Many car owners may be interested in the question of how to check the adsorber and its purge valve when the diagnostics showed it to be faulty (an absorber error popped up). It is quite possible to make such a diagnosis in a garage, however, for this it will be necessary to dismantle either the entire adsorber or only its valve. And to carry out such a test, you will need metalworking tools, a multifunctional multimeter (to measure the insulation value and the “continuity” of the wires), a pump, and a 12 V power source (or a similar battery).

What is an adsorber for?

Before moving on to the question of how to check the operation of the adsorber, let us briefly describe the operation of the gasoline vapor recovery system (in English called Evaporative Emission Control - EVAP). This will give a clearer picture of the functions of both the adsorber and its valve. So, as the name implies, the EVAP system is designed to capture gasoline vapors and prevent them from entering the surrounding air unburned. Vapors are formed in the fuel tank when gasoline is heated (most often during long-term parking under the scorching sun in the warm season) or when atmospheric pressure decreases (very rarely). The task of the fuel vapor recovery system is to return these same vapors to the engine intake manifold and burn them along with the air-fuel mixture. As a rule, such a system is installed on all modern gasoline engines in accordance with the Euro-3 environmental standard (adopted by the European Union in 1999).

The EVAP system consists of the following elements:

- carbon adsorber;

- adsorber purge solenoid valve;

- connecting pipelines.

There are also additional wiring harnesses leading from the electronic engine control unit (ECU) to the said valve. With their help, this device is controlled. As for the adsorber, it has three external connections:

- with the fuel tank (through this connection, the generated gasoline vapors directly enter the adsorber);

- with an intake manifold (it is used to purge the adsorber);

- with atmospheric air through the fuel filter or a separate valve at its inlet (provides the pressure drop necessary to purge the adsorber).

The adsorber is a kind of barrel (or similar vessel) that is filled with ground coal, in which gasoline vapors actually condense, after which they are sent to the car's power system as a result of purging. Long and proper operation of the adsorber is possible only with its regular and sufficient ventilation. Accordingly, checking the car adsorber is to check its integrity (since the body may rust) and the ability to condense gasoline vapors. Even older adsorbers pass the carbon contained in them through their system, which clogs both the system and their purge valve.

The solenoid valve for purge the adsorber directly purges the system from gasoline vapors present in it. This is done by opening it upon command from the ECU, that is, the valve is an actuator. It is located in the pipeline between the adsorber and the intake manifold.

As for checking the adsorber valve, firstly, it is checked that it is not clogged with coal dust or other debris that can get into the fuel system when it is depressurized from the outside, as well as with coal from the adsorber. And secondly, its functionality is checked, that is, the ability to open and close on a command coming from the electronic engine control unit. Moreover, not only the presence of the commands themselves is checked, but also their meaning, which is expressed in the time during which the valve must be open or closed.

Interestingly, in engines equipped with a turbocharger, a vacuum is not created in the intake manifold. Therefore, for the system to operate, it is provided with another two-way valve that operates and directs fuel vapor into the intake manifold (if there is no boost pressure) or to the compressor inlet (if there is boost pressure).

Please note that the canister solenoid valve is controlled by an electronic unit based on a large amount of information from temperature sensors, mass air flow, crankshaft position and others. In fact, the algorithms by which the corresponding programs are built are quite complex. It is important to know that the greater the engine air consumption, the longer the duration of the control pulses from the ECU to the valve and the stronger the canister purge.

That is, what is important is not the voltage supplied to the valve (it is standard and equal to the total voltage in the automotive electrical network), but its duration. There is such a thing as “adsorber purge duty cycle”. It is scalar and is measured from 0% to 100%. A zero threshold indicates that there is no purging at all, respectively, 100% means that the adsorber is purged as much as possible at a given time. However, in reality this value is always somewhere in the middle and depends on the operating conditions of the machine.

Also, the concept of duty cycle is interesting because it can be measured using special diagnostic programs on a computer. An example of such software is the Chevrolet Explorer or OpenDiag Mobile programs. The latter is perfect for checking the adsorber of domestic cars VAZ Priora, Kalina and other similar models. Please note that an additional scanner, such as an ELM 327, is required to use the mobile application.

