How to increase the voltage of a VAZ-2110 generator: increasing power

As you know, additional equipment is often installed on a car, which draws additional voltage from the on-board network.

Thus, the voltage indicator on a VAZ-2110 can drop to a critical level of 11 volts. If you also install additional air conditioning or heated seats, this may result in the starter not having enough power to start the engine. How to fix the problem? Make sure that the voltage in the on-board network increases. Video about increasing the voltage in the on-board network on VAZ cars:

How to increase the onboard voltage is very simple.

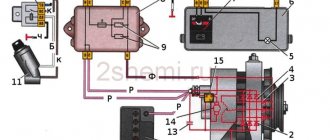

Where and how is a diode placed in the LV circuit on the generator in order to increase the voltage in the car network and better charge the battery? Here I propose a simple solution, raising the on-board voltage, without going anywhere in the car and its circuits. I searched in my archives and did not find the material from which I read this decision. “Structurally, voltage regulators have an upper limit of 13.6V. This is due to the “old” connection diagram, from which the new one was copied and “successfully improved”. In it, the necessary voltage from the on-board network, supplied to the regulator for comparison, passed through a chain of wires. On them it dropped to normal. According to the new scheme, we have a chronic undercharge of the battery. Which, with the arrival of winter, makes starting the engine in the cold quite problematic. But if you install a pre-heater, starting the engine will be much easier.

We increase the voltage - all options for solving the problem

So, many motorists may decide that the way out of this situation is to install a high-power generator, but at the same time they will have to replace the battery with a more capacitive one. This is done in order not to “kill” the battery that is installed on the car, since a voltage overload will lead to the destruction of the internal cells. This option is not suitable because it is too expensive.

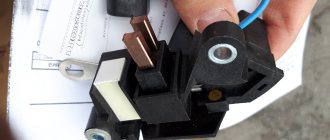

The second option is to install an additional diode from another diode bridge or marked KD202V. This is much cheaper than changing the generator and battery, but you will have to tinker a little.

To begin with, it is recommended to study automobile electrical circuits and the operation of the generator, as well as the charging circuit.

Interfacing the engine and generator

Rotation from the engine to the generator is transmitted by a belt drive or gearbox. But the gearbox has a large mass and high noise, so it is better to use a belt drive.

Engines and generators have different nominal speeds, so the pulleys on the shafts of these devices must provide a certain gear ratio. It is calculated simply: how many times the generator speed should be less than the engine speed, the same number of times the diameter of the generator pulley should exceed the diameter of the engine pulley.

Note! You should not take the pulley diameter too small, since strong bending of the drive belt will shorten its service life, and the efficiency will decrease, since part of the engine power will be lost due to bending of the belt. In practice, pulleys with a minimum diameter of at least 100 mm can be used.

It is tempting to use generators with original pulleys. But, if a flat belt is used, then it is quite difficult to find one of the required length, therefore, in order to facilitate the search for the right belt, the pulleys need to be made for a V-belt. There are many such belts of all possible lengths in any auto shop or car market, and their cost is low.

Pulleys are made of duralumin or textolite. Any turner can do this for a nominal fee. The main thing is to ensure a tight fit on the generator and engine shaft.

Electrical diagrams and indicators

To increase the voltage even more, at least to 14 volts, it is necessary to install a diode in circuit D, the voltage regulator. Any diode with a breakdown voltage of 20V and a current of at least 5A is suitable. The voltage drop is preferably no more than 0.6-0.7V. The 2D219B diode is excellent.

| 2D219A | 15 | 10 | 0.6(10A) | 20 (15V) | KD-11 |

| 2D219B | 20 | 10 | 0.6(10A) | 20 (20V) | KD-11 |

| 2D219V | 15 | 10 | 0.45(10A) | 20 (15V) | KD-11 |

| 2D219G | 20 | 10 | 0.45(10A) | 20 (20V) | KD-11 |

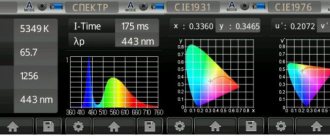

Let's look at the circuit diagrams of diodes:

Final voltage measurements and results

After the installation was completed and the entire electrical circuit was working, voltage measurements were made at idle speed of the running engine. The results surpassed themselves; the voltage in the entire electrical circuit increased.

