The cost of gasoline is inexorably rising, so more and more motorists are thinking about converting their car to gas. Installing an LPG on a car yourself is an excellent alternative to using gasoline. In this article we will tell you how to choose gas equipment and how to install it yourself.

Selecting a HBO kit

The easiest way is to choose branded equipment for a specific car brand.

Some of the popular representatives of model gas equipment are the brands Prins, BRC and Vially.

The kits from these brands contain all the necessary elements. Starting from gearboxes, injectors, valves and ending with special electronic modules that do not require programming or additional configuration.

Model gas equipment of a car is a system unified for a specific make/model of car or platform on which the car is assembled.

Such systems are equipped with all the necessary fasteners, which are unified by seating and designed to distribute the main components in safe places in the car.

The electronic part of the model equipment is pre-calibrated at the factory for a specific car model, and this greatly simplifies the setup and pairing of the gas equipment with the standard ECU system.

Often, when installing a certified model LPG in specialized services, the car does not fall out of warranty service. This point is only valid if gas equipment is installed in special services that provide a guarantee and cooperate with dealer centers.

Branded model LPG has a number of advantages and disadvantages.

Advantages of model gas equipment:

- does not require drilling a large number of holes and installing additional clamps and fasteners, model kits fit “in place” and are perfectly installed in the places provided by the manufacturer;

- does not require intervention in the vehicle’s electronic control unit;

- reliability;

- maintaining the dealer warranty (only when contacting specialized services).

Disadvantages of model gas equipment:

- high price;

- lack of choice (only a limited list of brands and modifications);

- large financial costs for installation in a specialized service.

If a car enthusiast does not have the desire or money to spend on purchasing branded LPG, then you can go the other way and choose a universal set of equipment. Such universal kits are presented in abundance in the assortments of many automobile stores.

One of the main advantages of a unified gas equipment is the ability to select individual elements. Starting from nozzles and gearboxes to special valves and filling containers.

The ability to select and purchase parts separately makes standardized sets of gas equipment very attractive for purchase. As a rule, installing an LPG with your own hands, assembled from various components, does not cause serious difficulties, but requires knowledge of certain skills.

Unified gas equipment kits vary in their characteristics (power, number of cylinders, type of fuel injection, presence of a turbocharger, etc.).

The limiting factors in this case will be only the engine power and the filling tank . The power of the engine will determine which gearbox and injectors will need to be installed, and the location of the filling tank is different on all cars, so this point is worth taking into account.

Advantages of universal gas systems:

- low cost;

- wide availability;

- compatible with a large number of brands and models of cars;

- possibility of individual selection of components for specific operating conditions of the machine.

Disadvantages of universal gas systems:

- there is a risk of running into a defect or counterfeit;

- requires additional work on installation and preparation of attachments;

- deprivation of the dealer warranty (if the car is under factory warranty and the installation is not carried out by a certified service center);

- requires adjustment of the electronic control unit.

HBO control unit 4th generation

The operation is regulated using an electronic control unit included in the 4th generation HBO kit.

First you need to select a location for installing the unit. During operation, free access to it is important, and at the same time, the length of the wiring must be kept to a minimum. The wiring coming from the controller is divided into several sections that will perform certain functions. The on-board network should be disconnected from the battery terminals before connecting. Next, you need to separate the wires responsible for powering the unit. There should be 3 of them in total: positive terminal, ground and positive terminal of the ignition switch. After separation, they should be connected.

We recommend: How to choose antifreeze for a car?

Next, you need to connect the wiring responsible for the operation of the injectors. It should be connected to the wiring leading to the injectors. Having determined the wires that will be connected to each of the injectors, they need to be connected. Next, we connect the connectors to the gasoline injectors and connect the connectors of the gas injectors.

List of required tools and equipment

Installing a 4th generation gas system with your own hands is not a difficult task. Before you carry out installation yourself, you need to acquire a certain set of tools.

No specialized tools are required to carry out work related to the gas system.

have :

- standard set of socket bits and sockets;

- pliers;

- WD-40;

- electric drill;

- a set of metal drills;

- thread tap (for injector threads);

- sealant and thread locker;

- a set of screwdrivers (including torx screwdrivers);

- torque wrench (optional);

- spare bolts, nuts and washers (preferably).

