January 23, 2017 Lada.Online 84 614 9

The adsorber is designed to capture fuel vapors and prevent them from entering the atmosphere. One of the elements of this system is the adsorber purge valve. Let's consider the main malfunctions of this part, as well as ways to eliminate them.

Diagnostics of the canister purge valve

If the canister valve on your car is faulty, this can lead to a variety of consequences for the fuel system and engine. Firstly, due to insufficient and poor-quality ventilation of the system, the fuel pump may suffer, and secondly, the gradual accumulation of fuel in the manifold can lead to failures during engine operation.

If your Lada Kalina “chokes” at idle or significantly loses traction, the adsorber sensor may be to blame. To determine whether the adsorbing mechanism on the Lada Kalina model is working, you need to open the gas tank after stopping the car and listen. If a characteristic “hissing” sound is heard from the gas tank area, this is the first sign of a malfunction of the ventilation valve in the adsorber.

In addition, the smell of gasoline in the cabin may indicate a malfunction. In this case, the adsorber must be replaced immediately to avoid more serious consequences for the engine. Of course, the smell of gasoline in the cabin may be caused by other reasons, but if all other elements of the fuel system are working properly, then the problem is in the purge valve, which you can replace with your own hands.

If you decide to repair the adsorber sensor yourself, you need to remove the entire device with the sensor, which is located on the gas tank. Then, using a simple file, try to cut off the mechanism cover and remove its components, including the purge sensor and the filter that needs to be replaced.

To make a new filter, you can use paralon or felt, as well as some cotton fabric. In general, repairing the adsorber sensor is not difficult, but you need to know what you are doing and take into account the nuances so that you do not have to make repairs after repairs.

A failed adsorber valve is dangerous because the gas tank begins to be poorly and poorly ventilated. This leads to deformation and damage to the fuel pump. A desiccant layer that is not well ventilated can cause fuel to accumulate in the intake manifold, causing poor engine performance.

A faulty canister purge valve is to blame for dips at idle. The Kalina engine has weak thrust. When the motor is running, the characteristic chirping sound will not be heard if the valve is faulty.

When unscrewing the gas tank cap, you need to listen carefully. If a characteristic hissing sound appears, this means there is a vacuum in the tank, that is, the ventilation system is faulty. If any signs of failure appear, the adsorber valve should be replaced with a new one. A faulty Kalina valve will affect the filtration and purge system.

Checking and purging the valve

The first signs that the Kalina adsorber needs to be repaired are the appearance of a persistent smell of gasoline in the car interior and difficulties that arise during draining the fuel. For repairs, it is necessary to remove the adsorber and disassemble it. Since the device is usually solid, for disassembly you will need to cut off the cover.

This can be easily done with a regular file. After repair work has been carried out and replacement of the main parts, the cover is usually simply sealed. For complete sealing, the seams are treated with resin. The resin dries within 12 hours. After this, it can be lightly sanded to bring the filter into proper shape.

Spent and unusable coal is poured out of the adsorber. Foam rubber is suitable as intermediate filters. Remove the old filters and replace them with new ones, prepared in advance. Some craftsmen believe that foam rubber is not particularly effective and will allow all the dirt and coal to pass through, so filters can be made from felt.

When the dry coal is filled in, felt filters are installed again. All the plates and springs are put in place, and then the filter itself. As can be seen from the above, it is not difficult to diagnose and repair the Kalina absorber valve; you can do it yourself. Good luck!

Main malfunctions of the adsorber

The adsorber is not “immortal” and can also fail. At the same time, a breakdown can be determined only by a number of indirect signs.

For example, a malfunction of the adsorber may be indicated by excessive pressure in the car tank. It’s easy to explain - the vapors accumulate, but there is simply nowhere for them to go. The malfunction manifests itself with hissing sounds when unscrewing the lid.

The second indicator of a breakdown is the floating speed of the car at idle. This phenomenon happens less frequently and there are many more reasons than just a malfunction of the adsorber, but you still shouldn’t lose sight of it.

In the cases mentioned above, the best solution is to simply replace the old device and install a new adsorber. Moreover, it will take no more than 10-15 minutes to complete the work.

