Replacing the input shaft bearing of a VAZ 2107

The gearbox on the VAZ classic (which includes the “seven”) is particularly reliable. Often the gearbox “survives” 1-2 engine repairs before it has to be repaired. But sooner or later, her turn comes. One of the gearbox parts that most often requires replacement is the VAZ 2107 input shaft bearing . The reason for its premature failure may be a factory defect or extreme driving style. If you “tear the gearbox lever”, constantly overload it with sudden accelerations or heavy loads when towing, even a high-quality bearing will not be able to hold out for long. Another reason for bearing failure may be neglect of regular gearbox maintenance regulated by the manufacturer. Many believe that replacing the input shaft bearing requires complete disassembly of the gearbox and prefer to entrust this operation to specialists at a service station. But practice has shown that complete disassembly of the gearbox is not required. You can change the input shaft bearing yourself without seriously disassembling the gearbox, and the operation does not require the highest qualifications or special devices and tools.

Replacement procedure

Replacing the bearing of the input shaft of the VAZ 2107 gearbox is necessary if this element has severe wear. The reason why bearings lose their working condition is an aggressive driving style.

You can replace this consumable with your own hands, without resorting to rebuilding the gearbox. However, this requires some experience, since the gearbox must be removed from its original location.

To remove this component, it is necessary to remove the bell from the gearbox, with which the box is attached to the block. Retaining rings are subject to removal. A set of tools is required: screwdriver, hammer. Using a screwdriver, you need to pick up the ring groove, applying some effort. As a result, the gearbox input shaft moves forward, after which the bearing should be tightened. To do this you will need a hammer. This procedure requires caution. When tapping with a hammer, the shaft should be rotated slightly. The duration of this procedure is influenced by the skill of the person.

Installing a new spare part also requires attention and professionalism. To install it in its original place, use a hammer. In this case, all blows must be applied to the inner ring of the consumable. At the same time, you need to pull the input shaft forward. As soon as the mechanism is in place, the removed box is installed on the vehicle.

Thus, the fact that the driver neglects the established rules for operating a Lada car has a negative impact on the input shaft bearing. In particular, a quick start occurs and heavy loads occur during towing.

Signs of a malfunction of the input shaft bearing of the VAZ 2107 gearbox

There are several signs that indicate a bearing is faulty:

- When the engine is running at neutral speed, extraneous noise is heard, which changes with increasing speed.

- The gearbox periodically taps while the car is moving. And the knock is present in any gear.

- Gears switch on or off spontaneously.

- The clutch does not engage due to a stuck bearing.

The problem cannot be ignored: misalignment of a faulty bearing will lead to breakage of the clutch basket. And even if misalignment does not occur, a worn part will cause rapid failure of the gearbox and/or clutch.

Bearing replacement can only be done on a removed gearbox. This is where the work begins.

Replacement of the gearbox input shaft oil seal 2101-07.

I created this video

for help from YouTube Video Editor ()

Any of the mentioned signs indicates a problem in the gearbox, which is not recommended to be ignored. If you do not immediately replace the primary shaft bearing, there is a high risk of the part being misaligned and the clutch basket failing. If misalignment can be avoided, then wear of the bearing will one day lead to breakdown of the clutch and (or) gearbox.

Please note that replacement of a faulty part is carried out on a removed gearbox. Therefore, start repair activities with this work. Details: How to remove a gearbox, video

Removing the VAZ 2107 gearbox

To remove the gearbox you will need a pit or a lift. The procedure is as follows:

- Disconnect (better remove) the battery.

- Engage neutral gear, disengage the handbrake, raise and hang the rear axle.

- Unscrew the bolts securing the cardan and the gearbox flange, and disconnect the cardan.

- Remove the exhaust manifold pipe by unscrewing the bolts.

- Disconnect the oxygen sensor.

- Remove the starter.

- Inside the car, remove the console and gearshift knob.

- Remove the gearbox protection.

- Unscrew the clamp connecting the catalyst to the exhaust pipe.

- Remove the clutch slave cylinder.

- Unscrew the speedometer cable, remove the boot and the reverse speed sensor wire.

- Remove the driveshaft.

- Unscrew the traverse while holding the gearbox.

- Unscrew and pull out the gearbox.