How the system works

Fuel vapor rises and concentrates at the top of the tank. When the pressure in the tank rises, vapors enter the fuel line and from there into the separator. There the process of cooling and condensation occurs. Some of the vapor settles on the walls of the separator, turns back into a liquid state and returns through the return fuel line to the tank. The other part, which did not have time to condense, enters the adsorber. The device is a regular plastic jar filled with crushed activated carbon. Vapors accumulate in the adsorber until the engine starts.

When we try to start the engine, the solenoid valve for purge the adsorber (“Kalina”) comes into operation. The signal to open it is supplied from the electronic engine control unit. At the moment of startup, the valve opens and gasoline vapors are supplied through the pipeline into the intake manifold receiver. Thus, fumes, which no one had even taken into account before, help save fuel and also do not pollute the environment.

External signs of malfunction

Before checking the adsorber purge valve, as well as the adsorber itself, it will certainly be useful to find out what external signs accompany this fact. There are a number of indirect signs, which, however, can be caused by other reasons. However, when identifying them, it makes sense to also check the operation of the EVAP system, as well as its constituent elements.

- Unstable engine operation at idle speed (the speed “floats” to the point where the car starts and stalls, because it runs on a lean air-fuel mixture).

- A slight increase in fuel consumption, especially when the engine is running “hot”, that is, in a warm state and/or in hot summer weather.

- It is difficult to start a car engine when it is hot; it is usually impossible to start it the first time. And at the same time, the starter and other elements associated with starting are in working condition.

- When the engine operates at low speeds, the loss of power is very noticeable. And at higher speeds there is also a decrease in torque.

In some cases, it is noted that if the normal operation of the gasoline vapor recovery system is disrupted, the smell of fuel may enter the cabin. This is especially true when the front windows are open and/or when the car is parked for a long time in a closed box or garage with poor ventilation. Also, poor operation of the system is caused by depressurization of the fuel system, the appearance of small cracks in fuel lines, plugs, and so on.

Adsorber for Lada Kalina - repair without spoiling

An electromagnetic valve, called an adsorber, is present on every engine with injection type injection. However, few people realize why this detail is needed. The adsorber is designed to accumulate fuel vapors that are heated in the fuel tank. Thus, when the engine starts, it is the vapors accumulated by the adsorber that enter the manifold and combustion chamber, for which a special purge valve is responsible, which regulates the condensate and ventilates the system.

How to check the adsorber

Now let’s move directly to the algorithm for checking the adsorber (its other name is the fuel vapor accumulator). The main task in this case is to determine how sealed its body is and whether it allows fuel vapors to escape into the atmosphere. So, the check must be performed according to the following algorithm:

- Disconnect the negative terminal from the vehicle battery.

- First, disconnect all hoses and contacts going to it from the adsorber, and then remove the fuel vapor accumulator directly. This procedure will look different for different machines, depending on the location of the assembly, as well as the mounting means with which it was secured.

- It is necessary to plug (seal) the two fittings tightly. The first one goes directly to atmospheric air, the second one goes to the solenoid purge valve.

- After this, use a compressor or pump to apply a slight air pressure to the fitting going to the fuel tank. Don't overdo it with pressure! A working adsorber should not leak from the housing, that is, be sealed. If such leaks are detected, then most likely the unit needs to be replaced, since it is not always possible to repair it. In particular, this is especially true if the adsorber is made of plastic.

Why do you need an adsorber?

Starting with Euro-2, the fuel tank ventilation system was changed on VAZ models. On other cars things are pretty much the same. There are no problems with the supply of fuel to the tank (pipe or hole in the plug with a valve). Air can get in through the plug, but not back. There is a check valve, and when the pressure in the tank increases, it closes. Gasoline vapors do not escape.

When the pressure decreases, the valve opens and air flows calmly into the tank. If we look specifically at the Lada Vesta, there is a plastic tube next to the filler neck.

This is precisely the connection with the atmosphere; a check valve is installed there, through which air enters the tank. Removing vapors from the gas tank is more complicated. Gasoline evaporates constantly, regardless of whether the engine is running or not. Therefore, fuel vapor purification must occur constantly. For this purpose, they decided to use adsorbers on cars.

This is not an innovation or an invention. Such devices are widely used in industry. They are used for gas purification. We decided to purify fuel vapors using the same principle.

How to check the adsorber valve

If after checking it turns out that the adsorber is in more or less working condition, then it makes sense to check its purge solenoid valve. It’s worth mentioning right away that for some machines, due to their design, some actions will differ, some of them will be present or absent, but in general the verification logic will always remain the same. So, to check the adsorber valve, you must perform the following steps:

- Visually check the integrity of the rubber hoses included in the fuel vapor recovery system, in particular those directly approaching the valve. They must be intact and ensure the tightness of the system.

