Main reasons

- Welding of liners with crankshaft journals due to oil starvation.

- Jamming of piston pins in the upper piston head. As with liners, the cause may be oil starvation. But the pin also jams due to misalignment of the upper head and piston pin. Due to the resulting misalignment, local zones of semi-dry friction and excessive tension appear, which can cause critical thermal expansion, scuffing and jamming.

- The piston is stuck in the cylinder due to engine overheating or poor heat dissipation.

- A broken piston blocks the movement of the connecting rod and the rotation of the crankshaft.

- Unqualified engine repair. Incorrect choice of thermal clearances when assembling the CPG, crankshaft, or unresolved malfunctions of the lubrication system can cause the breakdowns described above. Also, the cause of the wedge can be bolts and nuts accidentally dropped into the cylinders or intake tract.

- A bent valve blocks piston movement. The main reason for the “meeting” of valves with pistons is a broken timing belt. After a break or jump on several teeth of the timing chain at once and an impact, the valve stem bends. Severe deformation leads to the fact that the valve cannot move along the guide and blocks the movement of the piston on the approach to TDC. Valve desiccation will lead to similar consequences.

What jams in the engine

The engine design contains a large number of constantly rubbing mechanical pairs and under the influence of loads they are all subject to wear. Often the problem of unit jamming is the crankshaft bearings, but the piston can also jam. It is impossible to determine the source of the problem by eye. The reasons why an engine seizes can be different, including mechanical defects in the elements, a critically low level of lubrication, and overheating.

Mechanical causes of internal combustion engine jamming

Often, the normal functioning of the engine is prevented by foreign objects entering the space above the piston or into the combustion chamber. Fastening bolts and other small structural elements can get inside, for example, during repair work and cause jamming or complete failure of the unit. If you do not determine in time what caused the malfunction and do not influence the situation, then such a trifle as a poorly tightened nut that has become loose and fallen into the intake manifold will lead to serious consequences.

Jamming can occur due to a broken timing belt or chain, as well as when the damper or part of it gets under the belt or chain.

The entry of foreign bodies into the gas distribution mechanism is another common cause of a wedge in the power unit. They can get there in the absence of a timing cover and lead to breakage of the springs or desiccation of the valves. So, in order to find out that the engine is jammed due to foreign objects getting into the mechanism, to find and remove them, disassembling the timing belt is required. If you cannot turn the camshaft gear, then the problem lies with them.

Problems with the belt or chain of the gas distribution mechanism provoke deformation of the valves. This is followed by the impossibility of the piston entering the top dead center, which provokes impacts between the valve and the piston against each other. Valve jamming in guide bushings is also a common occurrence.

If the piston pin, which provides a movable connection between the connecting rod and the piston, leaves the piston, due to the lack of fixation, it can cause severe damage to the element.

When it is known that foreign metal elements have penetrated into the cylinder, it is possible to remove them without resorting to complete disassembly of the unit. A magnet and a rod of the required length will help you carry out the extraction procedure. To do this, lift the pistons of cylinders 1 and 4 (or 2 and 3, if foreign objects were not found in cylinders 1 and 4), unscrew the spark plugs and pull out the foreign body through the spark plug opening with a magnet.

Oil fasting

Motor oil, like other consumables, tends to wear out over time; oxidation occurs much faster when the vehicle is operated under heavy loads. Rubbing pairs without high-quality lubrication quickly fail, which leads to many serious consequences for the unit, including its jamming. Oil starvation entails a decrease in the thermal gap between elements due to strong heating, and parts made of soft metal can melt. Lack of lubrication has a detrimental effect on elements such as the crankshaft and camshaft, timing belt and cylinder-piston group.

When oil pressure drops, the crankshaft liners are the first to be welded, since they bear the main load. If the car stalls after a characteristic knock, it is better to immediately begin an inspection, because you can only understand that the engine is jammed by manually checking whether the crankshaft is breaking off.

