The movement of vehicles with their headlights on during the daytime became the norm after the approval of amendments to the Russian Traffic Regulations of 2010. However, the lack of standard daytime running lights (DRLs) forces drivers to use other legally permitted car lights as backlight. These could be low beam headlights or fog lights (PTF).

What shortcomings have been identified among the permitted types of headlights over the past 6 years of the law? How to get rid of them without violating the provisions of the current traffic regulations?

Why is it undesirable to use low beam?

The name “Low Beam” indicates its intended purpose – illuminating the roadway in the dark directly in front of the car, without dazzling oncoming traffic. The decision to use it as navigation lights was a necessary measure that did not require redesign of the structure or additional capital investments. The result: we wanted the best (to increase the level of safety on the roads), but it turned out as always (the load on the car increased).

Unlike standard DRLs, which begin to glow when the engine is started, low beam headlights (FBS) must be remembered to be turned on and off. Forgot to turn it on - fine, forgot to turn it off - dead battery. In both cases, the consequences are not rosy. The luminous flux emitted by low beam headlights is mainly directed downwards, so as not to miss imperfections in the asphalt. At a relatively large distance between oncoming cars, the effect of such a glow is practically absent. It turns out that when driving at a speed of about 100 km/h, it is difficult for drivers to react in a timely manner to vehicles that are moving or overtaking in the oncoming lane and creating a potential emergency threat. This is perhaps the main disadvantage of using low beams instead of DRLs, requiring increased concentration from drivers.

In some brands of cars, not only the FBS, but also other lighting devices, for example, dashboard lighting, are powered from one switch. There is no benefit from this during the daytime, but additional energy and fuel consumption is provided. Traveling around the city with frequent downtime in traffic jams and traffic lights also has a negative impact. In such cases, the generator does not have time to replenish the battery with energy.

Regular use of low beam headlights during the daytime has a negative impact on the reliability of all elements of the electrical circuit: the service life of the lamps and battery is reduced. As a result, at night, when you simply cannot do without FBS, one of the lamps may simply fail.

Guide to implementing the DRL function on a car

It is quite possible to install such a system with your own hands in a garage.

Let's consider the process of implementing the scheme using the example of a VAZ 2110 car with Bosch optics:

- First of all, you will need a double-insulated wire; it must be pulled from the inside of the vehicle to the right headlight. The wire itself should be connected to pin 87 of the relay; in some modifications of the car it may be marked with the number 88.

- Then you need to open the cover of the main lighting module; it is located closer to the radiator device. The ground wire is removed; as a rule, it is black or brown in color, after which the cable is cut in the middle with a utility knife. The end of the wire that comes out of the headlight must be insulated with electrical tape. And the other end is cut in the center. Then, a wire must be soldered to the cable going to the high-distance lighting source, which is subsequently laid through the ventilation hole of the optics. It can be found on the back of the lamp, in the upper part, near the turn signal. It is advisable to lay the wire itself on the outside of the headlight, through the low beam hole, and you can use tweezers for installation. Make sure that the newly installed cable inside the optics does not come into contact with the base of the light source. It is this wire that will serve as ground for the high beam light bulb.

- Having completed these steps, the wire should be connected to the relay contact number 30.

- Next, relay contact number 85 is connected to the green cable in the high-beam headlight connector.

- Then the relay contacts numbered 86 and 87 should be connected to ground. The best option would be to lay a separate cable to the spar stud. This is where the mass of wires from the optics itself, the turning lights, and also the fog lights converge. To prevent oxidation, all connections should be insulated with a special heat-shrinkable tube, and for greater reliability, electrical tape can be used.

- The next step will be to connect the cable in the mounting block with safety devices in the cabin; in particular, you will need a fog optics connector. That is, you will use a control button, a relay, and also a safety element for the fog lights. If necessary, you can install a separate switch in a more convenient location, for example, on the center console.

- Now all you have to do is connect the power. Power is taken from the 12-volt terminal after the ignition switch, this wire is usually blue-red in color. This connection will allow daytime lighting to be activated when the ignition is turned on; accordingly, it will also turn off when the key is removed. The final step will be to install a five-amp fuse on this section of the circuit in any convenient location. This will protect the circuit from possible voltage surges (the author of the video is the SuperWIRUSS channel).

What's wrong with custom LED DRLs?

