VAZ 21213 | Engine repair

5.16.1 Engine repair

Removal, repair and installation of the intermediate shaft Removal, repair and installation of the connecting rod-piston group Removal, repair and installation of the crankshaft Troubleshooting and repair of the cylinder block ...

5.16.2 Removal, repair and installation of the intermediate shaft

You will need a 12 key. The intermediate shaft drives the oil pump. In addition, the camshafts are driven through it. The intermediate shaft rotates in two plain bearings, which are bushings. 1. Remove the upper and lower camshaft drive chains (see “Replacing timing chains and gears”). 2. Remove the sprocket...

5.16.3 Removal, repair and installation of connecting rod and piston group

You will need: keys “10”, “12”, “14”, heads “15”, “19”, hammer. 1. Remove the cylinder head (see “Replacing the cylinder head gasket”). 2. Remove the engine oil pan and crankcase gasket (see “Replacing the Oil Pan Seal”). 3. Remove the oil pump (see “Removing, repairing and installing the oil pump”). 4. Unscrew the nuts 1 of the connecting rod bolts and remove...

5.16.4 Removal, repair and installation of the crankshaft

You will need: a key “10”, heads “15”, “17”, “19”. 1. Remove the oil pan and crankcase gasket (see “Replacing the Oil Pan Seal”). 2. Remove the oil pump (see “Removing, repairing and installing the oil pump”). 3. Remove the camshaft drive chains (see “Replacing timing chains and gears”). 4. Turn out six...

5.16.5 Troubleshooting and repair of the cylinder block

To determine the technical condition and repair of the cylinder block, remove the engine from the car (see “Removing and installing the engine”) and disassemble it. Remove the cylinder head (see “Replacing the cylinder head gasket”), the crankshaft (see “Removing, repairing and installing the crankshaft”), connecting rod and piston group (see “Removing, repairing and installing connecting rod and piston group” ), oil map...

General information

When creating the Niva car, the designers were faced with the lack of a motor of suitable power. The existing engines with a volume of 1.2-1.5 liters were not very suitable for a car with all-wheel drive. The situation was saved by the appearance of a larger engine, model 2106. By maximizing the cylinder diameter, its displacement was increased to almost 1.6 liters, and its power reached 80 horsepower. It was this engine that became the main power unit of the Niva for more than 20 years.

VAZ 21213 | Engine repair

4.5.3. Engine repair

It is not always easy to come to a conclusion about the advisability of a complete engine overhaul, since it is necessary to rely on a number of objective indicators.

High mileage is not a sufficient indicator of the need for major repairs. On the other hand, low mileage does not exclude the need for major repairs. The most important indicator, apparently, is the timeliness of routine engine maintenance. With timely oil and filter changes, as well as all other necessary maintenance work, the engine will serve reliably for many thousands of kilometers. On the contrary, insufficient or untimely maintenance can cause a sharp reduction in engine life.

Increased oil consumption indicates wear on the piston rings, valve guides and oil seals. You should make sure that leaks are not the cause of increased oil consumption, and only then draw a conclusion about the unsuitability of the piston rings and valve guides. To determine the probable cause of the malfunction, measure the compression in the engine cylinders.

Check the oil pressure with a pressure gauge screwed into place of the oil pressure sensor and compare the test result with the standard value. If the oil pressure is low, the cause may be worn main and connecting rod bearings or oil pump parts.

Loss of power, “dips” in engine operation, detonation or metallic knocks, increased noise from the gear mechanism, increased fuel consumption indicate the need for a major overhaul, especially if all these signs of abnormal operation appear simultaneously. If all adjustments do not lead to improvement, then the only remedy for abnormal engine operation is a major overhaul.

Overhaul consists of restoring engine parts to the condition specified in the technical data for a new engine. When carrying out a major overhaul, pistons and piston rings are replaced, cylinders are bored or honed. After repairing the cylinders, which is carried out in a specialized workshop, installation of repair pistons will be required. The connecting rod and main bearings of the crankshaft, as well as the covers of the camshaft bearing journals, must also be replaced; if necessary, the crankshaft journals should be ground until normal clearances with the connecting rod and main bearings are restored.

Valves are also subject to repair, since their condition at the time of repair, as a rule, is not entirely satisfactory. During an engine overhaul, components such as the starter, generator and ignition distributor are also repaired. As a result, the repaired engine must have the qualities of a new unit and withstand significant mileage without failures.

