The starter is a component that is not very demanding on the availability and quality of lubricant. It does not have rolling bearings (this does not apply to all starters), and the sliding friction surfaces are provided with copper-graphite bushings, which work perfectly without additional lubrication. The only exceptions are gear-type starters, the planetary mechanism of which requires lubrication. But they also use plastic gears with a low friction coefficient.

Starter design

Dismantled “crispy” starter bendix

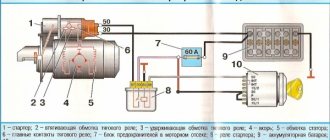

The brand depends on the purpose, characteristics, and function of the starting motor. Receiving power from the battery, the starter rotates the engine crankshaft. Structurally consists of nodes:

- Brush (commutator) motor.

- Bendix is a gear driven mechanism (overrunning).

- Traction relay.

This is the main unit of the electrical system that produces series excitation. That is, the starter is the main component of starting a car engine.

The main and only source of energy is the battery , which powers all electrical appliances while the machine is inoperative.

Small in size, but high in power, the starter is designed for easy starting and operation of a car in low temperatures.

How does a car start?

Not enough lubrication in Bendix

Turning the ignition key closes the contact bolts of the starter. Acting on the relay armature (traction) through the lever, the drive coupling is driven, which, by moving the gear, engages the flywheel rim.

The electrical circuit and the bendix are closed, causing the flywheel and crankshaft to rotate. Next, the piston group works, igniting the fuel mixture.

This completes the starter function, returning to the starting position. That is, the drive disengages from the ring, but the engine continues to operate. Cars with automatic transmission are equipped with a starter retaining coil, which allows the engine to start only if it is in the neutral position of the gear lever or the “P” position.

Why do you wash the engine compartment?

Some people think that washing the engine is superfluous and actually useless. There are also those who perceive cleaning the engine compartment solely as a pre-sale preparation procedure in order to profitably sell the car on the secondary market.

There are several reasons why periodic washing is the right decision on the part of the car owner:

- If you clean the engine from dirt, oil and other types of contaminants, it can last much longer. This is due to the fact that due to external contamination, the operation of the forced cooling system is disrupted;

- Dirt accelerates the wear of internal combustion engine components. It starts corrosion processes, reduces engine life, forces you to change consumables more often, etc.;

- Dirt negatively affects electrical and electronic systems. Debris can make negative changes to the operation of the ignition system;

- Oil accumulation can lead to unscheduled and unexpected fires. Even a small accidental spark, and the engine is already blazing.

But we must not forget that looking at a clean and tidy engine is much more pleasant than looking at an oily, sticky pile of iron.

So does the starter need to be lubricated?

On numerous forums on the Internet, there are different opinions on whether certain parts of the starter need to be lubricated. It’s worth saying right away that the planetary gearbox . By doing this you will only contribute to its normal operation. For this purpose, it is better to use: from expensive lubricants LIQUI MOLY Thermoflex or RAVENOL Arctic Green Grease AGG2, from cheap ones - “Litol 24”, graphite lubricant, CV joint lubricants. Also, the choice should be based not only on price, but also on operating temperature.

As for the gearbox shaft , for this it is better to use the above-listed Molykote 3400A Leedfree, Molykote BR 2 Plus, graphite lubricant, Castrol LMX, “Ciatim 201”. The choice again depends on price and temperature conditions.

There is an opinion that it is necessary to lubricate the copper-graphite bushings on the armature axis. Actually this is not true ! Their normal sliding is facilitated by graphite, which is powder applied to their working surface. As you know, graphite is excellent for gliding. At the same time, dirt does not accumulate on it.

Regarding the question of how to lubricate the starter solenoid relay and its armature, there is a recommendation not to lubricate it at all . The fact is that the lubricant in this place collects various dirt on itself, forming a dense mud layer, which undoubtedly harms the normal operation of the Bendix. And if this same lubricant thickens in the cold, then this will be all the more harmful for the mentioned elements of the starter and threatens emergency operation until it completely fails.

