Possible reasons

A VAZ may not start for several reasons, starting with low-quality gasoline and ending with carburetor malfunctions. More details about everything.

Poor quality gasoline

This reason is quite common, so car repair technicians recommend refueling at trusted gas stations. You can drive for some distance on low-quality fuel, but then the car may stop, and you will have to clean the filters and flush the carburetor.

Lack of gasoline

Sometimes it happens that gasoline quickly runs out because a leak has formed somewhere or the driver simply did not monitor fuel consumption. In this case, you need to refuel - and you can continue driving. Many drivers of used cars complain that their gas was simply drained if the car stood in one place for a long time.

Wiring

Don't forget about the quality of the wiring. Sometimes, due to a small break, the car may not start, and it is quite difficult to find the reason. Therefore, it is suggested to first check the wiring (ring it), and also clean the wires (oxidation or incorrect connection of the wiring also affects the operation of the vehicle).

Battery

A dead or faulty battery can also be the reason why your car won't start. If this is the reason, then you can replace it with a new one or connect a battery from a neighboring car (that is, “smoke the battery”). It is also necessary to check the wires that connect the battery.

Starter

A faulty starter can also cause the machine to not work. If you suspect that this is the reason, then before removing the starter itself, you need to check the wiring for breaks, as well as the battery charge level. A low battery charge results in poor starter operation.

It is also worth noting that the starter armature cannot rotate if the wire ends are oxidized. In this case, they need to be cleaned and reconnected. There may also be a short circuit of the armature to ground, or the lever or clutch could fail - these breakdowns can be detected by disassembling the starter.

Malfunction of the pump or fuel filter

If the pump does not pump fuel, then you should pay attention to this reason. Perhaps there is a gap somewhere

Or the fuel filter may be clogged. In any case, it is necessary to clean the filter and carefully inspect the pump.

Spark plug

It is worth noting that faulty spark plugs in most cases lead to engine problems. This could be idling, jerking, floating speed. The spark plugs must be removed and carefully inspected. If there are cracks, dirt or stains on the insulator, as well as black electrodes, if the threads are oily or damaged, then the spark plugs must be replaced. If the problem was with the spark plugs, then the car should start.

Carburetor

Carburetor malfunction is perhaps the most common problem. In addition, there can be many faults here. This could be either clogged jets or a malfunction of one of the valves; the air damper may also not close completely before starting. One reason could be a faulty diaphragm or ignition switch. If in the case of a clog the problem can be quickly resolved by cleaning the jets, then in all other cases it is necessary to remove the carburetor, look for the problem and fix it.

Ignition sensor

If your ignition sensor warns of a possible problem, then you need to figure out what this might be related to. It could just be a faulty light bulb, or there could be a more serious problem that could result in the car simply not starting.

Read about other problems with cars in the articles:

- Why won't the car start

- Why does the engine smoke?

Things to remember

To eliminate this malfunction, the starter should be removed, inspected for damage, and thoroughly cleaned of any deposits accumulated on it. A lubricant change will also be required.

Do not forget that overheating of the engine has a very negative effect on the performance of the car. By the way, this can happen not only on a hot day, but also in severe frost if the engine cooling system has failed. In order to make sure that the cause of the engine not working was its overheating, you should look for traces of coolant in the cabin under the floor coverings. But even if they were not there, it is necessary to disassemble the stove and see if all the pipes are in place, as well as in what condition they are. The fact is that a banal blockage of the radiator could have occurred, due to which there was a failure in the cooling system.

The intake valve is another detail that you should pay attention to if your VAZ-2107 completely refuses to start. It could burn out, and without any reason. As a result, the gases emanating from the car will receive a very high temperature, due to which the engine will overheat.

Car won't start. VAZ 2107 carburetor 2001 The starter turns but does not engage the engine in any way

Communities VAZ Repair and Improvement Blog The spark is lost on the VAZ 2107

Check the switch, Hall sensor, ignition coil. As a rule, the reason is in the switch.

candles. Or the fuel-air mixture does not enter the cylinders. Check the pipe leading from the carburetor to the cylinders. Apparently, after the engine is running, this crap (pipe) becomes clogged. Moreover, after the engine stops, the garbage disappears somewhere.

on the coil, check the middle wire (through the spark plug to the engine) if there is no spark, run for the armored wires, if there is a spark, then the jamb may be in the carburetor (idle speed sensor), blow it out, if this does not help, then remove the air, disassemble the carburetor, you can find the procedure on Google They will tell you where to look for jets. PS do the first part of the advice when the car does not start! otherwise there will be a spark!

everything points to the carb, most likely it is clogged with debris and fuel in the jets, that is, no, because the debris is hanging out

Distributor

The VAZ-2107 uses distributor ignition. If the car does not start, you should check the condition of the contacts on the high-voltage wires. When the season changes, condensation forms on them. The distributor has five outputs.

