The smell of gasoline in engine oil, where does it come from?

If the engine is an injection engine, then the breakdown of the fuel pump disappears immediately. The engine simply wouldn’t start without it. But injectors can indeed freeze, especially if the gasoline contains water. You can check the cause of burnt-out rings yourself - it will be enough to measure the compression.

Even the dipstick shouldn't smell like gasoline.

The first step is always to look at candles. If black carbon is present, the cause will be one of two things: either the mixture is too rich or it is misfiring. Try to distinguish the first from the second: if the engine “troubles”, you can hear it. In addition, the error with omissions must be diagnosed by the ECU - the Check lamp lights up.

Compression as a cause of gasoline smell?

It is unlikely that the compression rings, but not the oil scraper rings, burn out.

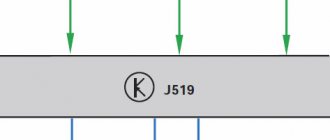

Three different rings on the piston

Therefore, it makes sense to perform an initial diagnosis:

- The smell of gasoline may be present in the engine oil, but the oil itself is not consumed or even “arrives.” Conclusion: the rings are not burned out, there is no need to check the compression.

- If both factors are present, that is, the smell of gasoline and oil consumption, then it is too late to take any measurements - burnt-out rings are already making themselves felt.

Nevertheless, in order to assess the level of the problem, in case 2 measurements are taken - a strong deviation from the norm will be detected.

If the deviation does not exceed 5-10%, you don’t have to think about any burnout of the rings. Example: 14.2-15-15.4-15. This is still the “norm”.

It turns out that the initial conclusion is not drawn from the measurement results, but only from observations of the oil level.

By the way, we considered only injection engines, but not carburetor engines or engines with direct injection.

Signs of changes in engine oil and possible consequences

Performing regular checks of the amount of oil in the engine allows you not only to promptly detect its decrease, but also to notice a possible deviation from the lubricant standard. Such changes include:

- color change;

- increased fluidity;

- the appearance of a fuel smell.

In addition to the appearance of an odor in the oil, the following non-characteristic signs in the vehicle’s behavior may indicate that gasoline has entered the engine lubricant:

- loss of power by the motor;

- increased fuel consumption;

- the appearance of extraneous noise in the power unit, especially when operating under load;

- the occurrence of malfunctions in the operation of the motor, it periodically begins to stall and stall;

- when the internal combustion engine is started, a special red emergency indicator is activated on the dashboard;

- The exhaust gases become thick, gray in color and smell like fuel.

If the smell of gasoline appears in the engine oil, as well as the indicated signs in the behavior of the car, it is necessary to immediately diagnose the engine, since gasoline in the oil practically kills all the quality characteristics of this lubricant. The following negative consequences are considered the most dangerous:

- Viscosity decreases, which reduces the protective oil film on interacting parts.

- The friction force increases. As a result, wear of engine elements and parts increases.

- An increase in temperature at the joints of parts, which leads to their deformation with subsequent jamming of the engine.

Checking and repairing a mechanical fuel pump at home

It is advisable to begin any repair work on the engine by washing and cleaning dirt and dust at least at the repair site. The fuel pump must be removed by unscrewing the two mounting bolts. It is better not to disconnect the inlet and outlet gas pipelines if they do not interfere with dismantling. Otherwise, they can be disconnected by plugging the incoming fuel line with a plug of the appropriate size, otherwise fuel will leak from it.

After removal, put the fuel lines onto the fittings and secure them with clamps. The outgoing gas line must be clamped with a clamp if it is rubber. If the tube is metal, disconnect it from the carburetor and plug it tightly with a suitable plug. Then try to pump gasoline into the engine using the manual pumping lever. If on the side adjacent to the engine housing there are streaks of gasoline in the oil or a clearly and sharply distinct smell of fuel appears, it means that the fuel pump diaphragm is not sealed.

Further actions are possible in two options: replace the fuel pump with a similar new one or repair the existing one. When repairing an already installed device, you must purchase a repair kit for the device model being repaired. As a temporary option, you can add a couple of layers of cellophane to the diaphragm, but this will not last long. Disassembly and assembly of the fuel pump must be carried out in accordance with the vehicle manual.

