Creation of VAZ-2101

Everyone knows that the VAZ 2101, or in common parlance “Kopeyka”, copied the external features and technical features from the Italian Fiat-124 model of 1966. Of course, all materials for production were used only Soviet ones.

The first stage of the plant was put into operation on March 24, 1971 and was designed to produce 220,000 cars per year. The following year, AvtoVAZ doubled its production capacity.

The VAZ-2101 was created as a low-power car (four-cylinder engine capacity was 1.2 liters; power - 62 hp at 600 rpm; maximum speed - 140 km/h) and with a relatively low price, so that everyone could afford to buy a legendary car.

Compared to the Italian prototype, the VAZ-2101 acquired rear drum brakes (instead of disc brakes), which were more durable and resistant to dirt. According to the characteristics of our roads, the ground clearance was also increased, the body and suspension were strengthened. In all subsequent years, the VAZ model was refined and subjected to modifications. But even in this (pristine) form, the VAZ-2101 was produced until 1982 and became a truly “people's” car.

Penny tales: myths and facts about the VAZ-2101

MYTH 1: The VAZ-2101 was a complete copy of the Fiat 124 - a myth

It is generally accepted that the VAZ-2101 is licensed, and therefore an exact copy of the Fiat 124, a car that became the European Car of the Year in 1967. However, in reality, over almost four years of joint work, Italian and Soviet specialists made about 800 changes to the design of the original car. And there were quite good reasons for this.

1 / 4

2 / 4

3 / 4

4 / 4

The Italian car (on the left) is similar to our Lada even in the theme of the advertising photos!

Articles / History of Russo-not-tourist: how the Fiat 124 became a Lada Critics of the domestic automobile industry, who criticize it for borrowing, often lack understanding of how difficult it is not only to create a car from scratch, but even to make a “local” version... 73894 14 34 09.11.2015

The first samples of the Fiat 124, which arrived for testing in the USSR in the summer of 1966, began to “crumble” on the roads of the Dmitrov test site after only five thousand kilometers! In particular, the body could not withstand travel on the cobblestones of the calibrated “Belgian pavement”; cracks appeared at the junctions of the roof and pillars, the rear axle housing burst, the rubber buffers of the front suspension failed... And that’s not all: in the conditions of Soviet reality, On winter roads sprinkled with sand and salt, the brake pads of the rear disc brakes wore down to metal in just a few hundred kilometers! In a word, “full-scale” tests showed that the Italian car clearly requires adaptation to our conditions.

In addition, Soviet specialists, even in the early stages of negotiations with the Italians, insisted on an overhead camshaft arrangement (OHC design) instead of the archaic design of the Fiat 124 engine, in which the camshaft was located in the cylinder block. As a result, the serial VAZ-2101 received a more modern engine, a reinforced body, rear drum brakes, increased ground clearance and many other improvements, thanks to which the new small car with honor stood the test of the harsh climate and not the best roads of a huge country. Thousands of new owners were happy to discover in the first year that the new car was much warmer and more stable in winter than Soviet cars of that time, and the Zhiguli engine started easily and confidently even in twenty-degree frost.

The Fiat 124 engine was made according to the OHV design - that is, with a lower camshaft

Two key differences between Lada and Fiat are the engine design and the type of rear brakes

MYTH 2: VAZ-2101 was somehow inferior to Muscovites - true

Along with the Zhiguli, new industrial standards appeared in the USSR - high-quality materials and new tires were introduced into use, and speed and comfort reached a new level.

At the same time, the first model of the Zhiguli inevitably and immediately began to be compared with the AZLK-412 - a car that was close to the “penny” in size, price and purpose, but at the same time it was a development of the “four hundred and eighth” and differed from the Tolyatti car in design. The Moskvich was inferior to the Zhiguli in terms of comfort, because the back seat was noticeably cramped, since part of it was eaten by the “hams” of the wheel arches. In addition, the Moscow car was noisier, and in the winter the interior (especially in the back) was not as warm as in the “Italian”. Finally, driving the Zhiguli was noticeably easier and more enjoyable even for a novice, and the spring rear suspension handled bumps better than the Moskvich’s springs.

1 / 2

2 / 2

Moskvich or Zhiguli? The “former foreign car” was more comfortable and faster, and Moskvich was more durable and unpretentious

But at the same time, Muscovites were less sensitive to bumps and irregularities. After all, the M-412 engine crankcase was reliably “covered” by a powerful front beam, while on Zhigulis many drivers sometimes punched the pan on rocky roads. The body of the Volga small car, even after Soviet modifications, did not like overloads and reckless off-road driving, which is why it could be irreversibly deformed even without obvious accidents! And the spring suspension did not tolerate overloads and quickly sagged for those owners who carried too much weight on their car.

In addition, the VAZ-2101 engine had its own “Achilles’ heel” - the infamous camshaft, which in the first decade, in rare cases, served at least 80-100,000 kilometers, while on Moskvich and IZh vehicles the owner knew about this part of the gas distribution mechanism I only remembered it during a major engine overhaul.

The driver's position behind the wheel of a Zhiguli was different from that to which Soviet drivers were accustomed. After all, in order to increase the space in the back seat, Fiat designers strongly tilted the steering wheel

And Moskvich was much more unpretentious - he calmly “digested” low-grade oils and “seventy-sixth” gasoline, while Zhiguli required the use of exclusively high-quality fuels and lubricants - AI-93 fuel, modern motor oil of category “G” with a package of anti-wear and oxidizing additives, antifreeze instead of water in a closed cooling system... Let's not forget that Moskvich, thanks to its simple and well-known design, was much easier to “get your hands on,” while servicing Zhiguli required a special tool.

