Silence when trying to start the engine

The Niva crankshaft cannot be turned by the starter.

There may be several reasons:

- Blown fuse.

- Poor contact between battery terminals.

- The battery is completely discharged.

- Failure of the starter solenoid relay.

- Failure of the intermediate relay that switches the starter circuit.

First of all, you should pay attention to the dashboard. When you turn on the ignition or the main electrical circuit in the engine, the lamps should light up on the dashboard or information should appear on the on-board computer, if we are talking about the Chevrolet Niva.

If this does not happen, the cause should be sought in the fuse box and in the battery contacts. During operation, oxides may form on these contacts, increasing the resistance. Loose contact connections can lead to sparking and burning.

If no blown fuses are found, you should check the reliability of the “+” contacts of the battery with the central wire and the “-” contacts with the vehicle ground.

To eliminate the malfunction, be sure to replace the fuses and clean the contacts. It would be a good idea to acquire even the cheapest tester in order to quickly check the presence of voltage in the electrical circuits of the car.

5.1. Engine

5.1.1. The engine will not start

Problems with starting a car engine can be divided into two main groups depending on the degree of engine heating.

Engine cold

From the moment the engine was turned off, at least 6 hours have passed at an outside temperature of +20 °C and at least 3 hours at –20 °C, the oil temperature in the engine crankcase coincides with the ambient temperature and to start the engine it is necessary to use the carburetor choke.

EXECUTION ORDEREngine is warm or hotThe oil temperature in the engine crankcase is higher than the ambient temperature and there is no need to use the carburetor choke to start the engine. Malfunctions in the starting systemMalfunctions in the starting system manifest themselves in abnormal operation of the starter. There are five main starter malfunctions: 1. The starter does not turn on. The reason is a violation of contact connections, a break or short circuit in the starter activation circuits, a malfunction of the additional starter activation relay, or a malfunction of the traction relay. 2. 3. The starter turns on, but its armature either does not rotate or rotates slowly. The reason is a discharged battery, broken contact connections, burnt contacts of the traction relay, dirty commutator or worn brushes, interturn or short circuit in the windings. 4. The starter turns on, its armature rotates, but the flywheel remains motionless. The reason is a weakening of the starter's attachment to the clutch housing, damage to the teeth of the flywheel or drive gear, slipping of the freewheel of the drive, breakage of the lever, drive ring or buffer spring of the starter drive. 5. The starter does not turn off after starting the engine. The reason is a malfunction of the starter freewheel, sintering of the contacts of the traction relay. In the event of such a malfunction, stop the engine immediately! 6. These malfunctions require qualified intervention from car service specialists. First, you can only check the degree of discharge of the battery using a voltmeter on the instrument panel and the tightness of the contact connections in the starter circuit. Checking the ignition systemYour vehicle is equipped with a high energy contactless ignition system. A voltage of about 40,000 V is supplied to the high-voltage wires, and although at low current levels it is not life-threatening, a possible electric shock when checking the ignition system can lead to serious consequences. Therefore, if you handle a high-voltage wire with the ignition on, use a thick rubber glove or, as a last resort, pliers with insulated handles. Before checking the ignition system, set the gear shift lever to neutral and leave the parking brake on. To check, you will need screwdrivers - slotted and Phillips, pliers with insulated handles and a tester or 12 V test lamp with two wires connected to it. You can also use a car carrier if you have one.

|

Clicking noises when trying to start the engine

If all contacts and fuses of the Niva are normal, you should turn the ignition key to the “start” position and listen to see if the relay clicks. If clicking sounds are heard clearly, the problem may lie in the starter voltage relay, the solenoid relay, or the starter coil circuit.

In “male” car services, the serviceability of the solenoid relay is usually checked by closing its contacts with a large screwdriver until the starter begins to rotate. For safety reasons, this should not be done under any circumstances.

If the problem is in the intermediate relay , then it is quite easy to replace it on the Niva. It is enough to insert the new relay block into the terminal block, observing the sequence and polarity of the connection.

To check the serviceability of the solenoid relay , the starter will have to be removed. After this, holding the starter, you should connect it to the battery and apply voltage to the contact of the solenoid relay. If a click is clearly heard, then the solenoid relay is working properly.