Starter lubrication: harm or benefit?

It is simply impossible to answer this question unambiguously, because what can harm some elements of the starter will be absolutely safe for other parts. Let's get to the bottom of this issue. Contrary to popular belief, lubrication of the anchor shaft in the area of the bendix stroke is mostly harmful than beneficial. Graphite lubricant accumulates dirt and dust in this place, and during prolonged inactivity of the car it can completely prevent the free movement of the bendix, as a result of thickening. Copper-graphite bushings on the armature axis also do not need lubrication, because their sliding is facilitated by graphite, which is powder-coated directly onto the bushings.

How to lubricate the starter during assembly - the best means and methods of using them

The starter is a component that is not very demanding on the availability and quality of lubricant. It does not have rolling bearings (this does not apply to all starters), and the sliding friction surfaces are provided with copper-graphite bushings, which work perfectly without additional lubrication. The only exceptions are gear-type starters, the planetary mechanism of which requires lubrication. But they also use plastic gears with a low friction coefficient.

What do we lubricate and how often?

The internal parts of the starter must be lubricated, such as:

- overrunning clutch;

- shaft;

- gearbox (if any).

Some experts also recommend lubricating the retractor relay and bushings, but we will look at the starter parts listed in the list.

Important! Be careful with the starter shaft so that the clutch with the gear does not jam; you can lubricate only the rear part, then this will not ultimately lead to breakage of the teeth.

It is better for car owners to adhere to the rule - lubricate the starter elements every 2 years of operation of the car or 40 - 50 thousand kilometers.

"Castrol"

"Castrol" is also considered a lubricant for the starter, which is used to process this element of the car. The product successfully combines all the advantages of lubricants. Therefore, it is used for cars of famous brands.

Castrol makes excellent oil, there are many competing brands that also make excellent products. More important than finding the best brand of car oil is finding the best oil for your car. The best motor oil will vary depending on the specific make, model, year, mileage, and requirements stated in the vehicle's manual.

List of tools required for repair

To repair a starter, approximately the same set is required, depending on the model and manufacturer of the unit. The table below provides an indicative list of tools that will be needed for repairs.

Table - Tools required to replace the front strut

This is interesting: Replacing the rear wing with your own hands - repairing a VAZ 2112 car

| Name | Note |

| TORX head | Required mainly when repairing starters from foreign cars |

| Head | “at 8”, “at 10”, “at 12”, “at 13”, “at 14”, “at 15”. Size varies depending on the make and model of starter. |

| open-end wrench | For access where a socket or spanner cannot reach |

| Vorotok | With ratchet and extension |

| Multimeter | To check the electrical parameters of the starter |

| Cardan for wrench | Required if access to the starter or wire mounts is difficult |

| Screwdriver | With flat or cross blade. On foreign cars, a specially shaped tip is sometimes required, for example, a flat one with a notch or an “asterisk” |

| Insulating tape | To restore insulation |

| Penetrating lubricant | For loosening stuck threaded connections |

| Rags | For cleaning dirt and grease residues |

In order to repair a faulty starter, it is recommended to purchase a special repair kit. It includes the main elements of the assembly that are most susceptible to wear. Sometimes such a repair kit includes some of the tools necessary to restore the functionality of the unit.

"Litol"

Litol 3 is a highly effective multi-purpose lubricant, blended using modern processing technology. Litol can be used for ball bearings, roller bearings, metal joints such as steel, in mining, quarries, agriculture, construction and general industrial applications.

This type of car starter lubricant is produced with high quality additives as anti-corrosion, anti-oxidation, adhesive agents and a special lithium thickener, which provides:

- Effective corrosion inhibitors and protects metal surfaces.

- Well protects against oxidation, ensures long service life of the starter.

- Excellent wear protection.

- Wide operating temperature range from -10 ºC to +140 ºC.