Finally, many drivers noted that it was more comfortable to sit behind the wheel of an AZLK (especially in the 2140 model) than in a “kopek” , where the driver’s legs and arms were bent more than usual.

MYTH 3: The first VAZ-2101 production consisted entirely of Fiat parts - a myth

The Kopeika was not the first Soviet car produced under a foreign license. But this particular car was the first “foreign car” that ordinary citizens could purchase with their own money. And if in the first years the very fact of the presence of Italian specialists at the plant and their constant “technical support” was perceived by contemporaries quite calmly, then around the end of the nineties, when the value of cars preserved in their original form increased sharply, rumors about exclusive cars began to circulate in the CIS countries the first years of production, which consisted entirely of Italian components. The arguments invariably included “bolts with the inscription Fiat”, and when selling Zhigulis of the first model, even cars produced in the late seventies were often listed as “pure Italians”!

Early “kopeks” could be distinguished by the so-called “crescents” between the radiator grille and headlight rims (1970-1971), as well as by the round mirror located on the wing (until 1975)

In reality, Italian engineers did control production in Tolyatti, but this happened until 1974. And if the first three models (VAZ-2101, VAZ-2102 and VAZ-2103 ) were indeed created with the direct participation of Fiat, then all subsequent Zhiguli based on the “kopek” ( 21011 , 2105) were developed in-house.

The first three VAZ models were created under the supervision of Fiat engineers

By August 1970, when mass production of the VAZ-2101 began, the production of all parts in the USSR had not yet been established, so the cars of the first years of production were actually actively equipped with foreign-made parts. For example, in the second half of 1970 and at the beginning of 1971, “kopecks” were equipped with more angular “fangs” of bumpers made by Fiat, as well as a “Fiat” starter, generator, steering gear, jack, and thus fasteners with a characteristic inscription. During this period, cars were equipped with a floor gas pedal, a rear license plate light, rear reflectors and a steering wheel cover made by the Italian company Stars. From Fiat's homeland in Togliatti, headlights (Carello), windshield wipers (Magnetti Marelli) and a carburetor (Weber) also came. However, over time, the number of foreign-made components decreased noticeably - they were mainly used to complete Zhiguli cars intended for export.

1 / 4

2 / 4

3 / 4

4 / 4

Pay attention to the triangular shape of the “fangs” on the front bumper - this is what Fiat parts looked like, delivered from Italy

MYTH 4: VAZ-2101 was popular abroad - true

The launch of a mass-produced car at VAZ pursued several goals, one of which was the receipt of foreign currency into the treasury through export deliveries of cars, which began a year after the start of mass production of Zhiguli. In order to perform adequately in foreign markets, brand new Zhiguli cars underwent almost four dozen different additional checks, which made it possible to identify even minor assembly flaws.

1 / 3

2 / 3

3 / 3

At the same time, Soviet Ladas (namely, the export Zhiguli received this euphonious name) in the early seventies did not lose much to the “co-platform” Fiats, but were significantly cheaper than European cars. True, in the early years, Autoexport supplied VAZ-2101 mainly to the CMEA countries - the so-called “socialist camp”. Motorists in Bulgaria, Yugoslavia, Hungary, Czechoslovakia and the GDR quite willingly switched from their Trabants, Wartburgs and Skodas to the new Soviet small car, in which the Italian “source” was easily guessed. Well, the “kopeck” began to be actively supplied to Western European countries in 1974, when the Fiat 124 had already been discontinued in its homeland, and the Soviet car did not compete with its Italian prototype.

In the countries of the “socialist camp” the new Soviet machine was received very warmly. And they didn’t shy away from capitalist ones either - at least those who wanted to buy “a lot of cars for their money”

The Fiat 124S was similar in finishing to the Soviet VAZ-21011. It’s interesting that this “late” Fiat was stopped being produced in Italy just at the moment when the modernized “kopek” was launched in the USSR.

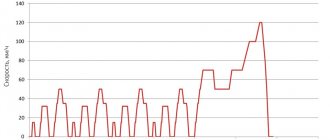

That is why the export of Soviet cars began to increase at a record pace: if in 1971 the USSR supplied 150,000 cars abroad, then in 1975 the figure doubled - to 300,000 cars a year! As you might guess, the lion's share of this volume belonged to the first model Zhiguli, which were supplied not only to the countries of Eastern and Western Europe, but also to Canada, New Zealand, as well as some Latin American countries - Bolivia, Panama, Peru and Uruguay. Lada-1200 (export designation VAZ-2101) was also purchased in England, where cars with right-hand steering were supplied.

1 / 2

2 / 2

Right-hand drive “penny” - it happened!

In 1979, the millionth Soviet-made car was delivered to the CMEA countries - and it was a Zhiguli! True, interest in the “kopek” abroad by this time began to rapidly fade away - for the spoiled “Europeans”, the first-born of the Volzhsky Automobile Plant had already become an outdated model. Therefore, they switched to other VAZ models, and production of the “pure one” was stopped in the spring of 1983, leaving in the range of models the “successor” VAZ-21013, which was a combination of the body of the VAZ-21011 model with a 1.2-liter 2101 engine.

1 / 4

2 / 4

3 / 4

4 / 4

MYTH 5: VAZ-2101 was produced in separate batches until the early nineties - a myth

The first model Zhiguli lasted on the assembly line for 13 years - until 1983. From 1974 to 1981, a modification of the VAZ-21011 was produced, distinguished by body trim and a more powerful 1.3-liter engine. Subsequently, the “eleventh” was replaced by the VAZ-2105, and the only direct successor of the “one” in the model range remained the VAZ-21013. This modification was produced until 1988, when the front-wheel drive family in the form of the three-door V8 and five-door VAZ-2109 and newer “classic” models began to gain momentum.