Replacing the bearing of the input shaft of the VAZ 2107 gearbox

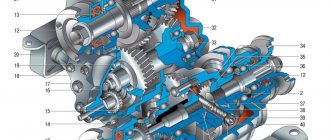

Remove the bell and retaining rings from the dismantled box. No further disassembly is required. The procedure is as follows:

- Using a powerful screwdriver, pick up the bearing of the input shaft of the VAZ 2107 gearbox by the annular groove . Serious efforts will be required, so you need to choose a screwdriver that is as strong as possible so that it does not break or bend.

- Push the transmission input shaft forward using the shaft bearing as a support.

- Slowly pull the bearing off the input shaft by tapping it with a hammer. Between hammer blows, the shaft must be rotated slightly to avoid bearing misalignment.

Knocking out a bearing takes from 5 minutes to half an hour. It all depends on the skill of the mechanic and on how closely the bearing is “affined” with the shaft.

The new bearing is pressed onto the shaft using a light hammer. The blows must be applied to the inner ring of the bearing. This should be done carefully and evenly, pulling the input shaft forward.

The advantage of this method is that there is no need to sort through the insides of the box, risking unbalancing it. Also, replacing a bearing without disassembling the entire gearbox significantly saves time.

After replacing the bearing, all that remains is to install the gearbox in place. Given its weight, it is advisable to carry out the work together. The operations are carried out in the reverse order of removing the box and do not cause any difficulties.

Main shaft bearing

The “Seven” gearbox has amazing “survivability”: for example, the gearbox can “survive” one or even two engine overhauls, after which the car owner will have to repair it. However, there are a lot of small parts in the design of the box, which, unfortunately, cannot boast of their service life. Most often, the driver has to slightly modernize the gearbox design by replacing the bearings.

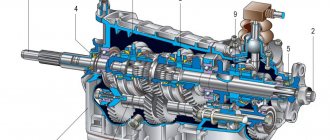

Open type metal bearings with the following characteristics are mounted on the input shaft of the VAZ 2107 gearbox:

- manufacturer - VPZ 23 Vologda;

- article - 2107–1701033/2101–1701068;

- length - 120 mm;

- width - 95 mm;

- height - 95 mm.

The main function of the input shaft bearing is to act as a rolling support, that is, to allow the shaft to move easily along its axis.

When Vologda bearings reach the end of their service life, drivers sometimes purchase products from other Russian companies. As practice has shown, imported bearings are distinguished only by their higher cost, and not by their high quality, so there is no point in overpaying for them. And the domestic manufacturer fully meets all the quality and durability requirements that motorists place on them.

When choosing a manufacturer, you should keep in mind that a higher price per unit of goods does not mean impeccable quality. However, four Russian factories already have a reputation as a supplier of reliable and affordable products:

- VPK plant - the approximate price for 1 bearing is 270 rubles;

- GPZ plant - the cost of the product is 190–200 rubles;

- the SPZ plant (3 gas processing plants) produces the most expensive analogue of Vologda bearings, price from 450 rubles;

- SPZ-4 plant - the pricing policy is quite loyal, a bearing for the input shaft will cost 220 rubles.

How to determine bearing wear

Being a composite device, any bearing can begin to fall apart over time. Therefore, its wear can be determined without disassembling the gearbox by ear and by those malfunctions in the operation of the gearbox that the driver will immediately notice.

Signs of malfunctioning bearings of the input shaft of the VAZ 2107 gearbox can be considered:

- Extraneous noises and crunching noises when the engine is running, even in neutral gear.

- Impacts in the cavity of the box while driving, even at low speed.

- Arbitrary switching on or off of gears.

- Inability to engage the clutch pedal due to the fact that the bearing on the shaft is jammed.

Any of these signs cannot be ignored: if the bearing fails, this can lead to serious consequences for the control of the machine. In addition, bearing misalignments will quickly affect the operation of adjacent devices.