- Disconnect the negative terminal from the battery. This is done to prevent false alarms of the system diagnostics and to enter information about the corresponding errors into the electronic control unit.

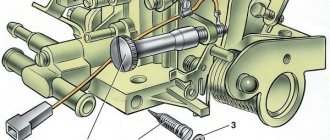

- Remove the absorber (usually it is located on the right side of the engine, in the area where the air system elements are installed, in particular the air filter).

- Turn off the electrical power to the valve itself. This is done by removing the electrical connector (the so-called “chip”) from it.

- Disconnect the inlet and outlet air hoses from the valve.

- Using a pump or medical bulb, you must try to blow air into the system through the valve (into the holes for the hoses). It is important to ensure the tightness of the air supply. To do this, you can use clamps or a thick rubber tube.

- If everything is in order with the valve, it will be closed and air will not be blown through. Otherwise, its mechanical part will fail. You can try to restore it, but this is not always possible.

- It is necessary to supply electric current from the power supply or battery using wires to the valve contacts. At the moment the circuit closes, you should hear a characteristic click, which signals that the valve has actuated and opened. If this does not happen, then perhaps instead of a mechanical failure there is an electrical failure, in particular, its electromagnetic coil has burned out.

- With the valve connected to an electric current source, you must try to blow air into it in the manner described above. If it is working properly, and therefore open, then this should work without problems. If it is not possible to pump through air, then the valve has failed.

- Next, you need to reset the power from the valve, and there will be a click again, indicating that the valve has closed. If this happens, it means the valve is working.

You can also check the adsorber valve using a multifunctional multimeter, switched to ohmmeter mode - a device for measuring the insulation resistance value of the electromagnetic winding of the valve. The probes of the device must be placed at the coil terminals (the places where the wires coming from the electronic control unit are connected to it; there are various design solutions), and the insulation resistance between them must be checked. For a normal, serviceable valve, this value should be within approximately 10...30 Ohms or differ slightly from this range. If the resistance value is small, it means that there is a breakdown of the electromagnetic coil (short interturn circuit). If the resistance value is very large (calculated in kilo- and even mega-ohms), then the electromagnetic coil breaks. In both cases, the coil, and therefore the valve, will be unsuitable for use. If it is sealed into the housing, then the only way out of the situation will be to completely replace the valve with a new one.

Thus, in order to know how to check whether the adsorber valve is working properly, you need to dismantle it and check it in a garage. The main thing is to know where its electrical contacts are located, and also to perform a mechanical inspection of the device.

Lada 2110 PhiX Logbook Removing the adsorber on a VAZ 2110

Crankcase ventilation valve

Hi all! Today, I will tell you how to properly remove the adsorber on a VAZ 2110-12. First, a little background. It all started when one day I removed the locker from the rear left fender and saw frayed hoses clogged with dirt and some kind of container, which, as it turned out later, turned out to be a separator. Judging by the condition of the hoses, it was clear that the adsorber was not performing its function, but was just cracking the valve in vain. Even then, the first thoughts crept in about getting rid of this device. Recently, in connection with the transition to DBP, I had to switch to a sports engine management program, in which the adsorber is not involved. I still don’t understand whether the customizer considered it unnecessary to turn it on, or whether the firmware did not allow this, but one way or another, I decided to completely remove the adsorber from under the hood. The procedure for removing the adsorber is not complicated, but there are some aspects that you need to know.

First of all, we remove the adsorber itself, along with the two-way valve.

We turn off the hose that comes from the gas tank and move it to the side. We carefully wrap the connector that went to the adsorber valve to the wiring harness and hide it under the decorative cover of the internal combustion engine. There is no point in removing connectors and hoses, they do not interfere, and if necessary, you can return the adsorber back.

We remove the hose coming from the throttle completely and plug the hole in the throttle assembly. I did it a little differently, to the fitting to which the adsorber hose was connected, I connected the small crankcase ventilation circuit, and plugged the upper ventilation fitting, i.e. I did it essentially like I had before on the mass air flow sensor

An important point, since the hose coming from the tank is now plugged, a hole with a diameter of 1-2mm should be drilled in the gas tank cap. I removed the lid cylinder plug and drilled a hole under it. This does not interfere with the air flow, but will protect against excess dirt.

