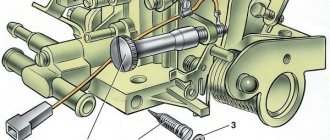

Internal structure of the fuel pressure regulator: 1 - housing; 2 - cover; 3—pipe for vacuum hose; 4 - membrane; 5 - valve; A - fuel cavity; B - vacuum cavity

The fuel pressure regulator is a diaphragm valve, which in systems with fuel recirculation is installed on the fuel rail. Well, in systems where such recirculation is not provided, the RTD is placed directly in the fuel tank.

On the one hand, the fuel pressure regulator is affected by a special spring, as well as pressure in the intake manifold. On the other hand, it is pressed down by the fuel supplied by the pump. When the fuel pressure begins to exceed the spring pressure and the pressure acting on the valve from the intake manifold, the diaphragm valve opens, letting in the required amount of fuel, and as soon as the pressure of the supplied fuel decreases, the pressure regulator diaphragm closes.

In simplified form, it all looks like this. There are two chambers, fuel is pumped into one, and the spring is located in the other. The chambers are covered by a membrane, which opens at pressure values exceeding the action of the spring. It should also be said that in car models of recent years, such a regulator may not exist. Its functions are performed by a special electronic sensor that measures the voltage in the electric pump that supplies fuel. This solution allows you to optimally maintain the required pressure and regulate the fuel supply by directly controlling the pump. But, although such a system is more accurate, nevertheless, it is often a mechanical RTD that is much more reliable and lasts much longer than an electronic sensor, which is subject to various negative influences.

Fuel pressure regulator diagnostics

In terms of its symptoms, a malfunction of the RTD is in many ways similar to malfunctions of the fuel filter or fuel pump. It is worth noting right away that if, during diagnostics of the fuel system, faults were found in the RTD, then the optimal way out of the situation would be to replace the fuel pressure regulator. This is explained by the fact that replacing individual parts, washing and cleaning the device will not return it to full functionality. Considering that the cost of the RTD is very affordable and acceptable, repairing the fuel pressure regulator is simply impractical.

You can diagnose the RTD yourself in one of the simplest and most effective ways: check the fuel pressure in the fuel system. This is done using a pressure gauge. It is measured with the engine idling; The pressure gauge is connected in parallel with the vacuum hose between the fitting and the fuel hose.

The measurements taken show pressure fluctuations in the system. It should increase, while being in the range from 0.3 to 0.7 Bar. If such indicators were not detected, then it is necessary to reconnect the fuel pressure regulator hose and reuse the pressure gauge. The fitting plug is unscrewed to measure the fuel pressure at the end of the fuel rail. The plug has a special sealing ring: you need to check it for integrity - it should not be elastic. If there are still defects on it, then it is changed either separately or together with the plug.

Signs of RTD malfunction

Fuel pressure regulator for VAZ 2110

No matter how reliable a mechanical RTD is, over time its parts wear out and malfunctions and malfunctions occur in the operation of this unit. And now we will look at the main symptoms of such problems.

- increased fuel consumption;

- drop in engine power;

- Unstable engine operation at idle speed;

- jerks and dips when accelerating and changing gears;

- inadequate response of the car to pressing the accelerator pedal;

Let's consider the causes of the main problems of RTDs. First of all, you should check the condition of the spring. Over time, it may lose its elasticity, and as a result, the valve opens earlier than necessary. As a result, fuel is returned to the tank in larger quantities than necessary. The pressure in the system drops and the engine loses power. In this case, the spring should be replaced if the design of the regulator allows it.

Sometimes, especially when working with domestic fuel, the membrane simply becomes clogged and cannot close completely or partially. This again leads to a decrease in fuel pressure in the system and all the ensuing consequences. In such situations, again if the design of the RTD allows, cleaning can be done. But repairs do not always help, since wear of the valve and its parts can cause the regulator to not perform its functions fully even after the breakdown has been eliminated.