It is important that the motorist understands the seriousness of the problem and takes steps to correct the problem as soon as possible. Oil starvation can be caused by the following factors:

- a critically low oil level that does not provide lubrication to the elements, causing them to run dry. The need to monitor the fluid level and its condition should become a habit to prevent breakdowns associated with lack of lubrication;

- an emergency decrease in oil volume is associated with leaks through oil seals, gaskets, due to a violation of the integrity of the pans, cylinder head, etc., or breakdowns of the main components of the unit;

- failure to change the oil or oil filter in a timely manner. As consumables wear out, they need to be changed, since their properties are lost over time; the replacement period is significantly reduced under severe operating conditions, so the time period recommended by the manufacturer can be reduced by almost half;

- the use of motor oils of inappropriate viscosity, which provokes a lack of fluid supply to the parts even when the level in the crankcase is normal. This applies to both too high viscosity characteristics and too low ones. Viscosity also increases due to accumulated dirt and deposits. The mesh becomes clogged and the oil pump cannot cope with the task. To fix the problem, you should disassemble and clean the oil receiver channels, without using flushing fluid, so as not to worsen the situation.

As a result of oil starvation, jamming of the shaft or pistons in the cylinders, failure of valves, and malfunction of oil scraper rings occur. The consequences can also become more severe in the form of large-scale destruction of the unit components, which can lead to the impossibility of restoring the engine and the need to replace it.

In the case of turbo engines, oil starvation of the turbine may also occur, which leads to malfunction of this part. The cost of repairing a turbocharged engine is high, so it is necessary to regularly monitor the quality and intensity of the lubricant supply.

Almost all components of the power unit suffer from oil starvation. If the crankshaft does not rotate when diagnosing engine seizure, the pan must be removed. If main bearings are found stuck to the crankshaft and rotated in the engine, replacing the bearings is not enough. In addition to checking the oil pump, it is also better to clean the channels, the blockage of which could lead to the problem of oil starvation. If the bearings are in good condition, it is necessary to remove the parts of the cylinder-piston group for diagnostics.

Engine overheating

The motor may jam while running due to overheating. Not only constant operation at high speeds and low engine oil levels lead to overheating of the rubbing pairs. Common reasons are:

- faulty thermostat;

- lack of coolant;

- faulty coolant heating sensor;

- antifreeze getting into the oil. The cause of this phenomenon is a violation of the integrity of the gasket or microcracks in the cylinder head and cylinder head;

- fan malfunction;

- radiator clogged.

Overheating can cause serious problems in the functioning of the power unit, including its jamming. In this case, there is also a possibility of complete failure of all motor elements. The coolant level should be checked regularly to avoid such problems. If the engine heating sensor is at a critical level, you should immediately turn off the engine or continue driving in neutral until it stops.

You can diagnose the engine yourself without removing it, but if the cause of the jam was not found during inspection, it is better to entrust the autopsy to professionals due to the high cost of repairs.

How to understand that the engine has caught a wedge?

The idea that the engine is seized comes after the starter relay clicks, which is not followed by rotation of the crankshaft. It is likely that the starter clicks but does not turn due to a dead battery or a malfunction of the starter itself. To identify a seized engine, you must try to turn the crankshaft by hand. You can do this in 2 ways:

- Turn the crankshaft using a wrench using the pulley bolt. The disadvantage is that on most modern cars the engine compartment layout limits access to the pulley;

- hang one side of the drive axle, engage the highest gear and try to turn the engine by the wheel.

You should not try to turn the crankshaft while towing the car on a cable. If the engine is seized, trying hard to turn the crankshaft can cause even more damage.

What to do and how best to repair a jammed motor?

Suppose the engine of your car still seizes, but you do not want to completely disassemble it for a major overhaul. In this case, remove the timing belt and try to rotate the camshaft gear(s). If the gear does not rotate in the direction of rotation of the CV, it is likely that the engine is seized due to the valves. In this case, we recommend starting the repair of a jammed engine by removing the valve cover and cylinder head.

If the crankshaft pulley does not rotate in any direction, remove the pallet to remove the main bearing yokes and connecting rod lower head caps. If bearings are found to be lifted, stuck to the crankshaft and rotated, replacing the plain bearings will still not be enough. We recommend not only checking the oil pump, but also removing the crankshaft to blow out the oil supply channels with compressed air. It is likely that the channel is coked, which has led to a local lack of lubrication. If the plain bearings are normal, it is necessary to remove and troubleshoot the CPG.

Oil fasting

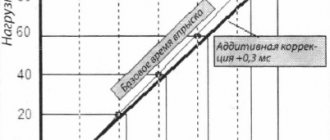

A lack of engine oil in loaded friction pairs leads to dry friction, which causes the parts to quickly overheat. Expansion due to heating leads to a decrease in the thermal gap, and due to increased temperature, local melting zones appear on parts made of soft alloys. This is precisely the destructive effect that oil starvation has on the sliding bearings of the crankshaft and connecting rods.