Four of them go to the cylinder spark plugs, and one (central) goes to the ignition coil. A white coating often forms on the metal ends. Because of this, the slider will not be able to transmit impulses to the coil. By the way, it would be a good idea to check the ignition distributor itself. The part looks like this:

If it is burnt, the part should be replaced. The price of a new element is 150 rubles. If a spark forms on the ignition coil when starting the engine, the high-voltage wire should be replaced. It also “pushes” on candles. You can see this at night. Small blue sparkles are visible near them. In this case, the wires are replaced as a set. They are inexpensive. New elements cost about 700 rubles.

Why does the VAZ 2109 not start? Finding the reason

Communities Lada Priora Lada Priora Club Blog what affects the clutch release limit switch

The first step is to check the fuel, spark and air.

I would advise you to first check the air supply (compression and valve timing), you can also start by checking the ignition system.

The marks on the pulleys may match, but the compression may fail a little, for example: on one cylinder there is 10 atm, on the second 9.5 atm, on the third 7 atm, and on the fourth 8 atm, this can only be corrected by engine repair. Of course, it is worth getting serious about repairing the engine, but for now we need to put it off, since we will need to start the car. Having such compression, the engine will work and even not bad, but at idle it will be under pressure.

VAZ 2109 will not start - a method for finding reasons

VAZ 2109 does not start: start checking with a spark, Hall sensor and the condition of the spark plugs. Then measure the compression, check the timing marks, fuel pump and starter.Read more

Checking the power system

Next, we begin to delve into the power system. You will need to make sure that the carburetor is at the correct level, the pump is supplying fuel properly, and the idle air valve is working without failure. Therefore, everything is in order with the fuel supply. Also, do not forget to check the spark plugs; after a couple of attempts to start the engine, they will probably flood.

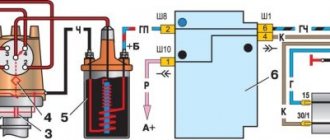

Checking the ignition system

Since the previous failure options were not confirmed, then the problem needs to be looked for in the ignition system. To carry out a routine check, simple instruments are useful; they can be bought without any problems at any auto store. But first you need to understand the structure and operation of the ignition.

And so, in our case, the VAZ 2109 has a contactless ignition system. This system includes:

- reel,

- distributor,

- switch,

- Hall Sensor.

The coil is connected to the battery with one terminal, and the second to the output transistor of the switch. The switch opens the output transistor when the signal drops to zero. At this moment, a high voltage current of approximately 25 kV appears in the secondary winding of the coil, and a current of more than 300 V appears in the primary winding. As a result, a high voltage voltage appears on the spark plugs, resulting in a spark appearing on the plugs.

But for a discharge to occur, the coil must be charged. Before the control pulse from the Hall sensor, the switch predicts when it needs to be shorted to ground in order to charge it.

Moreover, he does this in such a way that the charging time of the coil remains approximately unchanged. Otherwise, the coil will overcharge. To do this, the switch calculates the required period of the pulses that come from the Hall sensor. In other words, everything depends on the engine speed, the higher the speed, earlier the commutator begins to close the coil, but the time of the closed state will not change.

Now you can start testing. First of all, you need to check the spark on the candles - you can use a special spark gap for this. There is no result.

This means the hall sensor or switch may be to blame, or ground or power to the switch. In order not to guess for a long time, we will use AZ-1.

AZ-1 is an emergency ignition; it can be used in the rain or when driving through puddles. In other words, we can call it a substitute for a hall sensor.

The MD-1 sensor is an instant diagnostic, useful for checking the functionality of the ignition coil, hall sensor and ignition switch.

First of all, we used MD-1. This sensor is connected instead of the switch, as soon as it is hooked up, you need to turn on the ignition, do not start it:

- If the “P” LED lights up, this means that the ignition relay and ignition switch are working properly.

- LED “K” is on - the primary winding of the ignition coil is not damaged.

- turn on the starter: if the LED “D” blinks, it means the Hall sensor is in working condition.

If it does not blink, you will have to use the AZ-1 device and connect it instead of the Hall sensor.