How to lubricate the starter

1. Put the transmission in neutral, squeeze the handbrake, and jam the wheels with boots.

2. Remove the terminal blocks from the battery.

3. Remove the air filter as a whole.

The starter is located differently in different engines, but for the most part it is located to the left of the engine, when viewed from the hood. 4. Move the rubber fuse and unscrew the positive terminal.

5. Unscrew the nuts from the two studs with caps at “15” and remove the starter itself.

6. Proceed to disassembly once you have removed the assembly. Before placing it on the surface, thoroughly clean it to remove any remaining dirt or other debris. If there is such a need, then use kerosene, applying only locally.

7. Using the cap at “13”, remove the suction valve terminal block.

8. Unscrew the three bolts that secure the valve using a hexagon. It is likely that difficulties may arise, such as water and various weather conditions have already left their mark on them. Use WD-40 for this. If everything is already so tight, do not break it, otherwise the spitz will become unusable.

9. Take a drill and use a countersunk drill bit. Buy two studs marked M4x35 or, if possible, longer.

10. Using capes, unscrew the bolts and disconnect the two parts of the housing. Pry up the retaining ring on the rotor shaft, remove the thrust bushing, and remove the bendix. It may happen that you will need a metal shoulder that is slightly larger in diameter than the shaft in order to knock down the bushing. It all depends on how great the degree of wear is.

11. A shaft, three gears and a gearbox open in front of you. Use a rag to remove any old grease and scrub them dry.

12. Apply a little lubricant, but you shouldn’t tamp it down, because too much of it and frost can lead to jamming.

13. Put on the gearbox cover and install the coupling, lubricating its splines with grease.

14. While you are assembling it, visually inspect the brushes. If wire burrs are visible, then replace the module.

15. Place the cover on the rotor shaft and lubricate it.

16. Lubricate the clutch just a little so that it fits easily into the groove of the crankshaft and screw in the studs.

17. After reinstalling the starter, put back the air filter.

18. Test the car.

Based on the operating instructions for your vehicle, it is necessary to carry out a technical inspection every 50,000 kilometers and change the lubricant. Depending on the conditions in which the vehicle was used, the interval may be reduced by three to four times.

There can be two service options: fix everything yourself, or contact a service station for qualified repairs. As can be seen from everything described above, the procedure does not require any complexity, but patience and certain skills for sure. Regarding the purchase of components and spare parts, it is recommended to purchase them only in specialized stores or dealership centers. After all, with non-original products you doom the car and its components to subsequent early repairs. Well, the topic was sorted out step by step. I hope our advice will help you.

Which parts of the starter need to be lubricated?

Before moving directly to the choice of lubricant, it is necessary to decide which internal parts of the starter are to be lubricated. Let's list them:

- starter shaft;

- overrunning clutch;

- gearbox (if available).

As for the starter shaft, its rear part needs to be lubricated to facilitate the movement of the longitudinal clutch. Otherwise, there is a risk of a wedge between the clutch and the gear, which can lead to breakage of their teeth.

Also, some experts recommend lubricating the retractor relay and starter bushings. There are many different opinions on this matter. However, we are of the opinion that it is only necessary to lubricate the shaft, gearbox, and less often the overrunning clutch. You can read about the reasons below.

Not all starters have a gearbox; it depends on the design and model of the car. Its purpose is to reduce the mechanical forces on the starter, which reduces the current consumption. If the gearbox is not sufficiently lubricated, this will result in excessive load on the associated mechanisms and wear on the battery. Now let's move directly to the question of choosing a lubricant for a car starter.

This is interesting: VAZ 2112 hydraulic compensators with 16 valves are knocking: causes and solution to the problem

Starter lubricant must have the following properties:

- wide temperature range of use;

- surface protection from corrosion;

- high load capacity;

- low friction coefficient;

- long term of use.