During a major overhaul, important parts of the cooling system such as hoses, drive belts, thermostat and coolant pump should be replaced. The radiator must be examined for tightness and cleanliness of the internal channels. If you bought a repair engine or an incomplete cylinder block, then some suppliers do not provide a guarantee for the operation of these units without proper radiator flushing. When overhauling the engine, it is also recommended to replace the oil pump.

Before starting an engine overhaul, read the description of the relevant procedures to get an impression of the upcoming scope of work and the requirements for them. If you follow all the rules and regulations, and if you have all the necessary tools and equipment, major repairs are not difficult to carry out, but they will require a significant investment of time.

Approximately, it will take at least two weeks, especially if you have to contact a specialized workshop to repair and restore parts. Check the availability of spare parts and make sure to purchase the necessary special tools and equipment in advance. Almost all work can be done using a standard set of tools, although precise measuring instruments will be needed to check and determine the suitability of certain parts. Often, the condition of parts is checked in specialized workshops, which also receive recommendations for replacing or restoring certain parts.

You should contact a car service workshop only after completely disassembling the engine and checking the condition of all parts, especially the cylinder block, in order to decide which maintenance and repair operations will be performed in the workshop.

Since the condition of the cylinder block is a determining factor in deciding whether to further repair it or to purchase a new (or repair) cylinder block, you should buy spare parts or perform machining operations on related parts only after a thorough check of its technical condition. Accept that the true cost of repair is time - then you won't have to pay to install worn or rebuilt parts.

In conclusion, we note that the assembly of any units should be carried out with the utmost care in a clean room in order to avoid further failures of the repaired engine and ensure its reliable operation.

When performing major repairs yourself, various options are possible. The decision to replace the cylinder block, connecting rod-piston group and crankshaft depends on a number of factors, the most important of which is the condition of the cylinder block. Other considerations include the cost of repairs, access to auto repair shop equipment, availability of spare parts, time planned for the work, and personal experience.

Malfunctions

| FAULTS | CAUSES AND REPAIRS |

| The appearance of a characteristic knock at the bottom of the engine. | This indicates problems with the main bearings. The car must be towed by a tow truck to a service center and the appropriate repairs must be carried out. |

| The appearance of a pronounced knocking sound with a metallic sound. | The reason for this is problems with the bearing rods and piston pins. It should be said that operating a car with such problems may subsequently lead to the need for expensive major repairs. |

| Engine troubles at low speeds. | There may be several reasons for engine tripping: first of all, it is the use of low-quality gasoline. It is also possible that carbon deposits may appear in the combustion chamber. In rare cases, problems are observed in the operation of the injection system. Repair in this case is carried out only after a comprehensive diagnosis. |

| Loud knocking sound when the engine is not warmed up. | This may indicate the beginning of camshaft wear. This problem is typical for power units whose mileage exceeds 100,000 kilometers. It is necessary to carry out appropriate diagnostics and then replace the camshaft. |

Also interesting: Chevrolet Niva error codes with decoding

( 2 ratings, average 4.5 out of 5 )

Source

Causes of oil waste

Well, in general, this is the second question. First you need to find out where the oil goes from the engine if the leak is not visible from the outside? The debate about the natural waste of oil has been going on for many years. There is only one conclusion - if you don’t want the engine to “eat up” the oil, don’t fill it at all! The point is this. The service life of the engine is ensured by good lubrication, and even more so by the lubrication of the piston rings and, as a consequence, the surface of the cylinders in the form of an oil film. So much for natural insanity.

When designing a modern engine, oil loss due to waste is initially 0.1-0.3% of the volume of fuel used . In addition, with different types of operation (river transport, cars, generators), oil burn readings vary significantly! Well, since the engine of the VAZ 21213 is frankly “weak” and, due to the specifics of the vehicle’s operation, operates under increased loads, the passport parameter for oil waste does not last long, after which oil consumption begins to increase significantly. Why? In addition to the mentioned natural burnout, there are several other reasons:

Attention: In general, if you see all of the above defects in your car. If you are convinced that the CPG is worn out (by measuring the compression - at least 8 kgf), then replacing the piston rings of the VAZ 21213 is the most economical option for you. In case of such wear of the internal combustion engine, a good owner will, among other things, check the wear of the cylinders, connecting rod liners and, if necessary, replace not only them, but also the entire piston group with valve stem seals. Everything here is limited only by the price of the repair issue.