Let's consider a table of the results of the measurements obtained:

| Load | Voltage up to | Voltage after |

| without load | 14.2 | 14.45 |

| +dimensions | 13.8 | 14.45 |

| +PTF | 13.7 | 14.4 |

| +neighbor | 13.6 | 14.35 |

| +heater | 13.5 | 14.3 |

| +Fan | 13.4 | 14.2 |

| +far | 13.2 | 14.1 |

| + heating | 13.1 | 14.0 |

| +heater max | 12.9 | 13.95 |

Manufacturing and installation of a diode in a VAZ-2114 generator

Now that everything is ready, we install an additional diode, more powerful than the previous one. You will need half a meter of wire 2*0.75mm. We solder the ends to the female and male terminals No. 4. We dress them in cambric, or better yet, in heat shrink. By the way, the old one must be removed from the system. Let's take action:

- Now, solder the following circuit to the diode: mother to the cathode, folder to the anode.

- We insulate the diode. For example, we take a film container.

- We remove the “minus terminal” from the battery.

- We unscrew the “+” wires from the generator, disconnect the “D” wire to the tidy.

- Remove the generator cover.

- Through the slots in the cover, we connect the “mother” to the LV, the “father” to the standard wire.

- We carry out the assembly.

Now, everything is ready for the final check and measurements.

The best manufacturers of generators for cars

The data below is based on the experience and reviews of car owners.

StartVOLT

Description. The units are produced for domestic vehicles VAZ, ZAZ, UAZ, KAMAZ, PAZ, URAL. The manufacturer supplies modifications for foreign cars and commercial vehicles.

Positions for domestic models are represented by two types of generators: with internal and external ventilation.

StartVOLT units are superior to standard components in terms of output current power. They allow you to connect additional functions. Some modifications are equipped with voltage regulators based on chip technology.

Generators designed for commercial vehicles are smaller in size and have higher power. Car owners appreciate them for their ease of installation.

Each modification is developed for a specific car brand, so the dimensions of the unit fully correspond to the standard ones, and all components are interchangeable. StartVOLT products undergo full final testing on specialized D&V equipment.

Equipment. The StartVOLT generator kit includes a technical data sheet.

Life time. The recommended service life is 2 years.

Pros of StartVOLT

- Easy installation.

- Long service life.

- Good voltage readings at cold (14.5-14.6) and at operating temperature (14.3-14.4).

Cons of StartVOLT

- Voltage drop by 1-1.5 volts after 8 months of operation.

Pramo

Description. The company produces modifications for cars and trucks, as well as tractors and special equipment. Pramo components are produced for both wheeled and tracked vehicles.

The weight of the units ranges from 5 to 10 kg. In addition to the generators themselves, the Pramo-Electro company produces components: rotors, stators, rectifier units, voltage regulators, pulleys, covers.

Pramo products are somewhat different from analogues in their casting and design of support bearings. The bearings are attached using flanges. This makes the unit repairable. The diode bridge follows the design of Bosch generators - the leads of the stator winding are sealed on the bridge. This makes the contact more stable, however, in the event of a breakdown, it is impossible to repair this element.

Bench tests of the Pramo generator showed excellent results. For this purpose, an alternating current device with a built-in rectifier unit and an analog voltage regulator was taken.

While the engine crankshaft was operating at a speed of 700 rpm, the generator reached a value of 50 A. When the number of revolutions increased to 2500 rpm, the unit produced 100 A.

Equipment. The kit includes bolts, brackets and terminals.

Life time. The service life of Pramo generators is 120,000 km or 5 years.

Pros of Pramo

- Good voltage without sags when connecting additional consumers.

- Affordable price.

- Uninterrupted operation even after tens of thousands of kilometers.

Cons of Pramo

- The weak point is the bearing.

Motorherz

Description. Many car owners have appreciated the quality of generators from the German manufacturer Motorherz GMBH. The capacities of this company are distributed across different European countries.

It produces spare parts for trucks and is engaged in the reconstruction of units that have already been used. The Motorherz product range exceeded 100,000 items.

These include hydraulic and mechanical steering racks, fastening components, oil seals, pumps, tools, turbochargers, starters and more.

Each component is manufactured according to strict standards, so it fully corresponds to the quality of the original spare part. At the last stages of production, generators undergo thorough testing.