Many people do not know where the adsorber is located. But here everything is simple. Open the hood and look for a small cylinder-shaped device located in the lower left corner of the engine compartment.

The adsorber is only a seemingly insignificant element of your car. In fact, it performs important functions and can save your personal budget.

Therefore, if there is a malfunction, do not delay replacing the adsorber valve or the device itself. Have a good trip and of course no breakdowns.

It seemed like such an inconspicuous element, which at first glance is not important for the car, but without which it cannot work properly. Dips appear, the engine “troubles” and the gas tank may even collapse! And all this is due to a faulty adsorber valve

Many people don’t know what it is, how it works and MOST IMPORTANTLY what it affects. Today I will try to put everything into simple terms and describe the main symptoms of a malfunction. It will definitely be useful, so read and watch...

It will definitely be useful, so read and watch...

First, let's start with a definition.

Adsorber (from Latin sorbeo - absorb)

- This is a car system that serves to capture gasoline vapors that come out of the tank. When the engine is running, they are sent to the fuel injection system, namely to. When the engine is turned off, some of the vapors are captured by the separator (it directs them back to the tank), and the remaining vapors enter the adsorber, where they are neutralized.

Why do you need a fuel vapor recovery system?

An adsorber is a small part in a car designed to collect all gasoline vapors. The system allows fuel vapors to accumulate in a specially designed place called a separator, converting them into condensate and releasing them into the gas tank.

Valve on car

Untreated gasoline vapors pass through double system valves. The first valve is gravity and serves to protect fuel from leaking out of the gas tank during an emergency vehicle rollover. The second valve regulates the pressure created in the fuel tank.

Passing through the entire fuel system, gasoline vapors reach the adsorbing chamber and are absorbed by the activated carbon contained in it. When the engine starts, the purge valve starts to operate. If it is faulty, this may result in a loss of power from the power unit and increased fuel consumption.

The adsorber purge valve is installed inside the device filled with activated carbon. The device itself is located on the gas tank. The purge system is designed to ensure that everything functions correctly and without interruption. Ventilation and condensate removal are the main purpose of this electromechanical unit.

A slight chirping sound when the Kalina engine is turned on in cold weather or at idle speed means the canister purge valve is operating. To distinguish this noise from the sound of a faulty timing belt or rollers, you just need to sharply press the gas pedal - the chattering noise should not disappear or change. If this happens, then the cause of the noise needs to be looked for elsewhere.

Injection vehicles (including Kalina), whose environmental class belongs to Euro-3, must be equipped with an EPS. This prevents fuel vapors from entering the atmosphere, polluting it. In addition, the system guarantees more stable operation of the power plant and saves gasoline. How to check the adsorber valve included in the SUBS and how it functions will be discussed further.

The adsorber itself allows fuel vapors to accumulate in a special place - the separator. As a result, gasoline turns into condensate and goes back to the tank. Vapors that have not undergone treatment go through double valves of the system, one of which prevents fuel from spilling out during an emergency (for example, a coup), and the second “is engaged” in regulating the pressure in the tank.

The KPA is an electromagnetic locking device that operates from the vehicle’s on-board network. The valve consists of:

- plastic case;

- valve with spring;

- windings;

- metal core;

- connector

When the vehicle's engine is turned off, no voltage is supplied to the valve and it remains in the closed position. That is, on the motor side, the system that captures vapors is blocked. At the same time, the adsorber begins to “collect” vapors. When the power unit starts, voltage is applied to the valve, causing it to open and fuel vapors to enter the intake manifold. As soon as the ignition is turned off, the control unit is de-energized and the pipeline is closed: no vapors enter the receiver.

Cars of a high price category have a more complex evaporation system. Such machines have special sensors that can “calculate” the amount of air and vapor as a percentage. This allows you to more accurately control the supply of gasoline to the injector.

Gasoline belongs to the category of highly volatile hydrocarbons, and its vapors are highly volatile. While the engine is running, the gasoline in the tank heats up, at least a little. In addition, it sways while moving. These processes accelerate the evaporation of fuel, creating increased pressure in the container.

The introduction of a gasoline vapor recovery system made it possible to solve both of these problems simultaneously. With it, fumes are not wasted into the environment, but are used for their intended purpose, i.e. to ensure engine operation.