Such devices for instant diagnostics of non-contact ignition systems are sold on the Internet for literally 100 rubles. But if you do not have the opportunity to purchase one, then you will have to spend much more time and check each sensor separately with a multimeter.

Everything works, but the engine doesn’t want to start. After a thorough inspection of the ignition coil, carbon traces were found where the high-voltage wire was connected. Replaced the coil and wire. The engine immediately started working as before.

I hope this real-life incident will help you find the reason why your car won’t start either.

Troubleshooting

If you operate a car for a long time without carrying out diagnostics and technical inspections, then everything will end in failure. If the engine does not start, then this breakdown can be repaired in a few minutes or in a few hours, depending on the type of breakdown. How can you determine why the starter does not turn? The main types of breakdowns include the following factors:

The simplest but most common breakdown of the starter on the VAZ 2107 is oxidation of the contacts. Moreover, the contacts oxidize both on the device itself and on the battery.

A more complex breakdown is usually associated with a malfunction of the solenoid relay, as well as rotor wear, breakage of windings, brushes and slip rings.

Burnout of the solenoid relay contacts. The exact breakdown of the mechanism can be determined after its dismantling. After removing the unit, you should check the condition of the main components, both the solenoid relay and the device itself. The resistance of the windings, the presence of breaks or short circuits, the presence of oxidation, contacts, etc. are checked. Once the cause of the breakdown is identified, it should be eliminated if possible, or the entire mechanism should be replaced.

The main reasons why the device does not spin

Let's consider the main reasons for such consequences in which the starter does not function.

The battery is low. It is very easy to identify such a breakdown. If you turn the key in the ignition, and there are no signs of life in response, and the lights on the panel have completely gone out, then the reason lies directly in the battery. The problem can be corrected by charging the battery. If the battery has a weak charge, at which the control panel operates, then when you try to start the engine, clicks of the relay operation will be heard.

Lack of ground on the solenoid relay. The mass can disappear for several reasons: contact oxidation, wire breakage, loosening of the nuts. If there is no “mass”, then the unit may not show any signs of life, or may work only once in a while. The situation can be corrected by stripping the contacts and tightening them, or by checking the supply wires.

Break in the circuit. If the relay does not click after trying to start the engine, then the failure may lie in the ignition contact group. The fault can be determined by checking the presence of contact between the ignition and the starter.

Solenoid relay malfunction. A malfunction of the solenoid relay can be eliminated by replacing it or, sometimes, repairing it.

The malfunction may also consist of a broken wire between the solenoid relay and the starter relay, through which power is supplied when the key is turned in the ignition switch.

How to recognize malfunctions

The starter should not be blamed if the engine does not start for the simple reason that the fault may lie in other devices. The malfunction of the device in question on the VAZ-2107 can be identified by the following signs:

- The car does not start, but the starter is buzzing. The reason is a malfunction of the retractor mechanism.

- Silence from the starter when turning the key in the ignition.

- The engine starts after several unsuccessful attempts to start it.

- The device continues to function after the engine is started.

- The presence of noise, grinding and knocking when the car is moving.

The presence of one of the above-mentioned signs indicates that the fault must be sought in this mechanism.

Unit repair

The estimated service life of the product is about 5-6 years. If the mechanism is used significantly, it should be replaced with a new one. You can check the serviceability of the solenoid relay by applying power to the product. The “+” power from the battery is connected to terminal “50”, and the “ground” is supplied to the unit body. If the product is in good working order, a quick and loud click will be heard. There will be no click on a faulty device. You can replace only the solenoid relay, but first carry out a full diagnosis.

To check the health of the windings, you need to use a multimeter. Features of the continuity of the stator and armature windings are described in the material on repairing the device. You need to check the serviceability of the overrunning clutch by turning the gear. The gear should rotate freely in one direction, and together with the armature in the other. It is important to check brush wear. The height must be at least 12 mm.

This concludes a brief analysis of the main starter failures on the VAZ 2107. There is no difference in these devices, and it does not matter which “seven” you have - an injector or a carburetor. The only difference is that older VAZ-2107 models are equipped with older models of devices, while models new to the year of manufacture are equipped with gear starters, which are characterized by greater efficiency and reliability.

The starter turns, but the car does not start

Communities Lada Priora Lada Priora Club Blog Elimination of engine overheating on Priora

This is a frequently encountered situation for which the design with the VAZ 2114 is intended. The procedure for solving it must begin with answering the question of whether the spark is finite. For this purpose, we take an assistant, unscrew one spark plug, place an armored wire on its surface and very carefully (beware of touching live parts, hold the insulated part of the wire) apply the spark plug to the cylinder head cover. While the assistant turns the engine, watch the behavior of the spark plug. If there is no spark, you need to find it.