Despite the wide range of advantages, LED running lights (LED-DRL) are not without their disadvantages. For obvious reasons, Chinese manufacturers carefully hide the “other side of the coin”, trying to impose an advertised product on an inexperienced buyer for little money. Practice sometimes proves the complete lack of efficiency from cheap DRLs installed by yourself, which manifests itself as follows:

- the luminous intensity is significantly less than the minimum value established by the rules of 400 cd;

- the angle of propagation of the luminous flux does not meet the standards;

- poor build quality leads to failures and rapid failure of the DRLs.

Of course, you can buy high-quality DRLs with LEDs, pay for their connection and installation according to all the rules, and then enjoy the ride. However, the cost of a branded kit with installation services will amount to approximately 7 thousand rubles.

How to fix the problem?

If the LED lamp lights up when the light is off, how to fix it? There are different solutions. It all depends on the nature of the problem itself. For example:

- A cheap, low-quality LED lamp always glows in the dark after it is turned off. To eliminate this problem, it is necessary to replace it with quality products from a trusted manufacturer.

- If the lighting element is on because an illuminated switch is used, then this problem can be solved in different ways. For example, the easiest way out is to change the switch in the house to a regular one, without backlighting. You can simply cut off the specific wire that powers the backlight. This can be done after opening the switching device. But there is another way out - to preserve this function, it is enough to place a resistor in parallel on a certain section of the electrical circuit.

- If the LED light is on and the reason is in the wiring, then it will be extremely difficult to solve such a problem. To eliminate it, you need to find the location of the current leak. But this may entail certain difficulties. But when the light turns off, the bulbs will not light up. We talked about what malfunctions in electrical wiring can happen in a separate article. There is another way, simpler. When the lighting element is lit, it is necessary to connect a load (relay, incandescent lamp or resistor) in parallel with it. You just need to take into account the fact that the resistance in the connected load should be lower than in the light emitter. And as a result, the leakage current will flow to this load, but due to the fact that the resistance is insignificant, it will not light up.

Another effective way to eliminate the glow of LED bulbs is to add a capacitor to the circuit. This is explained in detail in the video tutorial:

A variety of methods can solve the problem of the glow of emitters with diodes so that they do not glow at full intensity when the switch is turned off. The main thing is to understand the root cause of the problem. We hope you now understand why the LED lamp glows after turning off and what to do to correct the situation!

It will be useful to read:

Source: samelectrik.ru

High beam at full intensity instead of DRL

There is another way to implement navigation lights that does not have the above disadvantages. Its essence lies in the use of high beam headlights, turned on at full intensity and used instead of DRLs. This method of inclusion has long been proposed by the Americans. However, this option has not become widespread in the European car market.

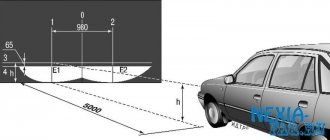

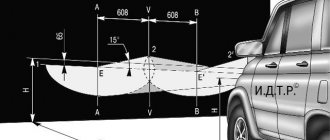

The essence of the method is to turn on two high-beam lamps in series, which leads to a twofold decrease in the voltage on them. Since the light bulb coil is a resistive load, the current decreases in proportion to the voltage. As a result, power consumption and light output are reduced by 4 times. Oddly enough, the effect from such DRLs is higher than from the low beam on. The light from them is softer and is directed at oncoming drivers.

Characteristics of DRL headlights

DRL lamp controller kit

Instead of daytime running lights, the driver can use DRL headlights; this development was invented by European specialists. In this case, the reflector uses a 12-watt halogen light source, very similar to an an-distance light. When installing such optics, the light flux will be directed not at the road surface, as with low beam lighting, but into the eyes of other motorists. But at the same time, it will not blind drivers, but will provide better visibility of the car on the road. If you are interested in this method, this function can be implemented using high beams, while the headlights will shine not at half, but only at a third of the power.

Principle of operation

How does high beam work at full intensity? When the driver turns on the high beams, the optics will glow rather dimly, but this is enough to identify their vehicle on the road. At the same time, the light will not blind other road users. Of course, for this you need to install a separate button. When this button is turned off, the optics will switch to high beam mode. It should be noted that this will not in any way affect the implementation of all long-range lighting functions (the author of the video is Vitaly Sussky).

Advantages and disadvantages

If you decide to use high beams at full intensity instead of DRLs, then if you implement the task correctly, you will be able to experience the following advantages:

- Firstly, you don’t have to buy LED optics separately and waste time installing them. Accordingly, if you don’t understand anything about electrics, you also save yourself from having to spend money on installing headlights.