All Motorherz products are certified according to ISO9001, ISO9002, PROTECT standards.

Equipment. The kit of German units includes all the necessary fastenings.

Life time. The warranty period is 120,000 km or 4-5 years.

Pros of Motorherz

- Uninterrupted operation.

- Doesn't drain the battery.

- Excellent bearings.

Cons of Motorherz

- Unsuccessful fastening in some modifications.

NIPPARTS

Description. The Dutch company NIPPARTS is a leader among suppliers of Asian spare parts in Europe. It does not produce parts, but only packages them. The concern cooperates with brands that produce high-quality products.

All products are ISO certified, with the most common ones being TUV and ECE R90 certified.

Car enthusiasts note that product quality depends on the color of the packaging. The red and black box contains Japanese parts from Koyo, 555, Kashiyama and Micro.

NIPPARTS generators are easy to repair. They are easy to install in their original place.

Equipment. The kit includes all the necessary fastenings.

Life time. The operating life of the generator is 160,000 km.

Pros of NIPPARTS

- Maintain standard dimensions.

- Uninterrupted operation with a large number of consumers.

- Excellent condition after tens of thousands of kilometers.

Cons of NIPPARTS

- It is not easy to find components for repairs.

ATE

Description. The ATE-1 company produces a number of spare parts: starters, generators, fuel systems, autonomous heaters, ignition systems.

All products are manufactured at a plant located in Moscow and are certified according to ISO9001:2000, ISO16949:2009 standards.

The quality of spare parts is controlled at all stages of production and sales. Multi-stage testing tests units under extreme temperatures, exposure to aggressive environments and shock or vibration.

The company's scientific base is working to improve generators.

The Automotive Electrical Equipment Plant produces generators for trucks and cars, buses, agricultural machinery and special equipment. The units are installed as a kit for carburetor and diesel engines.

Newer modifications have a modified rear end. They do not have a heating impeller.

Equipment. The ATE generator set includes all the necessary fasteners.

Life time. It is recommended to replace the unit every 120,000 km or 4-5 years of operation.

Pros of ATE

- Cheap cost.

- Excellent performance when all consumers are included.

- Maintainability.

Disadvantages of ATE

- The resource is sharply reduced in bad weather conditions.

Denso

Description. Denso generators were introduced in the 1960s. To this day, the company works hard to reduce the size and weight of the unit, but at the same time increase its productivity.

In 2000, the segmented conductor generator was introduced. Its winding uses a wire with a rectangular cross-section.

The filling density of the new modification was increased from 45% to 70%. The weight of the unit was reduced by 20% and productivity increased by 50%.

All Denso products meet vehicle specifications. The company never resorts to using remanufactured parts.

Denso production technologies are similar to those used for the manufacture of original components. The concern's generators are installed on Toyota, Ford, BMW, Opel, Fiat, and Land Rover cars. The units are repairable.

The manufacturer has optimized the dimensions of the rotor and stator. This improved the magnetic circuit, which had a positive effect on the overall power.

A small diameter roller increases rotor speed, and two blades reduce the weight, size and noise of the element. The pulley is made of metal.

Denso supplies generators with internal fan and segment conductor.

Equipment. The package includes all required fasteners.

Life time. The service life is 90,000 km.

Pros of Denso

- Exact dimensions.

- Interchangeability with most original units.

- Trouble-free operation.

Cons

- Expensive cost.

Mando

Description. Mando generators are actively used by professional car services. The Korean manufacturer develops modifications for trucks and passenger cars. The company supplies units to the assembly lines of Kia Motors and Hyundai Motors.

Generators for diesel power engines are equipped with additional components.

The rear covers of the units are made of aluminum. The rotor winding is placed on a steel shaft.

The stator design is a ring-shaped core with grooves for the turns of the winding, which is wound with copper wire.

The rotor shaft is equipped with ring contacts to supply current to the winding. The brush that supplies current to the armature winding is made of graphite. To prevent the generator from overheating, cooling impellers are installed on it.

Equipment. The kit may include a vacuum seal.

Life time. The recommended service life of Mando generators is 160,000 km.

Pros of Mando

- Original parts without the use of remanufactured parts.

- Long service life (up to 6 years).