If there's no spark

The ignition module is one of the main problems with the VAZ 2114 injector. It often breaks and sometimes a new one comes with a defect. You can read more about checking the ignition module in other material here. We would like to inform you that the problem may also lie in the chip that is connected to the module. The availability of food here must also be checked.

DPKV is another reason why there may be no spark. Since this common rumor sensor tracks the phases of cylinder operation, it is one of the main parts that allows accounting (software) of the ignition. Note that the possibility of its failure is lower than that of the ignition module. It is checked by an electrician on an oscilloscope; garage methods do not provide a clear assessment of the condition of the sensor (only replacement with a guaranteed working one).

ECU. “January” is a relatively reliable injector, but the “brains” will also malfunction at times. Often, the problem with it is recognized by a violation of the injection phases: nettles, a spark is supplied only to cylinders 4.5 and 4, or only to cylinders 1 and 3. If the problem is resolved, the usual cleaning of the contacts on the ECU chip, it is also subject to oxidation, which becomes a prerequisite for the loss of the signal.

Unless of course there is a spark

Not often, but such a problem does happen. By all indications, the car should start (gasoline is sprayed into the ramp, the starter turns, there is a spark, of course), but the engine does not catch on. There will be some pitfalls here.

Injectors. Most of them have a problem; it’s worth taking the car for diagnostics and cleaning it with an ultrasound. If failure occurs on the road, carefully examine the candles. If the injector supplies the mixture, you need to be in gasoline; if the spark plugs are dry, the possibility of an injector malfunction is high. But keep in mind that injectors occasionally become unusable all at once. Without quality installation, you are like a machine.

Finished starting, the engine should start.

Poor quality gasoline. It is understood that a serviceable engine should start almost on water, but it will just run poorly. In reality this is heresy. There are quite a few examples of “killed” engines after refueling (in the image of “Uncle Ashot”, so at completely official gas stations of recognizable brands). Keep this in mind. If the car does not start immediately or within a short time after refueling, there is no need to reset this option from your current accounts. The solution is to drain the gasoline and add another.

Lack of required pressure in the ramp. Here we return to the dilemmas with the fuel system. Maybe it's all about the pump or dilemmas with TPS (unlikely). If you have January 7.5, the prerequisite is a possible malfunction of the mass air flow sensor. In contrast to January 5.1, here Such a sensor is polled at startup and, if there is an error, the ECU may not allow the engine to start.

As a result, we note that in a number of circumstances of non-production in the presence of gasoline and spark, the following occur:

- the phases were set incorrectly when replacing the timing belt, or it broke or turned again - it’s worth checking;

- due to overheating, the cylinder head “started”;

- uneven compression in the cylinders, “stacking” of the rings.

Unplanted VAZ 2114 is a common situation, and there are a huge number of circumstances that cause it. Therefore, it is worth approaching this issue fully armed.

Fuel system problems

Of the fuel parts that allow accounting (software), the following reasons influence engine starting:

- presence of gasoline in the tank;

- the integrity of the fuel lines under the “belly” of the car;

- cleanliness of the filters: coarse cleaning (located in the tank) and fine cleaning (located under the car, to the right of the spare wheel compartment).

The car turns over but does not start VAZ 2114.

Also included in this category are electronic components that are directly related to the supply of fuel. This is an electronic fuel pump and fuel pump relay.

While inspecting other methods, you need to be one hundred percent convinced that the VAZ 2114 with an injector is filled. “Yes, there’s another l. five” according to the indicator on the tidy, or “I filled it up yesterday, I couldn’t spend that much” are not suitable. The tidy may lie; in other words, there will be leaks in the tank or fuel lines. Carefully check the car for fuel leaks, fill in 5-7 liters just in case. gasoline from a can.

The mesh in the tank gets clogged occasionally, leave the } myth option in the end, but the narrow cleaning filter is worth trying and changing if problems with the electronic part are excluded.

The operation of the fuel pump is checked by ear (after turning the key, you can hear its operation; if not, the pump has “died”, either the pump relay, or a broken wiring). According to the manual, you need to connect a pressure gauge to the fuel system. If the pressure does not stay within 2-2.5 atm, the VAZ 2114 does not grip due to insufficient fuel pressure.