Bendix replacement

Regardless of whether you are going to replace the bendix or rebuild it, you will first have to remove it from the starter. There are two types of starters:

- With a “beak”, where the front support of the starter shaft is made in its housing.

- And without the “beak” where the front starter support bushing sits in the crankcase.

The most common mechanisms are of the first type, the “beakless” ones are familiar from the VAZ of the “eighth” family.

Since you can change the Bendix on the starter only by removing the starter itself, first the battery ground is disconnected, and the power cable and the solenoid relay control wire are removed from the starter. Having unscrewed the fastenings of the starter to the crankcase, we pull it out.

Regardless of the design of the starter, the solenoid relay is first removed, since its plug later interferes. We unscrew the nut on the power terminal of the starter winding, remove the terminal, then unscrew the screws connecting the retractor to the housing. We take out the relay winding, after which the core can be easily disengaged from the Bendix fork.

Then we disassemble the starter. Having unscrewed the longitudinal coupling bolts of the covers, remove the “beak” or front cover of the starter. After this, you can easily remove the fork from the Bendix and pull the rotor towards you.

A thrust bushing is installed on the rotor, limiting the stroke of the bendix. Before removing the bendix from the starter, you need to compress this bushing. In garage conditions, an open-end wrench is used, the mouth of which fits onto the rotor shaft, but rests against the bushing with its jaws. Having firmly fixed the key in a vice, we rest the thrust sleeve against its jaws and apply a sharp blow to the end of the shaft through a drift made of durable wood, copper or aluminum, so as not to damage the shaft itself. After this, the retaining ring installed inside the bushing jumps off the groove and releases it. After removing the bushing, pull the retaining ring off the shaft by prying it off with a thin screwdriver.

After this, we take out the Bendix assembly. Installing the Bendix is done in the reverse order, and the main difficulties are caused by pressing the thrust bushing back. It should be taken into account that it is asymmetrical - on one side there is a wide chamfer, which makes it easier to enter the locking ring. When removing the bushing, the retaining ring is deformed; it must be straightened before assembly. The thrust bushing must be seated on the retaining ring without distortion, otherwise the edge may be squeezed out of the groove on the rotor, the ring will bend and will not allow the thrust bushing to be pressed into place.

Something else useful for you:

- Diagram, installation and connection of an additional starter relay

- Why does the starter hum but not turn over the engine?

- Troubles the engine. Main reasons!

Video: Replacing the Bendix starter

Starter lubricant selection

The Internet is full of forums where disputes take place regarding which starter lubricant is best.

The relevance of the issue arises if the starter has to be disassembled independently. If you leave this to the masters at the car service center, then you won’t have to choose. For those who still want to do this on their own, there are several variations: To choose the right lubricant option, you need to know its characteristics and scope of application. When the lubricant is exposed to low temperatures, it becomes very viscous, and at high temperatures there is a high probability of coking.

Before you start lubricating the starter, you need to select a frost-resistant lubricant that retains its properties to the greatest extent. Litol 24

It is fully functional in extreme temperature ranges from -40 to 120 degrees. Its viscosity ranges from 8 to 650 Pa-s. Can be applied to hinges and rubbing parts of electrical elements and mechanisms of a car.

Graphite grease

Its use is widespread in the temperature range from -20 to 70 degrees Celsius. Its viscosity is 100 pascals at an air temperature of 0 degrees. It is applied to parts that have been subjected to heavy loads, often the suspensions of tractors and cars.

Engine oil

It is better to use synthetic motor oil, because it is largely capable of maintaining its viscosity in low temperature ranges. It forms a fairly strong film on the surface of metal elements.

Castrol

Castrol LMX is lithium based. The temperature range is from -35 to 140. At 40 degrees Celsius, the viscosity is 83 Pascal.

Volkswagen Polo Sedan Highline Night blue › Logbook › Preventative inspection and lubrication of the starter…

Hello ladies and gentlemen!