- The quality meets the requirements for products on the conveyor.

Cons of Mando

- After installation, it takes time to grind in.

Krauf

Description. Krauf is a brand owned by the German concern Motorherz GMBH. The company's 70 factories are based in Southeast Asia.

The bulk of spare parts are supplied to secondary markets in Eastern Europe. Krauf's specialization can be called narrowly focused, since the manufacturer is limited to the production of gasoline pumps, generators, starters and pump elements.

All spare parts meet quality requirements according to ISO 9001 and ISO 9002 standards.

Krauf generators are suitable for domestic, European and Asian cars. Some modifications are designed specifically for American brands. Car enthusiasts appreciated the low cost of the units and their complete identity to the original.

The quality of components is controlled by specialists from Germany.

Equipment. Krauf generator kits include all necessary mounting hardware.

Life time. The recommended service life is 4-5 years or 120,000 km.

Pros of Krauf

- Affordable price.

- The quality is comparable to the original.

- Maintainability.

Cons of Krauf

- Possible fakes.

Delta

Description. Delta is a subsidiary of the ATL concern. The manufacturer's facilities are concentrated in the city of Arnsberg. The main specialization of the brand is the production of original starters and generators, as well as the restoration of units.

Only spare parts from well-known brands are accepted for restoration. Delta offers components for trucks, passenger cars, agricultural, road and construction vehicles. The main part of the products is manufactured for European and Asian cars.

Equipment. All necessary fasteners can be purchased with the Delta generator.

Life time. The service life is 120,000 km.

Pros of Delta

- Budget cost.

- Quality materials.

- Rigid impeller.

Cons of Delta

- The weak point is the bearing.

Bosch

Description. The German manufacturer Bosch produces generators for imported and domestic car brands. The units are characterized by stable operation at high speeds.

Most spare parts are delivered to conveyors. A special series of generators was the EL line for passenger cars. The units effectively cope with their task on city roads.

The design used proprietary HED diodes, which increased the generator performance by 76%.

You can separately purchase components for Bosch generators, such as relay regulators, bearings, solenoid relay, pulley and slip rings. The proprietary relay-regulator is suitable for all modifications of the unit. This element protects the battery and generator from network overload.

The gear relay is equipped with its own connection connector, stationary brushes and DFM feedback contact.

Life time. The guaranteed service life of Bosch generators is 160,000 km.

Pros Bosch

- Excellent condition after tens of thousands of kilometers.

- Stable work.

- Good response to controls.

Cons Bosch

- Weak points are slip rings and bearings.

We increase the voltage of the generator on a VAZ-2114 with our own hands: we increase the power

As you know, additional equipment is often installed on a car, which draws additional voltage from the on-board network. Thus, the voltage indicator on a VAZ-2114 can drop to a critical level of 11 volts . If you also install additional air conditioning or heated seats, this may result in the starter not having enough power to start the engine. How to fix the problem? Make sure that the voltage in the on-board network increases.

Video about increasing the voltage in the on-board network on VAZ cars:

The video will tell you how to increase the voltage of the generator and on-board network with your own hands, and will also tell you about some of the nuances and subtleties of the process

Gasoline generator device

The principle of operation of a gasoline generator is the same as that of most any power plants, based on the conversion of mechanical energy into electrical energy. An external force rotates the generator armature, and an electrical voltage is induced in the stator windings. In the case of a gasoline generator, the armature rotates the gasoline engine.

So, what is included in a gasoline generator? Main parts:

- Gasoline engine (two- or four-stroke);

- Generator;

- Monitoring, protection and management circuit;

- Speed stabilization device;

- Fuel tank;

- Frame for attaching all components.

We increase the voltage - all options for solving the problem

Voltage in the on-board network after modification

So, many motorists may decide that the way out of this situation is to install a high-power generator, but at the same time they will have to replace the battery with a more capacitive one. This is done in order not to “kill” the battery that is installed on the car, since a voltage overload will lead to the destruction of the internal cells. This option is not suitable because it is too expensive.

The second option is to install an additional diode from another diode bridge or marked KD202V . This is much cheaper than changing the generator and battery, but you will have to tinker a little. To begin with, it is recommended to study automobile electrical circuits and the operation of the generator, as well as the charging circuit.