The management system in Kalina consists of the following elements:

- fuel outlet and return lines;

- separator;

- adsorber;

- canister purge valve.

As you can see, the system is quite simple. Let's consider the purpose of each of its elements separately.

As for fuel lines, these are simply tubes through which gasoline vapors leave the tank, and also through which fuel returns back to it. The separator is used to collect fuel vapors and condense them. The adsorber is designed to capture those vapors that did not have time to turn into a liquid state. The adsorber purge valve (“Kalina”) is necessary to direct gasoline vapors to the intake manifold receiver.

Fuel vapor rises and concentrates at the top of the tank. When the pressure in the tank rises, vapors enter the fuel line and from there into the separator. There the process of cooling and condensation occurs. Some of the vapor settles on the walls of the separator, turns back into a liquid state and returns through the return fuel line to the tank.

When we try to start the engine, the solenoid valve for purge the adsorber (“Kalina”) comes into operation. The signal to open it is supplied from the electronic engine control unit. At the moment of startup, the valve opens and gasoline vapors are supplied through the pipeline into the intake manifold receiver. Thus, fumes, which no one had even taken into account before, help save fuel and also do not pollute the environment.

To control the amount of fuel vapor entering the combustion chamber, a special purge valve is installed on each car model with an injection-type engine, usually in the area of the gas tank. In general, an adsorber is a system consisting of several valves, each of which is responsible for certain parameters.

As for the adsorber for the Lada Kalina model, if this mechanism malfunctions, the car’s fuel consumption increases and the power level decreases significantly. However, recently experts have disagreed as to how exactly a malfunction of the adsorber affects the behavior of the engine and the car.

Components

In fact, this is a large plastic jar with activated carbon inside, because it is this composition that perfectly fights gasoline vapors. The main parts can be described as follows:

- Separator + gravity valve

- Pressure meter

- Filter part (usually carbon)

- Connecting tubes

- Solenoid valve

As you can see, there is absolutely nothing complicated. Separator - serves to catch part of the gasoline, then sends it back to the tank. Gravity valve - almost never used, but it is needed in emergency situations, for example during accidents, it prevents fuel from overflowing from the tank (for example, when a car overturns).

The pressure sensor is a very necessary thing - it monitors the pressure of gasoline vapors inside the tank, if necessary, it opens and resets it, preventing the structure from being damaged.

Similar articles

How to dry the valves of a VAZ 2112 16 valves

The filter part is, as I wrote above, a large jar into which coal powder is poured, in fairly large granules. This is done so that vapors can pass and condense freely.

Connecting tubes are needed to connect all the main parts, filters, sensors and valves, I think this is clear.

Solenoid valve - used to switch modes for capturing gasoline vapors, we will talk about it in more detail below.

Principle of operation

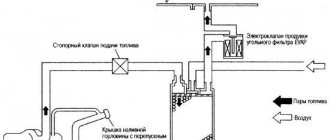

Engine power supply system diagram: 1 - separator; 2 - filling pipe; 3 — hose for supplying fuel vapor from the tank to the separator; 4 — pipe for removing fuel vapors from the separator to the adsorber; 5 — ventilation tube; 6 — ventilation tube hose; 7 — filling pipe hose; 8 — fuel tank; 9 - tee; 10 - adsorber;

11 — fuel supply tube to the fuel rail; 12 — tube for supplying fuel vapor to the solenoid valve for purge the adsorber; 13 — solenoid valve for purge of the adsorber; 14 — fuel rail with injectors; 15 — throttle assembly; 16 — fuel supply hose to the tee; 17 — fuel filter; 18 — fuel supply hose to the fuel filter; 19 - fuel module.

Fuel is supplied from a tank installed under the bottom in the rear seat area. The fuel tank consists of two stamped steel parts welded together. The filling pipe is connected to the tank with a gas-resistant rubber hose. A ventilation tube is welded into the upper part of the filling pipe, connected to the tank with a plastic hose.

Fuel module The fuel module, including the fuel pump, fuel pressure regulator and fuel level sensor, is installed in the fuel tank. For rough fuel cleaning, there is a strainer at the module inlet.