The injector does not start well when cold

The first thing you should pay attention to when an injection car is performing poorly is the sensors. Failure of some of them leads to difficulty starting the engine, since incorrect signals are sent to the ECU

It is usually difficult to start when cold due to:

- coolant temperature sensor, DTOZh informs the control unit about the state of the coolant, these indicators affect engine starting (unlike a carburetor car), adjusting the composition of the working mixture;

- throttle sensor;

- fuel consumption sensor;

- Mass air flow sensor (or MAP, intake manifold pressure sensor).

Often there is a problem with cold starting due to the fault of the fuel pressure regulator. Well, of course, whether it’s an injector or a carburetor, when a cold car doesn’t start well, if it stalls, the speed jumps, but after warming up everything is fine, then it’s imperative to check the condition of the spark plugs, and use a multimeter to check the coils and explosive wires.

Leaking injectors cause a lot of trouble when it’s hot outside, the car will have difficulty starting on a hot engine, and in the cold season a dripping injector will cause difficulty starting in the morning. To test this theory, it is enough to simply release the pressure from the vehicle in the evening so that there is nothing to drip, and look at the result in the morning.

We cannot exclude such a banal problem as air leaks in the power system - it complicates starting a cold engine

Also pay attention to the fuel poured into the tank, since its quality greatly affects engine starting

On cars such as the Audi 80 (with a mechanical injector), we first check the starting injector.

General advice: if the starter turns normally, the spark plugs and wires are in order, then you need to look for the cause of a poor start of a cold engine by checking the coolant sensor and checking the pressure in the fuel system (how much it holds and for how long), since these are the two most common problems.

Carburetor

Its malfunction is a common reason explaining why the car does not want to start.

We recommend inspecting the carburetor immediately after it is determined that everything is in order with the gasoline pump.

- unscrew the cap from the VAZ air filter;

- press the gas and crank the starter several times.

When all is well, gasoline will begin to flow into the intake manifold. If it is missing, it is necessary to deal with the carburetor. Usually the car does not start due to contamination of the jets. Wash them with a special solution (sold in stores).

Checking the fuel pump and fuel supply

The principles of fuel supply in carburetor and injection engine models are different, but periodically occurring malfunctions are largely similar. Fuel supply in both systems is carried out by a fuel pump. In the carburetor model it has a mechanical drive; in injection models it is an electric pump that creates high pressure in the fuel rail. Both types of pumps have built-in fuel filters, the clogging of which leads to failures when trying to start the engine.

An electrically driven fuel pump may not work due to the lack of supply voltage at its terminals. The culprit for this situation may be a blown fuse or broken wires. Problems may arise due to the fault of the carburetor; clogged jets will prevent the engine from starting. But most of the problems in the fuel system are inherent in the injectors. In such systems there are several sensors that monitor and regulate the operation of the power unit. Failure of the DPKV will make starting the engine impossible. Such problems can occur due to the fault of the pressure regulator in the fuel system. Poor starting of the engine injectors cannot be excluded from the organizers.

Fuel pump VAZ 2110

On injection engines, this requires relieving pressure in the fuel system using a special valve at the end of the fuel rail. Unscrew the cap and press the valve with a screwdriver. Gasoline should squirt out from under the valve. After this, release the valve and turn on the ignition. At this time, the fuel pump must start, restoring the released pressure in the system. If the pump is silent, turn on the starter. When the pump does not operate even when the starter is turned on, there is most likely a malfunction in its power supply system.

If the pump starts working, then we check the pressure in the fuel system again, releasing it through the same valve in the ramp. Splashing gasoline again indicates that everything is in order with the fuel supply system. When gasoline does not splash and does not appear from under the valve at all, we can talk about a faulty fuel pressure regulator in the rail (constantly bleeds gasoline through the return line into the tank) or some kind of plug in the main fuel line (for example, due to freezing of water in low-quality fuel ).

Fuel pump VAZ 2110 disassembled

On carburetor engines, checking the fuel supply is much easier. It is enough to remove the air filter cover, move the throttle lever of the first chamber of the carburetor, simulating pressing the gas pedal, and see if gasoline sprays from the spray nozzle. You can pump gasoline into the carburetor using the manual pumping lever, which is found on all mechanical gasoline pumps.

How to fix it

To diagnose the possible reasons why the engine does not start when the starter is working, it is recommended to start with the fuel system.

It needs to be checked taking into account:

- mechanical and electric fuel pumps;

- carburetor, injector;

- fuel filters;

- fuel supply lines.

If the engine does not start, then perhaps the cause is air getting into the fuel supply system. As for diesel units, in winter the so-called “freezing” of fuel is possible.