Perhaps the cause of the malfunction is oxidized and burnt contact pads of the starter . To check them, you should disassemble the solenoid relay and clean the contact group. Sometimes the solenoid relay is non-separable and must be replaced along with the contact group.

If the solenoid relay works, but the starter rotor does not rotate, it is necessary to check the condition of its brushes, which may have worn out so much that they have lost contact with the winding. In this case, repairing the starter costs little money.

If the rotor is jammed or its winding is burned out, it is best to replace the starter assembly.

Chevrolet Niva does not start: three different sensors

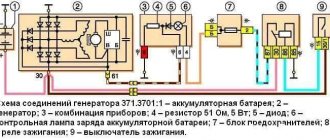

The crankshaft position sensor will not indicate its failure in any way. The Check light will not light up, the engine will simply not start. Finding this sensor is easy if you know where the alternator belt is (see photo).

DPKV sensor connector

Here we check the serviceability of the wiring, as well as the distance from the sensor to the “teeth” (0.8-1.2 mm).

The second suspicious element will be the temperature sensor. The engine may not start only if it breaks. In this case, the electric fan should work without turning off. That is, a break in the DTOZH sensor circuit is easily recognized.

Element “6” is DTOZH

In the photo there is a sensor, and to get to it, the air duct is removed.

If the idle speed control malfunctions, the engine on a Chevrolet Niva does not start, but the starter turns. By the way, the Check lamp may be on. Diagnostics:

- Just lightly press the gas and turn on the starter;

- If the engine starts, but without gas it does not start, it means the IAC is faulty.

The starter rotor turns, but does not rotate the engine crankshaft

In some cases, the starter turns on, but instead of starting the Niva engine, a whistle or grinding noise is heard. Possible causes of the malfunction in this case are failure of the overrunning clutch mechanism (“Bendix”) or jamming of the retractor relay rod.

In the first case, it is necessary to replace or repair the overrunning clutch, and in the second, clean the retractor relay rod and lubricate it with grease recommended by the manufacturer. Any Litol type lubricant is suitable for this.

The engine starts but soon stalls

The most common reason for this behavior of the Niva engine is the presence of any obstacle (air lock, clogged filter or failed fuel pump) in the path of fuel, or its complete absence. Look at the fuel level sensor. Perhaps you simply forgot to refuel your SUV, or the fuel left the tank against your will (it was leaked or drained by criminals).

In this case, be sure to check the integrity of the tank surface, all hoses and the filler neck shut-off device.

To check the serviceability of the fuel pump on gasoline carburetor engines, simply remove the hose from the carburetor inlet pipe and lower it into a previously prepared container.

After this, within 15-20 seconds you should crank the engine crankshaft with the starter, or pump up fuel manually. At the same time, a pulsating stream of fuel should appear from the hose. If this does not happen, the fuel filter must be replaced, and the fuel pump must be repaired or replaced.

In hot weather, when the car is left idle for a long time in the sun, another problem can occur: a vapor lock in the gas line. To remove it, you should use a regular tire pump, put its hose on the fuel supply fitting going to the gas tank and pump the pump several times. As a rule, this is quite enough to start the Niva engine.

In a Chevrolet Niva with electronic fuel injection, to determine the health of the fuel pump, you need to turn on the ignition and listen. When the electric pump is working properly, a quiet buzzing sound is always heard. If nothing happens when you turn on the ignition, and when you remove the hose, gasoline is not under pressure, you need to check the electrical circuit of the fuel pump, replacing the failed parts.

Another typical malfunction that causes the engine to stall is that the crankshaft position sensor (CPS) bracket is broken off. In this case, it is useful to check its fastening, as well as the condition of the wires and connectors.

Fuel rail

On the ramp next to regulator 5 there is a control fitting 3. It is closed with a cap, which is unscrewed and then carefully pressed on the spool.

If fuel flows, it means it is entering the ramp. But perhaps the necessary pressure is not created. Reasons: clogged filter cylinder, pump malfunction, etc.

The pressure should be 350 kPa (3.5 bar). It is controlled by unscrewing the spool and installing a pressure gauge. Before checking, you need to reduce the pressure!

If fuel does not flow, notice whether the pump turns on when the key is turned to the “I” mark. When the ignition is turned on “cold”, the pump should run for 10 seconds.

Additional mounting block

Know that fuse F2 and relay P4 are responsible for turning on the pump. There is also a main relay P5, and all these elements are located in a block mounted on the same bracket with the ECM (see photo).