Fuel level indicator sensor The fuel level indicator sensor controls the operation of the dial gauge and signaling device located in the instrument cluster.

Fuel pump Fuel pump - electric, submersible, rotary. The fuel pump is turned on by a command from the electronic control unit (controller) when the ignition is turned on, through a relay. The pump creates a pressure in the system that exceeds the operating pressure in the fuel rail

Fuel filter From the pump, fuel is supplied under pressure to the fuel filter. The fine fuel filter is non-separable, with a paper filter element. The filter is mounted on the fuel tank bracket, on the right. There is an arrow on the filter housing that must coincide with the direction of fuel movement.

Fuel pressure regulator with o-rings After the filter, a tee is built into the fuel delivery line, through which fuel is supplied to the fuel rail and the fuel pressure regulator located in the fuel module. The fuel pressure regulator is a valve that opens when the fuel pressure in the line exceeds, releasing part of the fuel into the tank. The pressure regulator is non-separable and must be replaced if it fails.

Fuel rail The fuel pressure in the fuel rail with the ignition on and the engine not running should be between 3.6 and 4.0 bar. The fuel rail is a tube with injectors installed on it. The ramp is attached to the inlet pipe with two screws. Fuel under pressure is supplied to the internal cavity of the ramp, and from there through nozzles into the intake pipe.

Injector with O-rings The injector is an electromagnetic valve that allows fuel to pass through when voltage is applied to it and is closed by the action of a return spring when there is no power. At the injector outlet there is a sprayer through which fuel is injected into the intake tract.

Elements of air supply to the throttle assembly: 1 - air intake; 2 — air filter; 3 — mass air flow sensor housing; 4 — air supply hose to the throttle assembly; 5 - hose of the main crankcase ventilation circuit. Air is supplied to the engine throttle assembly through the air intake, air filter and corrugated rubber hose.

Throttle assembly The throttle assembly is a throttle body (with channels made in it), on which the idle speed regulator and throttle position sensor are installed. The throttle assembly is mounted on the intake pipe. To avoid freezing of the throttle assembly at low temperatures and high ambient humidity, a heating unit is built into the assembly, through which the cooling system fluid circulates.

Idle air control (IAC). When the engine is idling (throttle valve closed), the controller controls the air supply using the idle air control (IAC). The idle air control is a stepper motor that moves the valve. The valve shut-off element (needle) changes the flow area of the channel and provides regulation of air flow bypassing the throttle valve.

When braking the engine, the throttle valve closes abruptly. In this case, the IAC increases the air supply bypassing the throttle valve, resulting in a leaner fuel mixture. This helps reduce hydrocarbon and carbon monoxide emissions. The idle air control is non-separable and must be replaced if it fails.

Separator The separator is installed in the right rear wheel arch. Fuel vapor from the tank is partially condensed in a separator, from which the condensate is drained back into the tank through a hose and filling pipe. The separator is equipped with a gravity valve that prevents fuel from leaking out of the tank when the vehicle rolls over.

From the separator, fuel vapors enter the adsorber (installed on the top of the fuel tank, on the left side) through a fitting labeled “TANK”, where they are absorbed by activated carbon. The second canister fitting with the inscription “PURGE” is connected through the solenoid valve for purge of the canister with the throttle assembly, and the third with the inscription “AIR” is connected to the atmosphere.

Canister The solenoid valve for purge the canister is installed on a bracket fixed to the air filter housing.

Canister purge solenoid valve When the engine is stopped, the purge solenoid valve is closed, and in this case the canister does not communicate with the throttle assembly. The controller, by controlling the solenoid valve, purges the canister after the engine has operated for a specified period of time from the moment it switches to the closed-loop fuel control mode (the control oxygen sensor must be warmed up to the required temperature).

The valve connects the adsorber cavity with the throttle assembly - and the sorbent is purged: fuel vapors are mixed with air and discharged through the throttle assembly into the intake tract and further into the engine cylinders. The greater the engine's air consumption, the longer the duration of the controller's control pulses and the more intense the purge.

Valve on car

What is the adsorber purge valve on Kalina?