After this, it is recommended to check the ignition system. You can unscrew one spark plug and check it for spark production, and then you can check all the other parts. If there is no sparking, then there may be problems in the functioning of the ignition module of the injection engine or the ignition coil similar to the carburetor.

If, during normal operation of the starter, the engine refuses to start, then problems should be sought in various systems of the power unit. First of all, this is the fuel system and ignition. In addition, other possible problems should be excluded, for example, contamination of injectors, etc. And if some checks can be carried out independently, then, for example, something related to electronics is better diagnosed at a service station.

How to act in winter

There is a single algorithm with which you can start a VAZ-2107 without serious problems in the fuel supply, ignition or power supply systems. To successfully complete the procedure, you will need to have on hand dry, calcined spark plugs, a working and charged battery, and a special spray for the carburetor. Let's look at the launch procedure in more detail:

- Try to remove the battery at night to keep it warm. If you have not done this in the evening, then before you try to start your car, place the battery in a warm place for 20-30 minutes. Remember that when frost sets in, this battery loses its capacity by a quarter, so the inrush current also drops.

- If the temperature drop was not significant or heating the battery did not help, then turn on music in the car or flash the headlights a little in high beam mode. These simple steps will put a strain on the battery. If the quality of the battery is poor, you can charge it at low currents.

- Reinstall the prepared battery and try to start the engine. First, depress the clutch fully, and only then start cranking the starter.

- Warm up the power plant so that the oil becomes more liquid. Smoothly release the clutch to heat the lubricant in the gearbox.

- If the injector stalls during the gearbox warm-up stage, use cylinder blowing. This may not help, then remove the spark plugs and heat them. They may be flooded.

- For a cold start, a special spray is produced, which is injected into the carburetor behind the air vent. If you have an injector, then inject the spray into the corrugated hose, which is also located behind the air vent.

You should also know another popular starting method in winter - “lighting up”. It’s suitable if frost catches you on the road, and there is no way to bring the battery into a warm place. For this you will need a special starting battery or another car with a well-charged battery. Observe the following rules:

- park cars not close to each other;

- use only special cables with clamps;

- To avoid overloading the generator, do not give too much gas;

- connect the terminals observing polarity;

- the car must run for 3 minutes before you disconnect it from the “donor”.

Another common way to start an engine is by pushing. They rarely resort to it if nothing else has affected the car. In severe frost it may be ineffective, so initially all other methods are used.

Frost will not take you by surprise if you prepare your car for the cold in advance:

- change antifreeze;

- install a new set of spark plugs;

- pour anti-freeze liquid into the washer reservoir;

- install wheel arch liners;

- change the tires to studded ones;

- Spray WD-40 into the locks.

Such preparation will help maintain the car's driving performance even with a significant drop in temperature.

We start the car ourselves

If your VAZ-2107 does not start for the first time since you have been using it, you should not rush to go to a car service using a tow truck. Moreover, regardless of whether your car is fuel-injected or carburetor-powered, you can check for faults yourself. To do this, follow these steps:

If the results of the check show that all of the above parts are in working order, you need to continue checking, only this time do it in more depth.

If the VAZ 2107 carburetor does not start...

The main option for equipping the seventh model of the Volzhsky Automobile Plant is the DAAZ emulsion carburetor, called “Ozone”. Adjusting a VAZ 2107 carburetor of this type is described in detail here. However, it is not uncommon for the “Seven” to be equipped with a carburetor made by an Italian company. It should be noted that there is a fairly large degree of similarity between these units, differing only in the systems that ensure engine operation in the “idling” mode. In addition, the carburetor modification “21073” is equipped with two fittings for the exhaust gas recirculation system.

Experts consider the following to be the most common malfunctions of this type of carburetor:

- Contamination of the dosing system (wells and jets) of the unit. Manifested by a disturbance in the dynamics of the vehicle's movement - twitching. It can be eliminated by flushing the wells and blowing out the fuel jets with compressed air.

- Oxidation of contacts or disruption of switching connections of the forced idle economizer. It is diagnosed when the engine stops when the accelerator pedal is suddenly released. Eliminated by restoring contact.

- Overfilling (underfilling) the fuel mixture. Symptoms: when accelerating (braking) the engine, the car jerks. Eliminated by adjusting the position of the floats.

- Violation of adjustments or contamination of the idle system. It manifests itself in the form of popping noises in the car muffler, accompanied by jumps in the tachometer needle. It can be eliminated by flushing and purging the idle fuel jets.

