The design and principle of operation of a four-stroke scooter engine

Manufacturers have been installing 4-stroke engines on motorcycles for a long time. New Chinese scooters are also equipped with a four-stroke internal combustion engine (Otto engine). This article has been written about the design and operating principle of this engine, as well as the differences between a 4-stroke engine and a 2-stroke engine. Help The inventor of the 4-stroke internal combustion engine (as well as the two-stroke engine) was the German Nikolaus August Otto (1832-1891).

Therefore, the internal combustion engine is sometimes called the Otto engine. For reasons of efficiency, more and more scooters are equipped with four-stroke engines. Although these engines, with the same cylinder volume, are inferior in power to two-stroke ones, they have their own advantages:

- fuel efficiency

-the four-stroke engine is quieter and more stable.

Unlike a two-stroke engine, in which the crankshaft, crankshaft bearings, compression rings, piston, piston pin and cylinder are lubricated by adding oil to the fuel; The crankshaft of a four-stroke engine is in an oil bath. Thanks to this, you do not need to mix gasoline with oil or add oil to a special tank (on models of two-stroke scooters with a separate lubrication system). It is enough to pour clean gasoline into the fuel tank and you are ready to go, eliminating the need to purchase special oil for 2-stroke engines. Also, significantly less carbon deposits form on the piston mirror and the walls of the muffler and exhaust pipe. In addition, in a 2-stroke engine, the fuel mixture is released into the exhaust pipe, which is explained by its design. Minor disadvantages that are more than offset by advantages include work on adjusting the thermal clearance of the valves and the acceleration time of the scooter from a standstill, which is slightly longer than that of two-stroke mopeds. The last problem can be eliminated by optimal tuning of the variator and centrifugal clutch.

So, let's move on to a description of the structure and operation of a four-stroke scooter engine.

Here is an animated model of a two-stroke engine, it also shows the principle of operation of the resonator, which returns the fuel mixture back to the cylinder. In a four-stroke engine, the exhaust channel is closed by a valve, so installing a tuning muffler designed for two-stroke engines will not bring anything (except noise). Animation( Click)

Four stroke engine

The working cycle of a four-stroke engine consists of four main stages - strokes. The piston is a metal cup surrounded by spring rings (piston rings) inserted into grooves on the piston. Piston rings prevent gases generated during fuel combustion from passing between the piston and the cylinder walls. The piston is equipped with a metal rod - a pin, connected to a connecting rod. The connecting rod transmits the linear reciprocating motion of the piston into the rotational motion of the crankshaft.

Intake - four-stroke engine

During the intake process, the piston of a four-stroke engine moves from top dead center (TDC) to bottom dead center (BDC). At the same time, the camshaft cam opens the intake valve, drawing a fresh fuel-air mixture into the cylinder of a four-stroke engine.

Compression - 4-stroke engine

The piston of a four-stroke engine rises from BDC to TDC, compressing the working fuel mixture. At the same time, the temperature of the combustible mixture rises significantly. The ratio of the working volume of the cylinder at BDC to the volume of the combustion chamber at TDC is called the compression ratio (not to be confused with compression). The compression ratio is a very important parameter; usually, the higher it is, the greater the fuel efficiency of the engine. But a four-stroke engine with a higher compression ratio requires fuel with a higher octane number, which is more expensive.

Combustion and expansion (piston stroke) - four-stroke engine

Shortly before the end of the compression stroke, the combustible mixture is ignited by a spark from the spark plug. As the piston moves from TDC to BDC, the fuel burns, and under the influence of the heat of the burned fuel, the working mixture expands, pushing the piston. The degree of “under-rotation” of the engine crankshaft to TDC when the mixture is ignited is called the ignition timing angle. Ignition advance is necessary so that the gas pressure reaches its maximum value when the piston is at TDC. Then the use of energy from burned fuel will be maximum. The fuel combustion rate practically does not change, that is, it takes a fixed time, therefore, in order to achieve maximum engine performance, you need to increase the ignition timing in proportion to the crankshaft speed level. In older engines, this adjustment was made by a mechanical device (centrifugal and vacuum regulator acting on a breaker). More modern engines use electronic ignition timing to adjust the timing.

Exhaust system - four-stroke engine

After BDC of the power stroke of a four-stroke engine, the exhaust valve opens and the rising piston forces the exhaust gases out of the engine cylinder. When the piston reaches TDC, the exhaust valve closes and the four-stroke cycle begins all over again. It must also be remembered that the next process (for example, admission) does not necessarily have to begin at the moment when the previous one (for example, exhaust) ends. This position, when both valves (intake and exhaust) are open at once, is called valve overlap. Valve overlap is necessary for better filling of the cylinder/s with the combustible mixture, as well as for better cleaning of the cylinder/s of a four-stroke engine from exhaust gases.