- Secondly, with the correct implementation of the circuit, you can ensure that the load on the battery will be lower. Accordingly, the likelihood that an older battery will discharge faster is minimized. This advantage is especially important for car enthusiasts who use dead batteries in the cold season, when they discharge even faster.

- Thirdly, the service life of low-beam lighting sources becomes longer. So you save yourself from more frequent financial costs for purchasing lamps.

- In addition, when implementing a DRL system, the luminous flux will shine a little higher, accordingly, the vehicle will be more noticeable in the flow of cars.

- When this feature is enabled, the tail lights will not illuminate, so they will not be able to “mask” the brake lights. This not only improves driving safety, but also allows you to increase the service life of the rear lamps.

- Also, you will not encounter the problem of dimming the interior lighting. When the side lights are on and the sun is bright outside, it will be more difficult for the driver to see the radio screen.

- Some car enthusiasts note that with the right approach, you can even achieve a reduction in fuel consumption. This figure is small, only about 0.15 liters per hour. However, this benefit can only be achieved if the engine is running correctly and fuel consumption is not increased beyond normal.

As for the shortcomings, in principle, there are none. The only disadvantages include the installation and implementation of the scheme, which can cause difficulties. But this problem can also be solved by carefully reading the instructions or contacting specialists.

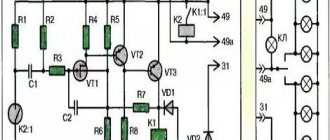

This is how the RHO-23 relay turned out:

The dimensions of the printed circuit board are only 20x38x8mm, which allows, after installation, to be sealed with hot-melt adhesive, packaged in heat-shrinkable tubing and secured to any wiring harness in the engine compartment with a cable tie.

What's new compared to its predecessor:

- Two in one: running lights relay and high beam headlight relay with smooth ignition in all modes

- Operating voltage range 10-32V. That is, you can easily install it on trucks with a 24V on-board network

- Two inputs for turning on the high beam at full brightness (active minus and active plus). RHO-23 can work as a high beam decoupling relay. On some cars, parallel connection of the radio control lights causes the high beam warning lamp on the dashboard to light up, which irritates most drivers. With RHO-23, this problem is solved easily and elegantly without additional snot.

- Full sleep mode when the ignition is turned off.

That is, when the ignition is turned off, it really does not consume anything - just 0 microamps. And it will never drain the battery when parked for a long time! We simply power the microprocessor from the ignition input, and the power part through the fuse from the battery positive. Those. Under no circumstances can it “accidentally” turn on when the ignition is turned off. - Like our predecessor, we have a mode for deactivating the running lights - to do this you need to blink the dimensions three times within two seconds. But unlike RHO-22, we DO NOT remember this state, and when the engine is stopped and then started, the DRL will turn on again. We have installed more than two hundred RHO-22 sets, and these clients periodically call me with complaints that “everything is broken.” But it turns out they simply deactivated the DRL mode, and in order to “fix” everything you need to blink the lights three times again.

- There are no adjustments in RHO-23; the optimal brightness is set at 40% from the factory. Less is difficult to see from afar, more is blinding even during the day.

The small dimensions of the board allow it to be placed directly in the mounting block. This is how elegantly we managed to install it into the electronics unit on the Pajero4 - it’s a gray box the size of a couple of packs of cigarettes installed inside the mounting block.

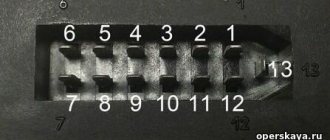

Assignment of contacts (pinout) RHO-23:

* – On Subaru Legacy and some other cars, it is necessary to connect (instead of one of the high beam lamps disconnected from the standard wiring) a 330-470 ohm resistor with a power of at least 0.5 W in order to remove the parasitic glow of the LED (high beam control) on the dashboard. The resistor will bypass the LED, which without it, due to some interference, glows barely noticeably, which misleads the car owner, who instinctively tries to “turn off” the distant one. Only relevant for LED lamps on the dashboard.

Installation and connection of DRL

Adhering to the placement diagram, it is quite possible to install running lights on a car with your own hands. The configuration of commercially produced models, as a rule, includes descriptions and parts for quick installation and connection to the machine’s on-board network. But with self-made daytime running lights you will have to tinker

Particular attention should be paid to the quality and correctness of the connection in order to avoid troubles with electrical wiring in the future.

As for ready-made assemblies, Philips LED DRLs have proven themselves well. They have the advantage of being easy to install, suitable for many brands of cars, have an impact-resistant body and a long service life.