The process of adjusting the Solex carburetor, described below, is maximally adapted to the conditions of a private garage and the absence of complex diagnostic equipment. It consists of several separate adjustments providing:

- required fuel level in the float chamber;

- setting the idle mode.

So let's get started.

Adjusting the level of the fuel mixture in the float chamber

- We start the engine and warm it up for several minutes, without making sudden or strong pressure on the accelerator pedal. We turn off the power unit and carefully, avoiding spilling gasoline, disconnect the fuel supply hose.

- We fold back the choke drive cable (choke) and remove the carburetor cover. We measure the distance to the surface of the fuel, which should be equal to 24.0 + 1.0 millimeters. Correction of the distance is carried out by bending the float tongue.

- After assembly, start the engine and lightly rev it up for 30-40 seconds. Then we take another measurement.

- We repeat these steps until the value specified above is reached.

Setting the idle mode "Solex 21073"

- This adjustment is performed with the engine preheated and stopped.

- We tighten the screw that regulates the “quality” of the combustible mixture until it stops. Be careful not to use excessive force when tightening, as stripped threads will not only negate all efforts to adjust the carburetor, but will also require its replacement.

- Unscrew the screw five turns. We close the air damper (by recessing the handle) and start the power plant. By manipulating the “quality” screw, we achieve minimum crankshaft revolutions.

- By slowly screwing in the screw, we achieve stable operation of the power plant, after which we make one revolution in the opposite direction. The optimal number of revolutions per minute in idle mode is 900. However, it can be increased to 1000-1100 in case of engine malfunctions.

The video will provide practical assistance in the process of troubleshooting the VAZ 2107 fuel supply system and adjusting the carburetor:

In conclusion, we note that the above settings are not a panacea for all the “sores” of the Solex 21073 carburetor. More serious defects require more careful adjustments and the use of appropriate equipment. However, the value of these instructions is their versatility, simplicity and accessibility in any environment.

No fuel supply

When problems arise with the fuel supply on a VAZ 2107, regardless of the engine type, it simply will not be possible to start the power unit. You will need to understand the reasons and fix the problem.

On the injector

On an injection engine, the fuel pump located in the tank may break down. We check its performance and, based on the results obtained, perform certain actions: repair or carry out further diagnostics. Checking the fuel pump on the injection “seven” is quite simple: just turn on the ignition and listen to the operation of the mechanism. If there are no signs of the node functioning, it is worth understanding the lack of performance in more detail.

On an injection VAZ 2107, fuel may not enter the engine due to problems with the fuel pump located in the tank

On the carburetor

With a fuel pump on a carburetor engine, things are somewhat more complicated: the mechanism will have to be dismantled, disassembled and the condition of its structural elements diagnosed. Malfunction of the pump leads to the fact that fuel does not flow into the carburetor float chamber or does not flow in sufficient quantities. You can try to pump up gasoline manually, and also check the fuel pump:

- The hose is removed from the outlet fitting and lowered into a prepared container with fuel, which is necessary to supply gasoline to the carburetor.

- The prepared hose is put on the outlet fitting, and its other end is lowered into another empty container.

- The assistant starts the engine and keeps the speed within 2 thousand rpm. In addition, a stopwatch is started.

- After a minute, check the performance of the fuel pump by measuring the amount of gasoline pumped.

If the fuel volume is less than 1 liter, the fuel pump is considered faulty.

Video: why fuel does not flow from the tank on a “classic”

To determine the reason why the engine on the “seven” does not start or starts, but with difficulty, it is not necessary to be a specialist or contact a service center. It is enough to understand at least a little which system in the car is responsible for what. This will allow you to correctly identify the faulty mechanism or element and take appropriate action.

Why is it dangerous to turn the starter for a long time when starting the engine?

Starting an engine is a process in which the starter and battery are directly involved. They are the ones who suffer the most when starting the engine for a long time. Accordingly, the following problems are possible:

- Low battery. Each time you try to start the engine, battery power is consumed. Moreover, if the attempt is not successful, then we can assume that the battery is consuming its charge “idle”. In order for the battery to charge, the engine must start and run for a while. Several unsuccessful attempts to start the engine, and you will get a discharged battery, which will need to be charged from the station, or you can start the engine “by lighting” in other cars;

- Starter failure. When the starter is cranked for a long time, it begins to overheat, which can negatively affect its components and lead to complete failure of the part. Also, do not forget about the bendix, which when trying to start the engine is connected to the crankshaft. If the engine does not start, there is a high risk of damage to the splines on the bendix or the bearing. If you constantly have to turn the starter for a long time when starting the engine, over time this will lead to its failure and the need for replacement.