Injection system on Kalina

The system that serves in the Kalina car to capture fuel vapors prevents their unplanned leakage into the atmosphere. These vapors are formed due to heating of the fuel in the gas tank, as well as when atmospheric pressure decreases. The vapors do not escape, but accumulate in the system; when the engine starts, they enter the intake manifold and burn in the power unit.

The system includes a special adsorbing mechanism consisting of technical activated carbon, a special valve with an electric-magnetic pulse and functional pipelines suitable for it.

The entire system is based on a so-called adsorber, which is capable of collecting all the fumes from the gas tank. Small granules of technical activated carbon, which are part of the absorbent part, absorb gasoline vapors and retain them inside.

The only tool you need for this procedure is a Phillips screwdriver. The work will not take much time and effort and can be done independently in a garage. First, you should disconnect the negative terminal of the battery and remove the power plug of the piston compressor (KPA).

In a Lada Kalina car, access to the valve is slightly difficult, so you will need to slightly loosen the clamp from the inlet pipe and remove it from the mass air flow sensor. Move everything unnecessary to the side so that it does not interfere with work, and secure it during repairs.

Replacing a valve on a car

If the mass air flow sensor interferes greatly, it can be dismantled, but it is better to simply move the valve mount to the side a little and remove it without any problems. The fastener must be bent a maximum of 1 cm and, with some effort, pull the valve up in the direction of the grooves. If everything is done correctly, the part will be removed quite easily and quickly.

Finally, it is necessary to disconnect the fittings from the system. One of them can be removed easily and without problems, but the second one will have to be tinkered with, since it is secured with a special latch. To release the second fitting from the grooves, you need to press slightly on the latch and use a suitable sharp object to pry the antennae, slightly moving the fitting to the side.

How to check the adsorber valve? Attach a regular medical syringe with the piston extended a short distance (2-3 cm) to the outlet fitting. To make connection more convenient, you can use a vacuum supply hose. Press the plunger of the syringe. If there is pressure in the valve, the syringe plunger will be difficult to press and tend to return to its original position.

Then you should connect a source of direct electric current with a voltage of 12 V to the valve and repeat the procedure with the syringe. In this case, the pressure inside should disappear, the valve will now open, and the syringe piston will easily move all the way down. If this does not happen, the valve must be replaced.

The gas tank of any car always contains vapors formed due to a decrease in atmospheric pressure or heating of the fuel. In order to prevent the leakage of fuel vapors into the vehicle, a special gasoline vapor recovery system (VPSU) is installed. Thanks to it, the vapors retained by the adsorber (essentially activated carbon) enter the intake manifold and burn in the engine cylinders. To regulate the amount of gasoline vapor coming from the adsorber to the manifold, a special solenoid valve is used.

All modern cars with automatic fuel injection, including the Lada Kalina, are equipped with a gasoline vapor recovery system (VAP). This is a mandatory requirement for cars whose environmental class starts from Euro 3. The system is designed primarily to prevent fuel vapors from entering the atmosphere, but in addition it allows you to maintain stable engine operation and also save fuel.

One of the main components of the SUPS is the canister purge valve. What this element is, how it works and what it is intended for, we will discuss in this article. In addition, we will look at the signs of valve malfunction, the reasons for failure, and also describe the process of replacing it using the example of a Lada Kalina car.

In fact, the adsorber purge valve (“Kalina”) is a conventional shut-off device driven by a conventional electromagnet. It consists of:

- plastic case;

- electrical connector;

- spring-loaded valve;

- electromagnetic winding;

- magnetic core.

Unlike fuel-injected cars of the Samara family, the Kalina adsorber is not located in the engine compartment, but next to the gas tank. It is impossible to get to it without removing the fuel tank. But the purge valve is located under the hood. It is mounted on the radiator frame and access to it is always free. You can easily find it, recognizing it by two tubes through which, in fact, gasoline vapors move.

How to repair a problem

When talking about repairing the adsorber, the fault should be clearly identified. For example, if we are talking about the Grant adsorber purge valve, the malfunction of which can be indexed by the lack of high-quality gas removal, a new VAZ adsorber purge valve can be a solution to the problem.

The repair of the adsorber valve itself comes down to using a Phillips screwdriver and its application. The procedure for influencing the Lada Granta adsorber sensor:

1) We remove the terminals so that there are no disastrous consequences.

