What is a spar, what does it look like, and where is it installed?

A spar is a structural unit of a car that looks like a rectangular pipe, that is, a metal profile with a rectangular cross-section.

The part passes through the front and rear of the body, acting as a support. Depending on the body design, an option with side members between the bumpers is possible.

This unit can be composite (assembled from several elements) or integral.

In the classic configuration, two spars are installed (left and right).

Example, left front side member of a VAZ 2110.

Each element is divided into three parts - middle, front and back. The main difference is the location.

Thus, the spar installed at the front and left is positioned at a level lower than the spar at the rear and the same unit, but only the wing.

The nodes are parallel to each other, but there may be cases where they are located at a minimum angle.

Spar on Nissan Bluebird HU14 SR20VE.

The starting material for production is aluminum or titanium. Sometimes component layers are used to add to the fortress structure. The cross section of the spar has the shape of the letter “P”. At the same time, in places of maximum load the cross-section is larger.

The main advantage of the part is its exceptional strength. These units are able to withstand maximum loads - the weight of the car, luggage, mass of units, and so on.

In addition, the side members cope with all the impacts that they receive when the wheels get into holes or in the event of an accident.

Structurally, these units form a U-shaped staircase frame laid on its side.

This type of design is an integral part of many SUVs and trucks.

As for passenger cars, the ladder principle is not applied in them. To visually see the detail, just look under the bottom of the vehicle.

Body structure of the VAZ 2108, location of the side members.

What does the spar consist of?

The structural element is represented by an ordinary beam of longitudinal section on which jumpers are installed. In the classical sense, a spar is an ordinary staircase frame. In appearance, it is a mesh box that provides increased resistance to shock and vibration loads. It is able to withstand the maximum weight of a loaded car. What the spar looks like becomes clear when looking at the photo and diagram of its structure.

Attention! Other types of design have also been developed. In SUVs and jeeps, the beams have a shape similar to the letter “P”. It is not advisable to use them on passenger cars.

Spars are made of very strong and lightweight metals: aluminum, titanium and other composite materials.

Purpose and tasks

The spar is literally the power part of the car. The purpose of the unit varies depending on the type of vehicle:

- In trucks and 4x4 cars, side members are the main unit that is part of the frame;

- In passenger vehicles, the task of the part is to strengthen the bottom of the car and the lower part of the trunk.

In the first and second cases, the U-shaped unit takes on the weight of the body, components and passengers of the vehicle.

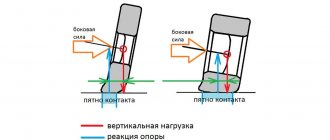

Another function is shock absorption. The task of the node is to absorb possible deformation. But here it is important to maintain a fine line between rigidity and pliability.

If you “overdo it” with the first indicator, then the unevenness of the road will be transmitted to the passengers inside the car. That is why the part of the body where people are supposed to be is made with maximum shock absorption (to reduce the impact force).

The shock-absorbing function is realized by installing a longitudinal force structure installed in the front and rear of the body. The main feature of the structures is the ability to dampen (smooth out) impacts.

Spars of VAZ 21 Volga.

A brief excursion into history

The development of the spar and the creation of various body elements are closely interrelated. This is not surprising, because on the first vehicles only frames were used as support.

At first they were made of wood, but over time they were replaced by durable metal structures.

In the last century, in the 1920s, Auburn developed the first spar frame with an "X" cross member.

Over time, the parts were improved and became one with the bottom of the vehicle.

At the present stage, spars are an integral part of the machine design, regardless of the type of supporting system.

Types

As already mentioned, side members occupy different positions in the car. Here, a lot depends on the characteristics of the body (truck, passenger car or truck).

The location is as follows:

- Parallel and horizontal to each other;

- Vertical, with a slight bend;

- Horizontal and minimum angle;

- Horizontal and slight bend.

The type of design that is mentioned first has found application in freight transport.

Mercedes-Benz truck frame with parallel-horizontal side members.

As for the other options, they are popular and used in passenger cars.

Rear left floor member of VAZ 21099.

Replacement video

The installation site is thoroughly cleaned, welding residues are removed, and the new spar is attached to the body by spot welding. Upon completion of welding work, everything must be carefully checked.