Even if the pressure is normal, the injectors may be clogged. In addition, their wiring may be damaged.

Case from practice

What happens if water gets into gasoline? In the summer - nothing. And in winter, the power supply system can become clogged with ice. All elements are at risk, from the pump to the injector valves!

Fuel supply line filter

A small amount of water is always present in fuel. If this number is increased, this is what happens:

- The first start always goes without problems;

- Then, after leaving the car in the parking lot, after 2-3 hours the owner will no longer be able to start the engine without repairs.

All of the above applies to any injection internal combustion engine, including the VAZ-2123. And the “first candidate for failure” will be the fuel filter. It is located under the bottom of the Chevrolet Niva and is encased in aluminum (see photo). However, this is done on many cars.

Pumping up excess air

One smart book says that the engine may not start due to the fact that the intake manifold draws in too much air. This means you need to check the fastening of all pipes. But not only.

Vacuum brake booster

The source of “excess air” may be a faulty VUT. The starter turns, the engine on the Chevrolet Niva does not start, and the reason, it turns out, must be sought in the brake system!

We won't look for anything. Let's do it simpler:

- The vacuum supply hose is removed from the amplifier side (see drawing);

- The hole in the hose is closed with a finger and one test run is performed;

- The engine starts, which means the cause has been found.

That's the whole trick. We wish you success!

Despite its apparent simplicity, defects in the air supply system are difficult to detect. Check the fit of the hoses on the fittings and the tightness of all clamps.

The starter turns the engine crankshaft, but the engine does not start

The widest range of Niva malfunctions, sometimes combined (several malfunctions at once that prevent the engine from starting and operating), is much more common than others. When describing such cases, we do not take into account engines with a faulty or unregulated gas distribution system, unregulated ignition and fuel supply system.

In frosty weather, the engine may not start due to insufficient battery charge. In this case, it is more advisable to remove it from the car, bring it to a warm room, thaw it, wipe it dry from condensation and charge it to the maximum voltage value.

If you urgently need to start the engine, you should unscrew the spark plugs, clean them of frost or condensation, then screw them back into place and try to start the engine again.

In some cases, you can use the emergency method . Boil water, remove the plastic casing and pour boiling water over the intake manifold. Then try to start again.

Under no circumstances should you start a cold Niva engine “from a pusher” or from a tow. There is a risk of serious damage to it.

Set of "electrical" reasons

The first step in diagnostics: remove the cap from any spark plug, install spark plug A17DVRM and, holding it with pliers, turn on the starter.

How to remove the cap

The spark plug must be held by the hexagon, the pliers must have insulated handles, and the spark plug body must touch the “ground”. As a result, a spark can be observed. If there is no spark, it means:

- The ECM is faulty or is not receiving voltage;

- The ignition coil module burned out;

- High voltage wires are faulty.

Ignition system is faulty

Another main obstacle to starting a VAZ 2121 gasoline engine is the ignition system. Malfunctions in the heating system of a diesel engine can also make it significantly more difficult, and in cold weather, completely impossible to start it.

If a gasoline engine does not start, you should first check for high voltage on the center wire, or on the spark plugs with a separate ignition system without a distributor.

If the car has a contact (battery) ignition system, you should check the gap between the contacts, the condition of the cam, and also the capacitor. If the gap between the contacts does not correspond to the required value or the capacitor is shorted to ground, the reason has been found !

In other cases, you should definitely check the wires, distributor cap, and spark plug insulators for high voltage leaks. If there are black carbon tracks and cracks on the surface of these parts, they must be replaced.

ignition system is checked in a similar way . Particular attention should be paid to the spark plugs. There should be no traces of soot, soot, or oily deposits on the surface of their electrodes. Only the presence of a gray or brownish-red coating is allowed, which appears as a result of the combustion of various additives in gasoline.

You should also pay attention to the gaps between the central and side electrodes. Typically, the gap should not exceed 0.7 - 0.8 mm. Other parts, for example, quenching resistors and silicone wires should not have a resistance higher than 15 - 20 kOhm. When identifying the cause, also pay attention to the condition of all contacts, the presence of moisture and condensation.