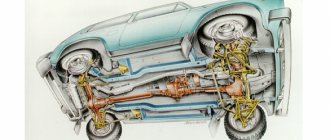

Transmission

The transmission is borrowed from the VAZ 2106. It is a four-speed manual transmission. The gearbox on the new modifications has been modified and received a fifth gear.

A common transmission malfunction is rapid wear of parts and subsequent failure of the unit. Transmission components make a lot of noise.

Every 10,000 km the crosspieces need to be lubricated. Cars from 2005–2009 have a defect in the cardan shafts—they vibrate while driving. You can’t do without a service station in this matter.

VAZ 2121 engine: characteristics, overhaul

Niva 2121 is a popular Soviet SUV produced by AvtoVAZ. The VAZ 2121 engine has undergone many modifications and changes since its first release. So, several modified versions of the power unit were released. The main competitor in the domestic market was the no less legendary UAZ 469 “Bobik”.

Specifications

The Niva engine has high technical characteristics, and the car itself has increased cross-country ability, since there is a 4x4 option. Over the history of production, the VAZ 2121 has had different engine versions installed, from a carburetor version to an injector and even a diesel version.

So, let's look at the main characteristics of modifications to the Niva power unit:

VAZ 2121

| Name | Index |

| Engine capacity | 1.6 liter (1580 cc) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Carburetor |

| Power | 80 horsepower |

| Fuel consumption | 12.2 l/100 km |

| Cylinder diameter | 79 mm |

| Valve mechanism | SOHC |

VAZ 21213

| Name | Index |

| Engine capacity | 1.7 liter (1690 cc) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Carburetor |

| Power | 82 horsepower |

| Fuel consumption | 11.0 l/100 km |

| Cylinder diameter | 82 mm |

| Valve mechanism | SOHC |

VAZ 21214

| Name | Index |

| Engine capacity | 1.6 liter (1580 cc) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 83 horsepower |

| Fuel consumption | 8.4 l/100 km |

| Cylinder diameter | 82 mm |

| Econorm | EURO-4 |

| Valve mechanism | SOHC |

VAZ 2131

| Name | Index |

| Engine capacity | 1.8 liter (1779 cc) |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 94 horsepower |

| Fuel consumption | 9.2 l/100 km |

| Cylinder diameter | 82 mm |

| Econorm | EURO-4 |

| Valve mechanism | SOHC |

Engine XUD9SD manufactured by Peugeot

| Name | Index |

| Motor type | Diesel |

| Engine capacity | 1.9 liter (1905 cc) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Diesel fuel |

| Power | 75 horsepower |

| Fuel consumption | 7.1 l/100 km |

The power units of the VAZ 2121 were equipped with 4-speed manual and 5-speed manual transmissions.

Basics of overhaul

Engine overhauls, except for diesel engines, are carried out typically for all models of Lada power units. So, if you do not take into account the 2131 model with a 16-valve engine, then all versions have a timing chain instead of a belt.

Taking into account the design and manufacturer's manuals, the Niva has a low engine life compared to passenger versions of VAZ cars. So, on average, the mileage before major repairs will be 100-120 thousand km.

Therefore, in order not to spend extra money, many vehicle owners try to repair the engine on their own. Considering the weight of the engine, you will naturally need helpers, at least to remove the engine from the car.

So, what manipulations need to be performed to carry out a major overhaul of the power unit.

The size of the piston group for VAZ 2121 engines with a standard piston size of 82 mm:

The selection of spare parts is carried out according to the Niva car engine repair catalog with the appropriate markings.

Engine tuning

Tuning a VAZ 2121 engine is an art. Since the car has the characteristics of an SUV, the engine is tuned accordingly. The air filter duct is installed as high as possible, and the motor from below is protected by a special tray, the purpose of which is not to allow water to pass through.

So, the modification of the Niva’s power unit is designed to increase cross-country ability and traction capabilities, since the vehicle is mainly designed for operation on rough terrain. So, many car enthusiasts bore the power unit in such a way as to add not only horsepower, but also traction.

As practice shows, tuning of VAZ 2121 engines and its modifications is carried out by tuning studios that are well versed in which unit needs to be modified.

Also, in the process of refinement, the ignition system and fuel injection are being modernized. For carburetor engines, an additional carburetor can be installed to increase the amount of fuel entering the combustion chamber.

For injection versions of engines, chip tuning is carried out, which can be aimed at increasing power or the balance between consumption and traction capabilities. Many car enthusiasts install additional sensors that help control the operation of the power unit.