If you have a set of spare parts for repair, it is advisable to replace all existing parts, especially the intake and exhaust valves and their springs. Wash the filter mesh thoroughly in clean gasoline or solvent. After assembly, it is advisable to check the functionality of the device and the tightness of the diaphragm. Checking this part is described above.

We recommend: Do-it-yourself illumination of car rims as a stylish type of tuning

You can check its functionality by disconnecting the outgoing gas line from the carburetor or pump and pumping it with a lever. A full stream of fuel should splash out of the hose or fitting with each press. After completing all repair work, you need to more carefully monitor the oil, its level and color for some time during operation to be completely sure that the problem has been eliminated.

Prevention

We should not forget that at the initial stage the problem of mixing oil and fuel can be completely solved without significant financial costs. Pay attention to this regularly! Nowadays, it is so common to find gasoline with impurities that will undoubtedly ruin your car. For example, this is toluene, benzene, modern manufacturers mix an incredible amount of ingredients to obtain higher profits. These substances accelerate the penetration of fuel into the lubricant.

In addition to fuel of poor quality, one should not forget about the oil itself, but even the best and most expensive relish loses its properties when using low-quality fuel. If after the next refueling it becomes noticeable that the car is running worse, there may be surrogates in the fuel. The best advice in this case, besides diagnostics to avoid repairs, is not to “feed” your vehicle anymore in such places.

As a preventive measure, you can suggest “walking” your car, making long and short trips along the highway. The thing is that during long driving, the oil heats up and condensation and fuel that gets into the lubricant decrease.

Methods for diagnosing the presence of gasoline

You can verify that the lubricant is diluted with gasoline yourself, as well as in the laboratory. Problems with the chassis are corrected at a service station.

An increased level of filled material indicates that fuel has entered the crankcase. You can independently check the compression, the condition of the injectors, carburetor, and spark plugs.

The following visual diagnostic methods are acceptable:

- paper test;

- viscosity check;

- oil stain method.

When testing, use a probe, a funnel, and a white sheet of paper. The paper test is designed to detect the amount of additives that are added to lubricants. A drop of oil flowing down at an angle onto the paper should not leave a dark mark.

Identify by smell

You can detect gasoline getting into the lubricant by smell. The remaining contents on the oil dipstick smell like gasoline or acetone. Tint characteristics depend on the quality of fuels and lubricants, the condition of the car at the time of inspection. The smell is coming from the filler neck of the tank.

A fuel spill can be detected by the strong smell of exhaust gases.

Drip test

You can evaluate the quality of the oil yourself by performing a rapid analysis. The engine is warmed up and the engine is turned off. After 5 minutes, a drop of lubricant from the oil dipstick is applied to a white sheet of paper. The results are assessed after the drop has dried.

The manufacturer provides an express test, the result of which is assessed in comparison with a photo table in half an hour. A drop that is applied to a sheet of paper dries within 24 hours.

The analysis is carried out according to the following parameters:

- contour of the spot;

- uniformity of spreading;

- diameter of the dried drop;

- number of rings.

This determines the degree of contamination, the presence of gasoline, and condensate. The dark color of the edges of the stain indicates a loss of detergent-dispersant properties and the presence of harmful impurities.

Drip test results:

- The central part (core) indicates the presence of insoluble impurities. Increased level of pollution with soot and dust. The core darkens as waste accumulates.

- The area around the core (edge) should be lighter under the influence of organic components.

- The diffusion zone is represented by a light ring. The width of the ring characterizes the content of organic impurities.

This type of lubricant cannot be used. A decrease in the diffusion zone is alarming regarding the loss of additives.

The appearance of a yellow outer circle and the absence of smooth edges is evidence of the presence of condensation. The presence of gasoline will be indicated by an additional ring. The width of the ring is comparable to the amount of fuel in the oil product.

Engine oil burning

The presence of gasoline is checked by heating the flammable mixture in a test tube with a closed lid. Oil vapors have a higher combustion temperature than fuel vapors.

