Tools and consumables

For work we will need:

- an electric drill and a set of grinding attachments installed in it;

- aerosol can or paint;

- in the latter case, you will also have to acquire a spray gun, as well as a compressor unit;

To paint wheels with paint you need a spray gun and a compressor unit

- primer and solvent;

- protective clothing and respirator;

- construction hair dryer;

- sandpaper;

- rags.

Types of car paints for wheels

Large car paint manufacturers usually produce a full range of paints and varnishes - rubber, acrylic, powder. Kudo remains the most popular brand; its products are distinguished by high quality and durability. Paints eliminate minor scratches, chips on wheels and other car parts, as they contain chemicals that increase wear resistance.

Another well-known brand is Motip; it has long been recognized as the best by automotive repair and tuning professionals. A number of paints are used for wheels and the body, others are intended only for rims. Most of the paints of this brand are sold in spray cans and are characterized by low consumption.

Rubber paints

Liquid rubber, or rubber paint, has become popular due to its versatility. It is well suited for all types of discs - cast, stamped steel, forged, titanium, and plastic elements. Even wheel caps are covered with liquid rubber to give them a more beautiful appearance. This type of paint comes in glossy and matte finishes.

The advantage of rubber coatings is its ability to harden quickly, forming a durable layer like rubber. A unique property is the ability to remove this layer at any time without damaging the surface or using special tools. The disadvantages are the high cost of paint due to high consumption, as well as greater susceptibility to scratches compared to acrylic enamel.

Powder paints

Powder paint has the highest protective properties. This paintwork material copes well with corrosion, the action of salts, alkalis, acids, and reagents. The paint is not afraid of water, resistant to mechanical damage, does not fade, and is heat-resistant. It can be applied to titanium, steel, various alloys, except aluminum (they can be deformed).

The disadvantages of powdered formulations include the complexity of the application technology - they cannot be used at home. The method involves melting the product in a special chamber at a temperature of +200 degrees and then applying it to a sheet or disk or other product. Otherwise, the powder will not stick to the metal, and the necessary equipment is quite expensive. Often this type of coating is used by the disc manufacturers themselves.

Acrylic paints

Acrylic-based products are suitable for all types of rims, there are no exceptions. Even on aluminum, a durable and high-quality result is obtained in a short time, and the color palette is the richest. Acrylic paints are sold in cylinders, cans, and other containers, but the most convenient method of application is aerosol spraying.

How can you paint car stampings?

Almost no one remembers the times when the need to paint stamped wheels was an almost insurmountable problem. Today, in addition to traditional ones, there are a variety of options for painting wheels. You can do this using:

- Powder paints. They allow you to create a reliable paint coating. The paint must be applied at a temperature not lower than 200°C. And for this you must use a special thermal chamber.

- Liquid rubber. The demand for liquid rubber is constantly growing. Essentially, it is a mastic containing rubber, to which a certain dye has been added. The convenience of this option is that the liquid rubber can be removed at any time.

- Acrylic enamel. This option is the simplest, since the paint is in spray cans. It is with their help that stamped discs are most often painted. Due to the fact that the paint is applied in several layers to the prepared surface, the coating can retain its appearance for two or even three years.

- Alkyd-melamine paints. The advantage of this option is the availability of a large assortment of colors. The paint is applied using a spray gun in several layers. The layers dry out very quickly. Distinctive features of the surface painted by this method are a high level of resistance to atmospheric agents and excellent light fastness.

Article on the topic: Flocking the car interior - a luxurious interior with your own hands!

There are a variety of materials and tools for painting stamped wheels.

How to paint wheels in two colors?

Repainting any wheels allows you to slightly update the appearance of the car.

It will become more visible in traffic. But this is not the only reason why they resort to this procedure. Damaged or corroded wheels are also painted for practical purposes to remove dents and scratches and stop the spread of rust. Some car owners prefer their own individual style. Painting the wheels in two colors is just what they might like. Moreover, to carry it out, it is not at all necessary to contact a service station that specializes in painting work. Everything can be done with your own hands with the proper approach.

Preparatory stage

Some craftsmen claim that painting wheels can be done without removing the wheels from the car. However, you should not be led by laziness - after all, only after completely disassembling the wheel can you carry out an inspection and identify possible damage. And complete protection against corrosion is possible only in this case.

Don’t forget that up to 70% of the quality of the final result depends on how well the preparatory work was done. It is for this reason that the preparatory stage must be treated very responsibly.

Beginning of work

Preparation for painting in two colors is an important step before painting. The entire result of future work depends on this, so it must be approached with due attention.

First, remove the rims from the car (if they are installed on it) and remove the rubber from them (preferably but not necessarily). If the disc has been painted before, then use a special remover for old paint.

Next, we sand the disc with a grinding machine, where possible, and where not possible, by hand. Sandpaper of grit P300 to P600 is used. The discs must be washed from time to time in order to remove dirt, paint residues, and rust from them. Before priming, they are washed again and then degreased (a solvent can be used).