Less often, but still, situations occur when the fuel pressure regulator simply jams. In this case, the engine completely stalls, and fuel begins to flow from all possible and impossible holes. Repair in such cases is unpromising and a clogged regulator is easier to replace. But for the fuel pressure regulator to become clogged to the point of complete obstruction, there must be absolutely no fuel, since the system has a fuel filter that is designed to clean the fuel, and since it seriously fails to cope, it is better to change the gas station.

It is possible that the fuel pressure regulator valve becomes partially clogged and begins to operate jerkily. These jerks are transmitted to the operation of the engine and are perfectly felt by the driver, and even by the passengers of the car. In this situation, cleaning the RTD has a much better chance of returning its performance to an acceptable level.

In general, the electronic fuel pressure regulator is less susceptible to fuel quality and other mechanical factors that have a negative impact on this unit, but it also has its own weak points and characteristic vulnerabilities. On the other hand, if you don’t pour frankly bad fuel into the car’s tank, change the fuel filter on time and generally take care of the car, then any RTD will run for a very long time.

The principle of operation of the VAZ fuel pressure regulator

To clearly control stable movement in the fuel rail, when the pressure is low, to send an alarm to the electronic control unit, and when the pressure is high, to let fuel flow through the return channel - these are the main tasks of the pressure regulator. Electronics has no logic; it is guided only by dry data. Depending on the car model and the number of special sensors, the source of the malfunction can be more or less accurately localized. In simple injection systems, such as in VAZ cars, diagnostics consists not so much in the ability to correctly read error codes on the diagnostic port, but in knowing the interconnection of system elements.

The fuel pressure regulator in power systems without a return channel is installed in the fuel tank; such systems are practically not used. The regulator that works with the recirculation system has three pipes.

- Inlet pipe.

- Atmospheric pressure control pipe.

- Fuel return channel pipe.

The regulator is technologically divided into two chambers, one of which is air, the second is fuel. They are separated by a membrane, which is under the action of a check valve spring. In that case. if the pressure in the system exceeds a certain parameter, and it is slightly different for all gasoline engines, then the spring is weakened, the pre-bypass valve opens and excess fuel goes back into the tank, where, passing through the filter, it again enters the fuel rail.

How to check RTD

As for checking the functionality of the fuel pressure regulator, in modern cars equipped with direct fuel injection, such diagnostics can be carried out exclusively using a pressure gauge connected between the fuel hose and the fitting. The instrument readings are compared with the standard pressure indicators for a given car model and based on this comparison, a conclusion can be drawn about the serviceability and functionality of the fuel pressure regulator.

But such diagnostics should be carried out by a qualified specialist, since there are a lot of subtleties and pitfalls here. Actually, only an experienced professional can make a decision about repairing or replacing the RTD. The effectiveness of repairing or replacing the fuel pressure regulator is also monitored using a pressure gauge. If you have an electronic pressure control unit installed, then it may need calibration or other fine tuning. But here, one pressure gauge will clearly not be enough, because the delicate electronics of a car require specific equipment and equally special skills to configure it.

Video about RTD

I’m driving quietly, enjoying myself, my favorite music is playing, suddenly I feel the car twitching, then everything is fine, it drives, the check engine light doesn’t come on, I thought it was a glitch and the road is not smooth) I drive into the yard, it stalls, I start it, it works, then it stalls again. I thought the pump had failed, checked it, it was working, but when I turned it on I could hear gasoline flowing into the tank through the return line, everything was clear) it was the fuel pressure regulator. Some people have it under the hood on the fuel rail and look like this

Let's look at the signs of fuel pressure regulator malfunctions

High fuel consumption Unstable crankshaft speed at idle Sudden engine stop at idle Poor engine dynamics and lack of power while the vehicle is moving High levels of CO and CH in the exhaust Difficulty starting the engine

The valve is completely inoperative - in this situation, fuel is not discharged into the tank and, as a result, the pressure in the fuel system increases. This pressure can be 3 - 5 kg/cm2 or more instead of the required 2.5 kg/cm2, which affects the amount of fuel entering the combustion chamber through the nozzles. The volume of fuel supplied through the nozzle at a pressure of 4 kg/cm2 will be greater than at a pressure of 2.5 kg/cm2, which will significantly affect its overconsumption. In this case, gasoline will not burn completely, since a complete combustible mixture should consist of one part fuel and 14.7 parts air

Which RTD is better to choose for LADA cars

Depending on the engine, configuration and year of manufacture, different fuel pressure regulators (FPR) can be installed on LADA cars from the factory. 1.6-liter engines (Lada Vesta, XRAY, Granta, Kalina, Priora) are equipped with RDT-380, and 1.8-liter engines (Lada Vesta, XRAY) are most often equipped with RDT-350. Do you know what the difference is between these fuel pressure regulators, and which one is better to buy?