After sufficient heating, open the lid and bring the test tube to the fire. If the content of the fuel component is high, a flame will appear. Setting the fuel mixture on fire on the dipstick cannot be considered convincing, even if gasoline could get into the oil.

Carrying out tests requires compliance with safety regulations.

Diagnostics

- sniff the oil dipstick - you may smell gasoline;

- leave a drop of oil on the paper; if it contains gasoline, you will see characteristic circles of stains;

- the “with a spark” method - set fire to warm oil, bring it to a boiling point to cause active evaporation of gasoline.

The reasons for gasoline getting into the oil depend on the characteristics of the internal combustion engine. But in any engine, fuel first enters the crankcase from the combustion chamber with the help of piston rings. If we pour gasoline into the cylinders of a new engine, it will eventually end up in the oil. Why is this happening? The fuel eliminates the oil film and overcomes leaks where the piston rings are located.

Carburetor

Speaking of a carburetor engine, the most common reason for mixing fuel and lubricant is damage to the fuel pump. This can also include improper operation of the needle valve or overflow of gasoline into the carburetor.

Let's summarize what has been said, the main causes of such problems are breakdowns in the fuel system, ignition system and, of course, in the operation of the engine itself:

| № | Helpful information |

| 1 | mixture too rich |

| 2 | breakdown of the carburetor, fuel pump |

| 3 | ignition system problems |

| 4 | engine malfunction, no fuel ignition (no spark) |

Since carburetor engines have a mechanical fuel pump installed, gasoline that gets into the carburetor when the pump diaphragm is damaged can get into the rod channel, that is, into the lubrication system. If the damage is minor, the problem is hidden, but if the gaps are large, gasoline does not reach the carburetor, the car begins to twitch and is difficult to start. The solution to the problem will include replacing damaged parts of the fuel pump and oil.

When searching for a problem, do not forget about computer diagnostics and “ringing” of sensors. In winter, it is a good idea to check the accumulation of draining gasoline under the carburetor.

Let's talk about engines with an injector; they have a slightly different fuel supply system. It is supplied from the fuel tank under pressure, which is already created by an electric pump, which prevents fuel from entering the lubricant at this stage.

Poor quality fuel

Sometimes the cause of incomplete combustion of the fuel mixture in the cylinders is the gasoline itself. It is not uncommon that the quality of fuel at gas stations leaves much to be desired. Moreover, gasoline may be mixed with other additives that make it more difficult to ignite. Unburned fuel mixture residues penetrate into the engine crankcase. In these cases, to fix the problem, you need to start using another gas station, but you will still have to change the oil.

Some experts advise, as a preventative measure, when driving on open roads, to allow the engine to run for a short time at high speeds. This type of driving leads to higher oil temperatures. This reduces the amount of condensate accumulated in the lubricant and gasoline entering the oil.

Treatment

You should not use the car until the identified breakdowns are repaired in order to avoid significant repair costs, which may increase.

As already mentioned, a very common situation is when the problem of gasoline getting into the oil is long-term in nature and occurs almost “asymptomatically”. Can you imagine, the pressure in the lubrication system drops sharply, the emergency oil pressure indicator lights up, the car jerks, roars, but does not drive?

General recommendations in this situation will be as follows, depending on the breakdown:

- ignition system repair;

- fuel pump repair;

- Troubleshooting the piston system;

- carburetor or injector repair;

- mandatory oil change;

- changing the fuel used (often it is low-quality fuel that damages the car).

Piston system malfunction

Eliminating this problem is considered the most expensive and difficult. This malfunction usually occurs if low quality oil and gasoline are used. Low-grade fuels and lubricants cause the piston rings to become coked. Fuel begins to leak through the gaps that appear between the piston and the cylinder walls. Then it gets into the oil sump.

To identify this malfunction, you will need to use a compressor. They measure data on the compression of the cylinders, each individually. If the readings differ by more than ten percent from the established standards, this indicates a malfunction. Piston rings that are susceptible to coking are washed with chemicals specially designed for this purpose. An oil change after such a procedure is mandatory. Usually the engine oil does not smell like gasoline after this procedure. If flushing the cylinder block does not help, which happens infrequently, then the engine is disassembled to replace faulty rings and pistons.