Replacing the Primary Shaft of the VAZ 2107 gearbox

replacing the input bearing

Vas

2107

The gearbox on the classic VAZ (called the “seven”) is especially reliable. Sooner or later there comes a time when it is urgently necessary to replace the input shaft bearing of the VAZ 2107 gearbox. Often the gearbox is “subjected” to 1-2 engine repairs before it is repaired. But at some point it was her turn. One of the parts of the gearbox, most often, is the need to replace the VAZ 2107 input shaft bearing . Replacing the silent blocks of the front levers on VAZ 2101 - 2107 cars is not an easy task. Self-change of oil in the gearbox of a VAZ LADA 2107.... The reason for its premature failure may be a factory defect or extreme driving style. Changing the oil in the transmission and rear axle of a VAZ 2106. If you “break the gear shift lever”, constantly overload it with sudden accelerations or heavy loads when towing, even a high-quality bearing cannot last long. Another reason for bearing failure may be neglect of regular maintenance of the gearbox, which is regulated by the manufacturer.

Many people believe that replacing the primary shaft bearing requires complete disassembly of the gearbox and prefers to entrust this operation to specialists in a car service center. Replacing the alternator belt for cars 16 shaft VAZ 2110 with 16 valves VAZ-2112. But practice has shown that complete disassembly of the gearbox is not required. Repair of the VAZ 2107 gearbox Remove the front gearbox shaft from the intake shaft hole. Change the bearing yourself Input shaft

this is possible without serious disassembly of the gearbox and the work does not require the highest qualifications and special devices and tools.

Symptoms of primary failure of the VAZ 2107 gearbox shaft bearing

There are several signs of bearing failure:

- When the engine is running at neutral speed, an unusual noise is heard that changes as the speed increases.

- The gearbox periodically knocks when the car is moving. And there is a knock in any gear.

- Gears switch on or off spontaneously.

- The clutch does not engage with the removed bearings.

Changing the bearing

When the box is dismantled, the bell and retaining rings are removed. You won't have to disassemble anything else.

The new bearing is pressed in by gently hitting its inner ring with a small and light hammer. During the process, the shaft must be pulled forward. In this case, there is no need to tinker with the insides of the gearbox, risking upsetting their balance. And replacing the input shaft bearing of a VAZ 2107 gearbox using the described algorithm takes much less time than using the traditional one. You will save at least 3 thousand rubles. (and most auto repair shops ask for more).

DIY crankshaft bearing replacement for VAZ 2105-2107

Car enthusiasts rarely encounter wear on the crankshaft bearing of VAZ 2105-2107 cars. Due to the low load, the bearing life exceeds 200 thousand km - this explains the fact that they try to time its replacement to coincide with the next major overhaul. If the bearing fails earlier, then you should not delay installing a new part - this may lead to other breakdowns. Today we will talk about the signs of a malfunction and look at how to replace a crankshaft bearing with your own hands.

Where is the crankshaft bearing installed and what is it used for?

The bearing installed in the crankshaft flange is not part of the engine, but of the transmission. The main purpose of this assembly is to center and support the transmission input shaft - it serves as a front rotating support. Anyone who has ever installed a gearbox on a car is familiar with the crankshaft bearing - it is so difficult to get into its inner race with the shank of the input shaft. As for the high service life of the part, it can be explained simply. The fact is that the rolling unit only works when the clutch is depressed. The rest of the time, the crankshaft and gearbox input shaft rotate at the same frequency. Despite the low load, it is recommended to replenish the lubricant supply in the bearing when replacing the crankshaft rear oil seal, repairing the clutch, etc. This way you will delay the need for repairs for a long time.

Symptoms of a problem

Although the input shaft support bearing is an inexpensive part, replacing it is a labor-intensive process. And this is connected not so much with the difficulty of dismantling the rolling unit itself, but with the need to remove other parts and assemblies of the engine. To avoid wasting hard work, bearing failure must be correctly diagnosed. Signs indicating this type of malfunction:

- Noise coming from a running engine when the clutch is depressed. A similar rustling or rustling noise also appears when the release bearing fails. And if the noise from the latter is detected even with slight pressure on the petals of the spring diaphragm of the clutch basket, then the gearbox support bearing will make extraneous sounds only when the clutch is completely disengaged.

- Wear or jamming of the bearing due to lack of lubrication leads to the fact that the input shaft of the gearbox is subject to the action of torque even while the driven disk is completely removed from the flywheel. In fact, this manifests itself with the same symptoms as with a clutch that “drives” - it is difficult to engage first gear when starting from a stop, jerks appear when changing gears while moving, etc.