Installing the KD202V diode into the generator

When everything is ready, we proceed directly to installing the diode in the generator to increase the voltage in the on-board network. Let's consider the sequence of actions:

- Remove the back cover of the generator.

Remove the back cover from the generator

Wires and diode to increase voltage

Installing heat shrink for male and female wires

Installed heat shrink for the soldered part

We install a voltage regulator with a diode in the generator

We put the back cover on the generator and take out the wires

As the measurements showed, after such an improvement, the voltage in the loaded network was 12.2-12.5 volts.

Electrical diagrams and indicators

To increase the voltage even more, at least to 14 volts, it is necessary to install a diode in circuit D, the voltage regulator. Any diode with a breakdown voltage of 20V and a current of at least 5A is suitable. The voltage drop is preferably no more than 0.6-0.7V. The 2D219B diode is excellent.

Features of a car generator

After turning the ignition key, current flows into the field winding. Here it is controlled by a voltage stabilizer, which is powered by the rectifier section.

A car generator produces alternating current, which, after rectification by a diode bridge, becomes constant. Thus, such a unit belongs to the group of DC valve generators.

Its distinctive feature is maintaining voltage within a narrow range of values. A special regulator, which is popularly called “tablet”, “chocolate”, “brushes”, is responsible for the voltage of the generator.

These devices increase the voltage to 13.6 Volts.

Today they are connected according to two main schemes. The older version is reliable, works stably, maintaining voltage at approximately a constant level. The updated scheme has many disadvantages.

The uniqueness of the automobile unit is that it generates electricity by converting the mechanical energy of the rotating engine crankshaft, which is connected to the generator pulley by a belt. At the same time, the engine speed is not a constant value.

Thus, the main task of this electrical unit is to charge the battery and supply all car consumers with stabilized voltage.

In this case, regardless of engine speed, the voltage should always remain within approximately 14 Volts. Otherwise, it will negatively affect both the battery and the electrical circuit. Overcharging and undercharging will have a detrimental effect on the battery.

Unsustainable breakdown - hurry up with repairs!

It would seem that there is something wrong here - there is not enough tension. The car runs on gasoline, not electricity. However, a lack of current power leads to an increase in fuel consumption, a decrease in engine power, and some electrical appliances stop working altogether and will require replacement in the future. This is especially noticeable in the dark, when many power supply devices are used.

The first sign of lack of voltage is dim high beams - their lamps require a large number of watts. In most cases, it turns out that the battery is poorly charged.

You can deal with this problem easily and quickly by charging it properly. However, sometimes this doesn't help. Look under the hood - the battery terminals may be loose or oxidized. If in a parking lot the current still maintains a constant voltage, then during driving, due to vibration, the terminals may move away, opening the circuit. To fix the problem, you need to thoroughly lubricate the fasteners and tighten the bolts; sometimes only replacing the old terminals with new ones will help.

Assembly of the structure and adjustment

The gasoline generator is assembled on a suitable platform. During assembly, the main thing is to ensure strict parallelism and location of the generator and engine pulleys in the same plane. Otherwise, the belt may slip off and cause increased wear. The distance between the pulleys is chosen so that the belt is tensioned and does not slip during operation.

Important! Don't overdo the tension. This will cause a decrease in efficiency and wear on the belt and pulleys, and most importantly, the bearings of the engine and generator shafts.

Having another pulley, even if it is of small diameter, you can make a belt tensioning device using a spring of the required elastic force.

The gas tank is placed in the highest part of the structure so that gasoline can flow by gravity into the carburetor. It is important to prevent the tank from heating up with the heat of a running engine. If necessary, provide thermal insulation using asbestos pads.

Important! Asbestos dust is not toxic, but it can be harmful to the lungs, so you need to wear a respirator when working with asbestos.

Don't forget the fuel filter.

The assembled structure should ensure ease of starting the engine and access to all elements: carburetor, spark plugs, voltage regulator.

The adjustment consists of setting the required voltage using the generator's standard regulator. Some generators, for example, from Samara and newer cars, have a built-in regulator that does not allow adjustment.

If the voltage is below the permissible level, the uninterruptible power supply will not start, giving a signal that the battery is severely discharged. A high value may cause damage to circuit elements.