VAZ-21011 differed from the “pure penny” in its finishing elements

1 / 5

2 / 5

3 / 5

4 / 5

5 / 5

However, right up to the collapse of the USSR (and even after it), there were rumors that in Togliatti small batches of “kopecks” were produced from time to time from leftover components, which, by the way, explained the fact that “penny” wheel caps were equipped with some batches of VAZ-2106 in 1990-1991.

1 / 3

2 / 3

3 / 3

In fact, production of the VAZ-2101 (more precisely, 21013) was discontinued in 1988, since by that time this model was very outdated even by Soviet standards and was easily replaced by other Zhiguli models - in particular, the more modern “five”.

MYTH 6: Vysotsky had a “penny” - true

In 1971, singer and actor Vladimir Vysotsky became one of the first lucky people to drive a new Soviet small car. Vysotsky drove a gray Zhiguli with license plate 16-55 MKL for only a short time: in July of the same year, Vladimir Semyonovich crashed his “penny”.

Vladimir Vysotsky never parted with his cigarette and guitar. But the actor, poet and bard also fell in love with cars, and his first personal car was a “penny”!

1 / 5

2 / 5

3 / 5

4 / 5

5 / 5

Moreover, there is a version that this did not happen by chance because of his aggressive driving style, but on a bet! Allegedly, after a football match, Vysotsky decided to take a “weak” deal from his neighbor, the owner of the same Zhiguli, but green. Two passionate fans decided to go towards each other and find out which of them would turn away first. Alas, both car owners lost in the dispute, significantly smashing both the gray and green “kopecks,” which was the reason for writing the comic “Song of a Car Envy.”

Be that as it may, Vladimir Semyonovich’s Zhiguli, damaged as a result of the accident, was restored, then deregistered in the fall of 1971 and sold, after which Vysotsky never returned to drive a Zhiguli, preferring foreign-made cars the Mercedes W116 executive sedan

MYTH 7: Soviet designers were to blame for problems with the camshaft - both myth and truth

After Soviet designers became familiar with the design of the Fiat 124, they had a number of questions and comments. In particular, the Soviet side, not unreasonably, considered the engine design with a lower camshaft and rod valve drive to be obsolete. At this time, Fiat itself was already testing engines with a gas distribution mechanism located entirely in the cylinder head, and our representatives personally saw prototypes with two overhead camshafts and a timing belt drive!

However, the Italian side had not yet worked out this scheme and insisted on supplying equipment for the production of an engine with a lower camshaft.

During numerous negotiations, Soviet specialists managed to “defend” the overhead camshaft, while agreeing to use cast iron to make the cylinder block instead of aluminum, which our representatives had previously insisted on.

The upper location of the camshaft was fundamental for Soviet designers. Subsequently, this decision played a cruel joke on many thousands of Zhiguli owners who were faced with premature camshaft wear

Thus, an overhead-shaft 1.2-liter 64-horsepower engine with a cylinder diameter of 76 mm and a piston stroke of 66 mm was put into mass production.

But it soon became clear that the camshaft located in the engine head wears out quite quickly and lasts only 40-60 thousand kilometers before replacing (or regrinding the cams)! There were several reasons. Firstly, due to the new scheme, the supply of oil to the contact area of the cams and the lever was not always sufficient - especially if its level was low, or the engine was started in severe frost, when the oil became noticeably thicker. Secondly, at VAZ, instead of 18KhN2M steel and cementing to great depths, they began to nitrid the shaft and use 40Kh steel for its manufacture. Finally, often the cause of premature wear of the camshaft was the car owner himself, who, in conditions of total shortage, poured anything into the engine of the unfortunate Zhiguli instead of the “Zhiguli” of the “G” group - “Moskvich” brand AS-8 or even “KAMAZ” oil.

In an effort to extend the life of the cams, the USSR even redesigned the camshaft! One option is additional oil collectors on the body to retain engine oil and supply it to the levers and cams.

Subsequently, the technology for manufacturing camshafts was improved, and the distribution of high-quality oils became widespread. Therefore, from about the beginning of the eighties, Zhiguli camshafts began to last 110-120 thousand kilometers until they were replaced, and in some cases, even until the first major overhaul of the engine.

However, one of the reasons for the “camshaft problem” of the VAZ-2101 was precisely the intervention in the engine design of Soviet designers, who insisted on such a design, but did not fully imagine the possible consequences of such a transfer.

Despite the shortcomings and even design features, Zhiguli became a real revelation for millions of Soviet citizens in the seventies. After all, it was the “penny” that allowed all those who were quite far from technology and avoided previous Soviet cars due to more labor-intensive maintenance to travel about their business in comfort. And even almost half a century after the start of production, this model with the touchingly naive expression of the round-headlight front is respected and already brings a nostalgic smile on the faces of those who once drove the same car for the first time - and not even while driving, but from the maternity hospital.

Characteristics of VAZ 2101

Domestic car designers paid special attention to modifications to the VAZ 2101 for more comfortable operating conditions in our country. As you know, the road surface in Russia is significantly different from Italy, so the body and suspension were significantly strengthened, which improved the technical characteristics of the VAZ 2101. The rear disc brakes from Fiat were replaced with drum ones. This was explained by their durability and resistance to dust and dirt, for which Soviet roadways were famous.

Changes affected almost everything, and most importantly – the engine design. Automotive designers increased the distance between the cylinders (this made it possible to bore the diameter of the cylinders) and moved the camshaft to the cylinder head. Changes also affected the clutch, gearbox, and rear suspension. As a result, the weight of the car increased by 90 kg. In total, there were more than 800 changes and differences in the design of the VAZ 2101.