- An irregular knock that appears from the gearbox indicates destruction of the bearing cage. In this case, the balls can spill out or clump together, causing an unpleasant sound and causing an imbalance in the crank and gearbox input shaft.

The latter happens rarely and indicates that the driver did not pay attention to noise and other signs of malfunction for a long time.

VAZ-2107 input shaft bearing: number, price, which one is better to buy, size (5 mortar, 4 mortar)

In the “Classics” manual transmission, the designers provide a radial open single-row ball bearing of class 6 accuracy, which absorbs 90% of radial loads. To select this spare part, you need to pay attention to the radial and axial clearance, ease of rotation, appearance of the product (no corrosion, cracks, nicks, cavities).

Before you buy a gearbox input shaft bearing for the “seven”, check out the list of recommended manufacturers. The listed manufacturers produce high-quality products at reasonable prices with exact dimensions in accordance with GOST 520-211.

Table of costs and recommended manufacturers

| No. | Manufacturing plant | Number (article/markings) | Price 2021, rub. | Set | |||

| Retaining ring | Bearing | Pressure ring | Installation instructions | ||||

| 1 | VBF (VPK) Russia Analogue | 50706АУ.P6R10.20Q6 | 270 | — | + | — | — |

| 2 | GPZ Russia Analogue | 6-50706AU | 200 | — | + | — | — |

| 3 | SPZ (3 gas processing plants) Russia Analogue | 6-50706AE1USH | 450 | — | + | — | — |

| 4 | SPZ-4 Russia Analogue | 6-50706AU | 220 | — | + | — | — |

What is the risk of crankshaft bearing failure?

Most often, after a suspicious rustling sound appears, the car will be able to travel for hundreds of kilometers. But don’t put off replacing the bearing for too long, since a seemingly trivial malfunction can turn into other problems:

- bearing destruction is the cause of increased vibration of the crankshaft, and this leads to wear of the rear oil seal and engine oil leakage;

- due to loss of support and imbalance, the input shaft shank experiences alternating loads, which may ultimately result in gearbox failure;

- the races of a jammed bearing can damage the seats on the gearbox shaft or in the crankshaft flange;

- When the separator is destroyed and the balls are lost, dismantling the outer and inner races becomes more difficult.

As you can see for yourself, you should not bring the matter to the point of complete destruction of the unit. Moreover, even a novice driver can pull the bearing out of the crankshaft.

Procedure for bearing replacement

To get to the faulty unit, you will have to remove the gearbox, clutch and flywheel. Carry out similar work on a lift, pit or overpass, using a special crankshaft bearing puller (a device for pressing out of blind holes).

Crankshaft bearing puller

The replacement procedure is as follows:

1.First, disassemble the crankshaft bearing removal tool into its component parts, otherwise you will damage the thread when installing it. After this, lubricate the conical protrusion on the puller bushing with engine oil or grease - this will protect its surface from damage.

2.Install the press-out spacer sleeve into the inner race of the bearing and drive the device in until it stops.

3.To remove the bearing from the crankshaft, do the following. First tighten the puller screw by hand. Then, holding the press-out sleeve from turning with a 14-point open-end wrench, tighten the screw with a 17-point socket. Resting against the blank wall of the hole in the crankshaft flange, the shank of the device moves out of the coupling, pushing it along with the bearing out of the socket.

4. Having removed the damaged part, wipe the seat in the crankshaft from dust and lubricate it with engine oil. Don’t forget to check and, if necessary, replenish the amount of lubricant in the new bearing - manufacturers often sin with excessive efficiency.

5. When installing the new VAZ 2107 crankshaft bearing in place, make sure that it does not warp. The final pressing is carried out with a hammer and a suitable mandrel. If one is not found, then use the dismantled unit or hammer the bearing with a hard rubber mallet.

6.Installation is complete when the top plane of the bearing is flush with the flange.

If you are unable to find a press-out, do not despair. Every experienced auto mechanic knows how to remove a bearing from a crankshaft without a tool. In this case, you will need: a drift with a diameter of 15 mm (you can use a suitable bolt) and plastic material - lithol, plasticine or bread crumb mixed with sawdust. It is placed through the opening in the inner race in such a way as to fill the space under the bearing. Then a drift is inserted into the hole and hit with a hammer. Expanding to the sides, the soft mixture squeezes the bearing out. This way you can replace the faulty unit and avoid troubles in the future.