Conclusion

VAZ 2121 engines are reliable, but have a short mileage before major repairs. Although, on the other hand, it is quite simple and quick to overhaul Niva power units, they are not picky about spare parts, and their cost is quite low.

Peculiarities

The VAZ 21213 four-cylinder eight-valve petrol engine has a displacement of 1.7 liters. The power of the power unit is 81 horsepower with a torque of 125 Nm.

Engines 21213 in their latest generation were equipped with an injector and ran on high-octane 93 gasoline. The cast iron cylinder block ensured maximum strength for this power unit.

The use of numerous automatic engine control systems made it possible not only to change the traction performance of this engine, but also significantly improved fuel efficiency. Niva in suburban mode consumes 8.3 liters of gasoline per 100 kilometers when driving at cruising speed.

Starting from 2014, Niva cars with a diesel engine are also offered to customers.

The Niva engine with an overhead camshaft is equipped with a chain drive, which significantly simplifies the service of this power unit. The chain drive does not require replacement of the tensioner or any adjustment during operation of the motor. We also note the presence of hydraulic compensators, which relieves the car owner of the need to carry out the procedure for adjusting the valve clearance. All maintenance work on this engine can be performed by the car owner himself, without contacting branded service stations.

Also interesting: Niva VAZ 21213 engine: characteristics, malfunctions and tuning

Tools and preparatory work

To adjust the valves, the Niva must be placed on a level surface. Work can be carried out both in the garage and outdoors; you can drive onto an overpass, but this is not necessary.

Tools and materials

From a special tool, which perhaps not every motorist has, you will need a probe 0.15 mm thick. Its width must be sufficient to be used for adjusting the intake valves. A feeler gauge with a thickness of 0.2 mm is also required. It is used to adjust the exhaust valve.

To work you need to have the following tools and materials:

A magnet on a telescopic holder is also useful for detecting and removing fallen fasteners. Almost all the tools - except for keys 13 and 17, as well as probes - are needed for disassembly in order to gain access to adjustable parts.

Preliminary preparation

First of all, you need to disconnect the battery. Next you will need to disconnect the air filter. To do this, you need to disconnect the crankcase gas hose from it. Then they begin to dismantle the filter housing cover by unfastening the four latches.

Now, to remove the cover, all that remains is to unscrew the 10-point nut, which is installed on the stud in the middle of the assembly. The filter housing is held in place with four 8mm nuts; they are easiest to remove with a spanner. Finally, you need to cover the carburetor with a technological cover (you can make it yourself from cardboard or plywood) to prevent dirt from getting inside it.

Next you should disconnect from the carburetor:

Continuing disassembly should begin by detaching the brake hose from the vacuum booster. Then the high-voltage wires are disconnected from the spark plugs and ignition coil. Remove the distributor sensor cover together with all wires. The spark plugs are unscrewed. Pull out the oil dipstick.

Gaining access to valves

To begin adjusting the clearances, you need to remove the valve cover. It is held in place by eight 10mm nuts. After tightening them, you need to remove all the brackets and pressure washers.

After this it will be possible to lift the valve cover. It is carefully removed from the pins - first its back, then its front.

In addition, you should check the tightness of the nuts that secure the bearing housing. If necessary, you need to tighten them. Secure bearing installation is important for proper camshaft operation. Therefore, the procedure will not be superfluous even if the main task is to adjust the valves.

How to choose a part: average prices

When choosing spare parts for Niva, look at the article number. The part must fit exactly your car model. Don't take the bottom from a Chevrolet Niva. It has different dimensions, which means the part will have to be trimmed.

When buying a new spare part, remember that the factory bottom does not have a number of elements:

They will have to be moved from the old flooring. If you are not sure of their safety, it is better to immediately order all the related parts. The average price of the bottom in the capital is 5,000 rubles. If you want to buy a spare part cheaper, contact a VAZ car dismantling center.

Repairing the bottom yourself requires patience and time. Spare no effort in processing the metal and cleaning it from rust. Poor preparation and careless attitude towards post-repair work will negatively affect the service life of the new body element.

How to assemble VAZ-21213, VAZ-21214 engines

We discussed engine disassembly in the article “Engine Disassembly”.

After disassembly, thoroughly wash the parts with kerosene, blow and dry them with compressed air (especially the oil channels of the parts).