For more than a year, when starting the engine, I listened to a squeak from under the hood, sometimes short for a split second, and sometimes for a couple of seconds. I got tired of this and decided to find the cause of this disgrace. I am far from being the only one like this, there are many of us and everyone is guilty of insufficient starter lubrication.

Before starting this procedure, I studied the theoretical part, in particular: how to remove the starter, how to disassemble it, what to lubricate and with what. In this entry, I will not describe the process of removing the starter; I myself used the entries in the Cafari bulletin board, well done Misha, he described everything perfectly - removing and disassembling the starter. I would rather focus your attention on the choice of lubricant and the parts of the starter that need to be lubricated.

The starter shaft is subject to lubrication at the point of contact with the roller bearing, and its rear part to facilitate the movement of the longitudinal clutch. Otherwise, there is a risk of a wedge between the clutch and the gear, which can lead to breakage of their teeth. The main gear of the starter shaft, which engages with the flywheel, cannot be lubricated; it only needs to be cleaned of dirt. The planetary gearbox is generously lubricated, which is designed to reduce the mechanical forces on the starter and reduce the current it consumes. A small amount of lubricant should be applied to the rotor gear. The bronze bushing of the rear cover can be lubricated with a thin layer, otherwise the grease may get onto the rotor commutator, although bronze bushings are not lubricated parts. But as for the lubrication of the solenoid relay and its armature, it is highly not recommended to lubricate this pair with grease. The lubricant in this place collects various dirt, forming a dense mud layer, which undoubtedly harms the normal operation of the Bendix. And if this lubricant also thickens in the cold, then this threatens the starter with emergency operation modes up to its failure.

Now let's move directly to the issue of choosing a lubricant for the starter components, because not only the fact of lubrication itself is important, but also what kind of lubricant is used. The selection of lubricant for the starter largely depends on the operating conditions of the machine, in particular, to what minimum value the temperature in your region drops in winter. When choosing a lubricant, you need to know its characteristics, primarily the operating temperature range, as well as kinematic viscosity.

Everything is more or less clear with the temperature range, but let’s talk in more detail about the kinematic viscosity of the lubricant. According to current standards, the kinematic viscosity of the base oil used to produce starter lubricant must be below 100 cSt (centistokes, 1 cSt = 1 mm2/s). Such compositions are intended for operation in conditions of very low temperatures, high speed of interaction of rubbing metal or other pairs and low mechanical load.

The most popular starter lubricants

LIQUI MOLY Thermoflex or RAVENOL Arctic Green Grease AGG2 with excellent viscosity characteristics, a wide range of operating temperatures and the ability to work even with plastic parts.

There are also more budget options, such as "Litol 24" (the most popular lubricant in Russia, but not suitable for the Far North), graphite lubricant (used in hotter regions due to its temperature capabilities), " Castrol LMX" (famous for , which can withstand high loads and temperatures from -35 to +170 degrees), “ Ciatim 201 ” (the most frost-resistant lubricant) and lubricants for CV joints (wide temperature range, but in winter conditions it is advisable to do without heavy loads).

The correct choice of lubricant largely depends on the operating conditions of the machine. In particular, it depends on the frost in which she drives. You need to monitor the mileage interval (which we wrote about above) and ensure that the lubricant is always of normal consistency.

Bendix starter from a different angle. Signs of wear are practically invisible.

Related to the application and characteristics of the lubricant. The lubricant should not lose its viscosity at sub-zero temperatures and not coke in hot weather. That is, frost-resistant lubricants are selected, which include:

- Motor synthetic . Retains viscosity properties at low temperatures with a long period of retention of the oil coating on moving, rotating joints.

- CV joint lubrication. Used in constant velocity joints of off-road vehicles (4x4), (6x6). The properties of the oil are maintained at −30+90°C. This is a plastic, mineral substance mixed with lithium soap and additives. Can be used at −40+120 °C. For example, CV joints differ from CIATIM-201 in so-called tribological properties.