Required Tools

You can install LPG on your car yourself or contact a service center. In any case, in order to carry out the work efficiently, you will need to take care of the necessary tools and equipment in advance. So, you need:

- set of fourth generation gas equipment;

- gas hoses with clamps, the length of which is 0.6-0.8 m, and the diameter is 4-5 mm and 12 mm for 0.5-1 m (for a 4-cylinder engine);

- gas tubes 40-70 cm long and 6 mm in diameter;

- a cooling system hose with two metal tees corresponding to the size of the inlet/outlet on the gearbox;

- thermoplastic gas tube. A product made of copper and aluminum is also suitable;

- automotive tools;

- drill;

- pliers;

- screwdriver;

- metal drills with a diameter of 4.8 mm, crown 3 cm;

- thread tap - 6 mm;

- electrical tape, construction tape, heat shrink tube;

- soldering iron and everything necessary for soldering wires;

- multimeter;

- metal clamps or brackets with self-tapping screws - will be needed for fastening lines under the bottom of the vehicle;

- car enamel or anti-corrosion treatment;

- bolts, nuts;

- engine intake manifold gasket

Attention! The length of all tubes, hoses and the diameter of clamps is determined taking into account the car model.

It is convenient to carry out work in an inspection hole or on an overpass. Instructions for installing Euro equipment will help you avoid mistakes. But it’s unlikely to be possible to do this without a tool.

Installation process

For car enthusiasts who have ever carried out repairs and maintenance of VAZ-made cars with their own hands, the installation of equipment will not cause great demands.

The main thing is to follow all prescribed instructions and check the reliability of the connections made.

There is no specific algorithm for installing a gas system on a car; you can start either by inserting the injectors or by securing the cylinder in the passenger compartment or trunk.

The stages of work can be divided into:

- design (fitting connections, planning the placement of parts);

- rough installation (drilling holes, laying lines);

- gearbox installation;

- injector insertion;

- securing the cylinder;

- final installation (connecting all elements together, securely tightening nuts and bolts, checking for leaks);

- electronic pairing and setup

Injection insertion and ramp installation

Let's start with the most difficult part, with inserting the injectors into the intake manifold. To do this, you will need to disconnect the air filter, electronic chips from the throttle and other elements attached to the intake tract. To remove the collector itself, you need to unscrew the fixing studs (less commonly, bolts) and carefully pull the collector off the studs.

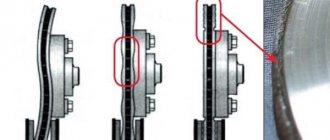

Once the manifold is removed, it is necessary to mark the holes for inserting the gas injectors. The distance from the adjacent plane of the cylinder head manifold to the insertion point can vary in the range from 1 to 7 cm. We select the insertion location with the largest diameter so as not to interfere with the normal air flow. Once the location for the injectors has been selected, the areas on the manifold that will need to be drilled should be marked.

The holes for the injectors must be drilled at an angle of 45-90 degrees in the direction of the air flowing into the engine. You should work with a drill at low speeds, and it is better to start with a small drill, and towards the end of drilling, replace the drill with a suitable diameter and drill the holes to the end

After drilling the holes for the gas injectors, take a tap and cut the thread. Now we thoroughly clean the intake manifold and install the injectors. Before inserting, it is advisable to use a thread locker and secure the nozzles to a locklight or clamp.

Now, depending on the fasteners, you should install the ramp. The mounting location can be on the intake manifold (most often) or on the valve cover (if convenient). To install, we repeat the operation of marking the marks, then simply drill out the landing grooves (it is IMPOSSIBLE to drill through the collector , as this will lead to its failure).

Gearbox installation

The gearbox can be placed almost anywhere. It should be placed strictly parallel to the movement of the vehicle, and the height of the location should not be very low or high. The optimal placement is just below the cylinder head valve cover.

Installing the gearbox is quite simple - we select a suitable mount, then drill holes on the car body and only after that install the gearbox .

It is advisable to treat the holes made with solid oil or pushsal, this is necessary to prevent the appearance of pockets of corrosion. During installation, it is imperative to use bushing washers in order to eliminate parasitic vibration and premature failure of the gearbox.

Installing the cylinder and pulling lines

The location of the cylinder depends on its type; toroidal ones are great for placing in the spare tire niche, and cylindrical ones are right behind the backs of the rear seats. There is nothing complicated in installing the cylinder - we select the optimal location and install the holding fasteners (in accordance with the instructions). If there is a valve on the cylinder, its outlet channel should be reliably isolated from the external environment with a sealant and led out into its nozzle.

To draw the lines, you will need to drill several holes in the trunk floor and run the tubes from the cylinder into them.

The line should be routed near the brake pipes. As practice shows, this arrangement is extremely successful.

Highways will rarely come into contact with the road surface. In the front part, “on the apron,” we also make mounting holes through which we “run” the line. As soon as the line is “stretched”, we fix its ends in the cylinder and reducer.

Electronics Testing and Calibration

It is better to entrust the adjustment of the electronic controller to specialists, since adjustment requires a lot of knowledge, experience and special equipment.

But checking connections for leaks is done by soaping all connections and visually checking for gas leaks; this can be done quite quickly and easily in a garage.