Something else useful for you:

Video: An easy way to replace a crankshaft bearing

How to remove the input shaft from the box

The gearbox must be installed on a flat surface so that nothing prevents its disassembly. Before starting work, it is important to clean the housing from dirt and liquid leaks so that debris does not accidentally get inside the housing.

To work you will need standard tools:

- set of wrenches;

- flat screwdriver;

- a thick bolt or a screwdriver with a powerful blade.

You need to pull the input shaft out of the gearbox strictly according to the regulations:

- Pull the oil level indicator out of the box body.

- Remove the bolt with flat washer and two nuts that hold the clutch cable bracket. Remove the cable mechanism from the gearbox.

- Unscrew the four bolts from the box cover and remove the cover.

- Unscrew the bolt with spring washer that secures one part of the input shaft.

- Before you start working with the input shaft, you will need to prevent the shafts from spinning among themselves. To do this, they need to be fixed: for example, insert a thick screwdriver between the teeth.

- Unlock the input shaft securing nut. It is very firmly planted and can take a long time to remove.

- After this, carefully pull the shaft out of the gearbox housing.

Photo gallery: main stages of work

For further work, you will need to wipe all the mechanisms in order to be able to carry out troubleshooting.

Accordingly, installation of the input shaft into the gearbox is carried out in the reverse order of removal.

Rejecting the input shaft

When the car and gearbox are operating normally, the driver, as a rule, does not have any suspicions about the exhaustion of the shaft and its elements. However, if the car starts to “strange things”, for example, the gear does not work or the speed starts to switch on in an arbitrary order, then you need to make sure that the box and, in particular, the input shaft are working.

Rejection is carried out with the gearbox removed, since only in this way can you carefully examine all the shaft parts and determine their suitability for further use.

The correct culling procedure is carried out according to the following scheme:

- Visual inspection of the input shaft for abrasions and deformations.

- General condition of the retaining rings and locking ring springs.

- Wear of splines.

- Scuffs and burrs on gears.

That is, a routine inspection of the mechanism allows you to determine the degree of wear of each element and, if necessary, replace them. It is important that the gears and the splined part of the input shaft do not have even the slightest damage, otherwise new parts will have to be installed.

Replacing the Input Shaft Bearing VAZ 2107 Video

VAZ 2107 Primary shaft bearing replacement video

VAZ-2107 cars are equipped with a reliable and low-maintenance gearbox. Often the engine is repaired once or twice, and the transmission continues to perform its tasks. Despite this reliability, the checkpoint will still have to be repaired.

The most common cause of bearing input shaft. You have it destroyed for two reasons - due to the extreme driving style of other defective details. For example, if you pull the gearshift lever harshly, otherwise overload the transmission with rapid acceleration, often tow other cars, replacement

The input shaft bearing will be needed very soon. There is another reason for unit failure - improper maintenance of the gearbox and non-compliance with the manufacturer’s rules.

There is an opinion among car owners that replacement

bearing on the input shaft of the gearbox is only possible if the operational disassembly of the unit is completed. As a result, they are likely to trust the work of WTO specialists. In fact, a working dismantling is not required to perform the above work. In addition, you can change the bearing yourself and without the participation of specialists. The reason is that there is no need to disassemble the gearbox, and the operation itself does not require complex tools and special skills from the contractor. However, more about everything.

How to determine bearing failure?

Problems with the input shaft bearing on the VAZ box2107

, is easy to recognize by a number of functions:

What kind of gearbox can be installed on a VAZ 2107

Initially, the “Seven” was produced with a “four-speed”, so you can install any VAZ gearbox from rear-wheel drive “Zhiguli” on it. You should know what functions the car will perform. If you use it as a workhorse, carry loads, pull a trailer, then a four-speed gearbox will do. It is more durable and resistant to variable loads. If high-speed driving on highways is necessary, then a five-speed gearbox is suitable.

It is possible to install boxes from foreign cars.

The best option is a box from an Italian Fiat model, since this is a prototype of our VAZ.

You can also install it from an early model BMW, but for installation you will have to redo the fastenings.