The 21128 engine is not included in the AvtoVAZ line, since tuning was carried out by its subsidiary Super-Auto. The studio specializes in small volumes of passenger cars with modernized engines. The design 21124 was taken as a basis, the cylinders were bored out by 0.5 mm to a size of 82.5 mm, the piston stroke was increased to 84 mm. Which made it possible to obtain from 1.8 liters of volume, 162 N*m of torque at 3500 rpm and 95 - 105 hp. With. (according to various sources).

ICE 21128

Since 2014, the Super-Auto studio has revised the design, the base being version 21126. The manufacturer returned to the standard cylinder size of 82 mm, the piston stroke remained 84 mm. With the same engine volume of 1.8 liters, the characteristics have changed - torque 165 Nm, but already at 4000 rpm, 123 hp. With. power.

Characteristics of engine 21128

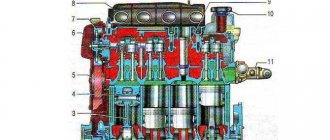

The priority task of the Super-Auto manufacturer was to increase the power of the 21124 internal combustion engine, which does not bend valves, which was taken as a basis, so changes took place in the engine:

- the engine diagram remains the same - DONS timing diagram with 2 overhead camshafts;

- a volume of up to 1.8 liters was added - the combustion chambers were enlarged, the cylinders had a size of 82.5 mm, the piston stroke was added to 84 mm;

- the safety of the valves is ensured - deep holes protect them from bending when they meet the pistons at the moment the timing belt drive breaks;

- compression ratio 10.5 units;

- Controller firmware January 5.1, throttle pipe cross-section 51 mm.

Forced motor 21128

As a result, the manual contained a description of the engine parameters - power in the region of 95 - 105 hp. With. and torque at 3200 rpm is about 160 - 162 Nm. The pistons were designed jointly by engineers from AVITI and Super-Auto, since a similar size did not exist in the AvtoVAZ line in principle. The connecting rods are also created for this internal combustion engine, length 129 mm, fastening with a 19 mm pin, fit on a non-standard crankpin 41.5 mm.

Accordingly, there was no crankshaft with connecting rod journals of this size and a crank radius for an increased piston stroke. It was developed separately, which influenced the increase in the cost of the power drive.

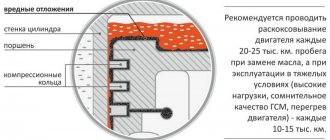

With a declared service life of 150,000 km, the manufacturer’s engine could not withstand 100,000 km and consumed a lot of oil - up to 1 liter per 1000 km. The environmental standard has dropped to Euro 2. A “long” piston stroke leads to increased loads on the side surfaces of the cylinders and intense wear of the rings/pistons. This results in high engine oil consumption and the system overheats.

A year later, Super-Auto management removed the ICE marking 21128-26 from production, replacing it with the following version designated 21128-27:

- the engine does not bend the valve, so a conventional timing belt with a service life of 50 - 90 thousand km is installed;

- cylinders returned to 82 mm size, lightweight pistons from Federal Mogul;

- Mecaprom connecting rods were used;

- a new version of controller firmware has been created;

- valve lift increased to 8.3 mm (0.7 mm more than the original);

- The eco standard has increased to Euro-4.

Modified version of the motor

As a result, the manufacturer provided a power of 123 hp. s and torque of 165 Nm at 4000 rpm.

Since two versions of the 21128 motor were developed, the technical characteristics have changed over time:

| Manufacturer | JSC Super-Auto |

| Engine brand | 21128 |

| Years of production | 2013 (2014) – … |

| Volume | 1597 cm3 (1.6 l) |

| Power | 78 kW (106 hp)/90.5 kW (123 hp) |

| Torque | 148 Nm (at 5800 rpm)/165 Nm (at 4000 rpm) |

| Weight | 116 kg |

| Compression ratio | 10,5 |

| Nutrition | injector |

| Motor type | in-line |

| Injection | distributed electronically controlled |

| Ignition | coil for each spark plug |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | combined with receiver, polymer |