2) Apply physical force and gently remove the valve.

3) We compare the new valve and the old one, because anything can happen in life. Buying an adsorber valve, of course, is a simple thing, but there are mistakes made by sellers/storekeepers who may mistakenly sell an unnecessary spare part.

New Lada: Tire pressure in winter for Lada Vesta, Grant, Priora. VAZ 2114/VAZ 2110

4) We insert a new valve, assemble this system, return the terminals to their place and enjoy life. The Grant adsorber purge valve, the price of which is almost equally low throughout the Grant sales area, is also a reason for a small, but still joy.

It is impossible in the course of the story about the adsorber not to mention the fact that a huge number of Lada Grant owners prefer to remove this device. There are two reasons for this action:

– lack of desire to repair

– lack of faith in the possible environmental benefits of installing this device in your car

Signs of a malfunction of the control unit

The work of dismantling a faulty valve and installing a new one is not difficult. To do this, you will need a Phillips screwdriver and the information you will learn in this article. In the case of the Lada Kalina car, “getting” the adsorber valve will be a little more difficult than in other models, but again, there is nothing complicated.

You must first remove the negative terminal from the battery, then loosen the fastening and try to remove the valve, applying a certain force. To finally remove the valve from the mount, it is also necessary to remove the fittings that are located under the latch. Then it is imperative to check the markings of the removed and new purge valve so that they match. If everything is done correctly, you need to do the same work in reverse order, and the new valve will fit into place without any problems.

In addition, on the Lada Kalina model you can independently carry out not only diagnostics, but also repair of the adsorber, but for this you need to have certain knowledge. It is better to entrust this to specialists, especially since the price of such work will be relatively low.

First, start the engine: at idle or in cold weather, you will hear a characteristic, barely audible chirping sound. It indicates that the valve is working properly. In order not to confuse this sound with the noise from a working timing belt, sharply press the gas. The character of the chatter should not change. The following signs indicate a malfunction of the control unit:

- lighting of the CHECK signal on the instrument panel;

- determination of error PO441 during testing;

- increased gasoline consumption;

- unstable operation of the power unit when driving;

- unstable idle;

- increase in CO2 content;

- a hissing sound when unscrewing the tank lid (a vacuum has appeared);

- the appearance of a fuel smell in the cabin.

Remove the negative terminal from the battery. If the mass air flow sensor (mass air flow sensor) interferes, remove the inlet pipe from it. Then bend the valve mount and pull it up. Now you need to disconnect a couple of fittings. The first one can be removed freely; to pull out the second one, press the latch and pry up the antennae, for example, with a thin screwdriver.

You need to take a medical syringe of suitable volume, simply pull out the piston 2-3 cm and connect it to the outlet fitting. If you press on the piston, it will move with difficulty, which indicates that there is pressure in the valve. Now connect the battery to the electrical part of the control unit and press the piston again: the resistance should disappear. If this does not happen, you will have to buy a new valve.

The adsorber purge valve (Lada Kalina), like any other electromechanical part, can fail. Signs of its malfunction are:

- the appearance of the message CHECK on the dashboard (during testing, an error code P0441 is detected, corresponding to a malfunction of the gasoline vapor recovery system);

- floating engine speed at idle;

- unstable engine operation while driving;

- increased fuel consumption;

- increase in CO2 level in exhaust gases.

In addition, in Lada Kalina cars, a malfunction of the canister purge valve can manifest itself in the appearance of a characteristic smell of gasoline in the cabin. This phenomenon occurs when the pressure in the vapor recovery system exceeds design values.

Diagnosing the valve is not difficult, but you need to know where to look for it.

EGR system malfunctions

Diagnosing problems with the described system is not as simple a task as it might seem at first glance. The trouble is that there are no pronounced symptoms characteristic of EGR problems. The engine seems to be running rough, it seems to be malfunctioning, but it doesn’t seem to be. And only a professional can suspect the exhaust gas recirculation system of such unstable engine operation. But before that, various sensors, components and systems of the car are checked. Actually, what problems may arise here:

- deposits of soot and other elements on the parts of the EGR valve, leading to it jamming in any position;

- burnout of the EGR valve;

- clogging of the USR line itself;

- violation of electronic control systems for the USR valve;

If a valve or line is simply clogged, cleaning them, in general, is not difficult, although in some cases such cleaning is simply impossible. Well, if the valve burns out, then you will have to change it, and this, as already mentioned, is by no means cheap.