From 1970 to 1986, the plant produced almost three million VAZ 2101 cars. When 19 years passed after the car was released, the AvtoVAZ Museum was replenished with a new attraction - the VAZ-2101.

VAZ 21099

This model is perhaps the most popular sedan in the CIS countries. Its production began in 1990 and successfully continued until 2004. VAZ 21099 was assembled at Ukrainian factories until 2011. The car differs from its predecessors in the dashboard, additional seat backs and interior trim. Depending on the year of manufacture, the car can be equipped with one of five types of engines. The 1.3-liter engine had a carburetor, and the 1.5-liter units had either a carburetor or a fuel injector. All models had a 5-speed manual transmission.

| Motor | Consumption (city) | Consumption (highway) | Consumption (mixed) | Fuel type |

| 1.3 MT 64 HP. | 9.1 | 5.8 | 7.7 | Petrol |

| 1.3 MT 135 HP. | 12.5 | 7.0 | 10.0 | |

| 1.5 MT 70 HP. | 9.1 | 5.7 | 7.7 | |

| 1.5 MT 78 HP. | 8.8 | 5.3 | 7.3 | |

| 1.6 MT 81 HP. | 9.0 | 5.8 | 7.8 |

Vehicle technical parameters

| Engine | |||

| Length, mm | 4073 | 4043 | 4043 |

| Width, mm | 1611 | 1611 | 1611 |

| Height, mm | 1440 | 1440 | 1440 |

| Wheelbase, mm | 2424 | 2424 | 2424 |

| Front track, mm | 1349 | 1349 | 1349 |

| Rear track, mm | 1305 | 1305 | 1305 |

| Ground clearance, mm | 170 | 170 | 170 |

| Minimum trunk volume, l | 325 | 325 | 325 |

| Body type/number of doors | Sedan/4 | ||

| Engine location | Front, longitudinal | ||

| Engine capacity, cm 3 | 1198 | 1198 | 1300 |

| Cylinder type | Row | ||

| Number of cylinders | 4 | 4 | 4 |

| Piston stroke, mm | 66 | 66 | 66 |

| Cylinder diameter, mm | 76 | 76 | 79 |

| Compression ratio | 8,5 | 8,5 | 8,5 |

| Number of valves per cylinder | 2 | 2 | 2 |

| Supply system | Carburetor | ||

| Power, hp/rev. min. | 64/5600 | 64/5600 | 70/5600 |

| Torque | 89/3400 | 89/3400 | 96/3400 |

| Fuel type | AI-92 | AI-92 | AI-92 |

| Drive unit | Rear | Rear | Rear |

| Gearbox type / number of gears | Manual/4 | Manual/4 | Manual/4 |

| Gear ratio of the main pair | 4,3 | 4,1 | 4,1 |

| Front suspension type | Double wishbone | ||

| Rear suspension type | Helical spring | ||

| Steering type | Worm gear | ||

| Fuel tank volume, l | 39 | 39 | 39 |

| Maximum speed, km/h | 140 | 142 | 145 |

| Vehicle curb weight, kg | 955 | 955 | 955 |

| Permissible total weight, kg | 1355 | 1355 | 1355 |

| Tires | 155 SR13 | 165/70 SR13 | 155 SR13 |

| Acceleration time (0-100 km/h), s | 22 | 20 | 18 |

| Fuel consumption in the urban cycle, l | 9,4 | 9,4 | 11 |

| Fuel consumption in the extra-urban cycle, l | 6,9 | 6,9 | 8 |

| Fuel consumption in the combined cycle, l | 9,2 | 9,2 | – |

VAZ 2111

This model is a modification of the “ten” with a station wagon body. At the Togliatti plant, such cars were assembled from 1998 to 2009, and in several branches the production of the VAZ 2111 continued until 2014. The main power unit of this car has always been a 1.5-liter engine with varying power depending on the number of valves. Some buyers were more impressed with the 1.6-liter engine. The 1.7 and 1.8 liter models had all-wheel drive, while the smaller models only had front-wheel drive.

| Motor | Consumption (city) | Consumption (highway) | Consumption (mixed) | Fuel type |

| 1.5 MT 72 HP. | 9.0 | 7.5 | 8.2 | Petrol |

| 1.5 MT 79 HP. | 10 | 5.7 | 7.2 | |

| 1.5 MT 92 HP. | 8.8 | 5.6 | 7.6 | |

| 1.5 MT 94 HP. | 9.0 | 7.5 | 8.2 | |

| 1.6 MT 81 HP. | 9.0 | 5.6 | 7.5 | |

| 1.6 MT 89 HP. | 9.0 | 7.5 | 8.2 | |

| 1.6 MT 90 HP. | 10.0 | 5.8 | 7.3 | |

| 1.7 MT 90 HP. 4x4 | 11.8 | 9.5 | 10.2 | |

| 1.8 MT 98 HP. 4x4 | 11.8 | 9.5 | 10.2 |

Brief description and history

It is the VAZ 2101 that is the oldest model of the Volzhsky Automobile Plant, with which the history of the domestic automobile industry began. On April 19, 1970, the first small car rolled off the assembly line of the plant. The model was based on the Fiat 124 of the 1966 model year. In fact, the first “kopecks” were practically Italian cars, because The technical characteristics of the VAZ 2101 and Fait 124 were not much different from each other: a 1.2-liter engine and an entry-level interior trim. There was practically no difference between the cars.

Subsequently, domestic car designers significantly improved the design of the car to suit the operating conditions in our country. The ground clearance has been increased because... The quality of the road surface did not always allow travel with convenience and comfort. The body and suspension were significantly strengthened, thereby improving the technical characteristics of the VAZ 2101. The rear disc brakes from Fiat were replaced with drum brakes. This was explained by their durability and resistance to dust and dirt, which was always enough.