RTD

is a device installed inside the electric fuel pump module and designed to maintain optimal pressure inside the fuel rail at different operating intensities.

Replacement of RTD 3.5 bar (350 kPa) with RTD 3.8 bar (380 kPa)

allows you to increase the fuel pressure in the rail to 3.8 atmospheres. In theory, the atomization of gasoline will improve on “tired” injectors, as a result: idle speed will be smoother, twitching during acceleration will go away, and engine response will improve. If the injectors are in good condition, there will be no noticeable difference.

vendor code

"pdt380".

Price

from 600 rubles.

Nuances when replacing

: The RTD on Lada Vesta, Granta, Kalina, Priora, Largus is replaceable (see how to disassemble the fuel module on the Lada Vesta), and on the Lada XRAY the RTD is changed together with the fuel pump housing assembly (you can buy a dismountable housing from the Lada Largus fuel pump).

Which RDT brand is better to buy?

One of the owners of Lada XRAY ( xrom-spb ) decided to test the performance of three different RTD 3.8 (noname, SEPO and UTOS):

According to the author of the video: the best is the RTD.

Will you change RDT 3.5 to RDT 3.8? Your reviews

After such a replacement, leave it in the comments.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

What do we pay attention to?

First of all, it’s time to inquire about the “health” of the fuel pressure regulator if the following symptoms attract your attention:

- The engine is extremely unstable. And it doesn’t “trouble”, as with problems with candles; the sound of the engine is uneven - not rumbling, but like a train rumbles at the junctions;

- At idle speed the engine may even stall. It is clear that this symptom is characteristic of many diseases: improper installation of the drive belt, flooded spark plugs, clogged carburetor... So if this is the only one present, you will most likely have to check many components;

- When driving, the engine runs jerkily and “sinks” are observed;

- abnormal consumption of gasoline (or diesel fuel). Again, a symptom can indicate different problems, so it is advisable to “make a diagnosis” based on the totality of symptoms;

- the level of carbon monoxide in the exhaust gases is exceeded (which is checked with an appropriate device or simply “by smell”);

- When switching to a higher gear, acceleration is weak and slow. The car loses its characteristic throttle response;

- the response to the gas pedal is delayed and weak (if this is not a characteristic feature of your car - for some VAZs and Chinese cars this behavior is quite normal).

If several of the described symptoms are detected, and the remaining components of the fuel system are normal, you will have to check the regulator itself.

Checking the RTD

In the old days, when driving exclusively in VAZs and GAZs, folk craftsmen came up with a universal “kneeling” method for self-checking that did not require any equipment.

Elementary actions:

the bypass valve was turned off/clamped and the outgoing stream was visually observed.

With the spread of injectors and carburetors becoming a thing of the past, the method became ineffective. (see “Differences between an injector and a carburetor”) Nowadays you will need a pressure gauge to check. However, a tire one, which almost every car owner has, is quite suitable.

The vacuum hose is removed, a pressure gauge is connected between the fuel hose and the fitting, the engine starts and idles. During the measurement, the pressure in the fuel system should rise from 0.3 bar to 0.7.

If this does not happen, the vacuum hose is changed and the measurements are repeated. This “knight’s move” did not help either - the problem is definitely in the fuel pressure regulator. It cannot be repaired, so we go to the spare parts store for a new one.