How to repair the adsorber and valve

It’s worth noting right away that in most cases both the adsorber and the valve cannot be repaired; accordingly, they need to be replaced with similar new units. However, as for the adsorber, in some cases, over time, the foam in its body rots, which is why the carbon contained in it clogs the pipelines and the solenoid valve of the EVAP system. Rotting of foam rubber occurs for banal reasons - from old age, constant temperature changes, exposure to moisture. You can try to replace the foam separator of the adsorber. However, this cannot be done with all units; some of them are non-separable.

If the adsorber body is rusted or rotten (usually also due to old age, temperature changes, constant exposure to moisture), then you can try to restore it, but it is better not to tempt fate and replace it with a new one.

Similar reasoning is valid for the solenoid valve of the gasoline vapor recovery system. Most of these units are non-separable. That is, the electromagnetic coil is sealed into its body, and if it fails (insulation breakdown or winding break), it will not be possible to replace it with a new one. Same with the return spring. If it has weakened over time, you can try to replace it with a new one, but this is not always possible. But despite this, it is still better to perform a detailed diagnosis of the adsorber and its valve in order to avoid expensive purchases and repairs.

Some car owners do not want to pay attention to the repair and restoration of the gasoline vapor recovery system, and simply “turn off” it. However, this approach is not rational. Firstly, this really affects the environment, and this is especially noticeable in large cities, which are not known for their clean environment anyway. Secondly, if the EVAP system does not work correctly or does not function at all, then under pressure gasoline vapors will periodically escape from under the gas tank cap. And this will happen as often as the temperature in the gas tank increases. This situation is dangerous for several reasons.

What is the threat?

Of course, you can continue to travel on roads with such a fault. The car will start to drive, but it will still have floating idle. In addition, if the malfunction of the adsorber is not corrected in time, then at the nearest gas station, when trying to fill the tank with gasoline, the cap can literally “shoot” from the gases that are formed, which are not removed in time. So it would be best to replace the defective part with a new one.

In addition, if the gas tank is poorly ventilated, this can lead to a vacuum. And as a result - deformation and damage to such an important spare part as the fuel pump. And an unventilated adsorber can also cause fuel accumulation in the intake manifold. And this can already affect the stability of the entire engine.

Purpose

This spare part was not always part of the car. We owe its appearance to modern requirements for the environmental performance of cars, and to be more precise, the Lada Granta acquired an adsorber thanks to Euro-3.

(Euro-3 is an environmental standard that was introduced in 1999, but Russian manufacturers were able to meet its requirements only in 2008.)

The adsorber, for which Granta became one of the first “shelters” in the domestic automotive market, is a spare part directly connected to the catalyst. It allows you to accumulate gasoline vapors to prevent them from entering the exhaust manifold.

Such actions allow you to preserve the catalyst and prevent its premature wear, since the combination of a cold catalyst with gasoline vapor is unacceptable. As soon as the engine warms up to the required temperature, the adsorber purge sensor is activated. The adsorber valve drives the vapors back into the gas tank.

What is an adsorber?

An adsorber is a device whose main purpose is adsorption. They are actively used in oil refining and some industrial sectors. In addition, these days adsorbers have found very wide application in vehicles equipped with internal combustion engines - they prevent gasoline vapors from entering the atmospheric air. Until recently, adsorbers were not part of automobile spare parts; their appearance was associated with stricter requirements for the environmental performance of vehicles.

These devices are equipped with injection systems; tubes connect them to the gas tank and throttle pipe. Switching operating modes is carried out by means of a valve; it closes when the engine is turned off, stopping contact between the device and atmospheric air. It is then that gasoline vapors enter the adsorber from the fuel tank, after which they are immediately absorbed.

When the engine starts, a special device that controls the injection system begins sending control pulses that initiate communication between the device and atmospheric air. The sorbent begins to be purged, and gasoline vapors enter the combustion chamber, where they are burned. The duration of control pulses and the intensity of sorbent blowing are directly dependent on the amount of air consumed by the motor.

The most important element of the described apparatus is the purge valve. The valves installed on the Lada Granta were inherited from the Lada Kalina, which makes possible malfunctions similar. Below we will look at problems that arise during the operation of the adsorber, as well as their symptoms and methods of elimination.