Almost everything has undergone changes, including the engine design. The distance between the cylinders was increased (this made it possible to bore the diameter of the cylinders), the camshaft was moved to the cylinder head. In addition to the engine, changes were made to the clutch, gearbox, and rear suspension. As a result, the weight of the car increased by 90 kg. In total, there were more than 800 changes and differences in the design of the VAZ 2101.

From 1970 to 1986, about three million VAZ 2101 cars were assembled at the plant. 19 years after the car left the assembly line, the first commercial copy took pride of place in the AvtoVAZ museum.

Existing modifications of the penny

It is thanks to this that, looking at the inscription VAZ-21011, you can immediately understand that this car was manufactured at the Volga Automobile Plant (VAZ), belongs to the small class of cars with an engine from 1200 to 1800 cubic centimeters (21) and is the first model of this car in this class (01) with the first version of the modification, which differs from the original by installing a 1300 cubic centimeter engine.

VAZ-2101 . This is the very first version of the Kopeyka, which was extremely popular both among motorists and among the developers themselves. It’s not surprising that this car became the basis for future modifications, because it was extremely successful. It is worth noting that the VAZ-2101 was equipped with a 1.2 liter engine.

VAZ-21011. The first modification we mentioned above. The main difference from the traditional “Kopeyka” in this model is the engine. It was much more powerful than the previous version of the car, and its volume was increased to 1.3 liters. The car has also undergone quite a lot of changes in terms of design. These changes mainly concerned improved ventilation of the cooling radiator - four additional slots appeared in front and the shape of the radiator grille was changed. Reversing lights were also installed on this modification from 1974 to 1983 inclusive.

VAZ-21013. The main difference between this modification and the VAZ-21011 is a less powerful engine, identical to that installed on the original “Kopeyka” (1.2 liters); otherwise, the changes made in 21011 were retained in version 21013. Ladas were also produced for export and these cars known under the name Lada 1200 in almost all countries of the Socialist Commonwealth. First of all, they appeared in Czechoslovakia, East Germany, Bulgaria, Yugoslavia and Hungary, and the total number of such cars amounted to more than 57 thousand cars. Over time, the Lada 1200 earned respect among foreign motorists and very soon these cars could be seen on the roads of Germany, Austria, France and even Nigeria.

VAZ-21012 and VAZ-21014. The fame of Zhiguli was not limited to the Soviet Union. Two modifications of the Zhiguli were produced especially for countries with left-hand traffic. First of all, they were distinguished by a right-hand steering wheel and a reinforced spring suspension of the right front wheel. The fact is that when the controls were moved to the other side, the weight of the car began to be distributed unevenly and it was necessary to organize such a compensation system. In total, these cars were produced from 1974 to 1982.

VAZ-2101 pickup. Nothing was wasted in the Soviet Union, not even defective Zhiguli cars. Instead of being written off due to body defects, they were converted into pickup trucks and later used for factory needs. Simply, the entire rear part of the roof immediately behind the front seats was cut off and a new cabin wall was installed. The rear doors were welded to increase structural rigidity and, as a result, the load capacity of such pickups could be 300 kg. Of course, such cars did not go into production, but some amateurs even independently carried out such improvements on their “Kopeykas”.

“Limousine” VAZ 2101. No matter how comical it may sound, cars of this modification not only existed, but were also extremely popular in Cuba. Here they were used as minibuses and coped with this task quite easily.

VAZ 21011

VAZ 2101

VAZ 21013

VAZ 21012

VAZ 21014

VAZ 2101 Pickup

VAZ 2101 LIMOUSINE

Tuning VAZ 2101

In 1971, the AvtoVAZ factories in Tolyatti began production of the VAZ 2101 Zhiguli car. The model was produced under license from the Italian automobile concern Fiat, the prototype was the Fiat 124. The new car made a splash throughout the Soviet Union, from Kaliningrad to Kamchatka. A compact subcompact car with full-width windows, a torquey engine and impeccable maneuverability immediately won the love of Soviet car enthusiasts.

Motorist ratings

According to the general assessments of motorists and experts, the VAZ-2101 became a real breakthrough and triumph in the Soviet automobile industry. Even young motorists who had recently received their license could use this car with virtually no restrictions. The restrictions only applied to speeds during the car's run-in. Thanks to Kopeyka, Soviet motorists realized that even in a small car you can feel comfortable, not freeze in winter and talk in the car without raising your voice. Of course, this was largely the merit of our Italian partners, because our Zhiguli took a lot from the Fiat 124.

Starting the engine in winter no longer turned into a ritual with blowtorches and buckets of hot water, as it once was. With the advent of the VAZ-2101, motorists even did without a starter handle, which for the most part became possible thanks to the two-chamber Weber 32 DCR carburetor, which were more advanced than their Soviet counterparts of that era. These carburetors later began to be produced in the Soviet Union under the DAAZ-2101 marking and over time even migrated under the hoods of Volgas and other domestic cars, where they were carefully installed by motorists. In general, the appearance of the VAZ-2101 was a real breakthrough in the car market in the Soviet Union, and even now not everyone has abandoned this car and they can still be found on city streets.

Didn't find the information you are looking for? on our forum.

Original and modification

However, the potential for further improvements to the model was so obvious that the AvtoVAZ design bureau carried out a number of technical improvements. And in April 1974, a modification of the “penny” was presented to the general public - the VAZ 21011 model.