Their only drawback is the price, which ranges from $60 to $100 per pair. To summarize, I would like to note that today daytime running lights on a car are a tandem consisting of practicality and safety. Thanks to their purpose, the car stands out from the general moving stream, and their light prevents potential accidents.

What to do and how to fix the problem

You can eliminate the causes of dim LED lighting yourself or, in some cases, by contacting an electrician.

The problem of poor wiring insulation can be solved by replacing it or re-insulating the damaged area. The location of poor-quality insulation is determined by special devices (homemade or purchased) in this way: within a minute, the maximum voltage is applied to the network and, with the help of special equipment, the location of the current leak is found. If you have no knowledge of electrical engineering, then it is better to trust a specialist.

Many manufacturers have begun to write on the packaging of LED lamps that their use is not recommended if there is a backlit switch. If there were no instructions on the packaging, you screwed the LED light bulb into the lamp, and it continues to glow faintly when turned off, you should try the following:

- replace the backlit switch with a regular one;

- remove the backlight (cut the wire that goes to the backlight bulb);

- Screw one incandescent lamp into the lamp, which will receive “extra” voltage. The value of this method is questionable, since it contradicts the idea of saving electricity;

- install an additional resistor with a resistance of 50 Ohms and a power of 2-4 W, which can be purchased at the store. Its connection is made parallel to the lamp in the ceiling lamp or in the socket, and the installation site is necessarily insulated with heat-shrinkable tubing. Thus, the voltage will not go to the LED light bulb, it will not light up after turning off, but the switch will remain illuminated.

LED lamps can burn when the switch is off due to the specificity of their design. Thus, the LED driver includes a capacitor capable of storing electricity. This design feature of LED light bulbs does not allow them to go out immediately after turning off, and they continue to glow faintly.

It is not recommended to purchase products from unknown manufacturers. They will not work correctly and will not last long and will burn after being turned off. In addition, a defective product can cause harm to the eyes due to flickering, white color temperature (instead of the declared warm light), etc.

If the electrical wiring is old, it must be replaced. In this situation, the best solution is to entrust the work to an electrician.

If the zero and phase are connected incorrectly, you need to reconnect: the phase to the switch, and the neutral wire to the light bulb.

The problem can be eliminated by purchasing a resistor made of special materials that prevent the accumulation of thermal energy.

Why does an LED lamp continue to burn dimly when the lights are off?

There are several reasons why an LED lamp continues to burn dimly even after being turned off, and there are several suggestions for eliminating them.

LEDs may burn dimly due to the poor condition of the wiring and its poor-quality insulation, incorrect connection of the lamps and their poor quality.

Poor quality insulation

If the wiring is old and the insulation is of poor quality, the LED lamp may burn dimly even when the light is turned off.

Poor-quality insulation allows current to pass, which is enough to make the LEDs glow weakly.

The difficulty in solving the problem of poor insulation is that you need to have special instruments to detect it. And if the wiring was installed in a hidden way, then you will need to open a section of the wall.

Illuminated switches

If your home has backlit switches, then when purchasing LED bulbs and strips you should pay attention to the instructions for their use. The packaging may indicate that this type of light bulb is not recommended for use with switches that have a backlight.

LEDs have a filter capacitor designed to smooth out the voltage. This device accumulates voltage inside itself, which “turns on” the LED light bulb.

When the light is on, all input voltage goes to the lamp. When the lights are turned off, the electrical circuit is open, but a small amount of current continues to flow to power the LED or neon light bulb in the backlight. The current, even such a small power, is enough to start the diodes, which begin to blink or glow dimly.

Tips for choosing LED lamps

When purchasing an LED cutter, it is recommended to pay attention to the following factors:

- Carefully read the instructions that come with the LED lamps. It specifies the rules for using the product.

- Some convenient lighting features are not easily compatible with LED bulbs. Timers, light intensity controllers, photovoltaic elements, and backlighting often cause failures in the normal operation of LEDs.

- Pay attention to the dimensions of the radiator. This element is responsible for removing a sufficient amount of thermal energy that is released when the light is on. The dimensions of the radiator and the power of the lamp must be consistent with each other.

- Radiator material. The best choice is an aluminum radiator. Ceramic and graphite products have proven themselves to be excellent.

- The quality of the joint between the light bulb body and the base. If there are obvious mechanical defects at the junction, the likelihood of problems with the lamp glowing when the switch is off increases. The base must be securely fixed to the body without play.