| An exhaust manifold | catalyst |

| Camshaft | 2 pcs., DONS circuit |

| Cylinder block material | cast iron |

| Cylinder diameter | 82.5 mm, then 82 mm |

| Pistons | lightweight, manufacturer Federal Mogul |

| Crankshaft | original |

| Piston stroke | 84 mm |

| Fuel | AI-95 |

| Environmental standards | Euro-2/4 |

| Fuel consumption | highway – 5.9 l/100 km combined cycle 7.5 l/100 km city – 9.8 l/100 km |

| Oil consumption | 0.7 – 1 l/1000 km, then 0.3 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W-30 and 10W-40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Mannol, Mobil |

| Oil for 21128 according to composition | synthetics, semi-synthetics |

| Engine oil volume | 3.5 l |

| Operating temperature | 95° |

| Motor life | declared 150,000 km actual 100,000 km |

| Adjustment of valves | hydraulic compensators |

| Cooling system | forced, antifreeze |

| Coolant quantity | 7.8 l |

| water pump | with metal impeller |

| Candles for 21128 | BCPR6ES from NGK or domestic AU17DVRM |

| Gap between spark plug electrodes | 1.1 mm |

| Timing belt | Gates, width 22 mm, service life 200,000 km |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | catalog number 90915-10001 replacement 90915-10003, with check valve |

| Flywheel | increased damper size |

| Flywheel mounting bolts | M10x1.25 mm, length 26 mm, groove 11 mm |

| Valve stem seals | code 90913-02090 inlet light code 90913-02088 exhaust dark |

| Compression | from 14 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 800 – 850 min-1 |

| Tightening force of threaded connections | spark plug – 31 – 39 Nm flywheel – 62 – 87 Nm clutch bolt – 19 – 30 Nm bearing cap – 68 – 84 Nm (main) and 43 – 53 (rod) cylinder head – three stages 20 Nm, 69 – 85 Nm + 90° + 90° |

Even after modification of the power drive, major repairs are possible after 150,000 km. This is due to the remaining “long” piston stroke, increased loads on the cylinder walls, and intensive production of ShPG parts.

Engine VAZ 21128

The VAZ 21128 engine is designed for installation in Priora class cars. It has increased technical characteristics and an engine capacity of 1.8 liters. The production of this power unit is carried out by.

Specifications

The VAZ 21128 engine began to be produced and installed on AvtoVAZ cars in 2003, and production continues to this day. The new engine has an improved design and increased power. Let's look at the main technical characteristics of the 21128 engine:

| Name | Characteristic |

| Brand | 21128 |

| Marking | 1.8 16V |

| Power | 98 horsepower |

| Type | Injection |

| Fuel | Petrol |

| Valve mechanism | 16 valve |

| Number of cylinders | 4 |

| Fuel consumption | 7.5 liters |

| Piston diameter | 82.5 mm |

| Resource | 200 - 250 thousand km |

All engines are equipped with a 5-speed gearbox. The cooling system is liquid type with forced circulation. Engine power can be increased to 123 hp without loss of service life. In case of complete modification, the engine may gain 400 hp, but the service life will be reduced by 2-2.5 times.

Service

Maintenance typical for cars produced by AvtoVAZ. The main maintenance operations are changing the oil and oil filter. To change the lubricant, 3.2 liters of engine oil is required. In turn, 3.5 liters of lubricant fits into the engine.

It is recommended to fill in semi-synthetic motor oils marked 5W-30, 5W-40, 10W-40, 15W40.

The maintenance map looks like this:

TO-1: Oil change, oil filter replacement. Carry out after the first 1000-1500 km. This stage is also called the break-in stage, since the engine elements are grinding in.

TO-2: The second maintenance is carried out after 10,000 km. So, the engine oil and filter are changed again, as well as the air filter element. At this stage, the pressure on the engine is also measured and the valves are adjusted.