Changing the RTD

- Those who are unsure of themselves can drive up to a service station with a new part, but believe me, nothing complicated will be required of you. Take a 24mm wrench and a five-point hexagon and begin the repair work;

- The fitting plug at the end is unscrewed. There is an o-ring there. If it is torn, cracked or stretched, replace the seal or the entire plug;

- The spool is unscrewed from the fitting. It is similar to the tire one, so you will recognize it;

- The vacuum pump is removed from the regulator;

- The nut is twisted - fastening the fuel drain pipe;

- The bolts are removed - 2 pieces - with which the RTD is fixed to the fuel rail;

- The regulator fitting is pulled out of the ramp hole, and the regulator itself is removed from the drain tube. It happens that the sealing ring gets stuck in the ramp. You need to carefully get it out of there; if intact, put it on a new RTD; if torn or cracked, replace it with a new one.

Installation of the purchased spare part is carried out in the reverse order. After finishing the installation, you should start it and listen to the engine to make sure that all problems are solved.

Finally, we note:

You shouldn’t raise the alarm and look for signs of a malfunction in the fuel pressure regulator as soon as the engine sneezes. RTD is a fairly reliable thing and does not “fly” very often. And if this happens, you will quickly understand what’s going on.

Faulty fuel pressure regulator: symptoms

The fuel pressure regulator is an element of the injection engine power system, which allows you to maintain the required fuel pressure in the fuel injectors at different operating modes of the internal combustion engine. In other words, the overall performance of the injectors and the stability of the engine depend on the serviceability of the fuel pressure regulator (FPR).

Considering that the pressure regulator is actually a diaphragm valve, failure of this element can greatly affect the operation of the engine. In this article we will look at the principle of operation of the regulator, highlight the main signs of its malfunction, and also talk about how to check the fuel pressure regulator.

Fuel pressure regulator: diagnostics, repair, replacement

Modern cars are equipped with electronic fuel pumps; mechanical ones are found only in cars manufactured before 2000. The task of this component is to ensure an uninterrupted supply of fuel. Everything functions well at high engine speeds, but problems arise when moving to low and idle speeds. Increased pressure damages fuel supply hoses and other system components. The fuel pressure regulator protects against such consequences. If there are malfunctions in it, this can be determined by several signs.

Why do you need a fuel pressure regulator?

As mentioned above, this regulator maintains the required fuel pressure necessary for normal operation of the injectors, taking into account one or another operating mode of the power unit. In other words, the RTD affects the amount and intensity of the fuel supply that enters the engine cylinders through the injectors.

Simply put, the amount of fuel supplied to the engine at the time of injection depends on the pressure that is created inside the fuel rail (rail), as well as on the pulse duration for opening the injector and the vacuum in the intake manifold.

For more accurate dosing and maintaining constant pressure, a diaphragm valve-regulator is used, which experiences fuel pressure on one side, and a spring force on the other. RTD is used in power systems where there is a so-called “return”. The regulator is installed at the fuel rail. Also, this element can be located in the fuel tank, while such systems do not have a return line.

- Let's first look at the common design in which the regulator is located in the fuel rail. The element operates on the following principle: the fuel pump forces fuel from the fuel tank along the line. The resulting fuel pressure acts on the regulator. The device itself has two chambers (a spring chamber and a fuel chamber), which are separated by a membrane. On one side, the membrane is pressed by fuel, which enters the regulator through special inlet holes, and on the other side, there is spring pressure and intake manifold pressure. If the fuel pressure turns out to be stronger than the spring force and the pressure in the inlet, then the regulator opens slightly, resulting in some of the fuel being discharged into the return line. The fuel returns through the return line to the fuel tank.

- In systems without a return line, the regulator is usually located directly in the tank. The advantages include the absence of an additional pipeline. The injectors are supplied with the required amount of fuel directly from the tank, that is, excess fuel does not enter the engine compartment, and there is no need to deliver it back to the tank. This also allows us to talk about less heating of the fuel and provides a number of additional advantages in the form of less intense evaporation.

Priora fuel pressure regulator

Every engine fuel system contains a fuel pump. Electric fuel pumps have recently been installed in gasoline engines; mechanical models are already outdated and are no longer used on modern vehicles. Mechanical fuel pumps live out their days on cars produced in the last century.