As you can see, assembling a home gas generator is quite feasible. A self-assembled gas generator can work no worse than a factory one, but you should know that this can only be done if you have at least some of the components. Manufacturing a power plant from scratch in the complete absence of parts will lead to costs exceeding the purchase of a finished structure.

All structural elements must be secured to a rigid base. For the base, the easiest way is to make a frame from steel corners 50x50 mm. The frame must have mountings for the engine, generator, converter and gas tank.

To reduce vibrations, all elements must be secured through shock-absorbing pads made of thick rubber.

Generator failure - how to determine?

A breakdown of the generator entails big troubles - electrical appliances may fail and the battery life will be reduced. So, if the voltage regulator relay fails, the generator may produce a voltage greater than required. This can cause problems in the correct readings of electrical appliances, as well as in the operation of the car's lighting.

To independently check the functionality of the generator, you will need a tester and an assistant. First of all, insert the key into the ignition and start the car. The battery light on the dashboard should illuminate to indicate a low charge or an open circuit. It is necessary to warm up the car to operating temperature and turn on all possible devices in it.

Then take a tester and check the voltage at the battery terminals. During this time, your partner should keep their foot on the gas pedal and maintain 3000–3500 rpm of the engine. The voltage on the tester in a VAZ 2114 car with a normal working generator should be at least 12–13 Volts. If the voltage is less, it is necessary to proceed with a detailed check of the device. Urgent repairs are also required if the current is greater than 14.7 Volts. This applies not only to the VAZ 2114, but also to other passenger cars.

When checking the operation of the generator, you need to listen to its sound. The presence of a characteristic hum or noise from belt friction indicates wear of its bearing, in which case a complete repair of the device is necessary. Also, quite often the ground contact on the car’s generator turns out to be poor, because the wire is located quite low in the VAZ 2114. During rainy weather, water gets on it, which causes oxidation of the contact terminal.

Selecting elements for a gasoline generator

How to make a gas generator with your own hands? The main parts are the engine and the generator. The engine can be any suitable gasoline engine from a chainsaw, motor cultivator, motorcycle or moped.

Thus, a 2 hp chainsaw engine. translated into kilowatts it has 1.47 kW.

If you have a choice, it is better to go with a four-stroke engine, since a two-stroke engine has the following disadvantages:

- The need to use a mixture of gasoline and special oil as fuel;

- It is impossible to use a large fuel tank, since the fuel mixture tends to separate, and the viscous and heavier oil will end up at the bottom of the tank;

- Low efficiency.

An equally difficult task is choosing a generator. It is theoretically possible to use any electric motor as an electric generator, since these devices are reversible and can perform each other’s functions. It is tempting to use an AC motor so that the output immediately produces an alternating voltage with the necessary parameters. But in practice this is not feasible for a number of reasons:

- Impossibility of accurately stabilizing the rotation speed of an internal combustion engine. Thus, as the engine speed changes, the output voltage and frequency will change;

- High complexity of the control scheme.

In industrial gas generators, special windings loaded onto a capacitor are used. As the speed increases, the voltage frequency increases, accordingly, the capacitor resistance drops, and the load on the control winding increases. It, creating additional magnetization, slows down the generator rotor, reducing the rotation speed.

The only way out of the situation is to use a DC generator.

Car generators are best suited for a homemade gas generator because:

- It is possible to stabilize the output voltage by using the vehicle's standard voltage regulator;

- Possibility of connecting any generator to replace a failed one;

- Convert DC voltage by using an uninterruptible power supply.

We need to dwell on the last point in more detail. It is clear that a car generator produces a constant voltage. Its value is 12-14 V. But how to convert it to an alternating voltage of 220 V? The solution is simple - use an uninterruptible power supply unit, which has a car generator connected instead of a battery.

It is quite possible that the uninterruptible power supply unit will be the most expensive part of a homemade home power station, since devices with a power of more than 500 W have a sharp increase in their cost. There are several options for increasing the permissible power:

- Conversion of an existing uninterruptible power supply to higher power values;

- Purchase of a faulty powerful one and its subsequent repair;

- Build your own design.

The first option requires great skill in repairing radio-electronic devices, since it requires:

- Replacing the standard transformer with a more powerful one;

- Replacing output transistor switches (possibly along with their wiring);

- Alteration or adjustment of current protection to a new output current range.