Most often, you can solve the problem with the starter cranking for a long time when starting the engine without contacting a service center yourself, thereby preventing early failure of the starter.

Checking the electrical equipment of the VAZ 2110

If there is something to burn in the working cylinders, then you need to look for what will make the mixture burn

This means that you need to pay attention to the car's ignition system. This could be the ignition distributor, high-voltage coil and wires, spark plugs

It doesn’t happen that all devices fail at the same time, so we should talk about them separately. We will assume that the distributor is installed correctly; in this case, a failure may occur through a breakdown of the cover or slider, or a failure of the Hall sensor.

However, most often the cause is poor contact in the power connector of the ignition distributor. An ignition module or coils that do not produce high voltage to produce a spark at the spark plugs can create problems. Injectors work in conjunction with ignition modules, of which there are usually two per engine. One ensures the operation of cylinders 1 and 4, and the second - cylinders 2 and 3.

In these systems, the electronic control unit, which generates control pulses for all systems, including the ignition, may be problematic. This block can only be checked by replacing it. The same can be done with ignition modules.

Electrical diagram of VAZ 2110

Sometimes the malfunction may come from the high-voltage coil; it does not produce voltage that can form a spark to ignite the air-fuel mixture. You can check its operation if you unscrew the spark plug from the cylinder and, together with the high-voltage wire, ensure its contact with the engine ground. At this time, you need to crank the starter and watch the spark plug. The absence of a spark confirms that the ignition coil is faulty. It is impossible not to dwell on such elements of ignition systems as spark plugs.

They are the ones who ignite the combustible mixture in the working cylinders of the engine. During their operation, the metal parts of their electrodes burn out, after which the gap increases, starting the motor becomes more difficult, or even becomes impossible. Check the condition of the spark plugs regularly, especially their gap, then problems can be avoided. You can continue to review situations when the starter turns, but the VAZ 2110, 2112, 2114 does not start.

It is simply impossible to take into account absolutely all cases, but to avoid such situations, carry out routine maintenance of the machine in a timely manner, use only high-quality operating fluids.

Repair of VAZ 2108 distributor (replacement of the vacuum regulator)

In distributors of VAZ 2108-09-099 cars, the VROZH quite often fails.

Its performance can be checked without removing the PR from the engine - we suck in air through the hose, and if a vacuum is not created, the regulator should be changed. The ignition timing regulator can be replaced on site without removing the distributor:

- unscrew the two screws of the distributor cover, and together with the high-voltage wires, move the cover to the side, disconnecting only the central wire;

- we pull out the slider, it can be removed by hand;

- Using a thin screwdriver, pull out the latch that secures the VROZH rod; you need to remove the fastening element carefully so as not to lose it;

- unscrew the 2 screws securing the “vacuum unit” and remove the device;

- We install the new part in place and put everything back together.

Replacing the VROZH can also be done by removing the distributor, which will even be more convenient. Remove the distributor as follows:

- disconnect the high-voltage wires from the PR cover;

- use a thin screwdriver to hook the retaining springy wire on the connector and remove the plug going to the distributor from the bottom left;

- we pull off the hose from the VROZH, make a mark on the PR body or notice how it stood;

- unscrew the three nuts that secure the distributor itself, and then remove the breaker - distributor.

It’s easy to install the distributor back - the camshaft spline has a groove shifted to one side, and therefore the PR is installed in only one position, it’s impossible to make a mistake here

During installation, you need to pay attention to the rubber O-ring - if the rubber has hardened, the part must be replaced. And in any case, the seal should be coated with an oil-resistant sealant, in which case oil leakage will be almost 100% avoided

Checking the ignition module

Often the problem of the inability to start the engine lies in a failed ignition module. This part is a special device that, using special coils, generates energy to generate a spark and further start. The simplest and most reliable way to check serviceability is to install a new module purchased from a store. If the engine started, the problem lay in this part. It should be noted that this process has its own characteristics and subtleties.

If it is not possible to purchase a new module for some reason, you can carry out diagnostics yourself, on site using a tester set to the “ringing” mode. Main stages:

- the module itself is carefully detached from the tips;

- one probe must be connected to the central contact;

- the second probe is connected to ground.

If after performing these manipulations there is no signal on the device, then there is no problem. If the connection is present, the ignition module must be replaced. Since there is a breakdown.