Consequences

Let's consider the possible consequences of driving with oil enriched with gasoline.

- Reduced performance of engine oil. Any lubricant for internal combustion engines, regardless of its quality level, performs many functions. When oil is diluted with gasoline, some of the important properties of motor oil drop critically. First of all, the viscosity of the lubricant decreases. This means that at operating temperature the protection of loaded friction surfaces decreases. Which leads to accelerated wear. Also, the oil will be more actively washed off from the friction surfaces and, in general, will be less well retained on the working surfaces, which will lead to increased loads on the contact patches when starting the engine.

- Increased fuel consumption. In some particularly advanced cases, consumption increases by 300-500 ml per 100 km.

- Increased risk of fire in the engine compartment. There are known cases when gasoline vapors flared up in the engine crankcase. In this case, the oil dipstick often shot out of the well or the gasket was squeezed out from under the valve cover. Sometimes the damage after a gasoline flash in the crankcase was more serious: a gasket under the pan or cylinder head broke, the oil plug broke, and a fire broke out.

There are several ways to determine the approximate amount of fuel in gasoline. Only in the sense of whether the problem is serious.

We recommend: The best engine cleaners

The first and simplest is to analyze the oil level in the crankcase. For example, if your car’s engine has already consumed oil, and you are used to periodically adding lubricant between changes, and then suddenly you discover that the level is stagnant or even rising, this is a reason to immediately stop using the car and start looking for the cause of gasoline getting into the lubrication system. This manifestation of the problem indicates an excessive amount of fuel getting into the oil.

The second method is a drop test of motor oil on paper. If a drop instantly spreads in a greasy oil trail over a piece of paper over a large radius, 2-3 times larger than the area covered by the drop, there is gasoline in the oil.

The third method is to apply an open flame to the oil dipstick. If the dipstick flashes in short flashes, or, even worse, begins to burn even after short-term contact with fire, the amount of gasoline in the lubricant has exceeded a dangerous threshold. Operating a car is dangerous.

Basic faults

Most breakdowns can be divided into two large groups, the properties and characteristics of which differ from the type of engine used.

Injection

- Failure of the electric pump. With this malfunction, the pump generates very low pressure, as a result of which the injectors are not able to spray gasoline, but simply spill it into the cylinders. Such a spill disrupts the quality formation and atomization of the fuel mixture, which does not burn completely, but seeps through the rings into the oil.

- Loss of injector tightness. In this situation, the injectors cannot close tightly and if the engine stops, a certain amount of fuel under residual pressure enters the manifold, and then through it into the cylinders. Subsequently, when the engine operates, this fuel is mixed with the lubricant.

- The presence of defects in the piston group of the power unit. Deformations on the walls of the engine cylinders, as well as the presence of scratches, chips or cracks on them lead to poor flushing of oil from the walls and, as a result, coking of the oil scraper rings occurs, which cease to perform their function.

- Failure of spark plugs. In the event of such a breakdown, the fuel mixture that enters the cylinder with a faulty spark plug does not ignite, settles on the walls, and then flows into the engine crankcase, mixing with engine oil.

Fuel in the lubrication complex

Owners of both foreign cars and Russian cars are aware of the problem of the appearance of the smell of gasoline from motor oil. In a two-stroke power unit, the fuel is a combination of gasoline and lubricant. In a four-stroke engine, these fluids should not come into contact. The oil circulates in a closed manner. If there is a smell of gasoline on the dipstick, it means that the fuel is mixed with the motor oil.

Carburetor

- The first reason should include problems in the piston group of the engine, which are similar to the indicated problems for injection engines.

- Fuel pump failure. The main reason for its malfunction is a violation of the tightness of a special diaphragm, which is responsible for preventing the fuel mixture from penetrating into the engine crankcase. If it ruptures, gasoline enters the crankcase and mixes with engine lubricant.

- Carburetor needle valve malfunction. With such a defect, the float chamber overflows, accompanied by the formation of an over-enriched fuel mixture, which, after further incomplete combustion, settles on the cylinder walls and through them enters the engine crankcase.

- Drain tube clogged. When this malfunction occurs, excess fuel from the carburetor gets inside the cylinders and flows into the crankcase when starting a cold engine.