CV joint grease can be used to lubricate Bendix

This means that the lubricant counteracts the appearance of scuffing and burrs on the body of rubbing parts. That is, under excessive load, the Bendix gear, pressing strongly against another similar part, squeezes out the oil film. This fact leads to hard lapping, creating scuffing on the metal up to friction welding. In our case, CV joint-4 can be replaced with LITOL-24, which has higher lubricating properties.

- Castrol. Available with a lithium component. The temperature range is −35+140°C, with a relatively low viscosity value. Includes fuel additives, transmission oils, and greases.

Castrol lithium grease

- Graphite . Used in units operating under excessive loads within the temperature range of −20+70°C. Lubricants with a cooling temperature of −15°C are considered summer, and −20°C winter. It has anti-friction properties and improved lapping of joints. Calcium additives as additives are resistant to being washed away by jets of water.

- Bendix lubricant belongs to the category of gear oils. By the way, it is advisable not to lubricate the starter shaft and splined part. The point is that they must be in a dry, clean state. Since the metal-brass pair is designed for better sliding, the bendix bushing and armature can be coated without risk with a thin layer of CIATIM-201 .

- Litolis a multi-purpose, frost-resistant, waterproof, lithium grease. It is used in transmission units not only of vehicles.

LITOL lubricant

Operating temperature range, for example, CIATIM 201 −60+90°C. It is used in worm and gear drives, rolling and sliding bearings, and friction units.

Litol 24

Operable in the range from -40 to 120 degrees. Viscosity from 8 to 650 Pa-s. The area of application includes hinges and friction parts of electrical machines.

Graphite grease

It is used in the temperature range from -20 to 70 degrees. Its viscosity is 100 Pa-s at zero air temperature. It is used in parts subject to heavy loads, mainly car and tractor suspensions.

Engine oil

When using motor oil, it is better to use synthetic oil, since it largely retains its viscosity at low temperatures. It forms a fairly strong film on the metal surface.

CV joint lubrication

Temperature range of use is from -30 to 120 degrees. Viscosity at -30 will be 1800 Pa-s. Area of application: constant velocity joints.

When servicing the starter with your own hands, it is best to lubricate the trunnions and shaft with engine oil; you can put Litol 24 or Castrol LMX in the gearbox. At the same time, keep in mind that you need to buy lubricant in trusted places to avoid counterfeits.

Ciatim-201

It is an oil thickened with lithium stearate. Used at temperatures from -60 to 90 degrees. The viscosity already at -50 will be 1100 Pa-s.

Castrol

Castrol LMX is lithium based. Temperature range from -35 to 140. Viscosity at 40 degrees is about 83. Used in heavily loaded units.

Precautionary measures

The chemical composition of specialized products is unsafe, so the user must remember some handling rules:

- It is required to protect the respiratory system - use a mask (respirator), wear gloves;

- It is advisable to use sleeves;

- safety glasses required;

- work uniform.

The drugs splash, contact with the skin or eyes is unacceptable, as they provoke inflammation or allergic reactions. Clothes can be damaged by oil stains from the engine compartment.

Review Reviews

The instructions for the vehicle indicate that its technical inspection is necessary after every 50,000 km. Then you need to lubricate the starter bearings.

It is important to take into account the specific conditions in which the vehicle was operated. To service your car, you can use your own strength or contact a car service center.

Knowing which lubricant to choose for a car starter, having studied the stages of performing such work, it will not be difficult to complete them. You just need to be patient and have some knowledge.

If you need to use spare parts and components, it is better to choose them from reliable suppliers. Cooperation with dealer centers is also practiced. The use of non-original parts and components often leads to the need for early repairs.

Let's sum it up

The article discussed the question of what lubricant to lubricate the starter. When this mechanism works, its gear goes inside the flywheel. This results in a force acting on the transverse direction of the starter shaft. And as a result of long-term use, the parts that take part in this process are subject to severe wear when the bushing takes the shape of an ellipse. Then the shaft begins to shift and the gap between the parts becomes larger. As a result of such changes, tooth misalignment occurs.