The new car had no obvious design differences, but all the small changes that were made nevertheless served as a radical update and, in fact, created a new generation VAZ 2101 model, which received the name VAZ 21011. “Eleventh” was different from the base model external features, engine characteristics and interior design. In addition, the VAZ 21011, the body of which differed slightly from the body kits of the “kopek”, looked updated due to the modernized radiator grille.

Classifications and numbering

It is worth saying that in addition to significant improvements compared to the Italian prototype, the domestic Zhiguli became the first car produced in the USSR to receive such a document as normal OH 025370-66. This document regulated the classification and designation system of rolling stock. Now, each new car in the series or trailer was assigned a four-digit number, the first two digits of which indicated the class of the car or trailer, and the last two - its model. Sometimes a fifth digit was also used, which indicated that this car was a modification of a certain model and one could immediately understand what changes had been made to this particular car. Also sometimes additional numbers were used in the number. The sixth digit could indicate what climate the car was intended for and whether it was intended for import. In rare cases, additional numbers were added through a hyphen, which showed that this car was an intermediate modification of the car.

External differences

The car received an engine with improved performance, a cylinder capacity of 1300 liters and a power of 69 hp. Exterior improvements affected primarily the front end; the radiator grille was replaced with a more modern one; four horizontal slots were made in the facing panel above the front bumper for better ventilation of the engine compartment. The characteristic “fangs” on the bumpers were abolished, and plastic linings were laid along the entire length. The rear pillars were equipped with technological openings for forced ventilation of the interior. The outside of the hoods is covered with decorative grilles.

The taillights have taken on a more modern shape, with reflectors integrated between the stop and turn signals. A reversing light was also installed. Inside, changes affected the instrument panel, the front seats, which became more comfortable, and the rear door armrests.

VAZ 2103

Another of the pioneer models, which first rolled off the factory lines of the Volzhsky Automobile Plant in 1972. The VAZ 2103 sold well in the countries of the socialist camp, where it was delivered under the name Lada 1500. Production of the model was discontinued in 1984, replacing it with the more advanced “seven”. The Troika was equipped with one of three engines (1.2, 1.3 and 1.5 liters in volume and power of 64, 69 and 75 hp, respectively). All power units were accompanied by a four-speed “mechanics”, and fuel was supplied using a carburetor.

| Engine | Consumption (city) | Consumption (highway) | Flow (mixed) | Type of fuel |

| 1.2 MT 64 hp | 8.8 | 8.2 | 8.6 | Petrol |

| 1.3 MT 69 hp | 11.4 | 8.2 | 10.0 | |

| 1.5 MT 75 hp | 11.5 | 8.3 | 9.4 |

Pendants

The chassis of the VAZ 21011 did not need modernization. The VAZ 2101 model was operated on Russian roads for two winter seasons, and no serious deficiencies were noted. The ground clearance was increased by 3 centimeters and that was where the improvements in driving characteristics ended.

The front suspension is a lever design - independent. The levers are stamped and attached to the cross beam using silent blocks. The connection of the levers to the trunnion is carried out by means of ball joints, upper and lower. Shock-absorbing functions are provided by steel coil springs combined with double-acting hydraulic shock absorbers. The suspension is equipped with a transverse bar that levels out vibrations.

The rear suspension is of a pendulum design - dependent, with a transverse stability beam. Depreciation is provided by reinforced coil springs working in conjunction with hydraulic shock absorbers. There are no sway limits in the vertical plane; the suspension is equipped with rubber buffers.

Soon the VAZ 21011 car had a new name - “LADA 1300”, under this brand the car was exported. At the same time, they created another modification - the “police” one. This is a VAZ 21016, on which a 2103 series engine was installed. The power of the vehicle's power plant for law enforcement officers was 77 hp, and these parameters were documented in accordance with GOST.

Sports achievements[ | ]

The sporting success of the Zhiguli was already built into the engine itself, with a camshaft in the cylinder head. It turned out that the engine lends itself well to boosting - Soviet racers received an excellent opportunity to build sports cars[2].

VAZ-2101 and their crews after the finish of the 1971 Tour of Europe Autocross VAZ-2101 Interior of a rally VAZ-2101 from the 1970s, replica

The debut of the VAZ-2101 in the sports arena took place at the beginning of 1971 in Riga at the team championship of the USSR Winter Rally Championship. Then - the USSR championship in circuit racing, where Togliatti cars were even brought into a separate class "Zhiguli". And already in the fall of the same year, VAZ-2101 cars took part in international competitions: three Soviet crews started in the Tour of Europe-71 marathon.

.

The route of this rally was laid across the territory of 14 countries of Western and Eastern Europe (including the territory of the USSR), and the total length of the distance reached 14 thousand kilometers. At the end of the tour, the VAZ-Avtoexport

won the Silver Cup in the team competition, and the crews Girdauskas-Madrevits and Lukyanov-Karamyshev also received awards in the individual competition.

The regularity of this fact was brilliantly confirmed later at the Tour of Europe-73

, where the teams racing the VAZ-2101 received both the gold and silver cups at once.

The VAZ-2101 was popular not only in the USSR as a racing car. The British, for example, in the 80s organized a special rally championship Lada Challenge

[3]. Subsequently, the model did not leave the tracks of both intra-Union and international competitions for many years, and VAZ-2101 is sometimes seen in amateur rallies even today.

Starts at the Nürburgring[ | ]

VAZ-2101 Zhiguli car produced in 1971, prepared by the CityMotorsport

, participated in the historic car race held at the prestigious Nürburgring circuit on October 1, 2004, and finished in thirtieth position overall and first in class[2].

In 2010, the VAZ-2101 again entered the track. This time, Mikhail Gorbachev's team took part in the FHR Historischer Langstrecken Cup

, held on the full version of the Nürburgring track.