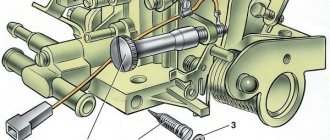

Four-stroke scooter engine: 1 - cylinder with head 2 - cylinder head cover 3 - carburetor 4 - inlet pipe 5 - electric starter.

For even greater clarity, watch a video that clearly shows the operation of a four-stroke engine. This video demonstrates a four-cylinder car with sixteen valves (that is, each cylinder has two intake and exhaust valves, for better purging) engine, but this does not change the essence.

Scooter power system. Scooter Engine System

Scooters are very popular due to their economical fuel consumption, the ability to ride without a license on certain models, and excellent maneuverability in urban conditions. You can easily get to your place of study, work or recreation on it, it’s nice to just ride with friends, or go fishing. Thanks to their narrow dimensions, scooter drivers never get stuck in traffic jams. Servicing a small “iron horse” is much cheaper than a motorcycle or car. But how not to get confused in the various characteristics of this equipment and choose a device that suits the user’s weight, height and terrain preferences? A detailed answer to this question is provided here.

Two stroke engine

In two-stroke engines, all operating cycles (the processes of injecting the fuel mixture, exhausting exhaust gases, purging) occur during one revolution of the crankshaft (and not two, as in four-stroke engines) in two (and not four) main strokes. Two-stroke engines do not have valves (as in four-stroke internal combustion engines); their role is played by the piston itself, which, in the process of movement, either closes or opens the intake, exhaust and purge windows. Therefore, a two-stroke engine is simpler in design.

The power of a two-stroke engine with the same cylinder dimensions and shaft speed is theoretically twice that of a four-stroke engine due to the twice as many power strokes. However, incomplete use of the piston stroke of a two-stroke engine for expansion, poorer release of the cylinder from residual gases and the expenditure of part of the generated power on purging lead to an increase in power by only 60 - 70%.

So, let's consider the design of a two-stroke internal combustion engine, shown in Figure 1: A two-stroke engine consists of a crankcase in which a crankshaft and a cylinder are installed on bearings on both sides.

Lubrication of all rubbing surfaces and bearings inside two-stroke engines occurs due to the fuel mixture - a mixture of gasoline and oil in a certain proportion. From Figure 1 it can be seen that the fuel mixture (yellow color) enters both the crank chamber of a two-stroke engine (the cavity where the crankshaft is fixed and rotates) and into the cylinder. There is no lubricant there anywhere, and if there was, it would be washed off with the fuel mixture. This is the reason why oil is added in a certain proportion to gasoline. The type of oil used is special, specifically for two-stroke engines. It must be able to withstand high temperatures and, when burned together with the fuel, leave a minimum of ash deposits, that is, soot.

Now about the principle of operation . The entire working cycle in two-stroke engines is carried out in two strokes.

What does a scooter consist of?

Scooter variator belt sizes

Belt sizes for popular scooters (Honda, Yamaha, Kymso, etc.)

Engines on Chinese scooters

Article review of engines that are installed on Chinese scooters and mopeds, for example 139QMB or 1P39QMB engines

Scooter fuel system

The structure and main components of the fuel system of a 4T scooter.

Scooter gearbox - device

A gearbox is a mechanism that transmits and converts torque, with one or more mechanical gears. Scooter gearbox.

The working principle of a four-stroke scooter engine

The design of a four-stroke scooter engine, as well as its advantages.

Scooter carburetor design

At first glance, a carburetor looks like a complex device, but with a little theory, it will be easier for you to adjust it. The first thing you need to know is at least the basics of the principle of operation of the carburetor and its main controls and adjustments. The throttle handle on the steering wheel is directly connected to the air damper and the metering needle attached to it. Air passing through the carburetor will pick up fuel from the fuel chamber.

Purge problem

The higher the crankshaft speed, the more power. But the design of two-stroke engines has this peculiarity - the faster the piston begins to move, the worse the combustion chamber of the cylinder is purged, since the exhaust gas supply and exhaust windows remain open for a very short time.

Chamber purging is the removal of gases and injection of fuel into the cylinder from the crankcase. Fuel begins to be sucked in and remain in the crankcase as the piston moves upward. Then, when the piston goes down, the inlet port closes and the purge window opens, through which a new portion of fuel is supplied and the gases of the previous spent fuel mixture are expelled (see the figure above, in the middle).

This simple design of a two-stroke engine eliminates the need to install a gas distribution mechanism (GRM), a purge pump, valves and a lubrication unit.

Purging while a two-stroke engine is idling (idling) is carried out differently. During operation at XX, purging is carried out by opening the damper to a small angle. This kind of purging is not of high quality, so at idle speed, as many have probably noticed, the engine of a chainsaw or lawn mower does not work stably. As for a chainsaw, for example, Echo (Echo), then you need to pull the choke halfway.