Installation of cylinder, lines and filling equipment

You should start installing HBO from a cylinder. If the car has a sedan body and a large trunk, then it is better to use a cylindrical cylinder with a larger capacity. You need to attach it to the rear of the luggage compartment of the car.

Hatchbacks have small trunks, so it is better to use a toroidal cylinder. To ensure reliable fastening of the cylinder, it is necessary to use rubberized tapes. To properly secure the cylinder, you should take measurements and mark points for future holes. It is also necessary to mark the places where the high pressure line will pass. Having made the markings, you should drill holes in the body in the appropriate places and apply an anti-corrosion primer.

When installing the cylinder, you need to ensure that the special valve is placed on the top of the cylinder. After this, you need to install the refueling device. It can be placed in any convenient place that does not become too dirty during operation of the machine. The main requirement is to place the line from the filling device to the cylinder in a place that is inaccessible to damage.

The main line is made of brass tubes. To avoid damage, the line should be placed next to the gasoline pipeline.

Operating principle and differences between buttons

The 1-2 generation button on the carburetor has two working positions and one neutral.

1st generation HBO button for carburetor

- I – the engine starts and runs only on gasoline (gas valve is closed, the red light is on).

- II – The internal combustion engine switches to gas, while the gasoline electric valve closes and the green lamp lights up.

- 0 (Neutral) – serves to burn gasoline from the carburetor float chamber.

Changing the fuel type should only occur through the neutral position. If you turn on the gas right away, two types of fuel will enter the combustion chambers and the engine will most likely stall.

Some copies have an indication of the fuel level in the cylinder, as well as an additional button for the pre-start supply of a portion of gas, which is needed to enrich the mixture when starting a warm engine on gas (for example, Lovato, Logo buttons for a vacuum reducer).

A key such as, for example, Stag 2-G already has a pre-start function built into it, with the ability to adjust by time.

In the injection version, instead of the middle position, there is an automatic mode (on some types, such as Stag 2-W, it can be extreme). In this position, the engine starts on gasoline, and when a certain engine speed is reached, the gas supply is automatically turned on.

Button for switching gas petrol 2nd generation to injector

The transition speed is regulated using a potentiometer on the side surface of the housing. This key can also come with a level indication.

The universal option involves installing a toggle switch on both the injector and the carburetor. The transition between modes is carried out using a jumper/jumper on the case (example SVG switch).

Universal switch

The 4th generation HBO button has an LED indication and 2 operating modes on/off. In the on position, the gas turns on automatically after the reducer-evaporator warms up to 35-45˚C. The temperature is programmed in the controller when setting up the equipment.

Stag 300

Button signals using Stag as an example:

- LED is on/off – the engine is running on gas/gasoline;

- blinks at intervals of 1 second. – the engine is not warmed up;

- flashes every 2 seconds – the system is ready to switch to gas;

- blinks every 4 seconds – the tank has run out of fuel;

- the buzzer beeps three times - the system switches from gas to gasoline due to lack of fuel;

- three short signals 1 long – ECU (control unit) error;

- two short beeps 1 long beep (with the ignition off) – maintenance of gas equipment is required.

In addition, the fourth version of the gas system has an emergency start on gas. The mode is activated as follows: hold the button with the ignition off until the LED lights up continuously. Then, without releasing the key, we start the engine. Deactivation occurs after stopping the internal combustion engine.

Types of buttons (video):

Selection table (with approximate prices):

| Name/labeling | injector/carburetor/generation | Level indication, +/- | Price in rubles |

| REG OMVL Dream XXI King | engineer/4 | + | 1020 |

| Logo 145 | engineer/4 | — | 280 |

| Logo 101 | carb./1.2 | — | 470 |

| Atiker (K01.003.000.020) | carb./1.2 | + | 600 |

| Stag 2-G | carb./1.2 | — | 550 |

| AEB 722 | carb./1.2 | + | 1050 |

| Tamona K-5 | carb./1.2 | — | 520 |

| Lovato | carb./1.2 | — | 590 |

| Torelli | carb./1.2 | + | 630 |

| Stag 2-W | engineer/2 | — | 600 |

| Tamona in-3 | engineer/2 | — | 540 |

| Stag LED-401 | engineer/4 | + | 750 |

| Stag LED-300 | engineer/4 | + | 580 |

Features of HBO connection

Gas equipment of any type is equipment that allows you to adapt a gasoline engine to power and operate on gas. Typically, the most popular and used units run on propane or methane. Regardless of the type, HBO is not a replacement for a standard injector or carburetor, but only a convenient and high-quality alternative. That is, by installing gas, any motorist has the opportunity to use his vehicle both by refilling with gas fuel and regular gasoline.