There are virtually no symptoms specific to problems with the EGR valve. This is, for example, unstable engine operation at idle speed, unmotivated dips in power, lack of pronounced acceleration when the throttle valve is fully opened, and other signs of disturbances in engine operation.

One way or another, do not rush to change the EGR valve or turn it off if there is no obvious damage to the valve and its parts. Perhaps the problem here is not entirely in the USR, because this system is closely interconnected with other components and systems for regulating air supply and exhaust gas removal.

Valve check

1. Disconnect the block with wires and visually check the condition of the contacts. If oxides are detected on them, we treat the terminals with a means for cleaning and protecting electrical contacts.

2. Remove the adsorber valve. We measure the resistance of the valve winding with a multimeter, which should be within 20-30 Ohms. The canister valve should be replaced if a short circuit or break is detected in the valve winding.

3. To avoid short circuit, one terminal of the valve should be insulated with PVC pipe. We supply 12 V from the battery to the valve terminals. At this moment, the valve terminals should open with a characteristic click. We repeat the test, creating a vacuum in the valve with a rubber bulb.

You will need a tester (voltmeter, multimeter) and a screwdriver. The KPA itself is installed on the radiator frame. The device can be recognized by seeing two tubes approaching it, through which the evaporation moves. Further:

- disconnect the electrical connector from the control unit by releasing the block lock;

- using a multimeter, check for the presence of voltage by touching the negative (black) probe of the device to ground, and the red probe to “A” (the letter on the block connector);

- turn on the ignition: the multimeter should show the vehicle's on-board voltage. If not, check the wiring.

If you suspect that the device is out of order, rush to diagnose it and, if necessary, replace it. No, its failure does not have critical consequences. The car has driven and will continue to drive, it’s just that the engine will work in emergency mode, and it will consume more fuel. But how to check the canister purge valve on Kalina on your own?

This process will not take much time. And all you need in terms of tools is a multimeter, a screwdriver and a pair of wires. We lift the hood and find the valve. Next, disconnect the wiring harness from it. To do this, release the block fastening clamp. First of all, let's check whether voltage is supplied to the valve. Turn on the multimeter in voltmeter mode.

We connect its black probe to the ground of the car, and the red one to connector “A” on the wiring harness block. Turn on the ignition and look at the instrument readings. The voltage at the terminals must match the battery voltage. If it is not there at all, or it is much smaller, the problem is not in the valve, but much deeper.

If the voltage is okay, we move on. Remove the purge valve. To do this, use a screwdriver to loosen the fastenings of the hose clamps and remove them from the fittings. Slide the valve up the bracket and remove it.

Testing the device involves connecting it directly to the battery terminals. We take one wire and connect it to the positive terminal of the purge valve. We connect the second wire to the negative wire and connect both wires to the corresponding battery terminals. At this moment, a click should be heard, indicating that the electromagnet has worked. In this case, the adsorber purge valve can be considered working. If nothing happened when connecting, the device will have to be changed.

Additional features

Of course, initially, created to create environmentally friendly engine operation, the Lada Granta adsorber, the price of which is insignificant, was underestimated.

Manufacturers tried with all sorts of tricks to circumvent this newfangled trend, but the law obliged all car manufacturers who did not comply with this innovation to pay heavy fines. Although AvtoVAZ has never been known for its large exports, it was forced to take measures to install an adsorber, since it has a small, but still a sales market. Today, the adsorber is installed on the Lada Granta without fail, since world research has revealed the following capabilities of this component:

– reduction in gasoline consumption

A similar result is achieved because the adsorber valve allows gases to be driven back into the gas tank, from where they enter the engine, which, when warm, is capable of processing them. If this device is missing, or the canister valve itself does not work, Granta loses fuel, which significantly increases consumption.

– normalization of exhaust system operation

Thanks to filtration, the likelihood of premature wear of the system and its components disappears.