Spars on VAZ “classic” cars, i.e. VAZ from the first to the seventh models have the same design. The weak points of these side members are the mounting points for the steering mechanism, cross beam, stabilizer bar mounting and on the right side of the pendulum mounting. By design, these places cannot be called weak, since it is in these fastening points inside the spar that amplifiers are installed, but they also do not withstand our road conditions and the service life of these vehicles.

Design advantages

Each design has advantages. Thus, “angular” spars allow the wheel to turn at a larger angle, and devices with vertical bending allow the vehicle’s center of gravity to be lowered and the bottom level to be lowered.

Parts with horizontal bending are structural elements that also make it possible to lower the level of the bottom, increasing safety in the event of a side impact.

To increase rigidity, the spars are strengthened with cross members. The latter come in different profiles - in the form of the letter K, X, or be straight.

This type of crossbar is made of a special profile made of reliable and deformation-resistant metal.

To increase reliability in freight transport, cross members and side members are combined with special rivets, and in passenger transport - by welding.

An important point is the fixation of the body on the frame, which occurs using special brackets.

Considering the spar design as a whole, it is worth highlighting the following advantages:

- Minimum weight and torsional rigidity;

- High level of controllability and dynamics, as well as minimal fuel consumption due to the low mass of the unit;

- Greatest passive safety. The latter is possible thanks to special zones that “absorb” excess energy and increase the level of comfort.

Toyota Mark II front side members.

Worth about:

- If one node breaks down, the integrity and connections of the structural elements are disrupted. This is due to the fact that the load is distributed evenly over the area;

- Difficulty in repair. In case of serious deformations, the only solution is to replace the unit.

Basic malfunctions and problems associated with side members, solutions

During operation, the following problems are possible:

- Deformation (curvature) due to exposure to loads over long periods of time. It is worth remembering that the spars are made of metal, which gets tired and damaged over time.

- If you get into an accident, the part may be severely damaged. In such situations, many car parameters are violated. So, in the event of an accident, it is possible that the suspension or power unit may shift in relation to the body part, the location of the wings or doors may change, the geometry of the body will be deformed, obvious cracks may appear on the outside, and so on.

If there is obvious damage (cracks appearing) in the part, the integrity of the structure is also destroyed.

That is why after an accident it is worth making sure that there is no deformation of the components. In practice, in 90% of cases after an accident, the front side members have to be repaired.

The method of restoration is determined taking into account the severity of the problem and damage to the damper section. So, the spar, which is part of the frame, is easy to change. If the assembly is part of the supporting body, then restoration work may be useless.

The possibility of repair depends on the degree of deformation:

- If the damage is minimal, the assembly is pulled out on a special stand, after which the parameters of the part are checked;

- If the deformation is severe, the best option is replacement. If you try to make corrections to a distorted part, you may change the structure and reduce the strength of the structure. The result is deterioration in body characteristics.

There may be situations where the replacement is not complete. In this case, new parts are attached by welding. The use of couplings to connect structures is prohibited.

We must not forget that the main function of the spar is to strengthen the body, so during the repair process maximum attention is paid to strength.

On the other hand, excessive strengthening of the unit leads to a decrease in shock-absorbing functions, which is unacceptable.

So when repairing, you should take this parameter into account and try not to overestimate the level of rigidity.

We repair side members

Do-it-yourself repair of side members can be divided into several successive stages.

Disassembly

The very first step will be to remove from the body those parts that will interfere. We dismantle everything that prevents free access to the side members. When removing parts from the body, be extremely careful; disassembly should be done after first disconnecting all electrical parts and wiring connected to them. If the wiring may be damaged when pulled, it should also be disconnected from the housing.

Pull

Having removed the body parts, you can begin to straighten the damaged spar to the shape it had before. To do this, we will need special grips that are attached to the car on the stand. The procedure itself can take quite a long time, but it must be done.

When stamping parts, the manufacturer usually provides so-called folds in the design. This solution helps to avoid uncontrolled deformation. A similar effect is achieved in two ways:

- by making slots and through holes in certain places;

- reducing the thickness of the metal section.

Repair

In case of minor damage, after the spar is pulled to its original position (you can check it using the table), straightening is performed - leveling with a hammer. Corners and edges should also be straightened.

After this, you should check that the spar has not cracked or fallen off at the welding points. If everything looks fine, you can apply a primer coat. The final stage will be painting and anti-corrosion treatment.