The main difficulty when starting a diesel engine with a known good fuel supply system is faulty glow plugs. To check them, just turn on the voltage supply to them for 10-15 seconds, and then try to start the diesel engine. Glow plugs with a burnt-out spiral are quite difficult to distinguish from serviceable ones, so they must be identified by their electrical resistance. If the spark plug resistance is too low (1 - 5 ohms) or tends to infinity (several megaohms), the spark plug must be replaced.

NIVA CLUB

International Niva Club

Message by [email protected] » Sep 29, 2010, 11:56 am

Good day to all! Guys, help, sometimes the car won't start! Even the caburator servicemen can’t understand what’s going on. In general, this is what happens! As soon as it’s damp outside, for example, it was yesterday after the rain, or before that in the spring, when there was a thaw and everything was flowing. In general, the engine spins vigorously as usual, but it doesn’t even catch. doesn't grasp at all. What I tried: (at the moment when it wouldn’t start) I installed new spark plugs, it was no use, I wiped the distributor cover, looked at all the contacts for the presence of water on them (everything seemed dry), I completely cleaned the carb (Solex). and everything is just useless...it also twists and doesn’t grab. and then out of the blue it grabs and starts right away. By the way, there is always a spark on all four spark plugs. And the most interesting thing is that when it doesn’t start like that (I tried this once), then I immediately press it from the pusher literally from two meters. brbrbrbrbr..with half a turn

Yesterday this crap happened again, but it started on its own after probably the tenth attempt. And in the spring I had a lot of trouble with this plant. In the summer there were no problems with the plant AT ALL. everything is as it should be! In winter, it also starts normally, but as soon as there is snot on the street, that’s it. what could be the problem?

Bladerunner: “I had similar bullshit - condensation gets into the carb and it sets on fire, I don’t even remember how I got over it. I changed the air filter, changed the lid of the pan. "

Here's what it would sometimes start after: Once after cleaning the carb it started right away, another time after unscrewing and tightening the spark plugs (just stupidly checking), but the rest is not clear at all! And yesterday I pulled the caps off the spark plugs from two, checked how the others were sitting, turned the key to start and off we went. Maybe try replacing the spark plug wires? They are old...maybe there is a problem with them?

simbir: “When it doesn’t start, you open the carb and press the gas sector, fuel should come from the accelerator, if there is none, there is a fuel pump, a needle, a filter in the carb. If there is fuel, then the problem is the ignition. Most of all it looks like a hall sensor or switch, take a close look at the slider, it’s even easier to replace it right away. And then we change the parts in ascending order of the price of the parts: hall sensor, wiring to the distributor/switch, switch, coil. And the point is not even that there is a spark, because it can disappear. Maybe you're starting it wrong somehow? How about playing with the gas pedal when starting up and so on?

«

Bladerunner: “nah, the hall sensor is in the distributor, and the XX sensor is in the carb. You downloaded a book from the “Do it yourself” series.. everything is written there with pictures.” Captain: “It was such garbage, the switch died. I replaced it, and how my grandmother whispered!

but there was a spark, and there was gasoline. Apparently, it wasn’t always there!”

No fuel supply

Often the engine does not start if the fuel supply system . Attempts to start such an engine are usually accompanied by popping noises, shots in the muffler, the appearance of black smoky smoke and a strong smell of gasoline from the exhaust pipe. A malfunction in a carburetor engine is usually determined visually.

It is enough to shine a flashlight into the primary and secondary chambers. If there are traces of gasoline on the walls, and fuel does not spray out of the accelerator pump nozzle, but flows out in a thin stream, it is necessary to urgently identify and eliminate the malfunction. To accurately determine a malfunction in an injection engine, you need special equipment connected to the vehicle’s diagnostic connector, capable of reading error codes and faults .

To determine the serviceability of the injectors, you should disconnect them from the ramp, and then ask an assistant to crank the engine with the starter. If gasoline flows out of the injector nozzle in a thick stream or does not flow out at all, the injector should be washed in an ultrasonic bath or replaced.

To avoid various surprises along the way, it is recommended that you always check all engine systems before leaving, eliminating minor faults. For example, loose contact, friction of wires and hoses on various protrusions, leaks of oil and other liquids, etc.

In this case, you can not only eliminate minor breakdowns, but also identify and prevent more serious ones, which can lead to significant expenditure of effort and money. Always stay mobile. Good luck on the roads!