- The consequences of broken spark plugs are the same as on an injection engine.

Piston damage

The use of low-quality fuel and lubricants provokes the occurrence of defects in the piston block of a carburetor engine or a working unit based on an injector.

Slag forms on the pistons and the piston rings wear out. The piston ring grooves become clogged. A gap forms in the walls between the cylinders and the piston, into which gasoline enters.

Oil is not sufficiently washed off from the walls in the presence of chips, cracks, or deformation of the pistons. The low-removable piston rings become coked and do not support normal operation of the unit.

Carrying out simple diagnostic procedures will help you understand what to do if the piston blocks are damaged. It is necessary to determine the level of cylinder compression and the presence of coking.

Incomplete combustion of the combustible mixture when the piston is damaged leads to loss of power.

Initially poor quality oil

Lubricating oils maintain normal engine operation by preventing premature wear of parts.

The manufacturer has established compliance requirements for motor oils for the safe operation of vehicles. The manufactured product is selected according to engine type and temperature conditions. The lubricant is supplied with additives compatible with the base.

Correctly set oil level maintains reliable operation of the car engine. Some quality parameters of fuels and lubricants are determined by visual methods. Characteristics of color and consistency are indicators of the quality of lubricating compounds.

Low-grade oils, burdened with low-quality additives, pose a threat to the engine. Using unsuitable fuel and lubricants causes the following problems:

- Difficulty starting the engine.

- Loud engine noise.

- Coating of working parts with rust, carbon deposits, soot.

- A knocking sound occurs inside a running engine.

- The oil pressure in the system decreases quickly.

Poor quality oil does not provide sufficient lubrication and causes overheating of working parts. The production of a counterfeit product uses a cheap base material. Additives do not correspond to the characteristics of the work and do not protect the working unit from damage.

Malfunctions and checking of injectors of the injection power system

If one or more injectors do not close completely, fuel may leak into the cylinder and through the piston clearances into the oil. First, you can check the pressure in the power system. To do this, you need to get a pressure gauge with a rubber hose for high pressure and an adapter for connecting to the fuel rail. The upper limit of the pressure measured by the pressure gauge must be at least 6 kgf/cm².

The adapter must be connected to the ramp, the pressure gauge must be connected to the adapter. Then you need to turn on the ignition. If the fuel pump starts, wait until normal pressure rises in the rail. Then turn off the ignition. If the fuel pump does not start when the ignition is turned on (this is not a malfunction), start the engine, check that the pressure rises to the nominal value, turn off the engine and turn off the ignition.

We recommend: How to glue moldings on car doors?

You need to observe the pressure gauge readings for 5-10 minutes. If the instrument needle has moved downward by more than a third (example: the nominal pressure was 3 kgf/cm², after stopping it dropped to 2 kgf/cm²), you should look for a leak in the fuel supply system. Next, you need to remove the fuel rail with injectors and place it in a place accessible for inspection.

Injectors that are not completely closed can cause fuel to enter the lubricant.

Each of the nozzles should be placed in a transparent container; you can use plastic glasses with a volume of 0.5 liters. Fuel lines and electrical connections must be connected. Then you also need to turn on the ignition and, if necessary, crank the engine with the starter.

While scrolling, you can visually check the operation of the injectors by the type of fuel being sprayed. Having reached the optimal pressure in the power system, you need to turn off the ignition and visually check each of the injectors for gasoline leakage through the nozzle. If you detect leakage on one or more injectors, you can measure the resistance of the windings with a tester.

If the measured resistance value differs from the nominal value (usually 10-15 Ohms), the injector is leaking, or the spray pattern is different from others, then the injector must be replaced in accordance with the vehicle manual. After completing the repair, it is also necessary to check the oil for a certain period of operation.

Troubleshooting

When you smell gasoline in the oil, it is usually recommended to go to a car service center. If things have gone too far, there is no other way out.

However, at the beginning, when there are no significant car malfunctions, the driver has the opportunity to fix the problems on his own. To do this, you need to quickly drive the car for a couple of kilometers, then drain the lubricant and check whether there is gasoline in the oil. If it is not there, then you have managed to get rid of the smell of gasoline.