TO-3: At this stage, which is performed after 20,000 km, the standard procedure for changing the oil, replacing the fuel filter, as well as diagnosing all engine systems is carried out.

TO-4: The fourth maintenance is perhaps the simplest. After 30,000 km, only the oil and oil filter element are changed.

TO-5: The fifth maintenance is like a second wind for the engine. This time a lot of things are changing. So, let's look at which elements need to be replaced in the fifth maintenance:

- Change of oil.

- Replacing the oil filter.

- Replacing the air filter.

- Replacing the fuel filter element.

- The timing belt and roller are replaced.

- Alternator belt if necessary.

- Water pump.

- Valve cover gasket.

- Other items that need to be replaced.

- Valve adjustment, which adjusts the gas distribution mechanism.

Subsequent maintenance is carried out according to the 2-5 maintenance map for the corresponding mileage.

Engine repair

Motor 21128 is the first belt-driven car in which, when the timing belt breaks, the valve does not bend. Due to the updated design and high piston stroke, problems arose during operation, namely large wear of the cylinder walls and oil wastage. Further actions are not difficult to predict - major repairs.

Moreover, it can be carried out after a short period of time - 100,000 km. Because of this, the motor received quite a lot of negative reviews at the start of sales and operation.

11 years after the start of production, the power unit was modernized in 2014. The designers nevertheless listened to the opinion of motorists and slightly changed the technical parameters.

The pistons and connecting rods have been lightened, the first ones are made by Federal Mogul, the connecting rods are made by Mecaprom. The camshafts are the same as on the 1.6 liter engine, but the lift of the intake and exhaust valves has been increased from 7.6 mm to 8.3 mm.

A different program was written for the new hardware, and the engine began to comply with the Euro-4 environmental standard.

Conclusion

The new engine 21128 for the Lada Priora showed itself to be an unfinished, but powerful and simple power unit. High technical characteristics and simplicity of design make it easy to repair and tune the engine. 2 years later, after modernization, it was decided to make a new engine with the marking - 21179, which was presented in 2021.

avtodvigateli.com

Design Features

Since the 21128 engine was produced in two versions, both designs should be considered. The version with bored cylinders based on 21124 had the following features:

- the boost was extremely unsuccessful, since it only allowed it to withstand the Euro-2 standard;

- but the safety of the valves when meeting the pistons is ensured (deep holes, as in the original);

- crankshaft and ShPG of original design, which increases the cost of production and overhaul by hand;

- the attachments are well located so that they do not interfere with engine maintenance and replacement of consumables;

- From the factory, the engines are filled with lubricants from Rosneft, the quality of which is insufficient for the normal operation of hydraulic compensators, and when using high-quality oil, the operating budget increases sharply due to high consumption.

Engine boost 21128

The second upgrade based on version 21126 is more successful:

- The volumes of the combustion chambers are preserved, not only due to the hardware, but also the software part of the ECU;

- pistons are of standard diameter, but the ShPG is foreign-made, the crankshaft is of a special design, repairs are expensive;

- the attachments are more reliable; the original intake air tract receiver is used.

Characteristics of two versions of motors 21128

The manufacturer also recommends using high-quality lubricant, but the consumption in this version of the internal combustion engine is slightly lower.

Operating principle of the K4M engine phase regulator

To improve the filling of the cylinders with the fuel mixture in all modes, 1.6 liter engines are equipped with a phase regulator of the intake camshaft.

Shifting the closing timing of the intake valves optimizes the filling of the cylinders with the fuel mixture depending on the crankshaft speed.

The result is increased torque at medium loads and increased power at high engine speeds.

At high crankshaft speeds, later closing of the intake valves ensures the supply of an additional portion of the fuel mixture due to the high speed of the mixture.

On the contrary, at low rotation speeds the inertia of the mixture is small.

Therefore, it is desirable to close the exhaust valves earlier to avoid insufficient filling of the cylinders and loss of torque due to the displacement of part of the fresh mixture.

The higher the crankshaft speed, the later the intake valves should close.