Inspect the block, especially carefully the crankshaft supports.

Cracks in any place in the block are not allowed.

If there is a suspicion of cracks in the block (coolant has entered the crankcase or oil has entered the coolant), check the tightness of the block on a special stand.

Carry out the check in repair shops that have the appropriate equipment.

Inspect the cylinders on both sides.

Scratches, nicks and cracks are not allowed.

When inspecting cylinders, we recommend illuminating the cylinder mirrors with a portable lamp - in this case, defects are visible much better.

1. To determine the wear of the cylinders with a bore gauge, we measure the diameter of the cylinder in four zones and two planes (parallel and perpendicular to the axis of the crankshaft).

2. To determine the wear of the piston skirt, use a micrometer to measure the diameter in a plane perpendicular to the piston pin axis, at a distance of 55 mm from the piston bottom.

3. Using a micrometer, measure the diameters of the connecting rod journals

4. Using a micrometer, measure the diameters of the crankshaft journals.

We grind the crankshaft journals to the nearest repair size if their wear or out-of-roundness is more than 0.03 mm, and also if there are burrs and marks on the journals.

5. After grinding the crankshaft journals, it is necessary to remove the oil channel plugs, thoroughly rinse the channels to remove abrasive residues and blow them with compressed air.

We assemble the engine in reverse order.

We install new crankshaft bearing shells of nominal or repair size (after grinding the journals).

6. In the first, second, fourth and fifth supports of the cylinder block we install the upper main bearing shells with grooves, and in the third support - a liner without a groove on the inner surface (the same as in the main bearing caps).

7. Lubricate the main bearing shells with engine oil and place the crankshaft in the supports.

We insert thrust half-rings lubricated with engine oil into the grooves of the fifth support.

8. We install a steel-aluminum half-ring on the front side of the fifth support, and a metal-ceramic half-ring (yellow) on the back side.

The surfaces of the half rings with antifriction coating (they have grooves) must face the thrust surfaces of the crankshaft.

9. Install the main bearing caps in accordance with the marks marked on their outer surface (counting is done from the camshaft drive side).

In this case, the locks of the upper and lower shells of each main bearing must be located on the same side.

10. Tighten the bolts securing the main bearing caps to a torque of 68.31-84.38 Nm (6.97-8.61 kgf m).

11. Pistons for cylinders are selected according to classes.

The cylinder diameter class, indicated by letters, is stamped on the bottom plane of the cylinder block (the plane of the oil pan mounting).

12. Classes of piston skirt diameters and holes for the piston pin are marked on its bottom

Replacement of body parts

Over time, body parts of the VAZ 2121 need not only repair, but also replacement. As mentioned above, the car body is a complex structure, and its repair is not simple. Essentially, body repair is divided into two parts: first, the geometry is restored, then the body is painted.

It is extremely difficult to completely restore parts at home. You need to have special equipment, know the specifics of the operation and have experience in such work. For this reason, some body parts are easier to replace with new ones than to repair.

Theory - VAZ engine repair. |

Theory of internal combustion engines. Evgeniy Travnikov Due to the fact that there are Niva-Niva-Niva around me, mostly 2121 and 21213, but there are also 21214 and 2131, then willy-nilly you begin to get imbued with the theory of the classic VAZ engine. The analysis of Kostya block 213, the practical questions that arose definitely led to the channel to Evgeniy Travnikov. The main link to the playlist on the classic engine, and everything connected with it, well, I divided Evgeniy’s video into “Nivovskie”, VAZ engine repair, and the rest.

Here about repairing the VAZ 21213 “Taiga” engine

Motor 21213, assembly (refilled version) Motor 21213 with elbow 2130 Motor VAZ-21213 (Disassembly, design review) Engine 21213 1.9 l for Niva Difference between heads 21011 and 21213

Niva with 1.8 engine

Niva-21213 with engine 1800 (assembly, fuel consumption) Engine for Niva 1.8, which we assembled Niva 1800, dynamic tests

Car services in St. Petersburg

STO NIVA 4x4 North st. Laboratory, 14A

Our first service, located in the north of St. Petersburg near Kalinin Square. The service provides a full range of car repair services from tire fitting to complex body repairs. Electrician's station, painting booth, 16 lifts and qualified personnel. Despite the name indicating that they belong to the repair of one brand, our specialists have the knowledge and skills to repair most cars on our market. For owners of Niva and Chevrolet Niva - a warehouse of all necessary spare parts.