The performance of the electric fuel pump must be such as to ensure uninterrupted fuel supply at any engine speed and under any load. But what to do when the engine is running at idle or low speed, and a small portion of fuel is required? After all, the pressure that is created in the engine power system for heavy loads will be excessive at idle speed. And excess pressure can lead to disastrous results - breakage of fuel hoses or other damage. For normal operation of the fuel system, there is a fuel pressure regulator.

What is a fuel pressure regulator?

The fuel pressure regulator (FPR) is a vacuum valve that transfers excess fuel through a return hose into the fuel tank. The RTD is a housing that contains a valve, a membrane and a spring. There are also three terminals in the housing: two terminals for the passage of fuel through the regulator, the third is connected to the intake manifold. As engine speed increases, the vacuum created in the manifold (at the third terminal) overcomes the force of the spring and moves the membrane, thereby opening the valve slightly. Excess fuel gets access to the second outlet and goes back to the gas tank. An RTD is often also called a check valve.

As a rule, the check valve is located on the fuel rail; it can also be embedded in the fuel return hose of the power supply system.

Causes of fuel pressure regulator malfunctions

RDT may fail for several reasons. For example, defective parts are found on Russian-made cars. There are significantly fewer defects on foreign models, but you can purchase a defective RTD by purchasing a non-original spare part.

Mostly the check valve breaks down due to natural aging. Let's say this can happen after a hundred thousand mileage or more. It should be noted that check valve failures are not common. Most often, in an RTD, the membrane dries out over time, less often the valve jams, and even less often the spring breaks or weakens.

Sensor failure may occur due to low-quality gasoline. For example, in winter, fuel was filled with water, and water got into the regulator.

Fuel pressure regulator: diagnostics, repair, replacement

If the fuel filter is not replaced on time, dirt gets into the parts of the power system, including the regulator. In this case, the RTD valve most often jams. It’s hard to imagine what could happen to the spring, but apparently, it still breaks sometimes.

Characteristic symptoms of fuel pressure regulator malfunctions

By what signs can you determine that an RDT is not working:

- the engine is very difficult to start, you need to turn the starter for a long time and at the same time keep the gas pedal pressed in order for the engine to start;

- The engine idles unsteadily or the speed is very low, the engine often stalls. At the same time, it does not gain power at all; when trying to accelerate, it results in a deep failure;

- The spam engine changes speed sharply, this is especially noticeable at idle:

- Fuel is leaking from the fuel hoses. Attempts to tighten and replace clamps and replace hoses do not help.

How to check the fuel pressure regulator for serviceability

The fuel pressure regulator is not an electrical sensor and cannot be checked using instruments. It should also be taken into account that the RDT cannot be disassembled or repaired. Someone writes that the fuel check valve can be repaired. I would like to see what it looks like and where you can buy a repair kit. Typically, RTDs are inexpensive, and even for that reason they would not be worth repairing if they were repairable.

You can verify that the regulator is working properly by checking the pressure in the fuel system. This is usually done with a mechanical pressure gauge, which is connected to the engine power system.

Measurement is carried out as follows:

- connect the pressure gauge to the fuel system;

- start the engine and look at the pressure gauge readings.

The standard system pressure for a passenger car is usually within 3 kg/cm2. When stopping the engine, the pressure should not drop immediately - the regulator closes the return flow. If the pressure gauge needle quickly goes to zero, the RTD is most likely faulty.

Another way to check: if you manage to pinch the fuel return hose while the engine is running, then if the regulator is working properly, the pressure in the fuel system should increase. The indication of the arrow of the device depends on the degree of compression. But there are foreign cars where it is impossible to clamp the return line - instead of rubber hoses there are metal tubes, or the hoses are very short.