Making a completely homemade design requires no less knowledge, but there is no need to reproduce many unnecessary functions of an industrial device. Thus, the cost of a homemade converter may be lower than the other components of a homemade power plant.

The easiest way is sometimes to use a faulty converter. They are often written off due to inoperability, although only the battery is faulty. The cost of powerful batteries for uninterruptible power supplies is high and makes up a large part of the cost of the device, so sometimes it is more profitable to purchase a new uninterruptible power supply than to change the battery in an old one.

Note! Despite the fact that the generator is connected instead of a battery, the battery, although of minimal capacity, is necessary to smooth out the pulsations of the generator. Otherwise, the uninterruptible power supply will not start or will fail.

You can also use ready-made inverter converters of the required power.

As already mentioned, it is very difficult to perform mechanical adjustments yourself. Electronic will require alteration of the generator.

Therefore, it makes sense to make a gas generator with your own hands using an inverter circuit, and use a converter from an uninterruptible power supply as a converter.

The choice of equipment is influenced by the following factors:

- engine power;

- engine speed;

- generator voltage;

- generator current;

- converter power.

The maximum power of a gasoline generator primarily depends on the engine power. The following devices have the following power and speed ratings:

- lawn mower (trimmer) – 0.5…2 kW, 8000…9000 rpm;

- chainsaw – 1.5…3 kW, 9000…12000 rpm;

- walk-behind tractor - 3...9 kW, 2000...3000 rpm.

The easiest way to create a gas generator with your own hands is on a generator from a car (Fig. below). A typical generator for a passenger car is capable of producing an output voltage of 13...14 V at a load current of 80...100 A. A simple calculation will show that the power of such a generator is no more than 1.4 kW. Larger values can be obtained using generators from trucks.

A car generator is well suited for creating a gas generator

Many trucks are equipped with 24 V generators.

The generator has the indicated characteristics at an average speed of 5000 rpm, which does not correspond to the normal speed of the listed engines. To equalize the values, you can use a belt drive with different pulley diameters (Fig. below). The number of revolutions on the driving and driven pulleys is inversely proportional to their diameters. But the transmitted power changes in the opposite way.

Belt drive with different pulley diameters

A gasoline generator made on an engine from a chainsaw or lawn mower requires a reduction gear to reduce the number of revolutions on the generator shaft by about half. The power transmitted by the engine to the generator pulley will also double accordingly. If you use an engine from a walk-behind tractor, an overdrive gear is required.

It is not advisable to use gearboxes in a homemade design, since the labor intensity of manufacturing the gearbox is high. A poorly designed gearbox greatly reduces the efficiency of the installation and serves as a source of additional noise.

The next necessary device is an inverter voltage converter (Fig. below).

Inverter converter – uninterruptible power supply

When talking about the power of the engine and generator, the power of the converter was not mentioned. It is this that can become the weak point of a homemade gasoline generator. Powerful converters are quite expensive. Remaking a low-power converter can only be done by those who are very well versed in radio electronics and know the principle of operation of the device.

It is not advisable to disconnect the battery of the uninterruptible power supply. It is used to load the generator and is designed to smooth out voltage surges at its output. Most car generators produce too much voltage at low loads.

Which generator is better to buy?

When choosing a generator for your car, be guided by several important criteria.

Value for money

Don’t forget: the performance of the entire car depends on the condition of the generator. The unit does not have the right to work “so-so”, therefore, when choosing, pay attention to the cost.

A cheap component may not fit into a regular place at all. Of course, original spare parts are the best option, however, not everyone can afford it.

In this case, you can use good analogues.

Package

Unfortunately, the products that are most in demand are counterfeited. To avoid getting a fake, carefully inspect the packaging.

It should indicate information about:

- Address of the supplier and manufacturer.

- Certification, which shows the degree of quality of the product.

- Warranty period.

- Original codes and applicability to car models.

- Parts identification.

The unit must be protected from mechanical damage by liners or seals.

Important points

The voltage (U) and capacity of the car battery are the main parameters that need to be paid attention to when choosing and checking a power source.

The main purpose of the battery is to start the engine during the period when the car's generator has not yet been connected to work, and the battery is the only power source.

To eliminate operational problems, the car owner should know the following points:

- What does the battery life depend on?