The first to suffer in the event of a drop in oil pressure are the crankshaft main liners, since they bear the greatest load when the engine is running. Due to the high temperature, the liners and journal of the rotating crankshaft stick. The consequence is the rotation of the liners in the beds and the appearance of a characteristic knocking sound (in such cases they say that the engine knocked). As the problem worsens, the journal-liner pair gets stuck so tightly that after stopping the engine and attempting to start it again, the starter simply cannot turn the crankshaft. This is the main sign of a jammed motor.

Signs of jamming

The engine will immediately signal a problem, and in this case movement is impossible. Often, when a malfunction occurs, drivers blame a dead battery, but charging it is not always able to fix the problem. There are certain symptoms that indicate a problem, which is jamming of motor elements.

This is often indicated by a click from the starter relay, after which the crankshaft stops rotating. The cause may be a dead battery or a malfunction of the starting mechanism. While driving, a sudden jamming of the engine can occur, then it immediately stalls, or a gradual loss of power, then the engine stops. It will no longer be possible to start the car again; the starter does not turn, and when trying to start the engine, a grinding and clanging of metal is heard. Sometimes, after inactivity, the unit still starts, but even if the startup is successful, if the problem is not resolved, you can no longer count on its normal and long-term operation. Often, before a jam, you can hear a rumble and the sound of metal parts hitting each other from under the hood.

You can diagnose engine seizure by starting the crankshaft manually:

- if the car model allows you to get to the pulley, you can turn the engine with a key using the pulley mounting bolt;

- Alternatively, it is also possible to hang the drive axle and turn the unit by the wheel manually in the highest gear.

It is not worth cranking the crankshaft by towing the car, since excessive force on the engine in attempts to start it can cause even greater deformation of the elements and lead to serious consequences.

Problem detected

In the first minute, it is not always clear what exactly happened - another unit is not spinning or the engine is jammed. What to do if the starter does not turn the crankshaft? They try to start with a simple visual inspection of the engine compartment.

They are trying to determine whether the engine can jam due to:

- Overheating (this can only be felt immediately after it stops).

- Lack of lubrication (check level).

- Inspect the external condition of all components; it is important to note the presence of leaks or mechanical damage. The coolant level is measured. Without it, the engine will also overheat.

If the engine is jammed, you should check the operation of the entire cooling system. Boiling of the liquid indicates a faulty bleed pump. The pump is responsible for circulation; without this, the temperature in the engine channels rises.

Useful tips

Unlike mechanical causes, many cases of engine overheating can be avoided if you regularly check the oil level and its condition, as well as monitor the coolant level and monitor the serviceability of individual elements (thermostat, cooling fan, pump and others).

It is important to understand that if the internal combustion engine first knocked and then jammed, then such a jammed engine may even show a “fist of friendship,” which is a serious breakdown. However, if a knock appears, but the driver turned off the unit in advance, there is a chance to avoid a large number of problems. After stopping the engine, you need to tow the car for inspection at a service station. Such actions in many cases can significantly reduce the final cost of engine repair.

Why does the crankshaft liners turn: the main reasons. What to do if the connecting rod bearing has turned, how to change the connecting rod bearings correctly.

What is the “fist of friendship” of a car engine. Why does this malfunction occur, the main reasons that lead to such a breakdown. Useful tips.

Why does the engine overheat? What should the driver expect and what damage may occur if the engine overheats. What to do if the internal combustion engine overheats.

Why a cold engine may knock: various malfunctions. Analysis of the nature of the knock in the power unit: ringing, metallic, muffled, etc.

What should be understood by the definition of “knocked engine”. Why does the engine start knocking? In what cases does a knocking sound in the engine indicate a breakdown of the internal combustion engine.

The most common causes of engine knocking are: piston knock, connecting rod knock, crankshaft knock. What to do if the engine suddenly starts knocking while driving.

Why doesn't the crankshaft spin?

The engine is jammed - check manually to see if the crankshaft can be torn off. If this does not happen, then you can engage any gear of the box and try to push the car. It is strictly forbidden to jerk the machine with a cable. This could cause even more damage.