In some cases, by squeezing the return hose, you can verify that the RTD is faulty without a pressure gauge. But this is only due to one sign - when the engine idles and does not develop speed at all. If, when the return line is pinched, all cylinders begin to fire and the engine acquires the required power, then the RTD is definitely faulty and needs to be replaced.

download photo to mobile phone Contents: Operating and technical manual

maintenance and repair of Lada Priora VAZ 2170

Section 5: Engine Lada Priora VAZ 2170

Design features of the engine power system on the Lada Priora VAZ 2170

| The engine power system includes elements of the following subsystems: - fuel supply system, which includes fuel tank 16 (Fig. 5.19), fuel pump 5 with a built-in fuel pressure regulator, fuel pipes 1 and 17, hose 18, fuel rail 2 (Fig. 5.20) with injectors 1, as well as fuel filter 2 (see Fig. 5.19); Rice. 5.20. Fuel rail and injectors Lada Priora VAZ 2170: 1 - injector; 2 - fuel rail; 3 - sealing ring; 4 — nozzle clamp; 5 — fitting cap for monitoring fuel pressure — air supply system, consisting of air filter 3 (Fig. 5.21), air supply hose 11, throttle unit 4; — a fuel vapor recovery system, including an adsorber 15 (Fig. 5.22), an adsorber purge valve 5, a fuel vapor separator 11, a gravity valve 10, connecting steam lines 1, 2, 12, 13, 14 and hoses 4. Functional purpose of the supply system fuel - ensuring the supply of the required amount of fuel to the engine in all operating modes. The engine of the Lada Priora VAZ 2170 is equipped with an electronic control system with distributed fuel injection. In the distributed fuel injection system, the functions of mixture formation and dosing of the air-fuel mixture into the engine cylinders are separated: the injectors carry out dosed injection of fuel into the intake pipe, and the amount of air required at each moment of engine operation is supplied by a system consisting of a throttle unit and an idle speed regulator. This control method makes it possible to ensure the optimal composition of the combustible mixture at each specific moment of engine operation, which allows you to obtain maximum power with the lowest possible fuel consumption and low exhaust gas toxicity. The fuel injection system and ignition system are controlled by an electronic engine control unit (ECU), which continuously monitors, using appropriate sensors, the amount of engine load, the speed of the vehicle, the thermal state of the engine, and the optimal combustion process in the engine cylinders. A feature of the injection system of the Lada Priora VAZ 2170 is the timing of the operation of the injectors in accordance with the valve timing (the engine control unit receives information from the phase transmitter). The controller turns on the injectors sequentially, and not in pairs or simultaneously, as in asynchronous injection systems. Each injector is activated through 720° of crankshaft rotation. |

Faulty fuel pressure regulator: symptoms

However, in start-up modes and in dynamic engine operating modes, an asynchronous fuel supply method is used without synchronization with crankshaft rotation.

The main sensor for the fuel injection system is the oxygen concentration sensor in the exhaust gases (lambda probe). It is installed in the engine exhaust manifold and, together with the engine control unit and injectors, forms a control circuit for the composition of the air-fuel mixture supplied to the engine. Based on sensor signals, the engine control unit determines the amount of unburned oxygen in the exhaust gases and accordingly evaluates the optimal composition of the air-fuel mixture entering the engine cylinders at each time. Having detected a deviation of the composition from the optimal 1:14 (fuel: air), which ensures the most efficient operation of the exhaust gas catalytic converter, the control unit changes the composition of the mixture using injectors. Since the oxygen concentration sensor is included in the feedback circuit of the engine control unit, the air-fuel mixture control loop is closed. A feature of the engine control system of the VAZ 2170 Lada Priora is the presence, in addition to the control sensor, of a second diagnostic oxygen concentration sensor installed at the outlet of the converter. Based on the composition of the gases passing through the neutralizer, it determines the efficiency of its operation.

The fuel tank 16 (see Fig. 5.19) is welded, stamped, installed under the floor of the body at the rear of the Lada Priora VAZ 2170 car and secured with two steel clamps 14. To prevent gasoline vapors from entering the atmosphere, the gas tank is connected through a gasoline vapor separator 11 (see . Fig. 5.22) and gravity valve 10 with steam lines 12, 13, 14 and 1 with adsorber 15. An electric fuel pump module (fuel pump) 5 is installed in the flange hole in the upper part of the gas tank