The amount of oil supplied to the phase regulator is determined by an electromagnetic valve installed on the cylinder head (see Fig. 2).

The valve is supplied with power in the form of an alternating signal of the degree of cyclic opening (amplitude 12 V and frequency 250 Hz).

This allows oil to be supplied to the phase regulator mechanism and thus change the phase angle.

The camshaft phase adjuster constantly changes the valve timing.

The ECU sends a variable signal to the solenoid valve, the degree of cyclic opening, the value of which is proportional to the required phase shift.

The phases constantly change from 0˚ to 43˚ according to the angle of rotation of the crankshaft.

When the crankshaft speed is in the range of 1500–4300 rpm, the ECU supplies voltage to the solenoid valve.

If 4300 rpm is exceeded, the power to the solenoid valve is cut off. In this case, the position of the phase regulator mechanism promotes filling of the cylinders at high crankshaft speeds. In this position, the locking plunger locks the mechanism.

At speeds up to 1500 rpm, no supply voltage is supplied to the solenoid valve.

Advantages and disadvantages

An important feature of the first version of the motor was the safety of the valves. In the second option this is not the case; the pistons bend the valves when they meet.

In modification 26, the cylinder head has bored combustion chambers, and the block itself has an increased cylinder size. After modification, motor 27 became safer for the environment.

Pistons 21128

Due to the increased power, it is recommended to operate internal combustion engines only with manual transmissions.

Price of a new and contract engine

Although the motor modification 21128 has many negative reviews, it will be difficult to buy it on the secondary market at a cheap price. The cost of engine 21128 on the market starts from 30 thousand rubles. For fifty thousand you can buy an average quality engine with low mileage.

Typically, all engines are tested at the manufacturer, and then checked by experienced mechanics. Only after double checking are they delivered to the customer. Plus there is a warranty on the motor.

What cars was it used in?

Due to the specifics of the Super-Auto tuning studio, engine 21128 was mounted on a limited number of passenger cars manufactured by AvtoVAZ:

- Lada 112 “twelfth” - Luxury version from Super-Auto;

- Lada Priora is a modernization from the same manufacturer.

Priora Super Auto

In principle, the characteristics of the engine allow it to outperform most foreign cars of the same class on the highway. However, during long-term operation, the motor definitely loses to them, since it has a low resource, even after modification.

What cars were the 21128 engine installed on?

The engine of the VAZ 21128 model can be seen on the following vehicles:

Similar article Technical characteristics of the OM 904 Mercedes Benz engine

- Lada Priora 1.8;

- Lada 112 Coupe;

- VAZ 21104-28;

- Priora Sedan 2170;

- Priora Hatchback 2172.

Basically, the first modifications of the 21128 engine were installed on the tenth car models, and the second modification was installed on the Priora.

Maintenance

After modification, engine 21128 version 27, produced after 2014, must undergo maintenance in the following mode:

- 10,000 km – filter and engine oil;

- 20,000 km – battery, spark plugs, attachment belt and crankcase purging;

- 40,000 km – remaining filters, coolant and hoses of this system;

- 100,000 km – timing drive and oxygen sensor.

Despite the factory tuning, the internal combustion engine device provides the possibility of additional modernization on its own.

Malfunctions, their causes and elimination

Since the first modification has been discontinued, only motor 21128, produced after 2014, is considered. The main “diseases” of the power drive are:

| Shaft does not rotate when starting | 1) damage to the flywheel ring 2) starter is faulty 3) failure of the ignition switch 4) starter relay failure | 1) repair or replacement of a part 2) replacement/repair 3) installation of a new lock 4)relay replacement |

| Problems starting the engine | 1) cold 2) warmed up | 1) repair of the control system, checking the tightness of the injectors, coolant temperature sensor, power system 2) replacing the air filter cartridge, tightening the battery terminals, repairing the power system |

| Noises in the starter | 1) loose fastening 2) worn out flywheel teeth | 1) tightening fasteners 2) replacing the crown |

| Engine overheating | 1)fan failure 2) thermostat failure 3) radiator clogged 4) low coolant level | 1) unit repair 2) replacement part 3)flushing channels 4) adding antifreeze to the level |

After modification, the 21128 engine consumes less oil, but its level should be constantly monitored.