Switching between the engine’s fuel supply cannot occur automatically, because this aspect of the machine’s operation is set personally by the motorist. To switch the engine operating mode to gas from gasoline or vice versa, special equipment called the LPG button is used.

In fact, this element of equipment design is a device that works together with both the gas equipment control unit and the electronic “brains” of the engine injector or carburetor. The principle of its operation is based on the fact that, using fine electronic tuning, pressing a button blocks the operation of one fuel distribution unit and connects another to the operation. Thus, the supply of gasoline is switched to the supply of gas, or the reverse operation is carried out.

It turns out that the button for switching engine operating modes is one of the most important components in controlling all gas equipment. Moreover, it does not matter whether the car has a 2nd generation HBO or a 4th generation HBO. In any case, a switch is needed and it plays the most important role, adapting the engine operating mode to the desires of the motorist.

Installation of 4th generation gas equipment in detail

The first and most important process when installing gas equipment is the installation of the reducer, since it is this part of the entire structure that is responsible for heating the compressed gas and its flow from the cylinder into the engine compartment. The quality of gas installation on a 4th generation car and gearbox determines the efficiency of all equipment, regardless of which generation you choose.

It is very important to choose a convenient place to install the gearbox. The gas reducer must be installed in a location that is most suitable for its dismantling, repair and replacement if such a need arises. Such a part can really be controlled and adjusted remotely. However, in some situations, mechanical adjustment or replacement may be necessary. If the gearbox is located in a hard-to-reach place, this will significantly complicate your work.

When installing 4th generation gas equipment, namely leading parts such as a gearbox or cylinders, you need to remember that this installation unit should not be placed in a place that is easily exposed to weather conditions, can get caught in a downpour, get dirty with dirt from the road or freeze under snow. It is important to remember that the correct installation of the main gas equipment components guarantees that the equipment will not malfunction and will serve as an excellent substitute for liquid fuel over a long period of time.

During the installation of gas equipment, it is also worth remembering that the installation scheme for gas equipment of the 4th generation should exclude the possibility of exposure to constant vibrations or other mechanical damage.

Some drivers often mount the 4th generation LPG in close proximity to the engine, which is unacceptable. This leads to constant forced vibrations and breakdowns of the gas cylinder system. To avoid unnecessary problems, install 4th generation gas equipment in the most secluded and at the same time protected and accessible place under the hood.

Cylinders of this design can be placed in the trunk. Thanks to their convenient shape, they do not take up much space and are perfect for almost any car model.

More details about cylinders for HBO 4th generation

As mentioned above, the reducer, cooling system and cylinders are the main leading parts of gas equipment, on the integrity and correct installation of which the coordinated operation of the entire structure and its individual elements depends. Therefore, it is worth talking about the cylinders that are used to equip a car with gas in more detail.

For all relatively new and modern models of gas cylinder equipment on cars, manufacturers produce toroidal cylinders. This means that you can place a cylinder of this shape in place of the spare wheel or conveniently place it in the body and not worry about it taking up a lot of space or being damaged while driving.

Features of gearbox installation

After running the lines into the engine compartment, they need to be routed along the left side to the gearbox installation site.

The gearbox must be properly secured to the car so that there are no problems in the future.

It is attached only to the load-bearing part of the car, that is, to the body or subframe. It is prohibited to install it on the engine. It is important that there is good access to it.

The gearbox is then connected to the cooling system of the power plant. To do this, it is inserted into the cooling system pipes through tees.

It is important that its insertion is parallel, that is, the flow of coolant into the gearbox should be made from one pipe, and its outlet through another, and not the same one.

Next, a vacuum pipe is connected to the gearbox. Vacuum is taken from the intake manifold.

A fitting cuts into it, and it is connected to the gearbox by a pipeline. If there is no fitting, you can wait to insert it for now.

After this, you can connect the high pressure line to the reducer. Only before this, a filter is included in the design to capture mechanical impurities - a “coarse” filter.

The key part of the 4th generation gas equipment is the multivalve

The multivalve for gas, which is installed on the 4th generation gas equipment, is the key and leading part of the entire structure. How to install 4th generation HBO? Along with the reducer and cylinders, the successful use of all gas equipment directly depends on the proper operation and consistency of this part.

The main and main function of the multivalve is to control the supply of gas to the car cylinder and close the valve in the event of an emergency condition of the car or when refilling cylinders. It is worth noting that the fourth generation gas equipment models are equipped with a large valve so that its design can be controlled by an automatic control system in the car, and also so that the valve more accurately performs its functions and leaves a minimum amount of space for accidental gas emissions when the body of the cylinders overheats or expands.

Let us note once again that it is not worthwhile to install gas equipment without knowledge of the principles of its operation and compliance with the requirements of the instructions. In this case, you risk the health of the entire car. Consider whether you need such risks, and only then make a decision about who will carry out the installation.