- What should the voltage be (in normal mode, after starting the engine and under load);

- What causes the decrease in capacity during the cold season and other issues.

Let's consider these questions in detail.

Normal voltage

What should be the normal voltage in the on-board network? The voltage in the vehicle's 12 V on-board network should be 14.2-14.4 Volts. This applies to all vehicles, from Zaporozhets to Gelendvagens. This parameter should be present when the engine is running under load.

If there is a voltage drop caused by insufficient battery charge at 12 volts, then when you turn on, for example, optics, this parameter will be below 14 volts. This is because the excitation winding of the generator device is powered by the battery through feedback. And if the battery is not fully charged, the network will not be able to ensure optimal winding current and normal operation of the generator device.

This manifests itself when outdoor lighting is activated and is accompanied by a general loss of electrical circuit power. The lighting may be dim when idling, but when the driver accelerates, the light will stabilize to normal. Therefore, battery diagnostics should be carried out not by voltage when starting the engine, but by the electrolyte density parameter. This will prevent a difference in readings between the electromotive force of the battery and its current.

Note that the voltage of the vehicle’s on-board network may vary depending on the climatic conditions of the region in which the vehicle is operated. If the car was driven from the south, and you live in the north, then a slight drop in this indicator in the car’s electrical circuit is allowed. If a vehicle is using a partially discharged battery, it must be charged, otherwise the entire charge will quickly decrease and the battery will be inoperable. If an old battery is used in a car, over time the active mass from the plates may begin to disintegrate and a short circuit may occur inside the structure. And this will cause a loss of capacity, that is, the ability to keep the battery charged.

Minimum battery input voltage parameter

When checking the parameters of the generator, it is worth taking into account the characteristics of the battery itself.

Many car owners are interested in what the voltage at the battery output should be for normal engine starting.

There is no exact answer here, but the average parameter should be 12.6-12.7 V. Depending on operating conditions, this indicator can be adjusted.

Some manufacturers claim that their product has a voltage of 13-13.2 Volts. This parameter is real, but you should not measure the voltage immediately after recharging with a generator or charger.

It is advisable to wait 1-2 hours before carrying out work. In this case, U should drop to a level of 12.7-13 V.

If this parameter begins to “float” or drops below 12 V, this indicates a 50% battery discharge or a generator malfunction.

It is recommended to check the charging circuit or use an external charger.

If you continue to operate the battery in this condition, sulfation of the lead plates occurs, which reduces the performance of the battery and reduces its service life.

In practice, such a decrease in voltage is not critical, because the battery can still be started, and then the generator recharges to the required level.

The main thing is to make sure that the charging circuit is working properly and that the voltage at the battery terminals is increasing.

If U at the output drops below 11.6 V, we can talk about the complete discharge of the power source.

In this case, further use of the battery is impossible - it must be removed, checked for serviceability, and charged from an external device.

Taking into account the above, we can conclude that the voltage on the battery with a working generator should be (with the engine off) 12.6-13.2 V. In practice, this parameter is slightly lower and amounts to 12.3-12.5 V.

This voltage indicates a slight undercharging of the battery. There's nothing wrong with that. The main thing is not to allow U to decrease below 12 V.

Consequences of long-term battery recharging

- Boiling of cans and increasing the concentration of acid in them.

- Oxidation settles on the contact group of the terminals and becomes overgrown with a green coating.

- Risk of destruction of the battery housing.

- Failure of signal lamps and vehicle lighting lamps.

- A sour smell appears in the cabin, this is a consequence of distilled water boiling away from the battery alkali.

- Destruction of the active plates of the battery due to their drainage.

- Burnout of fuses and sensors, as well as some electrical components of the car that negatively relate to increased voltage in the on-board network, such as multimedia, audio amplifiers, etc.

conclusions

Increasing the voltage of the VAZ-2114 generator with your own hands is real and quite simple. At the same time, the cost amounted to 500 rubles . It is worth noting separately that if you do not have the necessary skills or abilities to work with automotive electronics, then you should contact a car service center, where everything will be done quickly and efficiently, and of course, at the expense of the car enthusiast.

Many motorists have encountered the concept of low voltage in the network. The culprit of the situation was the generator, which produced an insufficient amount of current. Is there any way to increase the voltage produced by the unit? How to increase the power of the generator without damaging the circuit and the overall system.