Additional features

Of course, initially, created to create environmentally friendly engine operation, the Lada Granta adsorber, the price of which is insignificant, was underestimated. Manufacturers tried with all sorts of tricks to circumvent this newfangled trend, but the law obliged all car manufacturers who did not comply with this innovation to pay heavy fines.

Although AvtoVAZ has never been known for its large exports, it was forced to take measures to install an adsorber, since it has a small, but still a sales market. Today, the adsorber is installed on the Lada Granta without fail, since world research has revealed the following capabilities of this component:

– reduction in gasoline consumption

A similar result is achieved because the adsorber valve allows gases to be driven back into the gas tank, from where they enter the engine, which, when warm, is capable of processing them. If this device is missing, or the canister valve itself does not work, Granta loses fuel, which significantly increases consumption.

– normalization of exhaust system operation

Thanks to filtration, the likelihood of premature wear of the system and its components disappears.

Valve - as the most important component of the device

Speaking about how the adsorber valve works, it is necessary to introduce the device itself. It is, roughly speaking, a can of coal, which is equipped with a valve that allows the vapor to condense and direct. The canister purge valve is controlled by the ECU, which sends a signal to open/close it.

Important. The adsorber solenoid valve can create certain troubles for the driver. In the cold season, when starting a cold engine, a certain sound similar to clicking may be heard. This sound is normal, since the valve may not work correctly when cold.

In order not to confuse this sound with possible breakdowns, it is necessary to apply gas control. If there are no changes, you can safely attribute the clicks to the absorber.

What does a vapor recovery system consist of?

The management system in Kalina consists of the following elements:

As you can see, the system is quite simple. Let's consider the purpose of each of its elements separately.

As for fuel lines, these are simply tubes through which gasoline vapors leave the tank, and also through which fuel returns back to it. The separator is used to collect fuel vapors and condense them. The adsorber is designed to capture those vapors that did not have time to turn into a liquid state. The adsorber purge valve (“Kalina”) is necessary to direct gasoline vapors to the intake manifold receiver.

Features of valve operation

The Grant canister purge valve itself was inherited from Kalina. Thus, the Kalina adsorber purge valve and the Lada Granta adsorber purge valve are completely identical. This allows us to assert that the signs of adsorber malfunction in both cars are identical.

If we take into account the Kalina adsorber purge solenoid valve, malfunctions and their symptoms can be completely attributed to a malfunction of the adsorber of its younger brother.

The canister valve is knocking, clicking or clicking

What can you do about it?:

1. Contact an authorized dealer with the problem. If the adsorber valve is truly faulty, it will be replaced under warranty. If they consider that such valve operation is the norm, then there is no point in writing in support of AVTOVAZ.

2. Advice from car enthusiasts (you lose your warranty!). There is an adjusting screw on the side of the valve, which is filled with glue. Remove the glue and turn the screw clockwise 90 degrees. After this, the adsorber valve no longer clicks in the cold.

3. Owners of LADA cars advise spraying silicone grease into the adsorber hole:

If you decide to buy a canister purge valve, then look for it by article number:

Have you encountered problems with the adsorber valve?

Source

How to understand a malfunction of the absorber

Speaking about the adsorber valve, the symptoms of a malfunction will be fairly standardized, which makes it possible to obtain a fairly detailed description. So, signs of a malfunctioning adsorber valve:

– Constant smell of gasoline in the cabin.

This fact is caused by improper circulation of gases, which may have a certain leakage. Due to the proximity of the system to the air filter, odors freely penetrate into the cabin.

Signs of a malfunction of the canister purge valve on the Grant include this sound, familiar to all Grant owners.

(to fix this, you can tighten the nut, or you can purchase a new one; fortunately, the Lada Granta adsorber valve, the price of which is low, is available for purchase)

– Increased fuel consumption.

An inoperative adsorber ventilation valve is not able to control the correct path of gases, which does not allow them to be processed in the form of combustion.

– The amount of harmful substances released through the system increases.

Speaking about how the canister purge valve works and why, do not forget that increasing the environmental performance of a car is a primary task, which can be disrupted if the canister purge solenoid valve does not function correctly.

- Sounds similar to some hissing.

Strong hissing in the adsorber hose, the cause of which is the accumulation of gases, is not uncommon. Since modern requirements for cars do not allow gas emissions while parked, a certain accumulation is acceptable.

– Characteristic sounds coming from the gas tank.