A single-cylinder two-stroke engine has a contour blower, that is, a slot blower. At the bottom of the cylinder in the wall there is a special slot through which gas distribution occurs. During the compression and power strokes, that is, when the piston is up, the intake and purge ports must be closed.

Contour purge - this pre-piston volume (cylinder under the piston) is a purge pump. This design makes it possible to make engines of the smallest dimensions.

The structure of the scooter and its main components.

The structure of the scooter from the point of view of the organization of its main components can be viewed using the figures below.

The scooter is controlled, as a rule, by three elements: acceleration - 1) throttle; brake - 2) rear and 3) front. Of the two steering handles of the scooter, the gas handle is on the right. Brakes on both sides; rear and front - on the right or on the left, each manufacturer decides for himself how to arrange it.

In addition, the steering panel (so to speak) contains sensors, control buttons and switches (see picture). Usually like this: on the left - horn (1), turn signals (2), low/high beam switch (3); on the right is an electric starter (4), lights on/dimensions/off (5), and sometimes a stop button-switch (you can use it to turn off the engine without turning off the ignition, but you won’t start it until you turn it back on) (6). The number 7 indicates the throttle cable tension regulator. My scooter also has buttons to control the electronic clock. Sensors include a speedometer, sometimes a tachometer, a fuel level sensor; on two-stroke engines there is almost always an oil level sensor in the oil tank, light indicators, and turn signals. Also, scooters with hydraulic brakes usually have a “brake reservoir” (8) on the handlebars, which is used to determine the brake fluid level. I don’t think there’s any need to explain why there’s an engine in a scooter. The scooter can be equipped with a two-stroke or four-stroke engine - depending on this, the scooter device can be supplemented with additional components, for example, an oil pump for a two-stroke engine. (Well, diesel, rotary and jet engines are not yet installed on scooters. At least not commercially

Source

General structure of the scooter

Any scooter owner should know how his vehicle works, because without such knowledge it is not only impossible to find out the cause of the malfunction, but also to eliminate it. Almost all equipment, no matter in which country or in which factory it was produced, has the same design for a scooter, so after examining and repairing one moped, you can easily troubleshoot any other.

Scooters are rightfully considered one of the most economical and unpretentious means of transportation. Ease of operation, low engine power and amazing maneuverability have made scooters one of the most popular types of equipment.

If we consider the general structure of a scooter, then we can say that this vehicle contains an engine, transmission, suspension, chassis, plastic parts and control systems. The functions of the main components of mopeds should be considered in detail.

- In a scooter engine (the device is often an internal combustion engine - an internal combustion engine), the energy obtained from fuel combustion is converted into mechanical energy, which sets the vehicle in motion.

- The main function of the transmission is to transfer torque from the engine to the drive wheel (in the case of scooters, this is the rear wheel). The transmission of most mopeds that were produced from the beginning of 2000 to the present day consists of an automatic variator, clutch, gearbox, and a foot start system.

| The diagram shows the general structure of the moped: 1 – front fairing; 2 – steering control panel; 3 – protective steering fairing; 4 – seats for the passenger and driver; 5 – trunk located under the seat; 6 – wing; 7 – side fairing; 8 – rear wheel; 9 – power transmission; 10 – driver’s floor; 11 – suspension; 12 – brake system. |

- The chassis of the moped includes both wheels, the brake system and the suspension. It is thanks to the suspension, which ensures the connection of the wheels to the frame, that vibrations during driving are dampened, and braking or speeding up are carried out smoothly and softly.

| The photo shows the structure of the moped, or rather, the “engine and transmission” unit: 1 – the place where the engine is attached to the frame; 2 – engine cylinder; 3 – the transmission itself, which includes the scooter’s variator device, as well as the clutch; 4 – place to which the shock absorber is attached; 5 – wheel. |

Basically, all mopeds have either a two-stroke or four-stroke gasoline engine and, depending on such features, the moped or scooter can be supplemented with various components - for example, an oil pump.

It should be noted that the design of the scooter’s carburetor also refers to the “engine-transmission” unit, although it is not indicated in the photo.

- The scooter's control devices include a steering wheel, a series of ignition buttons, turn signals, headlight switches, brake levers and a speed controller.

- Plastic cladding refers to all mudguards, fairings, as well as tuning such as spoilers or panels that perform an aesthetic function.

Side mirrors, trunk, saddlebags and other parts that are not included in the basic structure of the scooter are called additional components or equipment.

Despite the fact that many motorcyclists are accustomed to scooters with an automatic centrifugal clutch, on the market you can also find two-wheeled vehicles with a mechanical gear shift system (for example, with a four-speed manual gearbox with an engine capacity of 49.3 cc). Such scooters are considered rare and require great driving skills from drivers.