- Ripple level. The correct glow is uniform, without any flicker. However, it is quite difficult to notice irregularities in the light. This is where a mobile phone video camera comes in handy - it makes it much easier to spot flickering.

It is recommended to purchase products only from well-established manufacturers. A low price very often has a downside - insufficient product quality.

Source: 220.guru

Why does the LED lamp glow when the switch is off?

There are several common reasons why LED bulbs glow when the switch is off:

- Low quality insulating materials.

- Using an illuminated switch.

- Low quality light bulb.

- Problems with electrical wiring.

- Features of the power supply circuit.

Poor quality insulation

Insufficient quality insulation in any part of the electrical circuit often causes problems with light. This malfunction has the most serious consequences, because to correct it you will need to disturb the finishing layer on the walls in order to replace the insulation.

To check the insulation for current leakage, apply high voltage to the network for 1 minute. This is necessary to simulate the conditions under which breakdowns occur in the electrical circuit.

Using Illuminated Switches

The answer to the question of why an LED lamp glows when the switch is off lies in the use of an illuminated switch. The inside of such a device contains a light diode with a current-limiting resistor. The reason the lamp glows is that even when the contact is disconnected, voltage still passes through them. However, the light bulb does not glow at full power, since the circuit contains a current-limiting resistor.

The lamp shines either constantly (if the current is sufficient) or intermittently (flashes because the current is too weak). However, even in the latter case, the current is sufficient to recharge the capacitor. As soon as sufficient voltage accumulates in the capacitor, the stabilizer chip turns on, and the light bulb immediately lights up. Operating the lamp in this mode leads to its rapid wear, since the number of operation cycles for microcircuits is finite.

In this case, there are several methods to eliminate the problem of the luminous light bulb. The easiest way is to remove the backlight from the switch. To do this, dismantle the housing and remove the wire directed to the resistor or light diode. It is also possible to replace the switch with another one that does not have a backlight function.

Another way to solve the problem involves soldering a shunt resistor parallel to the light bulb. You will need a 2 watt resistor with a resistance of up to 50 kOhm. If you do this, the current will flow through this resistor, and not through the light bulb power driver. Installing the resistor is not difficult. You just need to remove the lampshade and secure the resistance legs in the terminal block for connecting the network conductors.

It is enough to connect one resistor to the switch, there is no need to hang them on each lamp.

If you do not have sufficient knowledge of electrical engineering, you can do something simpler. To do this, place a regular incandescent lamp in the lighting fixture. The spiral of the light bulb will serve as a shunt resistor when turned off. However, this option is only suitable if there are several cartridges in the lighting fixture.

Low quality light bulb

Often the cause of a malfunction is an insufficiently high-quality lamp. In this case, there is only one way to solve the problem - replacing the product with a better one.

Electrical wiring problems

If errors are made during the installation of electrical wiring, one of the consequences of this may be the lamp glowing when the switch is already turned off. This situation happens when the zero is confused with the phase, and even after disconnecting the wires remain under the phase.

The situation should be corrected not only to get rid of the unnecessarily shining light bulb. This is also to avoid electric shock when replacing the lamp.

Features of the power supply circuit

To provide a brighter glow and reduce light ripple, a high-capacitance capacitor is sometimes added to the power supply circuit. This results in the fact that even when the switch is turned off, there is still enough charge in it to allow the LEDs to glow.

Tips for choosing LED lamps

When purchasing an LED cutter, it is recommended to pay attention to the following factors:

- Carefully read the instructions that come with the LED lamps. It specifies the rules for using the product.

- Some convenient lighting features are not easily compatible with LED bulbs. Timers, light intensity controllers, photovoltaic elements, and backlighting often cause failures in the normal operation of LEDs.

- Pay attention to the dimensions of the radiator. This element is responsible for removing a sufficient amount of thermal energy that is released when the light is on. The dimensions of the radiator and the power of the lamp must be consistent with each other.

- Radiator material. The best choice is an aluminum radiator. Ceramic and graphite products have proven themselves to be excellent.

- The quality of the joint between the light bulb body and the base. If there are obvious mechanical defects at the junction, the likelihood of problems with the lamp glowing when the switch is off increases. The base must be securely fixed to the body without play.

- Ripple level. The correct glow is uniform, without any flicker. However, it is quite difficult to notice irregularities in the light. This is where a mobile phone video camera comes in handy - it makes it much easier to spot flickering.

It is recommended to purchase products only from well-established manufacturers. A low price very often has a downside - insufficient product quality.

Source: stroyka.ahuman.ru