The engine is jammed - it is recommended to unscrew the spark plugs and repeat attempts to manually turn the crankshaft. The reasons may be foreign objects in the wells or scattered liners, which is a fairly rare case. The liquid in the pistons will be squeezed out when the spark plugs are unscrewed, and foreign objects and contaminants can be seen through the inch hole.

Additional sources of failure

If after basic checks it remains unclear why the engine jammed, it is recommended to recall previous events. Have you added oil before, and if so, what quality? Two oils of different types and viscosities could easily curdle and foam.

Adding low-quality additives to engine oil will also adversely affect the operation of its components. Similar consequences will occur when using oils not recommended by the manufacturer.

Fuel affects the condition of the pistons and rings. Too high an octane number leads to their deformation, and because of this, many people have had their engines seize up more than once. The cause of the malfunction may also be a malfunction of the ignition system.

What exactly jams in the engine and for what reasons

As a rule, the crankshaft jams. Or rather, its bearings. The piston jams less often. The main thing is that it is simply impossible to quickly answer the question of why the engine jammed.

The fact is that there are many reasons that can be divided into two main groups: mechanical damage and overheating.

Mechanical causes of internal combustion engine jamming

Foreign objects have entered the space above the piston or onto the piston head. This could be, for example, a missing/torn off nut. For example, the air filter mounting washer fell into the intake manifold, elements got into the intake when removing the carburetor, foreign objects could get directly into the combustion chamber, etc.

In this case, the piston jams, but not necessarily tightly. However, in most cases, serious repairs will be required to eliminate the consequences.

- A broken or skipped timing belt or chain, as well as a broken timing chain guide and a fragment of it getting under the chain itself.

By the way, when the cause of jamming is a problem with the chain or belt, the valves become deformed (bent), which is why they cannot return to their seat. As a result, the piston cannot enter top dead center and the valve collides with the piston head.

- Piston pin outlet. This is fraught with the fact that the piston head will remain loose with all the ensuing consequences.

- Loose crankshaft main cap nuts or connecting rod lower head nuts. This can happen when, during engine repair, these nuts were not tightened properly (the tightening torque was incorrect).

By the way, if it is reliably known that foreign metal objects have entered the cylinders, they can be removed without completely disassembling the engine. To do this, you will need a magnet and a rod of sufficient length (for example, a knitting needle). Having raised the pistons of cylinders 1 and 4 to the top position, you need to unscrew the spark plugs and remove a metal object through the spark plug well with a magnet. If there is nothing in cylinders 1 and 4, then 2 and 3 should be checked in the same way.

Engine overheating

Many causes of engine seizure are associated with engine overheating. The most common of them are:

- Lack of lubrication or low oil level. As you know, inside the engine itself, oil plays the role of not only a lubricant, but also a coolant.

- Coolant getting into the oil. Leads to the fact that the lubricating fluid loses its properties. Most often this occurs when the integrity of the gasket between the head and the cylinder block is damaged, but cracks in the cylinder head or cylinder head are also possible.

- Faulty thermostat or coolant pump.

Ridiculous cases

If the engine seizes, signs of thickened oil may indicate sugar entering the system. Similar consequences occur when stirring a raw egg, which, when the motor is running, will certainly heat up and weld all the channels. How the latter substance enters the system is known only to the owner of the car.

Sugar can be poured into the fuel by ill-wishers through the refueling hatch. There are many substances that change the composition of the oil. It happens that a driver may mistakenly pour a mixture that is lethal to iron into the engine neck.

A malfunction where coolant penetrates into the oil can also lead to jamming of the rubbing metals. This can be noticed when measuring the level using the dipstick. The changed composition is noticeable to the eye and to the touch: by color, viscosity, and the presence of foam. A whitish tint indicates a loss of oil quality.

Prevention

Engine wedging can be prevented by carefully maintaining the vehicle. Periodic inspections and constant monitoring of the performance of control and signaling units helps to avoid the situation when operation continues during malfunctions. It is important to notice the following conditions in time:

- visually low coolant level;

- visually low oil level in the crankcase;

- oil pressure sensor does not respond;

- deviations in economizer readings;

- change in engine thrust;

- extraneous sounds in the operation of the car: knocking, humming, ringing, grinding.

Immediate diagnostics in a car service center of suspiciously operating components will save you from expensive major repairs. It is recommended to stop operation if you are not sure about the serviceability of the engine.