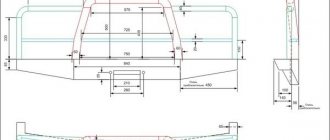

Preparing stamped discs for DIY painting

After removing the tire from it, the disk must be thoroughly washed. Regular detergents can be used for this purpose. If there are places with complex contamination, then chemicals are used to clean them. Next you need to take the following steps:

- Carry out a thorough inspection for damage. If deep cracks are detected, they are processed using a file. Detected dents are straightened.

- If, as a result of the inspection, pockets of corrosion were found, they should be eliminated. For this purpose, grinding or chemical treatment can be used.

It is advisable to dwell on the last point in more detail. In order for the fight against rust to be successful, it is necessary to prepare the following materials:

- A set of sandpaper from P60 to P120. The number of sandpaper used depends on the depth of damage to the metal surface.

- A rust converting chemical, plus some solvent.

- A lot of rags.

Processing should begin with grinding work.

For grinding, you can use a drill with a wire brush attachment.

You can sand with sandpaper either by hand or using an attachment for an electric drill. It looks like a metal brush. The goal of this stage is to make the entire surface of the discs absolutely flat.

When and why should you paint alloy wheels?

As it may seem, alloy wheels do not require maintenance. In fact, this is far from the case. First of all, they need to be regularly removed from dirt, washed and cleaned. At the same time, you should not use aggressive chemicals when washing, so as not to damage the protective varnish coating.

Further, in winter, varnish and paint are destroyed from the aggressive effects of salt and reagents. Also, flying stones and mechanical damage create microcracks in the protective coating. Then chips and other defects appear. The salt and chemicals that get there from the roads, already under the paint and varnish coating, actively destroy the paintwork and the disc material itself. As a result, large-scale paint peeling occurs.

To increase the service life of alloy wheels, painting is required at a minimum. This allows the protective coating to be restored. If the disc is severely damaged, a comprehensive restoration is needed, including repair of alloy discs.

Primer

Applying a layer of primer is necessary to ensure that the paint applies evenly and has good adhesion to the surface being painted. If this operation is not carried out, then the painting will not last more than six months. The primer is applied in two or three layers, each of which must dry well.

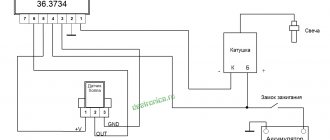

Article on the topic: What does carbon deposits on spark plugs and its color mean?

The surface of the last layer must be processed. For this, fine-grained sandpaper is used. This is necessary to improve the adhesion of the paintwork.

It is not recommended to use brushes to perform this operation - the structure of the structure to be painted is very complex, and therefore it is unlikely to achieve a uniform coating. It is better to do this with a spray gun or an aerosol can. In this case, the distance from the spraying angle to the surface should be from 200 to 250 mm.

Polymerization and coating thickness

Sometimes it is quite difficult to determine the quality of work by appearance, and visible defects will only be noticeable after you have picked up the car.

To more accurately check the uniformity of the coating layer, use a paint tester. It is very simple to work with it: just apply the work surface to the body and you will immediately see how much putty was put in a certain place. Remember that the factory paint surface is 200 microns thick. To this figure add 15% for errors.

Painting stamps

You can start painting only after the primer layer has completely dried. To ensure that the paint applies evenly, it is recommended to heat the surface to be painted with a hair dryer. For best quality, you need to apply several layers of paint, and each of them needs a certain time to dry completely.

Apply paint to the stamped disc

At the final stage, the painted surface is coated with varnish. It should also be applied in several layers - their number should not be less than two. The time required for the varnish to dry completely is usually indicated on its packaging.

The process of applying paint to stamped car wheels: video

Two-color airbrush

Transitions from one color to another may not be sharp, but smooth. They can be done using an airbrush. In this case, color pairs may differ only in tone. For example, red discs are shaded in places by burgundy and maroon spots.

On a note

Using airbrushing techniques, discs can be given a very original look. Smooth color transitions under a thick layer of varnish look especially attractive. By the way, you can add a little sparkle to the varnish, and then the wheels will become glamorous.

One of the most common subjects of wheel airbrushing is flame. By randomly darkening the main scarlet color, you can achieve the effect of burning wheels. True, such wheels will look terracotta when driving.

It is also useful to read: About repairing and painting a car with the so-called transition

Safety precautions during work

- The person doing the painting should not have exposed areas of the body at all stages. This will prevent chemicals from coming into contact with your skin.

- When cleaning the disc with a wire brush installed in a drill, be sure to wear safety glasses.

- At all stages, it is recommended to work in a respirator or any other protective mask. This will prevent mechanical and chemical elements from entering the lungs and nasal mucosa.

Almost anyone can paint stamped wheels with their own hands. And the opportunity to show friends and acquaintances a beautiful car part that you made yourself is a small price to pay for some inconvenience when doing this work.

Share with friends on social networks:

Telegram

Stamping processing process

The stamped disc must be thoroughly washed to remove foreign contaminants and dried. The next step is to clean off the rust and smooth out the welds, if any. To speed up this procedure, you can use an electric drill with special attachments.

Hard-to-reach places can be sanded yourself using sandpaper. Accumulated dust must be washed off periodically to clean untreated areas. In addition, immediately before priming and painting, you must carefully blow out the dust. Otherwise, it will spoil the surface of the stamped disc after painting. If the rust is deeply ingrained, you will have to use a special converter.