The preparation of the car for the start was carried out with the support of Rossauto

. The main rivals of the “one” were cars with an engine capacity of up to 1300 cm³, produced from 1965 to 1971. The crew included Andrey Oleinikov, journalist and driving instructor Dmitry Sokolov, and Alexey Mochanov. The crew took 56th place overall out of 70 cars[4].

"Weber" or "Ozone"

All engines of the VAZ family from 1971 to 1978 were equipped with a simple single-chamber Weber carburetor, economical and quite efficient. Since 1979, more advanced Ozone carburetors, which had autonomous idling, were already installed on cars. The new product did not catch on among Soviet car enthusiasts due to difficulties in adjustment and unreliable design.

In 1980, it was decided to install a new ignition distributor on the VAZ 21011 car, which was coded 30.3706-01. At the same time, the car received a two-liter windshield washer reservoir and a foot-operated drive switch.

What engine can be installed on a VAZ 21011 instead of the factory one?

The VAZ 21011 is an excellent option for tuning lovers, since the car has such a simple design that it is quite possible to turn it into anything without major modifications. The same applies to the engine compartment: amateurs can install a more powerful engine without the help of car service specialists.

However, you need to know moderation in everything: the body of the VAZ 21011 is designed for certain loads, and therefore a super-powerful engine can simply tear the car apart. Therefore, when choosing an alternative motor, it is best to pay attention to structurally similar options.

Engines from VAZs

Of course, this is the best way to optimize your “penny”, since “related” engines will fit the VAZ 21011 in almost all respects. Engines from 2106, 2107, 2112 and even from 2170 are considered optimal for installation. It is important that they fit the mounts “ kopecks" and will fit optimally with the gearbox.

Honorary title

Throughout the entire production period, the VAZ 21011 was produced side by side with its base model, the VAZ 2101. Both cars were considered the most popular and popular throughout the USSR. In 2000, the magazine “Behind the Wheel” conducted a global survey of the population of Russia and the CIS countries. In the small car category, the title “Best Car of the Century” went to the Kopeyka, the VAZ 2101 and its copy of the VAZ 21011. The recognition was worth a lot, because these models had long been out of production at the time of the survey. The photo of the VAZ 21011 was replicated in all print publications promoting the best examples of automotive technology as an example to follow.

VAZ 2108

Production of the small three-door V8 began in Togliatti in 1984. Until 2005, when the model was discontinued, it had not seen a single generation change, but was extremely popular in the Soviet and post-Soviet space. The 2108 was equipped with one of three types of gasoline engines. The 1.1-liter engine produced 54 hp. and was driven by a carburetor. The power of the 1.3-liter engine with a carburetor was 64 hp, and with an injector - 140 hp. 1.5-liter engines could produce 70 or 78 horsepower.

| Motor | Consumption (city) | Consumption (highway) | Consumption (mixed) | Fuel type |

| 1.1 MT 54 HP. | 8.2 | 5.2 | 6.8 | Petrol |

| 1.3 MT 64 HP. | 8.6 | 5.4 | 7.0 | |

| 1.3 MT 140 HP. | 9.5 | 7.8 | 8.2 | |

| 1.5 MT 70 HP. | 8.6 | 5.7 | 7.8 | |

| 1.5 MT 78 HP. | 8.0 | 5.4 | 6.7 |

VAZ 21011: characteristics

- Make – VAZ 21011.

- Body – sedan.

- Number of places – 5.

- Maximum speed – 145 km/h.

- Acceleration time to 100 km/h is 18 seconds.

- Fuel tank capacity is 39 liters.

- Start of production - April 1974.

- Discontinued in 1988.

- Length – 4043 mm.

- Height – 1440 mm.

- Width – 1611 mm.

- Front track – 1349 mm.

- Rear track – 1305 mm.

- Wheelbase – 2424 mm.

- Trunk capacity – 325 liters.

- Engine – petrol, carburetor, front, longitudinal.

- Drive – rear.

- Transmission – manual gearbox (4-speed).

- The front suspension is independent, wishbone.

- The rear suspension is pendulum, with a transverse stability beam.

- Front brakes are disc, non-ventilated.

- The rear brakes are drum brakes, self-adjusting.

- The steering mechanism is worm and hypoid.

- Curb weight – 955 kg.

- Fuel consumption is 9 liters per 100 km in the city, 8 liters per 100 km on the highway.

- Tire size – R13 165/70

VAZ 2109 body acquaintance

How much does a VAZ-2101 weigh with an engine and without technical specifications

Inside the car body practically does not cause any complaints from car owners, despite its small, compact dimensions. However, there is enough space for a trip of five people of average build. The low-mounted dashboard is quite easy to operate; if necessary, you can build in modern electronic components, but this will require you to spend a significant amount of money.

VAZ 2109 body dimensions

There is a slight drawback in terms of the material construction of the interior, which is made of plastic. This is a significant drawback, since such a building periodically rattles and needs technical modernization to strengthen it. However, this is quite easy to do and you don’t have to spend a lot of money.

Tuning VAZ 21011

The “eleventh” model is a wide field of activity for the owner’s creativity. Tuning a VAZ 21011 car is possible using “original” VAZ units and accessories. The results can be impressive, but you need to be prepared for significant expenses. Nevertheless, you can try.

So let's start with the engine. The tuned VAZ 21011 engine can be assembled based on the cylinder block from model 21213. The piston diameter is 82.4 mm, the piston stroke is 80 mm. The working volume of the cylinders is 17.05 liters. These data already guarantee power in excess of 100 hp. The crankshaft can be taken under number 213. It is better to use the standard camshaft. The generator will fit from the VAZ 2108. Solex 41 carburetor is the best option. The transmission perfectly matches the five-speed gearbox from the VAZ 2105.