Speaking about the Lada Granta adsorber, the malfunction of which is always characterized by extraneous sounds coming from the gas tank, it must be said that they are the most typical sign of a breakdown. In this case, the adsorber sensor may not give any indicators of malfunction, therefore, it must also be replaced.

Thus, signs of a malfunction of the Lada Grant canister purge valve are quite easy to identify. In addition, they are detected when simply refueling the car, which necessarily requires opening the gas tank cap.

How to get rid of the noise of the Lada Vesta canister valve

On cars that do not comply with Euro 3 standards, fuel vapors accumulated in the fuel tank, and when the driver unscrewed the gas tank cap to add fuel, he heard a hissing sound - this is how accumulated fuel vapors escaped from the tank through the tubes. This phenomenon is impossible on the Lada Vesta.

However, car enthusiasts are concerned about the knocking of the Lada Vesta canister valve. The sound resembles the clattering sound of small metal parts colliding with each other. The dealer and the manufacturer do not always recognize the malfunction of this mechanism.

If you decide to replace the adsorber valve on Vesta in order to get rid of the annoying knocking noise, get ready to work with wires and buy new spare parts.

The purge valve for the Lada Vesta received catalog number 82-00-248-821, its cost starts from 470 rubles. It is connected to a special tube and an assembled throttle pipe (84-50-006-406, cost from 450 rubles), to a damper (82-00-584-324, cost from 230 rubles).

How to repair a problem

When talking about repairing the adsorber, the fault should be clearly identified. For example, if we are talking about the Grant adsorber purge valve, the malfunction of which can be indexed by the lack of high-quality gas removal, a new VAZ adsorber purge valve can be a solution to the problem.

The repair of the adsorber valve itself comes down to using a Phillips screwdriver and its application. The procedure for influencing the Lada Granta adsorber sensor:

1) We remove the terminals so that there are no disastrous consequences.

2) Apply physical force and gently remove the valve.

3) We compare the new valve and the old one, because anything can happen in life. Buying an adsorber valve, of course, is a simple thing, but there are mistakes made by sellers/storekeepers who may mistakenly sell an unnecessary spare part.

4) We insert a new valve, assemble this system, return the terminals to their place and enjoy life. The Grant adsorber purge valve, the price of which is almost equally low throughout the Grant sales area, is also a reason for a small, but still joy.

It is impossible in the course of the story about the adsorber not to mention the fact that a huge number of Lada Grant owners prefer to remove this device. There are two reasons for this action:

– lack of desire to repair

– lack of faith in the possible environmental benefits of installing this device in your car

Price policy

Speaking about the Grant adsorber purge valve, which can be purchased today in all large and not so large places for selling spare parts for the Russian auto industry, it is impossible not to note its pleasant price. The Grant adsorber valve, the price of which is equivalent to the probability of its failure, allows for independent replacement and is a simple mechanism.

Thus, maintaining the environmental standards of the Lada Granta is truly a man-made matter. The adsorber has become a part that, in addition to caring for the environment, can significantly reduce fuel consumption and improve the operation of exhaust gas removal.

Why the check light is on on Kalina 8 and 16 valves What to do and how to act

- Failure of the oxygen sensor. This element controls the operation of exhaust gases and informs about how much oxygen is not produced during the combustion of the fuel mixture. On Kalina, depending on the number of valves, from 2 to 4 oxygen sensors are installed. It’s not difficult to find out what’s wrong if you have a home scanner (if you have the opportunity to use a multi-brand scanner, that’s great). The main reason for the malfunction of the oxygen indicator is its contamination with oil waste;

- Problems with the sealing of the fuel tank. In this case, air enters the system, which is fraught with additional fuel consumption and interruptions in engine operation, as evidenced by the activation of the check indicator;

- Catalyst failure. A malfunction of the unit that controls the exhaust of harmful gases is one of the reasons why the check can burn for a long time on both 16 and 8 valve Kalina. It is quite possible that the incorrect operation of the element in question is due to a malfunction of the oxygen sensor;

- If the check light is on, you need to check the spark plugs. Failure to replace them in a timely manner or driving on bad fuel leads to the formation of soot and lack of spark. Identifying a problem with your spark plugs shouldn't be too difficult. If there is a noticeable increase in fuel consumption, problems starting the car, malfunction of the catalyst and the check light comes on, you should first check the spark plugs;

- Another reason for the Check Engine sensor to operate for a long time is the failure of the mass fuel consumption indicator, as a result of which the car consumes more gasoline.