Foreign manufacturers recommend diagnosing a car this way. Take the highway frequently to dump excess fuel. Thanks to this, you will be able to get rid of the problem at its very beginning and prevent significant breakdowns. You won't have to spend money on expensive repairs.

Signs of a Leak

Is it possible to understand that there is a leak? You can find out about this by noticing a dark puddle under the car. It happens that lubricant leaks from under the valve cover lining, oil seals or crankcase gasket. Motor oil can only be mixed with fuel in the engine. It is possible to determine that gasoline has entered the oil liquid by the following signs:

- the viscosity of the oil changed, it became thinner;

- the car oil on the dipstick lights up if you bring the flame close to it;

- A drop of oil on a piece of paper leaves a greasy, growing stain.

Injection nozzles

In an engine with injectors, the smell of gasoline coming from the dipstick indicates a breakdown of the injectors and ignition system. In the first case, we are talking about the fact that the injectors lose proper tightness. After turning off the engine, fuel, due to residual pressure, seeps into the manifold and from there penetrates the cylinder block. The piston rings serve as a barrier to the crankcase, but if they are worn out, gasoline will still get there.

There is also a smell of gasoline if the ignition system is faulty. If a spark plug breaks, the fuel does not ignite in the cylinder block, that is, it is simply wasted. To fix the problem, you need to remove the fuel rail and check the tightness of all injectors one by one by supplying them with kerosene under pressure. Leaking parts and broken spark plugs need to be replaced with new ones.

Fuel in the lubrication system crankcase ↑

Owners of both foreign and domestic cars are familiar with the problem of an abnormal increase in the oil level in the crankcase, when the lubricant smells strongly of fuel. In a two-stroke engine, the fuel is a mixture of gasoline / oil, but in a four-stroke internal combustion engine, these two liquids should not mix. The circulation of lubricant in a working engine occurs in a closed circuit: crankcase - cylinder block - fuel filter - oil pump - cylinder head - cylinder block - crankcase. A strong smell of fuel coming from the dipstick, which measures the oil level, indicates that gasoline may have gotten into the oil, and you should look for the reasons.

Reasons requiring specialist intervention

The most unpleasant reason for gasoline getting into the oil of an engine with an injector is a malfunction of the piston group. The cylinder walls may be deformed, cracked, scratched or chipped. With prolonged use of oil with poor cleaning properties, the oil scraper rings become coked.

A breakdown is determined by measuring the compression in each cylinder. Measurements may differ from each other by one unit. If there is a larger gap in the compression values, we can talk about a malfunction in the specified cylinder. In such a situation, it is impossible to do without a major engine overhaul.

You can try to restore coked oil scraper rings using special chemicals, but such manipulations do not always produce a good effect.

What's the threat?

Gasoline, due to its solvent properties, dilutes the oil and therefore worsens its protective properties. If gasoline gets into the oil insignificantly, the noise level of the engine increases, as well as the degree of wear of loaded components. The higher the percentage of gasoline in the lubricant, the more serious problems it can cause, for example, major engine overhauls.

Examples include the following problems resulting from mixing gasoline and oil:

- the fuel correction coefficient is violated;

- acceleration is difficult, achieving maximum speed is difficult;

- piston failures are likely;

- damage to the carburetor and injectors, as a result, the engine completely fails.

To detect such problems in a timely manner, pay attention to the following factors:

- increased consumption, reduced power thrust;

- the exhaust changes - it is thick and has a characteristic smell of gasoline;

- the car stalls, the engine troits;

- the noise level of engines and extraneous sounds increases;

- The oil level rises, it becomes liquid and flammable, and the smell of gasoline appears.

Detection of one of the above signs in the operation of the car or a combination of them is undoubtedly an alarming signal for you. If you mix lubricant and fuel to create complex and aggressive chemical compounds, the mixture of gasoline and oil can cause serious damage to your car's engine.

The duration of this problem is especially dangerous: gasoline gets into the oil, as a rule, in equal small portions, which makes it invisible to the driver for a long time.

Read also:

How to drain gasoline from a tank?