Fig. 5.19. Fuel supply system of Lada Priora VAZ 2170: 1 — fuel pipes (plastic); 2 - fuel filter; 3 — fuel filter mounting bracket; 4 — sealing ring of the fuel pump; 5 - fuel pump; 6 — spacer ring; 7 — pressure ring for fastening the fuel pump; 8 — filling pipe hose; 9 — plug of the fuel tank filler pipe; 10 — lining of the neck of the filling pipe; 11 - clamp; 12 — fuel tank filling pipe; 13 — air outlet hose; 14 — fuel tank mounting clamp; 15 — connector (quick connector); 16 — fuel tank;

17 — fuel pipes (metal); 18 — fuel supply hose; 19 — bracket; 20 — nozzles; 21 - fuel rail

Rice. 5.21. Air supply system Lada Priora VAZ 2170: 1 — mass air flow sensor; 2 - sealing sleeve; 3 — air filter; 4 - throttle assembly; 5 — intake manifold; 6 — idle speed regulator or additional air regulator; 7 — hose clamps; 8 — thermostat; 9 — supply pipe of the coolant pump; 10 — heating hoses for the throttle assembly; 11 — air supply sleeve;

12 — clamps for fastening the air supply hose

Rice. 5.22. Fuel vapor recovery system Lada Priora VAZ 2170: 1 - front steam pipe; 2 — adsorber tube and purge valve; 3 - adapter; 4 — hoses; 5 — adsorber purge valve; 6 - clamp; 7 — fuel drain pipe; 8 — separator bracket; 9 — valve gasket; 10 — gravity valve; 11 — fuel vapor separator;

12 — rear steam pipe; 13 — middle steam pipe; 14 — steam pipe; 15 - adsorber

useful tips for motorists

When using site materials, an active link to car-exotic.com is required!

Fuel pressure regulator malfunctions

Problems in the engine power system can vary. For this reason, during diagnosis it is necessary to look for certain signs of a malfunctioning fuel pressure regulator. Most often, the main symptoms are considered to be when the engine does not pick up speed and does not develop full power, and also stalls in different operating modes. In the list of main signs, experts note:

- unstable operation at idle, the unit stalls at idle;

- loss of power, noticeable increase in fuel consumption;

- slow reactions to pressing the gas pedal;

- jerks and dips during acceleration, at the moment of throttling;

- the car does not accelerate, does not gain momentum;

Note that the malfunction of the RTD on gasoline cars is similar in symptoms to common problems with the fuel pump or its strainer. For this reason, when determining faults in the power system, a mandatory check of the fuel pressure regulator is necessary.

In other words, if the car stalls at idle, the engine power is lost, dips appear, the car jerks during acceleration or when changing gears, significant fuel consumption is noted, then the problem may not only be in the fuel pump grid, the motor or its relay, but also in the fuel pressure regulator.

Regulator malfunctions usually come down to the fact that the spring loses the required force, as a result of which the fuel is prematurely drained into the “return”, and the engine simply does not have enough fuel when you press the gas and increase the speed, as well as in transient modes. It turns out that the pressure in the fuel rail when the fuel pressure regulator spring is faulty is low, as a result of which the engine runs unstably, engine power decreases, the ECU is not able to correctly adjust the mixture composition for different operating modes, etc.

Failures in the operation of the RTD are also possible when the pressure regulator in the fuel rail begins to jam at certain intervals. In such cases, pressure drops occur in the fuel supply system, and the car begins to twitch. Let us add that the most common reasons for regulator failure, which results in signs of malfunction of the fuel pressure regulator on a diesel or gasoline car, also include wear and tear of the materials inside the device, that is, the valve simply wears out its service life over time. The service life and condition of the regulator are affected by the quality of the fuel and the content of various impurities in it, long periods of vehicle downtime without starting the engine, etc.

Signs and Symptoms of a Malfunctioning Fuel Pressure Regulator

- the engine stalls at idle;

- engine power is greatly reduced;

- when accelerating, it is not possible to achieve normal dynamics;

- the car reacts poorly to pressing the gas pedal;

- fuel consumption suddenly increases greatly;

- the amount of carbon dioxide emissions increases;

- the crankshaft rotation speed changes.