Overhaul of the block

Disadvantages and reviews of ICE 21128

Experienced mechanics recommend changing the oil more often with this engine than with others. For example, every 5 thousand kilometers there must be a mandatory procedure for changing the lubricant. Otherwise, scuffs will form on the valves and cylinder walls from low-quality and used oil with various impurities.

It is recommended to buy oil only in specialized stores and from well-known companies. The parameters of the lubricant should not deviate from 5W30, 5W40. To change the fluid you will need 3.5 liters of lubricant.

The car owner of engine 21128 will be plagued by frequent malfunctions of the oil pump, timing belt, thermostat and other minor problems. This cannot be avoided, since the engine is still not fully developed.

Coolant leakage is a frequent guest of this engine 21128. Therefore, it is necessary to measure the antifreeze level after 30 thousand kilometers and carefully monitor overheating. Motor 21128 does not like high temperatures. If other power units can withstand a temperature rise of up to 110 degrees Celsius, then 21128 will quickly fail at a constant elevated temperature.

The first thing that occurs is that oil seals and other rubber parts crack and dry out. Then cracks form on the cylinder head and the cylinders themselves.

Similar article 126 VAZ engine bends the valve or not

Troubleshooting is another drawback of the 21128 engine. It occurs due to the filling of low-quality fuel. Bad fuel contaminates the spark plugs and ignition coils. They fail faster. Fuel injectors also become clogged with dirt. As a result, engine 21128 begins to operate unstably.

If the sensors on the 21128 engine break, then the engine speed fluctuates. The most problems are with the following sensors:

- DMRV;

- RXX;

- DPKV.

The throttle sensor often suffers.

The rapid demise of hydraulic compensators occurs due to low-quality oil, which is poured from the manufacturer. And when changing the lubricant, the lifespan of the hydraulic compensators increases, but the cost of refilling with oil increases proportionally. Because good lubrication requires money, and the 21128 engine has a very strong burn. Especially if the engine has worked more than 250,000 kilometers.

Another malfunction that plagues car owners of cars with engine 21128 is the rotation shaft stopping during startup. This happens due to a broken flywheel ring or a faulty starter. There are other reasons - the starter relay breaks, or the ignition switch becomes unusable.

It is treated by replacing the listed parts or repairing them.

The engine starter may make noise when operating. This means that its fastening has become weak or the flywheel teeth have worn out. In this case, only replacing the flywheel or tightening the fastening will help. These works are performed by experienced mechanics in the service center. Although, if the car owner has experience working with the 21128 engine or has ever repaired similar ones, then he can carry out repairs in a garage.

Engine tuning

Since the 21128 engine is already a boosted version of the 21126, the possibilities for increasing power are limited:

- The piston stroke is already “long”, if you additionally bore the cylinders, it will take a long time to select a suitable ShPG and crankshaft;

- a new design receiver is already installed on the intake tract, but it is possible to install a “zero” air filter and a damper with a cross-section of 54 mm, a “spider” on the exhaust manifold instead of the standard one, this will bring the power closer to 130 hp. With.;

- tuning is possible by turbocharging the internal combustion engine - PK-23-1, cylinder head gasket from the 2112 engine, Nuzhdin 8.8 camshafts, channel cutting, Bosch 107 injectors and 51 mm exhaust pipe.

The main problem remains the long-stroke crankshaft, so upgrading this engine either does not bring a noticeable effect or turns out to be very expensive. We have to change the design laid down by the manufacturer, which is initially too aggressive.

Thus, before buying a car from Super-Auto with a 21128 engine, you should seriously think about whether it is worth choosing such power, overpaying for road tax and insurance, being content with a resource of just over 100,000 km. In addition, the pistons are not protected from “meeting” the valves, despite the Gates belt with a service life of 200,000 km.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them