Since difficulty arises in the operation of the starter, the current also increases. The winding and power wires become hot. The battery suffers from this. Due to severe wear, the starter has difficulty turning the crankshaft. And if you don't take action, the battery will be completely discharged.

To prevent the occurrence of such difficulties, it is recommended to take care of the condition of the starter. It is important to lubricate it. The frequency of such actions is every 50,000 km.

Experts believe that not all starter parts need to be lubricated, but only the planetary gear part. You can carry out this process yourself or use the services of a car service center. Timely lubrication will prolong the performance of the starter mechanism and battery.

"Ciatim-201"

"Ciatim-201" is a Bendix starter lubricant that has been known since Soviet times. The product contains lithium soap and liquid oil from petroleum. This product is also characterized by the presence of an antioxidant additive. Its composition may differ depending on the plant in which the product was created. The consistency of the product is similar to Vaseline. The operating temperature ranges from minus 60 to plus 90 degrees Celsius. The tensile strength parameters are 500 Pa.

Basic faults

Externally, a breakdown of the Priora starter can be recognized by the following signs:

- “turns” and at the same time starts the engine;

- does not “twist”;

- continues to “twist” after the key is released;

- creaks, clicks are heard;

- It spins, but for too long.

The reason may lie in a faulty battery, in the starter itself and fuses. The most common are those that are most likely to disable

Doesn't turn on

If the engine does not start, the problem may be:

- discharged or broken battery;

- no closure of contacts 50 and 30;

- terminals or tips are oxidized;

- interturn closure;

- short circuit to ground;

- open circuit “starter - traction relay”;

- the ignition module is faulty;

- break in the traction relay winding;

- brush wear;

- the anchor jams;

- the additional relay or the control circuit connected to it is damaged.

If the starter clicks but does not turn, there may be several reasons:

- the gear working with the bendix does not engage with the engine flywheel;

- the bearing of the armature shaft bushings is worn out;

- the starter mount or housing is broken;

- gear or flywheel teeth are damaged.

Doesn't turn off

When the Priora starter unit does not turn on, the problem may lie in the following:

- the freewheel slips;

- the battery is discharged or broken;

- sudden and severe voltage drop in the circuit;

- oxidation of contacts.

Reasons for slow performance may include:

- the battery is discharged or broken;

- terminals or tips are oxidized;

- the connection of wires from the power unit to the body is very weak;

- the contact bolts on the traction relay are loose or oxidized;

- brush wear;

- a short circuit or break has occurred in the armature winding.

Lada Kalina Sedan is my first car Logbook Phase sensor Replacing the Bendix starter is not a cheap job, and the unit itself can cause serious damage to the car owner’s budget. By repairing or replacing it yourself, you can avoid high costs.

The main causes of malfunctions affecting the reliable adhesion of the flywheel and overrunning clutch of the car starter include:

- Formation of deposits inside its body;

- Weakening or breaking of the overrunning clutch roller springs;

- Hull destruction;

- Roller wear.

Some of these faults can be eliminated by repair work; to eliminate others, it will be necessary to replace the starter bendix.

In some cases, repairs come down to soaking the front part of the starter in a container of gasoline and then drying it. Often, after such a procedure, the Bendix Ford Fiesta came into working condition and was not bothered by malfunctions for a long time. In this case, car owners did not even have to think about how to remove the bendix from the starter and put it back.

The following signs may indicate a retractor failure:

- After starting the engine, the starter does not turn off; it rotates at high speed and has a characteristic buzzing sound.

- After turning the key in the ignition switch, a click occurs, indicating that the device is activated, but no rotation of the starter is observed. Sometimes, if there is a break in the coil, the armature is stuck in a certain position, or there is no power, there may be no click.

- After turning the key in the lock, the starter begins to idle without affecting the engine flywheel.