All these problems arise due to the fact that the regulator becomes clogged or completely clogged over time. Another common cause of failure is weakening of the spring, leading to a strong decrease in pressure. In the absence of normal pressure, fuel supply decreases, power decreases and controllability deteriorates. Such problems are especially common on Ladas - Kalina and Priora, as well as on cars of the 2110, 2112, 2114, 2115 series.

To check the part, you need to carefully inspect it itself, the vacuum hose and all connections. Any leaks found must be corrected. It is also recommended to check the membrane. Disconnect the tube that goes from the RTD to the receiver and shake it. If no gasoline comes out from inside and there is no strong odor, then the membrane is in order.

RTD in diesel engines

Diesel vehicles running on the Common Rail system are also equipped with a pressure regulator. It fits into the fuel rail or is located on the high pressure fuel pump housing. The principle of operation is approximately the same. A special valve diverts unused fuel into the return line, preventing excessive loading.

Checking and replacing the fuel pressure regulator

As you can see, a malfunctioning pressure regulator has symptoms very similar to a malfunctioning fuel pump or a clogged fuel filter. At the very beginning, we note that if problems with this element are detected during the inspection, then it is preferable to replace the RTD with a new one. The fact is that replacing individual parts, cleaning attempts and other manipulations often do not allow the device to return to proper functionality. Considering that the price of a fuel pressure regulator is quite affordable, then any repair attempts can be considered impractical.

Measurements should show changes in pressure in the system within a certain range. The fuel pressure should increase, being within the range of 0.3 - 0.7 Bar. If this does not happen, then first you can try replacing the vacuum hose, and then repeat the measurements. To check the fuel pressure at the end of the ramp, you will need to unscrew the fitting plug. This plug also has a special ring for sealing. The specified ring should be checked for integrity; the element should remain elastic. If there are defects, then the ring or the entire plug also needs to be changed at once.

- After inspecting the ring, you can unscrew the umbrella from the fitting. Many drivers use a metal wheel valve cap to loosen it. Now the hose and the pressure gauge connected to it need to be connected to the fitting, after which the structure is additionally secured using clamps. Next, the engine can be started and measurements taken. Normally, the indicators should be about 2.9-3.3 kgf per cm2. Afterwards, you can disconnect the hose from the RTD, observing the pressure gauge readings. The pressure indicator should increase from 20 to 70 kPa.

- If the fuel pressure regulator still produces a low or zero reading, then you can think about replacing the device. Changing an RTD is not a difficult task, that is, you can do the replacement yourself in a garage. At the beginning of the procedure, you need to “bleed off” the pressure in the engine power supply system. To solve the problem, you need to unscrew the nut that secures the fuel pipe. Now you can unscrew a couple of bolts that usually attach the regulator to the fuel rail on most fuel-injected cars.

- The next step is to carefully remove the regulator fitting from the hole in the fuel rail and its final dismantling (the fuel pipe must be completely disconnected in advance). The final stage is the installation of a new or known-good element into the ramp, after which the functionality is checked in the manner described above using a pressure gauge. Finally, we would like to add that it is also recommended to additionally lubricate the O-rings with gasoline before installing a new RTD or in case of replacing the said rings.

Replacing the fuel pressure regulator and mesh - logbook Lada Priora Sedan 2010 on DRIVE2

After a long period of inactivity, the car started very poorly and sometimes you turned it off, after a couple of hours it started again poorly, I bought a sensor and a fuel strainer at the same time, disassembled it and remembered about the fuel level sensor, it was stupid for me, the needle was jumping, but it was too late, the stores were closed, and again then because of it I didn’t want to remove the pump, even though it wasn’t anything complicated... I took a regular pencil eraser and cleaned it and now the sensor shows everything perfectly)

Full size

unscrew all the nuts by 10, disconnect the tubes and pull it out

.

Full size

disconnect the wires

old mesh

.

Full size

This is a new pressure regulator, before installing, lubricate the rubber bands with a little oil and install

We wash out all the dirt and assemble the pump)

I installed everything back) now it starts up much better) A couple more photos of my friend’s car, the car is really cool) Excellent condition)