AutoXS.ru - Auto Encyclopedia

- 9-01-2020, 14:47

- Articles / Repair and maintenance

- Author: VexterXS

What does an engine sound like when it seizes? There are specific signs that will tell you that a disaster is about to happen. However, a seized engine can also be identified by the characteristic sound it makes, which anticipates an impending problem. At the initial stage of the problem, you will hear a slight pipe tapping sound when moving. The noise will come from the engine. At the next stage, a deafening metallic knock will be heard. Also called "dead man's knock," it occurs when the piston rod hits the crankshaft. If you notice signs of engine seizure, you should send the car to a service center. Early diagnosis can save you thousands of dollars.

The photo shows traces of rubbing of the piston skirt on the walls of the cylinder block. If you do not open the engine in a timely manner, a meat grinder may occur, as in the first photo...

Signs of a seized engine: how to determine that the engine is seized?

If there is a significant decrease in engine power, the low engine oil pressure indicator light comes on, or if there are strange noises coming from the engine compartment, you should have your vehicle's engine checked. Pay attention to the symptoms of engine seizure:

Pipe Tapping As previously discussed, a slight pipe tapping sound may indicate an engine stalling problem. The noise occurs when the starter hits the flywheel.

Smoke Smoke or even an open flame coming from under the hood can be another sign of a seized engine. Since the starter in this state cannot crank the engine, the wiring overheats, which causes smoke or even fire.

Engine failure is a fairly obvious sign of problems with your car. But the engine should not be brought to this state. A complete engine failure means that the engine will not start under any conditions. Battery-powered lights, radios and other components can continue to operate.

Loosening of engine parts When a part of an internal combustion engine, the piston, becomes loose, it can pierce the cylinder head. You can find out about such a problem by performing periodic engine checks.

Lack of engine oil is the most common cause of seizure. Low oil levels lead to increased friction, overheating and other problems that cause the engine to seize. This problem can also be caused by water or rust accumulated inside the engine. Another possible cause is breakdown or failure of engine parts, but engine seizure is unlikely.

On the video collection you can watch real cases of engine wedges from life:

Various cases

The course of action in the event of an engine malfunction depends on when it occurred. If the car suddenly stops while moving, then most likely there is a mechanical hit of a foreign body or a breakdown of the rotating unit. It is recommended to look for the faulty location and abandon further attempts to turn the engine by force.

After a long trip the engine was turned off. And the next morning it is impossible to scroll it manually. There is a high probability of curdled butter. Major renovation will be required. Most likely, you will be able to rotate the crankshaft, but with a lot of effort.

If the car has been standing for a long time and you need to start it, but the engine does not turn, then it is recommended to force the rotation through the gearbox by cable or manually. This often happens in cold weather, when mineral oil thickens greatly. There is no malfunction, you just need to warm up the oil or wait for warm weather.

How is it happening?

Most often, foreign objects enter through the carburetor flaps. Dust and larger inclusions also get there when cracks form along the air intake path. It is necessary to check the integrity of the pipes and the cleanliness of the filter.

After repairing the carburetor, a loose spare part could fall into the engine well. Similar consequences can result from careless installation of the engine head with valves. It would be a good idea to check the cleanliness of the lubricant by draining it from the crankcase. But the latest work is carried out on the pit under service conditions.

Belt break

A disastrous result is observed when the timing belt or chain breaks. Often the cylinder blocks even bend. At the moment of impact, the valve covers break. As a result, the engine has to be overhauled.

If repairs are insufficient, broken parts may remain in the crankcase; under some circumstances, they will again end up in the next engine wedge. A loose damper can also get caught under the timing belt or chain. Valves and cylinder blocks become deformed under incorrect operating conditions.

Scores appear that constantly touch the moving metal. At some point, when the wear becomes large enough, final wedging occurs and the crankshaft can no longer be turned.

The main causes of engine wedge

There are several more reasons that can be combined into one group - unqualified engine repair. It is possible that when assembling the CPG and crankshaft, the thermal clearances were not selected correctly. Or, for example, there are unrepaired faults in the lubrication system. Also, the reason for the occurrence of the previously described breakdowns can be simple carelessness or negligence when assembling/disassembling the engine. Some careless worker may accidentally drop and overlook a bolt or nut into the intake tract or cylinder.