The front suspension needs to be redone. Shorten the spirals by 1.5 turns. Shock absorbers should be of Plaza Standard brand. The rear suspension remains standard, but the 21213 Phobos coils are shortened by 3.5 turns.

The front brakes are calipers from a VAZ 2112, the discs are ventilated, the rear brakes remain as is.

The main brake cylinder of a dual-circuit system can be used from a VAZ 2108. The handbrake is standard, the pressure regulator is eliminated.

The wheels are forged LeMan ZEPP wheels. Tires R15 195/50 Yokogama Sport

In the interior we install the front seats from the VAZ 2107 model, the dashboard from the “six”.

VAZ 2113

Production of this three-door hatchback, which has basic elements of the VAZ 2108 and VAZ 2115, was launched in 2004 and was produced until 2014, being removed from the carrier only after the appearance of more modern models. Cars in this series were equipped with gasoline engines with fuel injection, which worked in combination with a five-speed manual transmission.

| Motor | Consumption (city) | Consumption (highway) | Consumption (mixed) | Fuel type |

| 1.5 MT 79 HP. | 9.2 | 7.6 | 8.4 | Petrol |

| 1.6 MT 81 HP. | 10.0 | 5.7 | 7.6 | |

| 1.6 MT 98 HP. | 9.8 | 5.2 | 7.4 |

The cost of used "elevens" today

The last VAZ 21011 car rolled off the assembly line in 1988. Today you can only buy a used and rather shabby car. The VAZ 21011 model, the price of which does not exceed 2 thousand dollars in good technical condition, can only be purchased by a connoisseur of cars of that time. And in any case, the car will require additional costs. It would be better then to buy a copy for $400 and carry out a major overhaul. And then take a souvenir photo of the VAZ 21011, which will be dear to you as a rarity from the distant past.

Interesting Facts

Regardless of the model type, the average fuel consumption per penny decreases or increases slightly. Although the car is expensive to refuel, it is in demand among many people, including young people. It is inexpensive to maintain, it is repairable and is suitable for the first experience of owning a vehicle.

There are several interesting facts in the history of the penny. Not many people know, but the end of production falls in 1982, while in 1977 the modernization of the kopeck was stopped. Despite this, the cars still drive today.

In 2000, a survey was conducted among motorists, in which more than 100 thousand drivers took part, and 80,000 of them recognized the penny as the best transport of the century, despite the high gas consumption. Volga took second place, and Lada 2109 took 3rd place.

Over the entire history of production, 2.7 million 2101 models rolled off the production line.

. At the same time, during production, the penny went through 800 types of changes of various kinds. Some of them appeared in new types of transport. It was the updates that made it possible to win the trust and love of the classics among many people. In addition, the penny was exported abroad, so you can see it even abroad. For this purpose, separate export models were created.

Part two. Corrosion

Causes of corrosion and sources of its damage Corrosion is the process of self-destruction of a material in the process of interaction with the environment. In our case, metal corrosion occurs due to:

- Winter “urban” operation;

- Cheap body restyling, under which all kinds of dirt accumulates;

- Storing the car in damp, unventilated areas.

Places of the VAZ 2101 body most susceptible to corrosion

As the experience of most car owners shows, parts of the VAZ 2101 body that are most susceptible to corrosion are located in hard-to-reach places where moisture does not evaporate for a long time (gaps, bends, flanges), namely:

- wheel arches;

- hinged elements and places of their attachment (hood, trunk, doors, sills, fenders).

And if no measures are taken, then it can move to other, more significant power elements (spars, joints of the sub-engine frame, central pillars, etc.). Depending on the degree of surface destruction, it depends on how we will restore the damaged part.

Stage one

The oxidation process is in the initial stage (chips, scratches), only a slight color change has occurred. At this stage, you can get by with small losses - cleaning the surface with a fine abrasive wheel and then polishing the surface.

Stage two

Both the color of the paint changes and its swelling occurs, that is, the destruction process occurs evenly over the surface of the element.

Corrosion of the rear wheel arch of a VAZ 2101

This type of corrosion is not so terrible; it most often occurs due to poor preparation of the element for painting. It can be relatively easily cured by repeated stripping and subsequent filling with cold-set epoxy mastic. This type of mastic has high strength, sufficient adhesion, and is easy to apply to the damaged area. It contains plasticizers and hardeners, which increase the plasticity of the resin and its impact strength, as well as fillers that reduce the shrinkage of the resins and ensure that the coefficients of thermal expansion of the metal and the resins are brought closer together.

Stage three

In this case, the destruction process already goes deep into the metal (spots, cavities, holes), which requires deeper cleaning of the affected element followed by soldering (tinning) or replacement of the entire element or its individual parts.

Tinning the body of a VAZ 2101 with tin

By the way, if you heat the metal with a torch flame to a light red glow and at the same time it does not begin to crumble into gushing sparks, then it can still be used for welding. Well, when the VAZ 2101 body parts cannot be restored at all, I replace them with new ones using resistance welding and electric welding operating in a gas environment (semi-automatic). Most often, the front and rear fenders with panels require replacement. Methods for repairing and replacing these parts can be taken as basic; to do this, you just need to find out the location of the seams for joining the elements:

Welding seams of the front tail

Welding seams of the rear tail

Front and roof welds

Rear and roof welds

To obtain optimal rigidity of elements with minimal deformation, it is best to weld parts every 50 millimeters, using small ties of 20 millimeters. As you have already noticed, do-it-yourself body repair of a VAZ 2101 is a very labor-intensive and responsible process, the quality of which directly affects the safety and service life of the car.